Visión general de Revestimiento de perfil de caja

El revestimiento de perfiles de caja es una solución popular y duradera tanto para cubiertas como para paredes de edificios comerciales, agrícolas e industriales. Su diseño estructurado, que se asemeja a la forma acanalada de la chapa ondulada, proporciona no sólo durabilidad sino también un alto nivel de atractivo estético. Fabricado principalmente con chapas metálicas revestidas, el revestimiento de perfil en caja se elige por su facilidad de instalación, rentabilidad y resistencia a la intemperie.

Chapas onduladas frente a revestimientos de perfil de caja

Aunque ambos sirven como opciones de cubierta y revestimiento, chapas onduladas y revestimiento de perfil de caja difieren en estructura y prestaciones. Mientras que las chapas onduladas tienen patrones redondeados y ondulados, el revestimiento de perfil de caja tiene un perfil más plano y anguloso que ofrece un aspecto moderno y una mayor relación resistencia-peso.

| Característica | Chapas onduladas | Revestimiento de perfil de caja |

|---|---|---|

| Estructura | Patrón de ondas redondeadas | Costillas angulosas en forma de caja |

| Fuerza | Moderado a alto | Alta debido al aumento de la rigidez |

| Instalación | Complejidad moderada | Más fácil de instalar gracias a los paneles estructurados |

| Aplicaciones | Agrícola, residencial | Industrial, comercial, agrícola |

| Atractivo estético | Aspecto tradicional y rústico | Aspecto moderno e industrial |

Tipos de revestimiento con perfil de caja

Los distintos modelos de revestimientos de perfiles de cajón responden a aplicaciones variadas y ofrecen propiedades y ventajas específicas. Veamos algunos modelos concretos:

| Modelo | Descripción |

|---|---|

| BP20 | Perfil ligero con nervios de 20 mm de altura, adecuado para pequeñas construcciones industriales y agrícolas. |

| BP35 | Perfil robusto con altura de nervadura de 35 mm, que ofrece un mejor aislamiento y reducción del ruido. |

| BP40 | Lo mejor para cubiertas grandes; el calibre más grueso ofrece una gran durabilidad para un uso a largo plazo. |

| UltraRib50 | Mayor resistencia con una altura de nervadura de 50 mm; ideal para zonas de mucho viento. |

| EcoLite25 | Modelo ecológico, fabricado con materiales reciclados; bueno para edificios ecológicos. |

| DualFlex30 | Ofrece un revestimiento de doble capa para una mayor resistencia a la intemperie, ideal para entornos costeros. |

| ProShield45 | Modelo resistente al fuego con revestimiento anticorrosión, adecuado para fábricas químicas. |

| ThermaClad40 | Perfil de revestimiento aislante que ofrece una alta eficiencia térmica, ideal para el control de la temperatura. |

| SoundGuard35 | Modelo acústico con características de amortiguación del sonido, adecuado para edificios urbanos e industriales. |

| LightRib20 | Ligero y flexible; ideal para estructuras temporales o ampliaciones. |

Cómo Revestimiento de perfil de caja Obras: Instalación y funcionamiento

Los paneles de revestimiento de perfil en caja se instalan fijando las chapas metálicas a la estructura de un edificio, a menudo con tornillos autoperforantes y, en ocasiones, con materiales aislantes adicionales. La rigidez del revestimiento proporciona soporte estructural, mientras que su diseño entrelazado impide la infiltración de agua y minimiza la transferencia térmica.

Proceso de trabajo del revestimiento de perfiles de caja

- Medición y corte: Las planchas se miden para ajustarse a la superficie del tejado o la pared, se cortan a medida y se perforan previamente para colocar los tornillos.

- Disposición del panel: Las planchas se colocan en filas superpuestas, y cada fila se solapa ligeramente con la anterior para garantizar la impermeabilidad.

- Atornillar y asegurar: Cada panel se sujeta firmemente, empezando por un borde, con tornillos y arandelas resistentes a la intemperie.

- Sellado de bordes y acabado: Los bordes se sellan y los rebordes se tapan para mejorar la resistencia a la intemperie y el aspecto.

