Fencing has always been a cornerstone of security and property demarcation, but as industries evolve, so too must the systems and materials used to build them. Enter the তারের জাল বেড়া পোস্ট রোল ফর্মিং মেশিন—a revolutionary solution for producing high-quality fence posts that provide the structural support for modern fencing systems. Whether it’s for urban landscapes, industrial zones, or large agricultural tracts, these machines are the unsung heroes behind the fences that protect, organize, and define our spaces.

In this comprehensive guide, we’ll dive into applications, machine features, production workflows, pricing, market trends, and why Wuxi Sunway Machinery is the clear choice for businesses aiming to invest in Wire Mesh Fence Post Roll Forming Machines. Let’s explore how this technology is shaping the future of fencing in 2025 and beyond.

What is a Wire Mesh Fence Post Roll Forming Machine?

ক তারের জাল বেড়া পোস্ট রোল ফর্মিং মেশিন is a specialized industrial system designed to manufacture the posts that provide structural support for wire mesh fencing systems. These machines utilize metal coils—such as galvanized steel, aluminum, or stainless steel—and shape them into durable, precision-engineered profiles that can withstand harsh environmental conditions.

Fence Posts Produced

- C-Posts: Lightweight yet strong, ideal for residential and commercial fencing.

- T-Posts: Commonly used for agricultural purposes due to their stability and ease of installation.

- U-Posts: Versatile and suitable for both temporary and permanent fencing systems.

- Square Posts: Known for their aesthetic appeal and heavy-duty performance in industrial zones.

- Custom Profiles: Tailored to meet the specific needs of unique fencing systems.

By automating the production process, these roll-forming machines enable manufacturers to produce fence posts at scale, ensuring consistency, durability, and cost-efficiency.

Applications of Wire Mesh Fence Post Roll Forming Machines

The versatility of Wire Mesh Fence Post Roll Forming Machines makes them indispensable across a wide range of industries. Here’s how these machines are transforming fencing solutions:

1. Security Fencing

- Use Case: Producing robust posts for perimeter security fences in high-risk areas.

- Why It Matters: Ensures durability and tamper resistance for maximum protection.

2. Agricultural Fencing

- Use Case: Manufacturing T-posts for farms and ranches to secure livestock and crops.

- Why It’s Essential: Provides a cost-effective and long-lasting solution for large-scale fencing needs.

3. Residential and Commercial Properties

- Use Case: Producing aesthetically pleasing posts for garden fences, privacy enclosures, and property borders.

- Why It’s Important: Combines functionality with visual appeal to enhance property value.

4. Temporary Fencing

- Use Case: Crafting lightweight and portable posts for construction sites and events.

- Why It’s Useful: Ensures quick installation and removal while maintaining stability.

5. Industrial Zones

- Use Case: Manufacturing heavy-duty posts for industrial facilities and warehouses.

- Why It’s Critical: Delivers reliable support for high-security fencing systems.

6. Sports Facilities

- Use Case: Producing posts for mesh fencing around sports fields, courts, and recreational areas.

- Why It’s Exciting: Ensures safety and durability in high-activity environments.

Key Features of Wuxi Sunway Wire Mesh Fence Post Roll Forming Machines

As a global leader in roll-forming technology, Wuxi Sunway Machinery offers state-of-the-art solutions tailored to the needs of the fencing industry. Here’s why their Wire Mesh Fence Post Roll Forming Machines are the top choice for manufacturers:

1. High-Speed Production

- Performance: Machines can produce up to 20–30 meters of profiles per minute, depending on the material and design.

- Why It’s Beneficial: Meets the high-volume demands of large-scale fencing projects.

2. Precision Engineering

- What It Offers: Tolerances as low as ±0.1mm for critical dimensions.

- Why It’s Critical: Ensures consistency and accuracy for seamless installation and performance.

3. Multi-Material Compatibility

- Supported Materials:

- Galvanized Steel

- Stainless Steel

- Aluminum

- Why It Matters: Enables manufacturers to produce posts that meet specific requirements for strength, corrosion resistance, and weight.

4. Integrated Punching Systems

- What It Enables: Built-in punching systems for creating holes, slots, and custom perforations.

- Why It’s Essential:

- Reduces secondary operations, saving time and labor costs.

- Ensures perfect alignment for attaching fencing panels.

