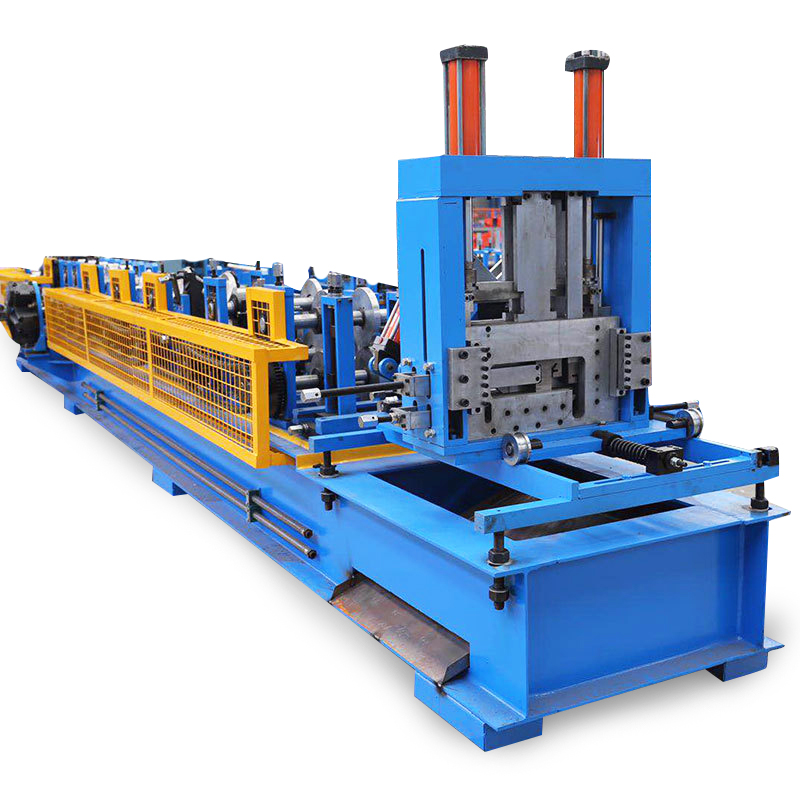

পারলিন রোল ফর্মিং প্রক্রিয়া নির্মাণ শিল্পে পারলিন রোল ফর্মিং প্রক্রিয়া একটি গুরুত্বপূর্ণ ধাপ, যা ধাতু শীটকে পারলিন আকারে রূপান্তরিত করে। এই কাঠামোগত উপাদানগুলি ভবনের ছাদ ও দেয়াল ব্যবস্থাকে সমর্থন প্রদান করে অপরিহার্য। তবে এই প্রক্রিয়া সর্বদা সহজ নয় এবং বিভিন্ন সমস্যা দেখা দিতে পারে যা চূড়ান্ত পণ্যের গুণগত মানকে প্রভাবিত করে। এই লেখায় আমরা পারলিন রোল ফর্মিং প্রক্রিয়ায় সাধারণ সমস্যাগুলো অন্বেষণ করব এবং সেগুলোর সমাধান প্রদান করব। ঠিকাদার, প্রকৌশলী বা উৎপাদক যাই হোন না কেন, এই লেখা আপনাকে সর্বোত্তম ফলাফল অর্জনে এবং ব্যয়বহুল ভুল এড়াতে মূল্যবান অন্তর্দৃষ্টি প্রদান করবে।

পারলিন রোল ফর্মিং প্রক্রিয়ায় সাধারণ সমস্যাসমূহ

পারলিনের অসমান আকৃতি:

পারলিন রোল ফর্মিং প্রক্রিয়ায় সাধারণ সমস্যাগুলোর মধ্যে একটি হলো পারলিনের অসমান আকৃতি, যা বিভিন্ন কারণে সৃষ্ট হতে পারে। এই সমস্যার একটি সম্ভাব্য কারণ হলো রোলারগুলোর ভুল সেটিং বা অ্যালাইনমেন্টের অভাব, যা ফর্মিং প্রক্রিয়ার সময় অসমান চাপ বিতরণের দিকে নিয়ে যায়। এই সমস্যা এড়াতে রোলারগুলো সঠিকভাবে অ্যালাইন করা এবং চাপ বিতরণ সমান করা অত্যন্ত জরুরি। রোলার এবং মেশিনের নিয়মিত রক্ষণাবেক্ষণও এই সমস্যা প্রতিরোধে সহায়ক।