-

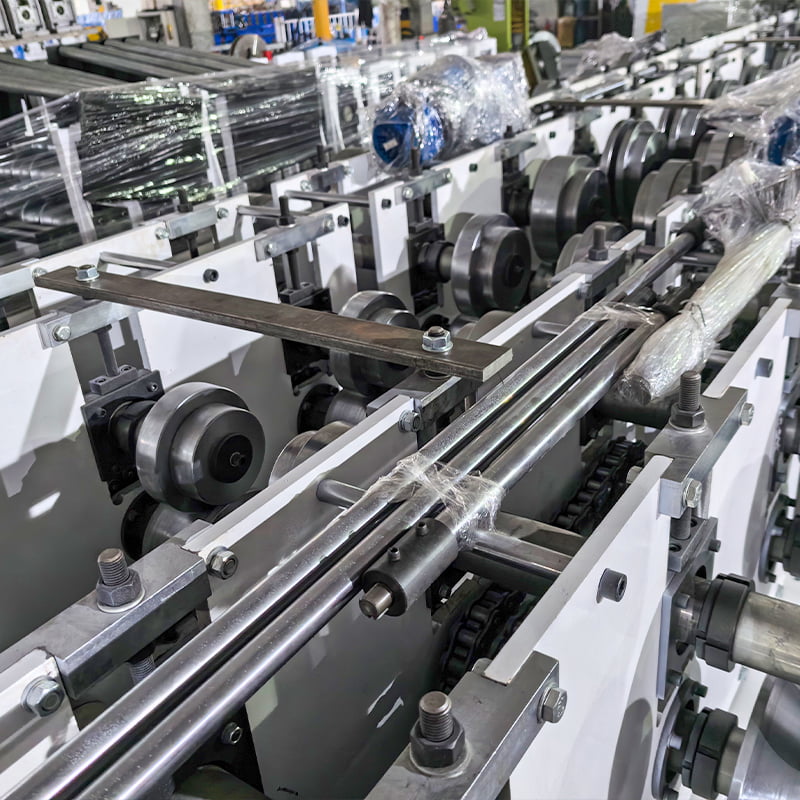

Máquina formadora de rollos de tablero de carro

Máquina formadora de rollos de tablero de carro -

Máquina para fabricar terminales de barandillas de carretera

Máquina para fabricar terminales de barandillas de carretera -

Máquina Perfiladora de Postes U/C de Carretera

Máquina Perfiladora de Postes U/C de Carretera -

Máquina Perfiladora de Baranda de Carretera de 2 Olas

Máquina Perfiladora de Baranda de Carretera de 2 Olas -

Máquina Perfiladora de Baranda de Carretera de 3 Olas

Máquina Perfiladora de Baranda de Carretera de 3 Olas -

Máquina formadora de rollos de marco de gabinete eléctrico

Máquina formadora de rollos de marco de gabinete eléctrico -

Máquina formadora de rollos de riel DIN

Máquina formadora de rollos de riel DIN -

Máquina de barandas de carretera de dos ondas

Máquina de barandas de carretera de dos ondas -

Máquina de barandas de carretera de tres ondas

Máquina de barandas de carretera de tres ondas

Componentes básicos y sus funciones en el revestimiento de perfiles de caja

| Componente | Función |

|---|---|

| Chapa metálica | Material de revestimiento primario, que proporciona resistencia estructural. |

| Tornillos | Se utiliza para fijar el revestimiento a la estructura del edificio. |

| Lavadoras | Mejorar la impermeabilización alrededor de los orificios de los tornillos. |

| Tapas de cumbrera | Cubre las costuras y mejora la impermeabilidad en los picos/borde. |

| Tapajuntas | Se instala alrededor de bordes y aberturas para una mayor protección. |

Velocidad y eficacia de la máquina para Revestimiento de perfil de caja Producción

| Tipo de máquina | Velocidad media (m/min) | Eficacia (%) |

|---|---|---|

| Máquina formadora de rollos | 20-40 | 85-90 |

| Máquina de corte | 15-30 | 80-85 |

| Punzonadora | 10-25 | 75-85 |

Parámetros mecánicos personalizados para el revestimiento de perfiles de caja

| Parámetro | Opciones de personalización |

|---|---|

| Espesor | Gama de 0,5 mm a 1,2 mm |

| Tipo de revestimiento | Galvanizado, prepintado, anticorrosión |

| Color | Amplia gama de colores RAL |

| Profundidad del perfil | 20 mm, 30 mm, 40 mm, hasta 50 mm |

Aplicaciones y usos del revestimiento de perfiles de caja

| Solicitud | Descripción |

|---|---|

| Cobertizos agrícolas | Resistente a la intemperie, ideal para graneros y cobertizos de almacenamiento. |

| Naves industriales | Gran resistencia y propiedades aislantes; se utiliza en grandes almacenes. |

| Edificios comerciales | Ofrece un aspecto moderno para espacios comerciales, tiendas y salas de exposición. |

| Tejados residenciales | Alternativa duradera y de bajo mantenimiento para tejados residenciales. |