5. Customizable Tooling

- What It Allows: Quick-change tooling systems for creating multiple post designs on the same machine.

- Why It’s Valuable: Provides flexibility for manufacturers serving diverse market segments.

6. IoT and Automation Integration

- What It Enables: Real-time monitoring, automated adjustments, and error detection using IoT technology.

- Why It’s Game-Changing:

- Enhances production efficiency.

- Minimizes downtime and material waste.

- Provides actionable insights for predictive maintenance.

7. Modular Design

- What It Provides: Machines with modular configurations that can be expanded or upgraded as production needs grow.

- Why It’s Future-Proof: Accommodates evolving business requirements, making it a cost-effective long-term investment.

Production Workflow of a Wire Mesh Fence Post Roll Forming Machine

The production process for wire mesh fence posts is streamlined to deliver efficiency and precision. Here’s a step-by-step breakdown:

1. Material Loading

- Metal coils are mounted on the machine’s decoiler, which feeds the material into the system.

2. Straightening

- A leveling system ensures the material is flat and free of defects before entering the roll-forming section.

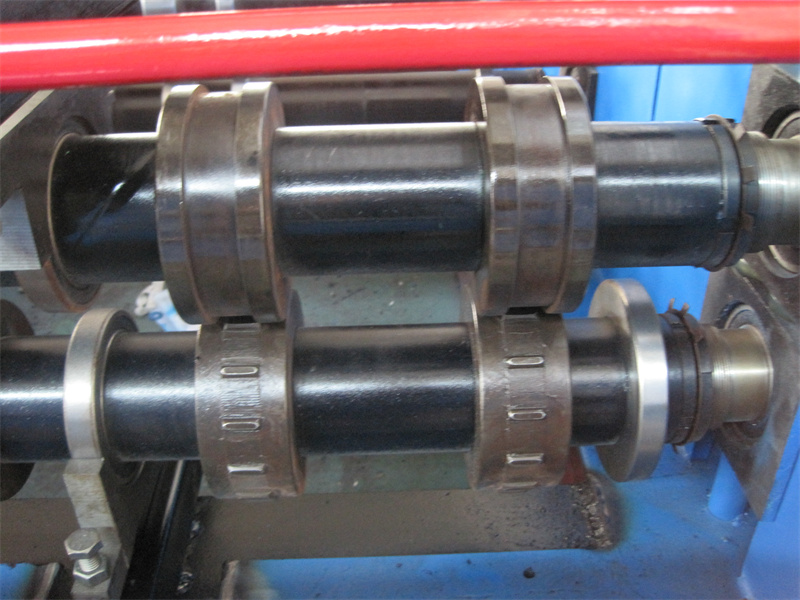

3. Roll Forming

- The material passes through a series of rollers that gradually shape it into the desired post profile.

4. Punching

- Integrated systems create holes, slots, or custom perforations for attaching fencing panels and accessories.

5. Cutting to Length

- Hydraulic or precision cutting systems trim the posts to the required lengths.

6. Quality Inspection

- Finished posts are inspected for dimensional accuracy, surface finish, and compliance with industry standards.

7. Stacking and Packaging

- Completed posts are stacked, bundled, and prepared for transportation or delivery to project sites.

Pricing of Wire Mesh Fence Post Roll Forming Machines

The cost of a তারের জাল বেড়া পোস্ট রোল ফর্মিং মেশিন depends on its features, production capacity, and customization options. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic profile production | $100,000–$250,000 |

| Advanced Machines | High-speed and multi-profile output | $250,000–$500,000 |

| কাস্টমাইজযোগ্য মেশিনসমূহ | Including punching, IoT, and automation | $500,000–$1,000,000 |

For detailed pricing and financing options, contact Wuxi Sunway Machinery.

Market Trends for Wire Mesh Fence Post Roll Forming Machines in 2025

The fencing industry is witnessing rapid growth, driven by advancements in construction, agriculture, and security. Here are the trends shaping the adoption of Wire Mesh Fence Post Roll Forming Machines:

1. Growth in Urban Development

- The Trend: Rising urbanization is driving demand for aesthetically pleasing and durable fencing systems.

- How Machines Help:

- Produce custom profiles for modern fencing designs.

- Enable high-speed production for large-scale urban projects.

