Roll forming equipment is a type of machinery used to produce items like steel, aluminum, and PVC by pressing them through rolls of varying shapes. There are several different types of roll forming machines that serve the same function but use different materials. The 5 Types Of Roll Forming Machines And What They’re Used For in this blog article describe the difference between each type of machine.

একটি রোল ফর্মিং মেশিন কি?

ক রোল গঠনের মেশিন is a type of machine that is used to form metal into shapes and sizes that are not possible with other types of machines. This process is done by passing the metal through a series of rollers, each of which is slightly different in shape. The metal is then forced through the rollers by hydraulic pressure, which allows it to take on the new shape.

Roll forming machines are used in a variety of industries, including automotive, aerospace, construction, and appliance manufacturing. They are also used to create parts for consumer products such as bicycles and lawnmowers. In addition, roll forming machines can be used to create art objects or sculptures.

রোল ফর্মিং মেশিনের প্রকার

There are several different types of roll forming machines, each designed for a specific purpose. Here is a rundown of the most common types of roll formers and what they are typically used for:

- Universal Roll Forming Machine: A universal roll forming machine is the most versatile type of machine, capable of performing a variety of tasks. They can be used to create everything from simple shapes to complex parts with multiple curves.

- Thread Rolling Machine: A thread rolling machine is designed specifically for creating threads on fasteners and other small parts. These machines use a series of dies to roll the threads onto the part, providing a stronger and more precise grip than traditional threading methods.

- Wire Forming Machine: A wire forming machine is used to create all kinds of shapes out of wire. These machines can bend, twist, and cut wire to create anything from simple hooks to complex sculptures.

- Hydraulic Press: A hydraulic press is a powerful machine that uses high-pressure fluid to shape metal and other materials. Hydraulic presses are typically used for stamping, forging, and sheet metal working applications.

- Laser Cutting Machine: A laser cutting machine uses a high-powered laser beam to cut through materials like metal, glass, or plastic. Laser cutting machines are often used for precision applications such as creating electrical components or medical devices.

-

দ্রাক্ষাক্ষেত্র পোস্ট রোল ফর্মিং মেশিন

দ্রাক্ষাক্ষেত্র পোস্ট রোল ফর্মিং মেশিন -

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য সিগমা Purlin রোল ফর্মিং মেশিন

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য সিগমা Purlin রোল ফর্মিং মেশিন -

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য Z Purlin রোল তৈরির মেশিন

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য Z Purlin রোল তৈরির মেশিন -