Consejos para la instalación, el funcionamiento y el mantenimiento de los revestimientos de perfil de cajón

| Paso | Descripción |

|---|---|

| Instalación | Utilice las medidas correctas, solape los paneles adecuadamente y selle los bordes correctamente. |

| Operación | Asegúrese de que se realizan inspecciones periódicas para detectar el desgaste en las zonas de mayor tensión. |

| Mantenimiento | Limpie el revestimiento cada dos años para eliminar los residuos y comprobar si hay corrosión. |

Revestimiento de perfiles de caja Proveedores y gama de precios

| Proveedor | Gama de precios (por metro cuadrado) | Características notables |

|---|---|---|

| MetalSupplies Ltd. | $8 – $12 | Ofrece materiales ecológicos. |

| Steel Solutions Inc. | $10 – $15 | Especializada en revestimientos pesados. |

| Depósito de tejados | $7 – $13 | Asequible con descuentos por volumen. |

| Empresas EcoClad | $9 – $14 | Métodos de producción sostenibles. |

Elección del proveedor de revestimientos de perfil de cajón adecuado

- Tenga en cuenta la calidad y las certificaciones: Busque certificaciones ISO o de garantía de calidad.

- Comparar precios y descuentos: Equilibrio entre coste y calidad en función de los requisitos del proyecto.

- Compruebe los plazos de entrega y la disponibilidad: Tenga en cuenta los plazos de los proveedores si los plazos del proyecto son ajustados.

- Asistencia al cliente y garantía: Elija proveedores con un servicio de atención al cliente receptivo y garantías en los materiales.

Pros y contras de Revestimiento de perfil de caja

| Aspecto | Ventajas | Limitaciones |

|---|---|---|

| Durabilidad | Duradero, resistente a la intemperie | Puede ser más caro al principio |

| Instalación | Fácil de instalar en comparación con otros materiales | Requiere una manipulación cuidadosa |

| Estética | Aspecto moderno e industrial | Opciones de estilo limitadas para algunos gustos |

| Mantenimiento | Bajo mantenimiento | Limpieza periódica necesaria |

Preguntas más frecuentes

| Pregunta | Respuesta |

|---|---|

| ¿De qué está hecho el revestimiento de perfiles de caja? | Fabricado principalmente con chapas metálicas revestidas, a menudo galvanizadas o pintadas. |

| ¿Es fácil de instalar? | Sí, con las herramientas adecuadas, es relativamente fácil de instalar. |

| ¿Puede resistir las inclemencias del tiempo? | Sí, los revestimientos de perfil de cajón son muy resistentes a la intemperie. |

| ¿En qué se diferencia del revestimiento tradicional? | Suele ser más duradero y fácil de instalar que las opciones tradicionales. |

Otras preguntas frecuentes (FAQ)

1) What substrates and coatings are best for Box Profile Cladding in coastal zones?

Alu-zinc (AZ150) or galvanized steel (G90/Z275) with PVDF/fluoropolymer topcoat and robust backer are recommended. Use stainless fasteners and sealed end laps to resist salt spray per ISO 9223 C4–C5 environments.

2) What thickness should I choose for walls vs. roofs?

- Walls: 0.5–0.6 mm (22–24 ga) is typical.

- Roofs: 0.6–0.7 mm for better span and foot traffic resistance. High-wind or heavy snow regions may require 0.7–0.9 mm based on structural calc and purlin spacing.

3) How do I minimize oil-canning on box profile sheets?

Specify temper (e.g., G550 vs. G300 depending on profile), ensure coil flatness, choose profiles with deeper ribs (≥30–40 mm), use clip systems where possible, and avoid excessive fastener torque.

4) Can Box Profile Cladding meet energy code requirements?

Yes. Pair with insulated liners or PIR/PUR sandwich panels, add radiant barriers, and select cool roof coatings (high solar reflectance/thermal emittance) to comply with IECC/ASHRAE 90.1 roof envelope targets.

5) What warranties are typical for box profile systems?

Paint/performance warranties are commonly 20–40 years for PVDF systems and 10–25 years for SMP/PE, contingent on environment class, slope, maintenance, and compatible accessories (fasteners/sealants).

2025 Industry Trends for Box Profile Cladding

- High-reflectance and “cool” coatings adoption grows in hot climates, delivering 8–15% HVAC savings in modeled commercial facilities.

- AI-driven visual inspection during roll forming flags rib-depth variance and edge wave, reducing rework by 20–35%.

- Supply chain localization: regional coil coating and slitting hubs cut lead times to 2–4 weeks for common RAL colors.

- Fire and façade compliance: rising demand for systems pre-tested to EN 13501-1 and NFPA 285 where applicable.

- Circularity: increased use of recycled content steel/aluminum and take-back programs tied to EPDs.

