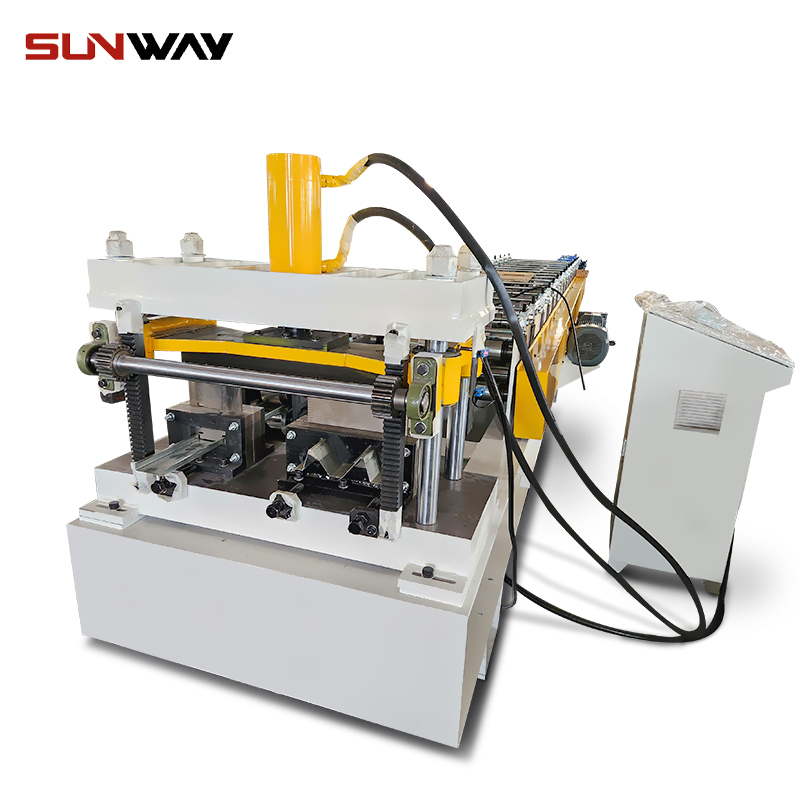

El diseño arquitectónico ya no se trata solo de funcionalidad; la estética juega ahora un papel igualmente importante en la construcción moderna. Desde paneles de pared intrincados hasta techos y fachadas decorativos, estructuras decorativas están redefiniendo el atractivo visual de espacios residenciales, comerciales e industriales. La producción de estos componentes decorativos depende en gran medida de la precisión, eficiencia y versatilidad de Máquinas perfiladoras de estructuras decorativas.

Estas máquinas están diseñadas para producir una amplia gama de perfiles estéticamente atractivos y estructuralmente sólidos, incluyendo paneles de pared, techos, fachadas, molduras y perfiles. Ya sea para edificios altos, interiores de lujo o instalaciones industriales, Máquinas perfiladoras de estructuras decorativas permiten a los fabricantes satisfacer la creciente demanda de componentes arquitectónicos funcionales pero visualmente impresionantes.

En esta completa guía, exploraremos qué son estas máquinas, sus aplicaciones, características clave, precios, consejos de resolución de problemas y tendencias futurasy por qué Maquinaria Wuxi Sunway es el líder de la industria en tecnología de perfilado para estructuras decorativas.

¿Qué son las máquinas formadoras de rollos para estructuras decorativas?

Máquinas perfiladoras de estructuras decorativas son máquinas industriales especializadas que moldean láminas o bobinas de metal en perfiles intrincados utilizados en diseño arquitectónico e interior. Estas máquinas pueden producir una variedad de elementos decorativos, como paneles corrugados, falsos techos, revestimientos de fachadas, molduras y perfiles, con alta precisión y consistencia.

La demanda de estructuras decorativas está en aumento a medida que arquitectos y diseñadores buscan crear espacios únicos y visualmente atractivos. Estas máquinas no solo satisfacen requisitos estéticos, sino que también garantizan la integridad estructural y la durabilidad de los componentes.