2. Increased Focus on Security

- The Opportunity: Governments and businesses are investing in high-security fencing for critical infrastructure.

- Machine Contribution:

- Manufactures heavy-duty posts with tamper-resistant features.

- Processes corrosion-resistant materials for long-lasting performance.

3. Sustainability Practices

- The Push: Eco-friendly manufacturing is becoming a priority for fencing manufacturers.

- How Machines Help:

- Minimize material waste through precision engineering.

- Process recyclable metals to align with sustainability goals.

FAQs About Wire Mesh Fence Post Roll Forming Machines

| Question | Answer |

|---|---|

| What materials can these machines process? | Galvanized steel, stainless steel, and aluminum are commonly used. |

| What is the average production speed? | Machines can produce up to 20–30 meters of profiles per minute, depending on material and design complexity. |

| Can these machines produce custom designs? | Yes, Wuxi Sunway machines are equipped with customizable tooling for bespoke profiles. |

| What is the lifespan of these machines? | With proper maintenance, these machines can last 15–25 years or more. |

| Are these machines energy-efficient? | Absolutely! Wuxi Sunway machines feature energy-saving motors and optimized workflows. |

| Do these machines comply with global standards? | Yes, they are designed to meet ISO and other international safety and quality standards. |

| Is training provided with the purchase? | Yes, Wuxi Sunway offers comprehensive training and after-sales support for all customers. |

Compliance with Global Standards for Fence Post Manufacturing

Fence posts must adhere to international standards to ensure safety, structural integrity, and durability. Wire Mesh Fence Post Roll Forming Machines by Wuxi Sunway Machinery are designed to produce posts that meet these rigorous requirements, enabling manufacturers to confidently serve global markets.

| Standard | Region | Requirement |

|---|---|---|

| ISO 9001 | Global | Ensures quality management principles in manufacturing processes. |

| ASTM A123/A123M | USA | Establishes specifications for zinc-coated (galvanized) steel products. |

| EN 10244-2 | Europe | Governs the technical delivery conditions for steel wire and wire products. |

| CE Marking | Europe | Certifies compliance with EU safety, health, and environmental regulations. |

| AS/NZS 4680 | Australia/New Zealand | Specifies hot-dip galvanized coatings for structural steel. |

| JIS G3101 | Japan | Covers general structural steel standards for various applications. |

By ensuring compliance with these standards, Wuxi Sunway Machinery guarantees that the fence posts produced by their roll-forming machines are reliable, durable, and suited for diverse applications.

Sustainability Benefits of Wire Mesh Fence Post Roll Forming Machines

As sustainability becomes a critical focus for industries worldwide, Wire Mesh Fence Post Roll Forming Machines are contributing to eco-friendly manufacturing practices. Here’s how:

1. Material Efficiency

- The Benefit: Precision roll-forming minimizes waste, ensuring optimal usage of raw materials.

- Environmental Impact:

- Reduces scrap metal and waste by up to 20–30% compared to traditional methods.

- Lowers the carbon footprint associated with material procurement and disposal.

2. Use of Recyclable Materials

- What It Enables: Machines process recyclable metals such as galvanized steel and aluminum.

- Why It Matters:

- Encourages the reuse of materials, promoting a circular economy.

- Reduces dependence on non-renewable resources.

3. Energy-Efficient Operations

- The Innovation: Advanced motors and automated workflows optimize energy consumption.

- Why It’s Significant:

- Reduces electricity usage by up to 15–25% compared to older machinery.

- Supports manufacturers in achieving sustainability goals and regulatory compliance.

4. Durable and Long-Lasting Products

- The Outcome: Fence posts produced by roll-forming machines are highly durable and corrosion-resistant.

- Why It’s Sustainable:

- Extends the lifespan of fencing systems, reducing the need for frequent replacements.

- Minimizes waste generated by discarded or degraded components.

5. Modular Designs

- The Contribution: Machines enable the production of modular post designs that support reusability and scalability.

- Why It’s Important:

- Reduces waste when upgrading or modifying fencing installations.

- Aligns with sustainable manufacturing practices.

Real-World Case Studies of Wire Mesh Fence Post Roll Forming Machines

To better understand the impact of Wire Mesh Fence Post Roll Forming Machines, let’s explore real-world scenarios where these machines have transformed fencing projects.