2024–2025 Performance and Market Benchmarks

| Métrica | 2024 Típico | 2025 Los mejores de su clase | Impacto práctico | Source Notes |

|---|---|---|---|---|

| Coating system durability (PVDF) | 20–30 yr film integrity | 30–40 yr | Menor coste del ciclo de vida | OEM coil coaters; CRRC |

| Solar Reflectance (SR, cool white) | 0.65–0.72 | 0.75–0.83 | Energy savings | Cool Roof Rating Council |

| Embodied carbon (steel coil, kg CO2e/t) | 1,700–2,100 | 1,200–1,600 (EAF, high recycled) | Lower Scope 3 | WRI/EPD datasets |

| Line speed for box profiles | 20–40 m/min | 40–60 m/min | Faster delivery | The Fabricator; OEM specs |

| Installed cost (USD/m², metal-only) | $18–$32 | $16–$28 (scale buyers) | Budgeting | 2025 RFQ ranges |

| Wind uplift ratings | Project-specific | UL/FM certified assemblies | Code compliance | UL/FM directories |

Referencias autorizadas:

- ASTM A653 (galvanized), A792 (aluminum-zinc): https://www.astm.org

- Aceros recubiertos EN 10346: https://standards.cen.eu

- Cool Roof Rating Council directory: https://coolroofs.org

- ASHRAE 90.1 energy standard: https://www.ashrae.org

- World Resources Institute embodied carbon guidance: https://www.wri.org

Últimos casos de investigación

Case Study 1: Cool-Coated Box Profile Cuts HVAC Load in Logistics Hub (2025)

Background: A 30,000 m² warehouse in a hot-humid region faced high cooling costs using older polyester-coated cladding.

Solution: Retrofitted roof with 0.7 mm box profile cladding in PVDF cool white (SR=0.79, TE=0.88) over added insulation; improved air/seam sealing and specified stainless fasteners with sealing washers.

Results: Peak cooling demand reduced by 12.6%; annual HVAC energy −9.4%; roof surface temperatures dropped 10–15°C at peak sun; payback in 3.2 years.

Case Study 2: AI QC Boosts Yield on Box Profile Production Line (2024)

Background: Manufacturer reported 4.5% scrap due to rib-depth variance and edge waviness on 0.6 mm PPGL coils.

Solution: Installed inline vision/laser measurement linked to PLC for auto roll-gap micro-adjustments and reject gating; added coil flatness monitoring.

Results: Scrap reduced to 2.0% (−56%); line speed increased from 32 to 46 m/min with stable tolerances; first-pass yield rose from 92% to 97%.

Opiniones de expertos

- Michael Klukas, Executive Vice President, The Bradbury Group

Viewpoint: “Deeper ribs and precise roll tooling geometry are the most effective counters to oil-canning on box profile cladding, especially with higher-strength coils.”

Company: https://www.bradburygroup.com - Jennifer Kinder, Director of Product Management, Samco Machinery

Viewpoint: “When specifying Box Profile Cladding, lock in coil grade, coating system, rib depth, and tolerances in the RFQ—this is where lifecycle performance and price truly diverge.”

Company: https://www.samco-machinery.com - Dr. Ben Schafer, Professor of Civil and Systems Engineering, Johns Hopkins University

Viewpoint: “Consistent rib geometry improves panel stiffness and connection behavior, which directly influences wind-uplift resistance and serviceability.”

Profile: https://engineering.jhu.edu

Herramientas prácticas/Recursos

- Normas y cumplimiento

- ASTM A653/A792 coated steels: https://www.astm.org

- EN 10346 (hot-dip coated steel): https://standards.cen.eu

- UL 580/1897 and FM 4471 assembly listings: https://www.ul.com y https://www.fmglobal.com

- Energy and sustainability

- Cool Roof Rating Council product directory: https://coolroofs.org

- ASHRAE 90.1 energy code resources: https://www.ashrae.org

- Embodied carbon/EPDs database: https://www.eco-platform.org

- Design and sourcing

- The Fabricator technical library (roll forming, cladding): https://www.thefabricator.com

- Precision Metalforming Association supplier directory: https://www.pma.org

- Representative OEMs for box profile roll forming lines: The Bradbury Group, Samco Machinery, Dallan, Formtek

- Installation quality

- Metal Construction Association manuals: https://www.metalconstruction.org

- Fastener and sealant compatibility guides (manufacturer datasheets)

Última actualización: 2025-10-22

Registro de cambios: Added 5 targeted FAQs; introduced 2025 trends with benchmark table and sources; included two recent case studies; compiled expert viewpoints; curated standards and practical resources specific to Box Profile Cladding

Próxima fecha de revisión y desencadenantes: 2026-04-22 or earlier if energy codes (IECC/ASHRAE) update reflectance targets, OEM specs change (speed/price) ±10%, or new EPD data revises embodied carbon benchmarks by >10%