কয়েল সেট বা ক্রস ব্রেক:

কয়েল সেট বা ক্রস ব্রেক পারলিন রোল ফর্মিং প্রক্রিয়ায় আরেকটি সমস্যা যা দেখা দিতে পারে। এই সমস্যা ঘটে যখন ধাতব শীট ফর্মিং প্রক্রিয়ার পরেও স্থায়ী বক্রতা প্রদর্শন করে। কয়েল সেট বা ক্রস ব্রেক পারলিনের গুণমানকে নেতিবাচকভাবে প্রভাবিত করে এবং উৎপাদন বিলম্বিত করে। এই সমস্যা এড়াতে অভ্যন্তরীণ চাপ কম থাকা উচ্চমানের ধাতব শীট ব্যবহার করা গুরুত্বপূর্ণ। রোল ফর্মিং মেশিনে শীট দেওয়ার আগে লেভেলিং সরঞ্জাম ব্যবহার করলে কয়েল সেট বা ক্রস ব্রেক প্রতিরোধ করা যায়।

এজ ওয়েভ:

এজ ওয়েভ হলো এমন একটি সমস্যা যখন ধাতব শীটের প্রান্তগুলো ফর্মিং প্রক্রিয়ার সময় অসমান চাপ বিতরণের ফলে তরঙ্গাকার আকৃতি প্রদর্শন করে। এই সমস্যা চূড়ান্ত পণ্যের গুণমানকে প্রভাবিত করে এবং প্রত্যাখ্যান ও অপচয়ের কারণ হয়। এজ ওয়েভ প্রতিরোধে রোলারগুলো সঠিকভাবে অ্যালাইন করে সমান চাপ প্রয়োগ করা অত্যাবশ্যক। অভ্যন্তরীণ চাপ কম থাকা উচ্চমানের কাঁচামাল ব্যবহার করলে এই সমস্যা এড়ানো যায়।

বাকলিং:

বাকলিং হলো একটি সাধারণ সমস্যা যা ঘটে যখন পারলিনের দৈর্ঘ্য তার প্রস্থ অতিক্রম করে, যা বাঁকানোর প্রভাব সৃষ্টি করে। এই সমস্যা রোল ফর্মিং মেশিনের ভুল সেটিং বা উপাদানের অপর্যাপ্ত শক্তির কারণে হতে পারে। বাকলিং এড়াতে রোল ফর্মিং মেশিন সঠিকভাবে সেট করা এবং ফর্মিং প্রক্রিয়া সহ্য করার জন্য যথেষ্ট শক্তিমান কাঁচামাল ব্যবহার করা জরুরি।

স্প্রিং ব্যাক:

স্প্রিং ব্যাক হলো এমন একটি সমস্যা যখন ধাতব শীট ফর্মিং প্রক্রিয়ার পর তার মূল আকৃতিতে ফিরে যায়, যা পারলিনের অমঠ্যাক্ষর মাত্রা সৃষ্টি করে। এই সমস্যা রোলারের ভুল সেটিং, উপাদানের ধরন এবং পুরুত্বের মতো বিভিন্ন কারণে হতে পারে। স্প্রিং ব্যাক সমাধানে রোলারের সেটিং সংশোধন করে সঠিক চাপ প্রয়োগ করা এবং ধাতব শীটের পুরুত্ব ও ধরন ফর্মিং প্রক্রিয়ার উপযোগী হওয়া নিশ্চিত করা দরকার।

অন্যান্য সমস্যা:

পারলিন রোল ফর্মিং প্রক্রিয়ায় অন্যান্য সাধারণ সমস্যাগুলোর মধ্যে রয়েছে উপাদান ফাটা, ওয়েল্ডিং ত্রুটি এবং মাত্রাগত তারতম্য। এই সমস্যাগুলো সমাধানে উচ্চমানের কাঁচামাল ব্যবহার, রোল ফর্মিং মেশিনের নিয়মিত রক্ষণাবেক্ষণ এবং অপারেটরের সঠিক প্রশিক্ষণ ও মেশিন হ্যান্ডলিং নিশ্চিত করা অত্যাবশ্যক।

পারলিন রোল ফর্মিং প্রক্রিয়ার সমস্যাগুলোর সমাধান

রোল ফর্মিং মেশিন সামঞ্জস্য করা:

পারলিন রোল ফর্মিং প্রক্রিয়ায় যে সমস্যাগুলো দেখা দিতে পারে তার সমাধানে রোল ফর্মিং মেশিনের সেটিং সঠিকভাবে সামঞ্জস্য করা জরুরি। উদাহরণস্বরূপ, পারলিনের অসমান আকৃতির সমস্যা সমাধানে রোলারের অ্যালাইনমেন্ট পরীক্ষা করা, রোলার চাপ সামঞ্জস্য করা এবং রোলারের দূরত্ব সমান করা উচিত। বাকলিং প্রতিরোধে রোলার সেটিং সংশোধন করে সঠিক চাপ প্রয়োগ করা এবং উপাদানের পুরুত্ব ফর্মিং প্রক্রিয়ার উপযোগী হওয়া নিশ্চিত করা দরকার।

উচ্চমানের উপাদান ব্যবহার:

পারলিন রোল ফর্মিং প্রক্রিয়ায় ব্যবহৃত কাঁচামালের গুণমান চূড়ান্ত পণ্যের গুণমানের উপর উল্লেখযোগ্য প্রভাব ফেলে। অতএব, অভ্যন্তরীণ চাপ কম থাকা উচ্চমানের উপাদান ব্যবহার করা অপরিহার্য, যা কয়েল সেট বা ক্রস ব্রেক, এজ ওয়েভ এবং উপাদান ফাটার মতো সমস্যা প্রতিরোধ করে। কঠোর গুণমান নিয়ন্ত্রণ অনুসরণকারী নির্ভরযোগ্য সরবরাহকারীদের কাছ থেকে উপাদান ক্রয় করা জরুরি যাতে প্রয়োজনীয় মান পূরণ হয়।

মেশিনের সঠিক রক্ষণাবেক্ষণ:

রোল ফর্মিং মেশিনের সঠিক রক্ষণাবেক্ষণ তার সঠিক কার্যকারিতা নিশ্চিত করে এবং পারলিন রোল ফর্মিং প্রক্রিয়ায় সমস্যা প্রতিরোধ করে অত্যাবশ্যক। নিয়মিত রক্ষণাবেক্ষণের মধ্যে রয়েছে মেশিন পরিষ্কার করা, রোলার পরীক্ষা করা, চলমান অংশগুলোতে লুব্রিকেশন করা এবং কোনো ক্ষয়প্রাপ্ত অংশ পরীক্ষা করা। কোনো ক্ষতিগ্রস্ত বা ক্ষয়প্রাপ্ত অংশ অবিলম্বে প্রতিস্থাপন করতে হবে যাতে মেশিন এবং চূড়ান্ত পণ্যের আরও ক্ষতি না হয়। অপারেটরের সঠিক প্রশিক্ষণ এবং মেশিন হ্যান্ডলিংও দুর্ঘটনা এবং মেশিনের ক্ষতি প্রতিরোধে গুরুত্বপূর্ণ।

উপসংহারে, পারলিন রোল ফর্মিং প্রক্রিয়ায় দেখা দিতে পারে এমন সমস্যাগুলো সমাধানে রোল ফর্মিং মেশিন সামঞ্জস্য, উচ্চমানের উপাদান ব্যবহার এবং মেশিনের সঠিক রক্ষণাবেক্ষণের সমন্বয় প্রয়োজন। এই সমাধানগুলো অনুসরণ করে নির্মাতা, ঠিকাদার এবং প্রকৌশলীরা প্রয়োজনীয় মান পূরণকারী উচ্চমানের পারলিন উৎপাদন করতে পারেন এবং ভবনের কাঠামোগত অখণ্ডতা ও স্থায়িত্ব নিশ্চিত করতে পারেন।

পারলিন রোল ফর্মিং প্রক্রিয়া নির্মাণ শিল্পের একটি গুরুত্বপূর্ণ ধাপ যা ধাতব শীটগুলোকে পারলিনে রূপান্তর করে। তবে প্রক্রিয়ার সময় বিভিন্ন সমস্যা দেখা দিতে পারে যা চূড়ান্ত পণ্যের গুণমানকে প্রভাবিত করে। এই সমস্যাগুলো কাটিয়ে উঠতে রোল ফর্মিং মেশিনের সেটিং সঠিকভাবে সামঞ্জস্য করা, উচ্চমানের উপাদান ব্যবহার এবং মেশিনের সঠিক রক্ষণাবেক্ষণ অপরিহার্য। এই সমাধানগুলো অনুসরণ করে নির্মাতা, ঠিকাদার এবং প্রকৌশলীরা প্রয়োজনীয় মান পূরণকারী উচ্চমানের পারলিন উৎপাদন করতে পারেন এবং ভবনের কাঠামোগত অখণ্ডতা ও স্থায়িত্ব নিশ্চিত করতে পারেন।