Características clave de las máquinas formadoras de rollos para estructuras decorativas

- Capacidades de diseño intrincado: Produce perfiles complejos y detallados para aplicaciones decorativas.

- Versatilidad de materiales: Procesa una variedad de materiales, incluyendo aluminio, acero galvanizado, acero inoxidable y metales pre-recubiertos.

- Perfiles personalizables: Admite diseños personalizados adaptados a proyectos arquitectónicos específicos.

- Acabado de alta calidad: Garantiza superficies suaves e impecables para un mayor atractivo visual.

- Producción a alta velocidad: Facilita la producción en masa sin comprometer la calidad.

- Integración de la automatización: Reduce los costos laborales y asegura uniformidad en cada lote.

Aplicaciones de las máquinas formadoras de rollos para estructuras decorativas

La versatilidad de Máquinas perfiladoras de estructuras decorativas las hace indispensables en diversos sectores, incluyendo construcción, diseño interior y desarrollo de infraestructuras. A continuación, se detallan algunas aplicaciones clave:

1. Paneles de pared

- Caso práctico: Producción de paneles de pared corrugados o planos para paredes exteriores e interiores.

- Por qué es esencial: Mejora tanto los aspectos estéticos como funcionales de los edificios, ofreciendo durabilidad y resistencia al clima.

2. Sistemas de techos

- Caso práctico: Fabricación de falsos techos decorativos y paneles acústicos para oficinas, aeropuertos y auditorios.

- Por qué es beneficioso: Mejora el atractivo visual y el rendimiento acústico de los espacios interiores.

3. Revestimientos de fachadas

- Caso práctico: Creación de sistemas de fachadas para edificios altos, centros comerciales e infraestructuras públicas.

- Por qué es importante: Proporciona un exterior atractivo mientras protege el edificio de factores ambientales.

4. Molduras y perfiles

- Caso práctico: Elaboración de molduras decorativas, perfiles y cuentas de esquina para detalles arquitectónicos.

- Por qué es relevante: Añade elegancia y refinamiento tanto a interiores como a exteriores.

5. Techos decorativos

- Caso práctico: Producción de paneles y perfiles para sistemas de techos decorativos.

- Por qué es necesario: Combina atractivo estético con protección duradera contra los elementos.

6. Sistemas de tabiques

- Caso práctico: Fabricación de paneles para tabiques modulares en espacios comerciales e industriales.

- Por qué es innovador: Ofrece flexibilidad en la gestión del espacio manteniendo una apariencia moderna y profesional.

Características clave de las máquinas formadoras de rollos para estructuras decorativas de Wuxi Sunway

Cuando se trata de precisión, fiabilidad e innovación, Maquinaria Wuxi Sunway destaca como líder global en tecnología de perfilado. Estas son las características clave que hacen que sus máquinas formadoras de rollos para estructuras decorativas sean la opción preferida de los fabricantes:

1. Capacidades de diseño avanzadas

- Qué ofrece: Máquinas equipadas con herramientas avanzadas para producir diseños y patrones intrincados.

- Por qué es fundamental: Satisface la creciente demanda de perfiles decorativos únicos y personalizados.

2. Flexibilidad del material

- Qué procesa:

- Aluminio

- Acero inoxidable

- Acero galvanizado

- Metales prepintados

- Por qué es versátil: Admite una gama de materiales para diversas aplicaciones arquitectónicas.

3. Acabado superior

- Lo que garantiza: Perfiles con superficies suaves y acabados impecables, listos para instalación sin procesamiento adicional.

- Por qué es beneficioso: Reduce la necesidad de operaciones de acabado secundarias, ahorrando tiempo y costos.

4. Herramientas modulares

- En qué consiste: Sistemas de herramientas de cambio rápido para producir diferentes perfiles con un tiempo de inactividad mínimo.

