The demand for renewable energy solutions, particularly solar power, has skyrocketed in recent years. To meet the growing need for efficient and durable solar panel mounting systems, specialized machines like the Hat Profile Solar Mounting Roll Forming Machine have become essential. These machines are designed to produce high-precision hat-shaped profiles that form the backbone of solar mounting structures.

In this in-depth guide, we’ll explore everything you need to know about Hat Profile Solar Mounting Roll Forming Machines, including their applications, benefits, specifications, pricing, and why Wuxi Sunway Machinery is the leading choice for businesses worldwide. Whether you’re a solar industry veteran or new to roll-forming technology, this guide has got you covered.

Overview of Hat Profile Solar Mounting Roll Forming Machines

So, what exactly is a Hat Profile Solar Mounting Roll Forming Machine? Picture a machine that transforms flat sheets or coils of metal into perfectly engineered hat-shaped profiles. These profiles are integral to solar mounting systems, providing the structural support needed to secure সোলার প্যানেলs in place.

The machine uses a series of rollers to bend and shape the metal into the desired profile, ensuring accuracy, consistency, and efficiency. With the increasing adoption of solar energy, these machines play a crucial role in manufacturing components that meet the industry’s stringent standards.

Applications of Hat Profile Solar Mounting Roll Forming Machines

Hat profiles are specifically designed for strength, durability, and ease of installation, making them a popular choice in the solar energy sector. Here’s a breakdown of their key applications:

1. Solar Panel Mounting Systems

Hat profiles form the structural framework that holds solar panels in place, whether on rooftops, ground-mounted arrays, or floating solar installations. Their unique shape provides excellent load-bearing capacity and resistance to environmental stresses.

2. Renewable Energy Infrastructure

Beyond solar panels, hat profiles are used in renewable energy projects where lightweight and durable structures are needed, such as wind turbine frameworks or hybrid energy systems.

3. Agricultural Solar Systems

In agrivoltaic systems (combining agriculture and solar panels), hat profiles are used to elevate panels above crops, maximizing land use while providing shade and protection.

4. Rooftop Solar Installations

Rooftop solar mounting systems often rely on hat profiles for their lightweight yet sturdy design, ensuring easy installation without compromising the roof’s integrity.

5. Custom Solar Applications

From carports to solar-powered shelters, hat profiles are used in a variety of custom solar projects where versatility and strength are essential.

By investing in a Hat Profile Solar Mounting Roll Forming Machine, manufacturers can tap into these lucrative markets with ease.

Types of Hat Profile Solar Mounting Roll Forming Machines

Not all solar mounting projects are the same, and neither are the machines used to produce their components. Here’s an overview of the different types of Hat Profile Solar Mounting Roll Forming Machines:

1. Standard Hat Profile Machines

These machines produce a single, standard hat profile, ideal for manufacturers with a focused product line.

2. Multi-Profile Machines

Need versatility? Multi-profile machines can produce a variety of hat profiles with quick tool changes, making them perfect for businesses serving multiple industries.

3. Fully Automated Machines

For high-volume production, fully automated machines handle everything from material feeding to cutting and stacking, requiring minimal human intervention.

4. Custom Hat Profile Machines

If your project requires unique dimensions or materials, custom machines can be designed to meet specific requirements.

Comparison Table: Types of Hat Profile Solar Mounting Roll Forming Machines

| Machine Type | অটোমেশনের স্তর | উৎপাদন গতি | Ideal For | Price Range (USD) |

|---|---|---|---|---|

| Standard Machines | Medium | Medium | Focused solar panel systems | $30,000–$50,000 |

| Multi-Profile Machines | High | High | Versatile production needs | $40,000–$70,000+ |

| সম্পূর্ণ অটোমেটেড মেশিন | Full | High | High-volume, industrial production | $50,000–$100,000+ |

| Custom Machines | Variable | Variable | Unique or specialized applications | Dependent on design |

Benefits of Hat Profile Solar Mounting Roll Forming Machines

What makes these machines a must-have for solar panel manufacturers? Let’s take a closer look:

1. Precision Engineering

The profiles produced are consistent and meet the exacting standards required for solar mounting systems.

2. High Production Efficiency

With speeds of up to 30 meters per minute, these machines are perfect for high-volume production.

3. Material Versatility

Whether you’re working with galvanized steel, aluminum, or stainless steel, these machines can handle it all.

4. Reduced Waste

The roll-forming process minimizes material waste, making it both cost-effective and environmentally friendly.