চূড়ান্ত টিপস হিসেবে, রোল ফর্মিং মেশিন প্রশিক্ষিত এবং দক্ষ কর্মীদের দ্বারা পরিচালিত হওয়া নিশ্চিত করা গুরুত্বপূর্ণ যারা প্রক্রিয়ার সময় দেখা দিতে পারে এমন সমস্যা চিহ্নিত করে সমাধান করতে পারেন। মেশিনের নিয়মিত পরীক্ষা এবং রক্ষণাবেক্ষণ সমস্যা প্রতিরোধ করে এবং মেশিনের আয়ু বাড়ায়। উচ্চমানের উপাদান ব্যবহার এবং গুণমান নিয়ন্ত্রণ পদ্ধতিতে কঠোরভাবে অনুসরণ করলে কয়েল সেট বা ক্রস ব্রেক, এজ ওয়েভ, উপাদান ফাটা এবং বাকলিং-এর মতো সমস্যা প্রতিরোধ করা যায়। এই টিপসগুলো অনুসরণ করে পারলিন রোল ফর্মিং প্রক্রিয়ায় জড়িত যেকোনো ব্যক্তি প্রয়োজনীয় মান পূরণকারী উচ্চমানের পারলিন উৎপাদন নিশ্চিত করতে পারেন এবং নিরাপদ ও স্থায়ী ভবন নির্মাণে অবদান রাখতে পারেন।

Additional Frequently Asked Questions (FAQ)

1) How do I diagnose the root cause of edge wave in the purlin roll forming process?

Start with incoming coil (crown, camber, residual stress via mill cert), then check entry guides, leveling/flattening effectiveness, and roll flower progression. Use a feeler gauge across edges after pass 1–3 and thermal-check bearing temps. If wave reduces after leveling adjustments, coil stress is the primary culprit; if it worsens downstream, review pass alignment and roll gap symmetry.

2) What’s the best way to control springback on high-strength steels (S450–S550)?

Use larger inside bend radii, add overbend in late passes, employ crowned rolls where needed, and slow forming speed slightly on critical passes. Recipe-based compensation (per grade/thickness) and inline angle measurement help keep flange angle within ±0.5°. Reference: AISI S100 cold-formed design guidance.

3) When should I use a corrective leveler before the purlin roll forming line?

Use for coils showing coil set, cross break, or camber beyond spec. As a rule of thumb: if flatness deviation >5 mm over 1 m or visible cross break persists after de-coiling, run through a multi-roll corrective leveler to reset the yield surface before forming.

4) How tight can tolerances realistically be for punched holes and lengths on CZ purlins?

With servo-electric punching and an encoder-synchronized flying shear, many 2025 lines achieve ±0.3–0.5 mm hole position and ±0.5–1.0 mm cut length on 1.5–2.5 mm galvanized steel when coils are within flatness spec and guides are calibrated weekly.

5) What preventive maintenance has the biggest impact on dimensional consistency?

Weekly: verify roll gaps with feeler gauges, check pass-to-pass alignment, clean rolls. Monthly: calibrate encoders, check shear blade clearance, inspect bearings. Quarterly: validate recipe offsets, inspect leveler backups, and conduct a full lubrication audit. Document in a CMMS to correlate maintenance with defect rates.

2025 Industry Trends: Purlin Roll Forming Process

- Shift to servo-electric punching/shearing reduces hydraulic downtime and improves hole repeatability for faster site bolting.

- Inline vision/laser systems feed SPC dashboards, enabling automatic recipe tweaks that cut scrap from edge wave and springback.

- Increased use of higher-strength steels (S500–S550) to meet wind/seismic code demands without added weight.

- Data interoperability via OPC UA/MQTT to MES/SCADA supports predictive maintenance and energy KPIs (kWh/ton).

- Sustainability focus: energy-regenerative drives and recycled-content coils prioritized in procurement.