- Por qué es flexible: Permite a los fabricantes cambiar entre proyectos de manera eficiente.

5. Producción de alta velocidad y alta precisión

- Lo que ofrece: Procesa hasta 40 metros de material por minuto con desviaciones mínimas.

- Por qué es esencial: Mantiene el ritmo con la alta demanda de componentes de construcción decorativos.

6. Integración de IoT y automatización

- Qué incorpora: Sistemas habilitados para IoT para monitoreo en tiempo real, control remoto y mantenimiento predictivo.

- Por qué es innovador: Mejora la eficiencia operativa y minimiza el tiempo de inactividad de la máquina.

7. Durabilidad y fiabilidad

- Lo que garantiza: Máquinas construidas para manejar producción continua manteniendo una calidad consistente.

- Por qué es importante: Asegura valor a largo plazo y fiabilidad para los fabricantes.

Precios de las máquinas formadoras de rollos para estructuras decorativas

El coste de un Máquina formadora de rollos para estructuras decorativas varía en función de sus características, capacidad de producción y opciones de personalización. A continuación se ofrece una guía general de precios para 2025:

| Tipo de máquina | Capacidades | Gama de precios (USD) |

|---|---|---|

| Máquinas estándar | Producción básica de perfiles decorativos | 200.000–200.000–200.000–400.000 |

| Máquinas avanzadas | Producción de alta velocidad con acabado integrado | 400,000–400,000–400,000–800,000 |

| Máquinas personalizables | Adaptada para diseños únicos y alta complejidad | 800,000–800,000–800,000–1,500,000 |

Para obtener información detallada sobre precios y opciones de financiación, póngase en contacto con Maquinaria Wuxi Sunway.

Ventajas de usar máquinas formadoras de rollos para estructuras decorativas

Máquinas perfiladoras de estructuras decorativas ofrecen numerosas ventajas que las hacen invaluables para fabricantes y arquitectos por igual:

1. Mayor atractivo estético

- Por qué es importante: Produce diseños intrincados y acabados suaves que elevan el atractivo visual de las estructuras.

2. Alta eficiencia de producción

- Por qué es beneficioso: Permite la producción en masa de perfiles decorativos, reduciendo tiempos de entrega y cumpliendo plazos ajustados.

3. Capacidades de personalización

- Por qué es valioso: Admite diseños personalizados, permitiendo a los fabricantes atender requisitos arquitectónicos únicos.

4. Eficiencia de costes

- Por qué es práctico: Minimiza el desperdicio de material y reduce la necesidad de procesamiento secundario, bajando los costos totales de producción.

5. Durabilidad

- Por qué es fundamental: Produce componentes resistentes a la corrosión, al clima y al desgaste, asegurando un rendimiento duradero.

6. Sostenibilidad

- Por qué es relevante: Procesa materiales reciclables y se alinea con prácticas de construcción ecológicas.

Resolución de problemas comunes en máquinas formadoras de rollos para estructuras decorativas

Incluso las máquinas avanzadas pueden enfrentar desafíos ocasionales. Aquí hay problemas comunes y sus soluciones:

1. Dimensiones desiguales del perfil

- Síntomas: Los perfiles no coinciden con las especificaciones de diseño, causando problemas de ensamblaje.

- Posibles causas: Rodillos desalineados o calibrado incorrecto de la máquina.

- Solución:

- Vuelva a calibrar la máquina y asegúrese de la correcta alineación de los rodillos.

- Realizar controles de calidad periódicos durante la producción.

2. Imperfecciones superficiales

- Síntomas: Los perfiles tienen rayones, abolladuras o acabados inconsistentes.

- Posibles causas: Rodillos desgastados o manipulación inadecuada del material.

- Solución:

- Reemplace los rodillos dañados.

- Asegure el manejo y almacenamiento adecuado de los materiales crudos.

3. Cuestiones de alimentación de material

- Síntomas: Atascos de material o alimentación irregular, interrumpiendo la producción.