5. Customization Options

From profile dimensions to material types, these machines offer a high degree of customization to meet diverse project requirements.

When you choose a machine from Wuxi Sunway Machinery, you’re investing in cutting-edge technology that delivers these benefits and more.

Specifications of Hat Profile Solar Mounting Roll Forming Machines

Understanding the technical specs can help you choose the right machine for your needs. Here’s what to look for:

| Specification | বিস্তারিত |

|---|---|

| Material Thickness | 0.5mm–2.5mm |

| Material Type | Galvanized steel, aluminum, stainless steel |

| গঠন গতি | 10–30 meters per minute |

| বেলন উপাদান | High-strength steel with chrome plating |

| কাটিং সিস্টেম | Hydraulic or servo cutting for precision |

| নিয়ন্ত্রণ ব্যবস্থা | PLC (Programmable Logic Controller) with HMI |

| পাওয়ার সাপ্লাই | Typically 380V/50Hz (customizable for regional standards) |

Why These Matter:

- Material Compatibility: Determines the projects you can take on.

- Speed: Impacts production efficiency.

- নিয়ন্ত্রণ ব্যবস্থা: Ensures accuracy and reduces errors.

At Wuxi Sunway Machinery, we design machines with these specs and more, ensuring you get a product that’s both reliable and efficient.

Pricing: What to Expect

The price of a Hat Profile Solar Mounting Roll Forming Machine depends on several factors, including its features, automation level, and customization. Here’s a breakdown:

General Price Ranges

- Standard Machines: $30,000–$50,000

- Multi-Profile Machines: $40,000–$70,000+

- Fully Automated Machines: $50,000–$100,000+

- Custom Machines: Pricing varies based on design and capabilities.

Factors Affecting Price

- Automation Level: Fully automated machines are more expensive but offer significant labor savings.

- Customization: Tailored machines for unique profiles or materials come at a premium.

- Material Capability: Machines that handle a wider range of materials are generally pricier.

For competitive pricing and exceptional value, check out Wuxi Sunway Machinery. We offer flexible payment plans to make high-quality machinery accessible to businesses of all sizes.

Maintenance Tips for Hat Profile Solar Mounting Roll Forming Machines

Proper maintenance is key to maximizing the lifespan and efficiency of your machine. Here are some tips:

1. Daily Cleaning

Remove debris and dust from the rollers and feeding area to prevent wear and tear.

2. Lubrication

Keep all moving parts well-lubricated to ensure smooth operation.

3. Inspect Rollers

Check rollers regularly for signs of wear or damage and replace them as needed.

4. Calibrate Settings

Ensure the machine is calibrated correctly to maintain production accuracy.

5. Schedule Professional Maintenance

Periodic servicing by professionals can identify and fix potential issues before they escalate.

For expert maintenance and support, trust the team at Wuxi Sunway Machinery.

FAQs About Hat Profile Solar Mounting Roll Forming Machines

Let’s address some common questions about these machines:

| Question | Answer |

|---|---|

| Can the machine handle multiple profiles? | Yes, multi-profile machines can produce various hat profiles with quick adjustments. |

| What materials can it process? | Most machines can handle galvanized steel, aluminum, and stainless steel. |

| What’s the average production capacity? | Depending on the model, machines can produce up to 5,000–10,000 meters of profiles per day. |

| Is training provided? | Yes, manufacturers like Wuxi Sunway Machinery offer training as part of their service. |

| Do you offer financing options? | Absolutely! Flexible payment plans are available to suit your budget. |

Advanced Technical Advantages of Hat Profile Solar Mounting Roll Forming Machines

Let’s be honest—choosing the right roll forming machine is a big decision. While the Hat Profile Solar Mounting Roll Forming Machine is a standout choice for the solar energy industry, its technical advantages set it miles apart from traditional manufacturing methods. Here’s why:

1. Optimized for Lightweight Strength

The hat profile design is inherently strong while remaining lightweight. This makes it perfect for solar mounting systems that need to withstand wind, rain, and environmental stresses without adding unnecessary weight to rooftops or ground-mounted installations.

2. Superior Corrosion Resistance

Solar mounting systems are often exposed to harsh weather conditions. These machines are designed to work with materials like galvanized steel, aluminum, and stainless steel, ensuring the final product is corrosion-resistant and long-lasting.