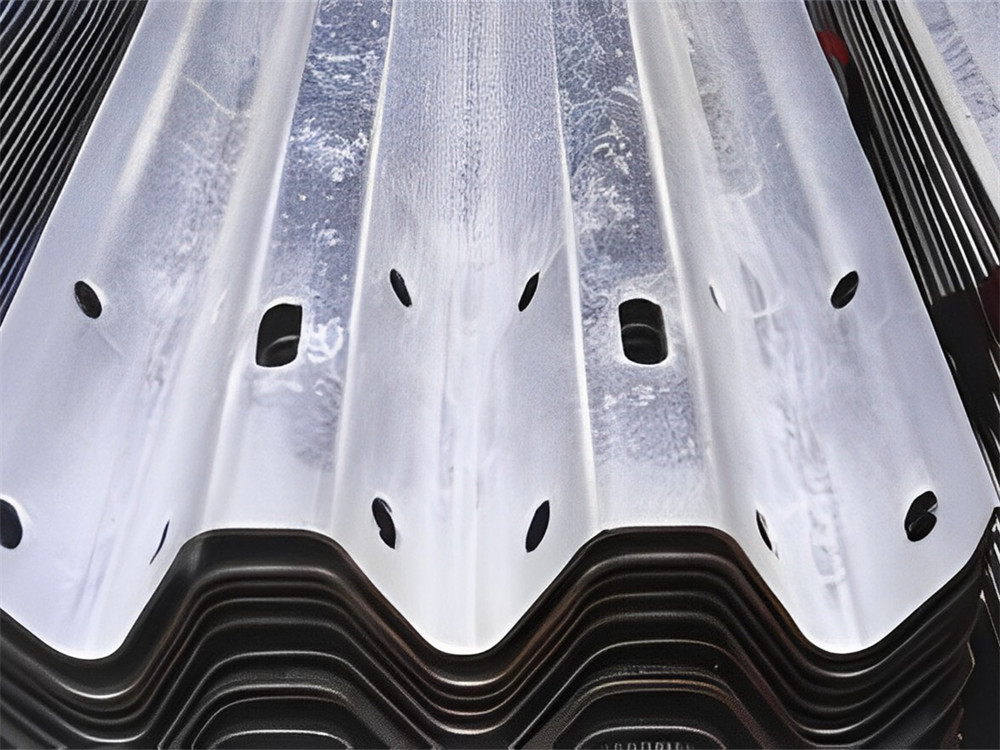

ফ্লোর ডেক রোল তৈরির মেশিন

ফ্লোর ডেক রোল তৈরির মেশিন -

সি সেকশন ব্রেসিং ওমেগা স্টোরেজ র্যাক খাড়া পোস্ট রোল ফর্মিং মেশিন

সি সেকশন ব্রেসিং ওমেগা স্টোরেজ র্যাক খাড়া পোস্ট রোল ফর্মিং মেশিন -

স্টিল বক্স প্লেট মেকিং রোল ফর্মিং মেশিন

স্টিল বক্স প্লেট মেকিং রোল ফর্মিং মেশিন -

বক্স মরীচি স্টীল রোল শেল্ফ কলাম জন্য মেশিন গঠন

বক্স মরীচি স্টীল রোল শেল্ফ কলাম জন্য মেশিন গঠন -

প্যালেট র্যাকিং স্টেপ বিম পি বিম রোল তৈরির মেশিন

প্যালেট র্যাকিং স্টেপ বিম পি বিম রোল তৈরির মেশিন -

গুদাম শেল্ফ খাড়া রোল গঠন মেশিন

গুদাম শেল্ফ খাড়া রোল গঠন মেশিন

what are the different types of roll forming machine used for?

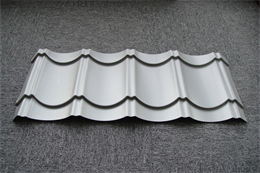

Roll forming machines are used to create various types of products. Some of the most common applications for roll forming machines include creating panels for roofs and walls, framing for doors and windows, and creating pipe and tubing.

Roll forming machines can also be used to create a variety of other products, including auto body parts, metal furniture, and appliance parts. With the right tooling, a roll forming machine can produce just about any type of metal product you need.

benefits of the different types of roll forming machine

- Increased Productivity – A roll forming machine can help to increase productivity in your manufacturing process. This is because it can help to speed up the process and allow you to produce more products in a shorter amount of time.

- Reduced Costs – Using a roll forming machine can also help to reduce costs associated with your manufacturing process. This is because it can help to reduce the amount of scrap material that is produced, as well as the amount of time that is needed to produce each product.

- Improved Quality – The use of a রোল গঠন machine can also lead to improved quality in your finished products. This is because the process helps to ensure that each product is formed correctly and with consistent dimensions.

- Increased Flexibility – Another great benefit of using a roll forming machine is the increased flexibility it offers. This means that you can easily change the shape or size of the products that you are manufacturing, without having to purchase new machinery or retool your existing machinery.

- Enhanced Safety – Finally, the use of a roll forming machine can also help to enhance safety in your workplace. This is because the process helps to eliminate sharp edges on your finished products, which can prevent injuries from occurring during the manufacturing process or when using the products.

উপসংহার

There are many different types of roll forming machines available on the market, each with their own unique set of capabilities. When choosing a roll forming machine for your business, it’s important to consider what type of product you’ll be manufacturing and what your production volume requirements will be. With so many options available, there’s sure to be a roll forming machine out there that’s perfect for your needs.

FAQ

রোল গঠন প্রক্রিয়া কি?

রোল গঠন একটি ক্রমাগত প্রক্রিয়া যা শীট মেটালকে একটি প্রকৌশলী আকৃতিতে রূপান্তরিত করে পরপর সেট করা ম্যাটেড রোলগুলি ব্যবহার করে, যার প্রতিটি ফর্মে শুধুমাত্র ক্রমবর্ধমান পরিবর্তন করে। আকারে এই ছোট পরিবর্তনের যোগফল একটি জটিল প্রোফাইল।