- Posibles causas: Material de baja calidad o sistema de alimentación desalineado.

- Solución:

- Utilice materiales de alta calidad con un grosor uniforme.

- Ajuste el sistema de alimentación para una operación fluida.

Preguntas frecuentes sobre máquinas formadoras de rollos para estructuras decorativas

| Pregunta | Respuesta |

|---|---|

| ¿Qué materiales pueden procesar estas máquinas? | Aluminio, acero inoxidable, acero galvanizado y metales pre-recubiertos. |

| ¿Cuál es la velocidad de producción? | Hasta 40 metros por minutoen función de la complejidad del perfil. |

| ¿Pueden estas máquinas realizar diseños personalizados? | Sí, las herramientas modulares admiten perfiles decorativos personalizados e intrincados. |

| ¿Son ecológicas estas máquinas? | Sí, minimizan el desperdicio de material y admiten materiales reciclables. |

| ¿Cuál es el precio de estas máquinas? | Los precios oscilan entre De 200.000 a 1.500.000en función de las características y la personalización. |

| ¿Son compatibles estas máquinas con la integración de IoT? | Sí, las funciones habilitadas para IoT permiten la supervisión en tiempo real y el mantenimiento predictivo. |

Historias de éxito reales: Cómo las máquinas formadoras de rollos para estructuras decorativas están moldeando proyectos icónicos

Máquinas perfiladoras de estructuras decorativas han sido fundamentales en la creación de algunos de los hitos arquitectónicos más icónicos del mundo. A continuación, ejemplos de cómo estas máquinas han entregado resultados excepcionales en aplicaciones reales:

1. Transformando los cielos urbanos en Oriente Medio

Cliente: Una firma líder de construcción en Dubái especializada en edificios altos.

Desafío: La firma requería paneles de fachada diseñados a medida para un rascacielos de lujo, combinando estética moderna con durabilidad para resistir condiciones climáticas extremas.

Solución: Wuxi Sunway Machinery proporcionó una máquina formadora de rollos con herramientas avanzadas para producir perfiles de fachada de aluminio únicos con patrones intrincados.

Resultado:

- Produjo más de 50.000 metros cuadrados de paneles de fachada decorativos en menos de seis meses.

- Redujo los costos del proyecto en un 20 % mediante un uso eficiente de materiales y producción de alta velocidad.

- Entregó un exterior visualmente impresionante que se ha convertido en un hito en el skyline de Dubái.

2. Revestimientos sostenibles para oficinas en Europa

Cliente: Una firma arquitectónica en Alemania enfocada en diseños de edificios sostenibles.

Desafío: El proyecto requería paneles de revestimiento de pared ecológicos para un edificio de oficinas corporativas, alineados con los estándares de sostenibilidad de la UE.

Solución: Wuxi Sunway suministró una máquina capaz de procesar aluminio y acero reciclados, asegurando precisión y producción ecológica.

Resultado:

- Produjo 30.000 metros cuadrados de paneles de revestimiento utilizando materiales 100 % reciclables.

- Ayudó al proyecto a obtener la Certificación LEED Oro para construcción sostenible.

- Mejoró la eficiencia energética del edificio integrando capas de aislamiento térmico en los paneles.

3. Techos interiores de lujo para un hotel en Asia

Cliente: Una cadena de hoteles de lujo en Singapur.

Desafío: La cadena necesitaba falsos techos decorativos con diseños intrincados para un hotel de cinco estrellas, asegurando un ambiente upscale y lujoso.

Solución: Wuxi Sunway entregó una máquina formadora de rollos especializada para producir paneles de techo detallados con acabados suaves.

Resultado:

- Produjo más de 15.000 paneles de techo decorativos en tres meses, cumpliendo el ajustado cronograma del proyecto.

- Mejoró la estética interior del hotel, ganando elogios de huéspedes y expertos de la industria.

- Redujo el tiempo de instalación en un 25 % mediante perfiles diseñados con precisión.