3. High Precision and Consistency

Accuracy is critical in solar mounting systems, where even minor deviations can result in poor panel alignment. Hat Profile Roll Forming Machines use advanced rollers and cutting systems to produce profiles with millimeter-level precision, ensuring every piece is identical.

4. Enhanced Production Speeds

Time is money in manufacturing. With forming speeds of up to 30 meters per minute, these machines can meet the demands of large-scale solar projects without compromising quality.

5. Eco-Friendly Production

The roll-forming process minimizes scrap and waste, making it an environmentally friendly choice. Plus, the materials used (aluminum, steel) are 100% recyclable, aligning perfectly with the renewable energy ethos.

6. IoT Integration and Smart Features

In 2025, smart manufacturing is the norm, not the exception. Many high-end machines, such as those from Wuxi Sunway Machinery, come equipped with IoT capabilities for real-time monitoring and predictive maintenance alerts, ensuring maximum uptime.

These technical advantages make the Hat Profile Solar Mounting Roll Forming Machine a must-have for any solar energy manufacturer looking to stay competitive in the modern market.

Workflow Optimization: From Coil to Finished Product

Understanding the workflow of a Hat Profile Solar Mounting Roll Forming Machine can help you identify areas for improvement and ensure seamless production. Let’s break it down step by step:

Step 1: Material Loading

The process begins with loading coils of raw material (such as galvanized steel or aluminum) onto the machine’s decoiler. Advanced models feature automatic decoilers that handle heavy coils with ease.

Step 2: Feeding System

The raw material is fed into the machine’s rollers. Automatic feeding systems ensure accurate alignment, reducing errors and speeding up the process.

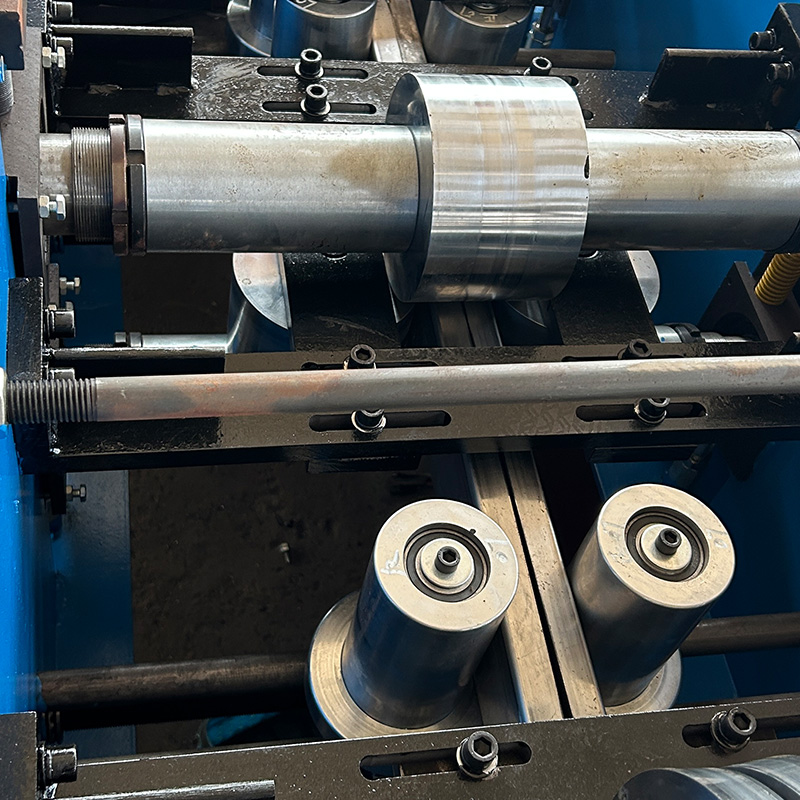

Step 3: Roll Forming

The material passes through a series of rollers that gradually bend it into the desired hat profile shape. The rollers are precisely calibrated to ensure uniformity and avoid material deformation.

Step 4: Punching (Optional)

Many solar mounting systems require pre-drilled holes for bolts and screws. Machines with integrated hydraulic punching systems can handle this step in-line, eliminating the need for secondary operations.

Step 5: Cutting

Once the profile is complete, it’s cut to the required length using a hydraulic or servo-driven cutting system. Precision cutting ensures clean edges and minimal waste.

Step 6: Stacking and Packaging

The finished profiles are automatically stacked and packaged, ready for transportation to the installation site or storage.

Real-Time Monitoring and Adjustments

Machines equipped with IoT and PLC systems allow operators to monitor and adjust production parameters in real-time, ensuring efficiency and minimizing downtime.

