In the construction industry, precision, durability, and efficiency are key to ensuring safe and reliable structures. Metal deck scaffolding, a foundation for many construction sites, provides the strength and support needed for workers and materials. But when it comes to producing these vital components, the Precision Roll Forming Machine for Metal Deck Scaffolding stands out as a game-changing solution. Designed for efficiency and accuracy, these machines enable manufacturers to produce high-quality scaffolding decks that meet stringent safety and design standards.

In this comprehensive guide, we’ll explore everything you need to know about Precision Roll Forming Machines for Metal Deck Scaffolding—their features, applications, pricing, benefits, and why Wuxi Sunway Machinery is a leader in this space. Whether you’re a manufacturer scaling up production or a contractor looking for durable scaffolding solutions, this guide will provide the insights you need.

What is a Precision Roll Forming Machine for Metal Deck Scaffolding?

ক Precision Roll Forming Machine for Metal Deck Scaffolding is an advanced manufacturing system specifically designed to create metal scaffolding decks. These machines take raw metal coils like galvanized steel or aluminum and use a series of rollers to shape them into scaffolding decks with precise dimensions and structural integrity.

What makes these machines unique is their ability to produce scaffolding decks with features like anti-slip patterns, drainage slots, and custom embossments, ensuring safety and durability on construction sites. With automated systems for cutting, punching, and stacking, these machines streamline the production process, saving time and reducing material waste.

Applications of Metal Deck Scaffolding

Metal deck scaffolding manufactured using these machines is indispensable for various construction and industrial applications. Here are some of the most common uses:

1. Construction Sites

- Metal scaffolding decks provide a safe and stable platform for workers and materials during building construction or repairs.

2. Industrial Maintenance

- Factories and industrial facilities use scaffolding decks for maintenance and equipment installation tasks.

3. Oil and Gas Refineries

- Scaffolding decks are essential in oil and gas refineries for accessing high structures and ensuring worker safety in hazardous environments.

4. Temporary Stages and Platforms

- Metal decks are used to create temporary stages and platforms for events, exhibitions, and concerts.

5. Shipbuilding and Aviation

- Scaffolding decks play a critical role in shipbuilding and aircraft maintenance, providing platforms for assembly and inspections.

6. Bridge and Infrastructure Projects

- Large-scale infrastructure projects, such as bridges and dams, heavily rely on durable scaffolding decks to support workers and equipment.

Key Features of Sunway Precision Roll Forming Machines for Metal Deck Scaffolding

Wuxi Sunway Machinery is a trusted name in roll-forming technology, and their Precision Roll Forming Machines for metal deck scaffolding are designed to exceed industry expectations. Here’s what sets these machines apart:

1. High-Speed Production

- Produce up to 20–25 meters of scaffolding decks per minute, ensuring quick turnaround times for large-scale projects.

2. Customizable Deck Profiles

- The machine can produce scaffolding decks with various widths, thicknesses, and patterns, including:

- Width: 200mm–500mm

- Thickness: 1.0mm–2.5mm

- Anti-slip patterns and drainage slots for added functionality.

3. Advanced PLC Control System

- User-Friendly Interface: Operate the machine with ease using a touchscreen control panel.

- Programmable Settings: Store multiple deck profiles for quick and seamless transitions.

- Real-Time Monitoring: Track production metrics, error logs, and system performance in real time.

4. Integrated Punching and Embossing

- Machines come with hydraulic punching systems to create drainage slots or attachment holes and embossing units for anti-slip patterns.

5. Precision Cutting

- Equipped with a servo-driven cutting system, the machine ensures clean edges and accurate deck lengths, reducing post-production work.

6. Robust Material Compatibility

- Handle a variety of materials, including:

- Galvanized steel

- Aluminum

- Stainless steel

- Pre-coated steel

7. Compact and Durable Design

- Despite their high capacity, Sunway machines are designed to occupy minimal floor space and are built with high-strength steel frames for longevity.

8. Safety Features

- Emergency Stop Buttons: Strategically placed for quick operator access.

- Protective Covers: Shield operators from moving parts.

- Overload Protection: Prevents damage caused by power surges or material jams.