4. Sistemas de pared modulares para infraestructuras públicas en Norteamérica

Cliente: Un contratista gubernamental en Canadá trabajando en estaciones de tránsito público.

Desafío: El contratista requería paneles de pared modulares para estaciones de metro, combinando durabilidad con una estética de diseño moderno.

Solución: Wuxi Sunway proporcionó una máquina formadora de rollos optimizada para producir paneles modulares con sistemas de montaje integrados.

Resultado:

- Produjo paneles modulares que redujeron el tiempo de instalación en un 40 %, acelerando la finalización del proyecto.

- Mejoró la durabilidad de la estación, asegurando una vida útil de más de 25 años.

- Entregó una apariencia limpia y moderna que mejoró la experiencia del commuter.

Tendencias futuras en la fabricación de estructuras decorativas para 2025

La industria de fabricación de estructuras decorativas está evolucionando rápidamente, impulsada por avances tecnológicos, preocupaciones ambientales y preferencias estéticas cambiantes. Estas son las tendencias clave que moldean el futuro de Máquinas perfiladoras de estructuras decorativas:

1. Sostenibilidad y fabricación verde

- Tendencia: Los arquitectos y constructores demandan cada vez más componentes decorativos ecológicos que se alineen con los objetivos globales de sostenibilidad.

- Impacto en las máquinas: Las máquinas formadoras de rollos optimizadas para procesar materiales reciclables como aluminio y acero recubierto dominarán el mercado.

2. Personalización avanzada para estructuras únicas

- Tendencia: Los diseños personalizados están ganando popularidad, con arquitectos buscando perfiles decorativos a medida para estructuras icónicas.

- Impacto en las máquinas: Máquinas con herramientas modulares y compatibilidad con CAD permitirán la producción de perfiles altamente personalizados.

3. Materiales ligeros y de alta resistencia

- Tendencia: Los materiales ligeros como aleaciones de aluminio se utilizan ampliamente para reducir la carga estructural y mejorar la eficiencia en el transporte.

- Impacto en las máquinas: Las máquinas capaces de procesar materiales ligeros pero de alta resistencia verán

4. Integración de características funcionales

- Tendencia: Los componentes decorativos ahora se espera que incluyan características funcionales como aislamiento, insonorización o iluminación integrada.

- Impacto en las máquinas: Las máquinas perfiladoras con capacidades de procesamiento multicapa serán esenciales.

5. Expansión en los mercados emergentes

- Tendencia: La rápida urbanización en Asia, África y Sudamérica está impulsando la demanda de estructuras decorativas asequibles.

- Impacto en las máquinas: Las máquinas eficientes en costos con altas tasas de producción atenderán las necesidades de los mercados emergentes.

6. Integración de IA y automatización

- Tendencia: La adopción de IA e IoT en los procesos de fabricación está mejorando la eficiencia y reduciendo errores.

- Impacto en las máquinas: Las máquinas perfiladoras habilitadas para IoT con sistemas de control de calidad impulsados por IA se convertirán en estándares de la industria.

Innovaciones en máquinas perfiladoras de rodillos para estructuras decorativas en 2025

La próxima generación de Máquinas perfiladoras de estructuras decorativas está lista para revolucionar la producción de componentes arquitectónicos. Estas son las innovaciones de vanguardia que hay que seguir:

1. Ajustes de diseño en tiempo real

- Qué permite: Máquinas equipadas con sistemas impulsados por IA para ajustar diseños y especificaciones en tiempo real durante la producción.

- Por qué es valioso: Reduce el tiempo de inactividad y garantiza una adaptación rápida a los cambios del proyecto.

2. Procesamiento multicapa

- Qué ofrece: Máquinas capaces de producir paneles multicapa con materiales integrados de aislamiento o insonorización.

- Por qué es revolucionario: Satisface la creciente demanda de componentes decorativos con beneficios funcionales.