By optimizing each step, manufacturers can achieve faster turnaround times, higher product quality, and reduced costs.

Hat Profile Solar Mounting Roll Forming Machine vs. Other Roll Forming Machines

How does a Hat Profile Solar Mounting Roll Forming Machine compare to other types of roll-forming machines? Let’s take a closer look:

| Feature | Hat Profile Solar Mounting Machine | C/Z Purlin Roll Forming Machine | বক্স বিম রোল তৈরির মেশিন |

|---|---|---|---|

| Primary Application | Solar panel mounting systems | Structural building frameworks | Racking and shelving systems |

| Material Thickness Range | 0.5mm–2.5mm | 1.5mm–3.0mm | 1.5mm–4.0mm |

| উৎপাদন গতি | 10–30 meters per minute | 10–25 meters per minute | 10–20 meters per minute |

| অটোমেশনের স্তর | High | Medium to High | High |

| Customization Capability | Excellent | High | Moderate |

| Typical Cost Range (USD) | $30,000–$100,000+ | $25,000–$60,000+ | $30,000–$100,000+ |

Key Advantages of Hat Profile Machines:

- Specifically designed for solar mounting applications.

- Offers lightweight and corrosion-resistant profiles.

- Highly customizable for different solar panel systems.

For businesses in the renewable energy sector, a Hat Profile Solar Mounting Roll Forming Machine is the clear choice. Explore more options for roll-forming machines at Wuxi Sunway Machinery.

Maintenance for Maximum Longevity

To keep your machine running smoothly and efficiently, regular maintenance is essential. Here’s a quick guide:

Daily Maintenance

- Clean rollers and feeding components to remove debris.

- Inspect for signs of wear or damage on critical components like rollers and blades.

Weekly Maintenance

- Lubricate all moving parts, including rollers, chains, and gears.

- Check the alignment of rollers to ensure consistent profile shaping.

Monthly Maintenance

- Inspect hydraulic systems for leaks and ensure optimal pressure levels.

- Test the PLC and IoT systems to ensure accurate data collection and error notifications.

Annual Maintenance

- Conduct a full inspection of electrical systems and replace any worn-out components.

- Recalibrate the machine to maintain precision and efficiency.

For expert advice and servicing, you can always rely on Wuxi Sunway Machinery, which provides top-notch after-sales support.

FAQs About Hat Profile Solar Mounting Roll Forming Machines

Here are some of the most frequently asked questions about these machines:

| Question | Answer |

|---|---|

| Can the machine produce profiles for other applications? | Yes, multi-profile and customizable machines can handle a variety of profiles beyond solar mounting systems. |

| What materials are best for solar mounting profiles? | Galvanized steel, aluminum, and stainless steel are commonly used for their strength and corrosion resistance. |

| What’s the average production capacity? | Depending on the model, machines can produce up to 10,000 meters of profiles per day. |

| Is on-site training available? | Yes, training and installation support are often included with the purchase of a machine. |

| Does Wuxi Sunway offer financing options? | Absolutely! Flexible payment plans are available to meet your budget needs. |

Still have questions? Contact Wuxi Sunway Machinery for personalized guidance and support.

Why Choose Wuxi Sunway Machinery?

When it comes to roll-forming technology, Wuxi Sunway Machinery is a global leader. Here’s why:

1. Decades of Expertise

With years of experience, we specialize in designing roll-forming machines tailored to diverse industries.

2. Custom Solutions

We understand that every business is unique. That’s why we offer customized machines to meet your specific requirements.

3. High-Quality Standards

All our machines comply with international quality standards, ensuring durability and performance.

4. Global Reach

From Asia to Europe, Africa, and beyond, our machines are trusted by manufacturers worldwide.

5. Comprehensive Support

From installation and training to maintenance and spare parts, we’re with you every step of the way.

Conclusion: Why the Hat Profile Solar Mounting Roll Forming Machine is a Game-Changer

In the renewable energy industry, efficiency, precision, and scalability are non-negotiable. A Hat Profile Solar Mounting Roll Forming Machine meets all these demands, making it an indispensable asset for manufacturers of solar mounting systems.

And when it comes to choosing a supplier, Wuxi Sunway Machinery is the clear choice. With a proven track record, advanced technology, and unmatched customer support, we’re your trusted partner in the roll-forming industry.

So, are you ready to power up your production line and contribute to a greener future? Let’s roll forward—together! 🌞🚀