2024–2025 Performance Benchmarks for Purlin Roll Forming

| KPI | 2024 Typical Plant | 2025 Best-in-Class | What It Improves | Sources |

|---|---|---|---|---|

| Scrap rate (all defects) | 2.5–4.0% | 1.0–2.0% | Material cost, rework | DOE AMO; The Fabricator |

| Length tolerance (±) | 1.0–1.5 mm | 0.5–1.0 mm | Fit-up, re-cuts | OEM specs; industry reports |

| Hole position (±) | 0.6–1.0 mm | 0.3–0.5 mm | Faster bolting | Servo-electric punch data |

| C↔Z changeover | 25–45 min | 5–12 min | OEE on high-mix | SMED/OEM case studies |

| Energy intensity (kWh/ton) | 130–170 | 95–130 | Utility cost, CO2e | DOE AMO guidance |

| First-article approval time | 30–60 min | 10–20 min | Throughput | Inline metrology + SPC |

Authoritative references:

- U.S. DOE Advanced Manufacturing Office: https://www.energy.gov/eere/amo

- The Fabricator (roll forming): https://www.thefabricator.com

- AISI/Steel.org design specs (cold-formed steel): https://www.steel.org

- OPC Foundation (OPC UA): https://opcfoundation.org

- ISO 13849-1 functional safety: https://www.iso.org/standard/69883.html

Latest Research Cases

Case Study 1: Cutting Edge Wave with Inline SPC and Leveler Optimization (2025)

Background: A regional purlin manufacturer had recurring edge wave and rejections on 1.8 mm S350 coils from multiple mills.

Solution: Added corrective leveler recipes by supplier/heat, deployed inline laser flatness sensors, and integrated SPC rules to trigger automatic roll gap fine-tuning.

Results: Edge-wave-related scrap fell from 1.2% to 0.4%; first-pass yield rose to 97.6%; coil-to-coil setup time reduced by 18%.

Case Study 2: Springback Control on S550 CZ Purlins for High-Wind Projects (2024)

Background: EPC contractor needed longer spans with S550 material; springback caused flange angle deviations >1°.

Solution: Implemented overbend in final two passes, adjusted bend radii, and added inline angle camera with closed-loop recipe offsets.

Results: Flange angle variation cut to ±0.4°; site bolting time reduced 12%; overall OEE improved from 72% to 80%.

Expert Opinions

- Dr. Benjamin Schafer, Professor of Civil Engineering, Johns Hopkins University

Key viewpoint: “For high-strength purlins, maintaining consistent section properties through precise forming directly affects stability limit states like lateral-torsional buckling.”

Profile: https://engineering.jhu.edu - Jennifer Kinder, Director of Product Management, Samco Machinery

Key viewpoint: “Servo-electric punching combined with laser verification has become a proven route to halve hole-position variability in CZ purlin roll forming.”

Company: https://www.samco-machinery.com - Phil Paxton, President, The Bradbury Group

Key viewpoint: “Plants investing in sub-15-minute C-to-Z changeover and connected controls are seeing double-digit OEE gains in high-mix environments.”

Company: https://www.bradburygroup.com

Practical Tools/Resources

- Standards and design

- AISI S100 Cold-Formed Steel Specification: https://www.steel.org

- Eurocode 3 (EN 1993) resources: https://eurocodes.jrc.ec.europa.eu

- ASTM A653 (galvanized sheet) and A1008: https://www.astm.org

- Process control and analytics

- NIST Manufacturing resources (SPC, metrology): https://www.nist.gov/manufacturing

- OPC Foundation (OPC UA for machine data): https://opcfoundation.org

- Rockwell FactoryTalk Analytics / Siemens Industrial Edge: https://www.rockwellautomation.com, https://www.siemens.com

- Maintenance and reliability

- DOE AMO Energy Management toolkits: https://www.energy.gov/eere/amo

- FIWARE and MQTT docs for IIoT integration: https://www.fiware.org, https://mqtt.org

- Industry media and OEM discovery

- The Fabricator (roll forming channel): https://www.thefabricator.com

- Precision Metalforming Association (PMA): https://www.pma.org

- Representative OEMs: The Bradbury Group, Samco Machinery, Formtek, Dallan (check product pages for purlin roll forming process specs)

- Safety

- ISO 13849-1 functional safety overview: https://www.iso.org/standard/69883.html

Last updated: 2025-10-22

Changelog: Added 5 FAQs; inserted 2025 trend insights with KPI table and sources; included two recent case studies; curated expert viewpoints; compiled tools/resources aligned with E-E-A-T and target keyword variations

Next review date & triggers: 2026-04-22 or earlier if AISI/Eurocode revisions publish, OEMs release new sub-5-minute changeover systems, or plant data shows scrap >2% or hole tolerance >±0.6 mm