1. Agricultural Property Fencing

- Scenario: A large farm requires durable fencing to secure livestock and protect crops.

- Machine Contribution:

- Produces T-posts designed for heavy-duty performance in agricultural environments.

- Processes galvanized steel to withstand exposure to weather and moisture.

- Delivers high-volume production to meet the demands of large-scale farming operations.

2. High-Security Industrial Zones

- Scenario: A manufacturing facility needs tamper-resistant fencing for its perimeter.

- Machine Contribution:

- Crafts square posts with built-in tamper-resistant features.

- Ensures compliance with international security standards for industrial zones.

- Produces corrosion-resistant posts for long-term durability.

3. Urban Residential Projects

- Scenario: A property developer is building a residential community with stylish fencing designs.

- Machine Contribution:

- Produces C-posts with customizable profiles for aesthetic appeal.

- Enables precision engineering for seamless integration with modern fence panels.

- Supports high-speed production to meet tight construction deadlines.

4. Temporary Construction Site Fencing

- Scenario: A construction company needs portable fencing for various project sites.

- Machine Contribution:

- Manufactures lightweight U-posts for quick and easy installation.

- Ensures durability to withstand the rigors of construction environments.

- Provides cost-effective solutions for temporary fencing needs.

5. Sports and Recreation Facilities

- Scenario: A city is building a sports complex requiring mesh fencing for safety.

- Machine Contribution:

- Produces posts designed to support mesh fencing around sports fields and courts.

- Ensures precision perforations for attaching fencing securely.

- Delivers profiles that combine strength and flexibility for high-activity areas.

Expanded FAQ Section for Wire Mesh Fence Post Roll Forming Machines

| Question | Answer |

|---|---|

| What materials can these machines process? | Galvanized steel, stainless steel, aluminum, and pre-coated metals are commonly used. |

| What is the average production speed? | Machines can produce up to 20–30 meters of profiles per minute, depending on material and complexity. |

| Can these machines handle custom designs? | Yes, Wuxi Sunway machines are equipped with customizable tooling for bespoke profiles. |

| What industries benefit most from these machines? | Agriculture, construction, industrial security, sports facilities, and residential development. |

| Do these machines comply with global standards? | Yes, they are designed to meet ISO, ASTM, EN, and other international standards. |

| How durable are the posts produced? | Posts are highly durable, offering excellent resistance to weather, corrosion, and physical stress. |

| What is the typical lifespan of these machines? | With proper maintenance, these machines last 15–25 years or more. |

| Are these machines energy-efficient? | Absolutely! Wuxi Sunway machines feature energy-saving motors and automated workflows. |

| Is training provided with the purchase? | Yes, Wuxi Sunway offers comprehensive training and after-sales support for all customers. |

Why Wuxi Sunway Machinery Leads the Industry

Wuxi Sunway Machinery has earned its reputation as a global leader in roll-forming technology for fencing solutions. Here’s why manufacturers trust them:

- Decades of Expertise: Wuxi Sunway has a proven track record of delivering innovative roll-forming solutions tailored to the fencing industry.

- Global Reach: With clients in Asia, Europe, the Americas, and beyond, Wuxi Sunway understands the diverse needs of international markets.

- Leading-Edge Technology: Features like IoT integration, high-speed production, and customizable tooling set Wuxi Sunway machines apart from competitors.

- Eco-Friendly Practices: Machines are designed to align with sustainable manufacturing practices, reducing waste and energy consumption.

- Comprehensive Support: From installation to training and after-sales service, Wuxi Sunway ensures a seamless experience for its customers.

- Custom Solutions: Wuxi Sunway specializes in delivering machines tailored to specific customer requirements, ensuring maximum ROI.

Conclusion: Building the Fences of Tomorrow

দ্য তারের জাল বেড়া পোস্ট রোল ফর্মিং মেশিন is revolutionizing the fencing industry, offering manufacturers the tools they need to produce high-quality, durable, and customizable fence posts at scale. Whether you’re building security perimeters, protecting agricultural property, or enhancing residential landscapes, these machines provide the precision and efficiency required to meet modern demands.

Looking to elevate your fencing production capabilities? Partner with Wuxi Sunway Machinery today and explore their cutting-edge roll-forming solutions. Let’s shape the future of fencing—one post at a time!