3. Sistemas avanzados de recubrimiento

- Qué integra: Sistemas en línea para aplicar acabados anticorrosivos, resistentes al fuego o decorativos durante la producción.

- Por qué cambia el juego: Reduce los pasos posteriores a la producción y garantiza una calidad consistente.

4. Máquinas modulares y portátiles

- Lo que aporta: Máquinas diseñadas para un transporte fácil y una instalación rápida, ideales para la producción en sitio.

- Por qué es conveniente: Permite a los fabricantes producir componentes más cerca del sitio de construcción, ahorrando tiempo y costos.

5. Supervisión inteligente y mantenimiento predictivo

- Qué incluye: Sistemas habilitados para IoT para monitorear el rendimiento de la máquina y predecir necesidades de mantenimiento.

- Por qué es esencial: Minimiza el tiempo de inactividad y extiende la vida útil de la máquina, asegurando una producción consistente.

Por qué Wuxi Sunway Machinery lidera la industria del perfilado de rodillos decorativo

Maquinaria Wuxi Sunway ha ganado su reputación como líder global en tecnología de perfilado de rodillos. Estas son las razones por las que es la opción preferida de los fabricantes de estructuras decorativas:

1. Décadas de experiencia

Con años de experiencia en el diseño de soluciones de perfilado de rodillos, Wuxi Sunway tiene un historial probado de excelencia.

2. Tecnología punta

Incorpora funciones avanzadas como IoT, IA y procesamiento multicapa en sus máquinas.

3. Excelencia en la personalización

Ofrece soluciones personalizadas para producir perfiles decorativos únicos que cumplen con requisitos específicos del proyecto.

4. Alcance mundial

Confiada por clientes en Asia, Europa, las Américas y África, convirtiendo a Wuxi Sunway en una marca verdaderamente internacional.

5. Compromiso de sostenibilidad

Diseña máquinas que apoyan la fabricación ecológica, alineándose con los objetivos globales de sostenibilidad.

6. Apoyo integral

Proporciona servicios integrales, incluyendo consultoría, instalación, formación y soporte postventa.

Visite su sitio web oficial para obtener más información sobre sus ofertas o solicitar una solución personalizada para sus necesidades de producción de estructuras decorativas.

Preguntas frecuentes sobre máquinas formadoras de rollos para estructuras decorativas

| Pregunta | Respuesta |

|---|---|

| ¿Qué materiales pueden procesar estas máquinas? | Aluminio, acero inoxidable, acero galvanizado y metales pre-recubiertos. |

| ¿Cuál es la velocidad de producción? | Hasta 40 metros por minutosegún el material y la complejidad del perfil. |

| ¿Pueden estas máquinas producir diseños personalizados? | Sí, los herramientas modulares admiten diseños personalizados para proyectos arquitectónicos únicos. |

| ¿Son ecológicas estas máquinas? | Sí, minimizan el desperdicio de material y admiten materiales reciclables y sostenibles. |

| ¿Cuál es el precio de estas máquinas? | Los precios oscilan entre De 200.000 a 1.500.000en función de las características y la personalización. |

| ¿Son compatibles estas máquinas con la integración de IoT? | Sí, las funciones habilitadas para IoT permiten la supervisión en tiempo real y el mantenimiento predictivo. |

Conclusión: Construyendo estructuras estéticas y funcionales con tecnología avanzada de perfilado de rodillos

El futuro de la arquitectura radica en combinar belleza con funcionalidad, y Máquinas perfiladoras de estructuras decorativas están en el corazón de esta transformación. Desde la creación de fachadas visualmente impresionantes hasta la producción de paneles multifuncionales, estas máquinas empoderan a los fabricantes para redefinir la construcción moderna.

¿Listo para revolucionar su producción de estructuras decorativas? Aliéntese con Maquinaria Wuxi Sunway y descubra cómo sus soluciones de perfilado de rodillos de última generación pueden ayudarlo a lograr su visión arquitectónica. Juntos, demos forma al mundo de mañana —un perfil a la vez.