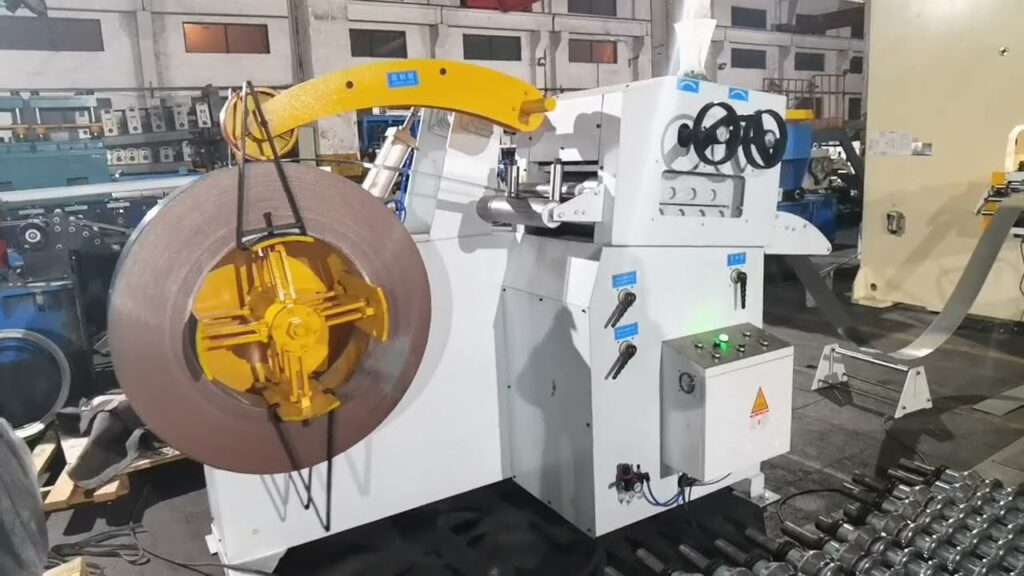

Production Workflow of a Precision Roll Forming Machine for Metal Deck Scaffolding

Understanding the production process helps manufacturers appreciate the efficiency of these machines. Here’s how a Precision Roll Forming Machine for Metal Deck Scaffolding operates:

1. Loading the Material

- Metal coils are loaded onto the automatic uncoiler, which ensures smooth feeding into the machine.

2. Roll Forming

- The material passes through a series of rollers that gradually shape it into the desired scaffolding deck profile.

3. Punching and Embossing

- Holes, slots, or anti-slip patterns are added using the integrated punching and embossing systems.

4. Cutting

- The servo-driven cutter trims the scaffolding decks to the required lengths with precision.

5. Stacking and Output

- Finished scaffolding decks are automatically stacked and prepared for packaging or transportation.

Pricing of Precision Roll Forming Machines for Metal Deck Scaffolding

The cost of a Precision Roll Forming Machine depends on its features, production capacity, and level of automation. Here’s a general pricing guide for 2025:

| Machine Type | Primary Use | উৎপাদন গতি | Price Range (USD) |

|---|---|---|---|

| Standard Machines | Basic scaffolding deck production | 10–15 meters/min | $50,000–$80,000 |

| High-Speed Machines | Large-scale production | 20–25 meters/min | $80,000–$120,000 |

| Fully Customizable Machines | Advanced profiles and applications | 15–25 meters/min | $120,000–$180,000 |

For an exact quote and financing options, contact Wuxi Sunway Machinery.

Advantages of Using Precision Roll Forming Machine for Metal Deck Scaffolding

Investing in a Precision Roll Forming Machine for Metal Deck Scaffolding offers several benefits:

1. Increased Productivity

- High-speed production ensures you can meet tight deadlines and large orders with ease.

2. Superior Quality

- Consistent shaping, punching, and cutting guarantee scaffolding decks that meet international safety standards.

3. Cost Efficiency

- Automated processes reduce labor costs and material waste, improving overall profitability.

4. Customization Flexibility

- Produce a wide range of scaffolding deck designs to cater to diverse construction needs.

5. Scalability

- High production capacity makes it easier to scale operations as demand grows.

Environmental Benefits of Precision Roll Forming Machine for Metal Deck Scaffolding

Sustainability is a growing priority in the construction industry, and Wuxi Sunway Machinery is committed to delivering eco-friendly manufacturing solutions. Here’s how their machines support sustainability:

1. Reduced Material Waste

- Precision shaping and cutting optimize material usage, minimizing scrap.

2. Energy Efficiency

- Advanced servo motors and hydraulic systems consume significantly less energy compared to older machines.

3. Use of Recyclable Materials

- Machines can process recyclable materials like galvanized steel and aluminum, supporting green building initiatives.

4. Long-Lasting Products

- The durable scaffolding decks produced using these machines have a long lifespan, reducing the need for replacements.

FAQs About Precision Roll Forming Machines for Metal Deck Scaffolding

| Question | Answer |

|---|---|

| What is the maximum material thickness the machine can handle? | Sunway machines can process materials up to 2.5mm thick. |

| Can the machine produce custom anti-slip patterns? | Yes, embossing patterns can be fully customized via the PLC system. |

| Is operator training provided? | Yes, comprehensive training is included with every purchase. |

| What is the warranty period? | Sunway machines come with a 12-month warranty, with extended service options available. |

| What materials are compatible with the machine? | Galvanized steel, aluminum, stainless steel, and pre-coated steel. |

Automation Trends in Precision Roll Forming Machine for Metal Deck Scaffolding

Automation has become a cornerstone of modern manufacturing, and Precision Roll Forming Machines are no exception. By integrating advanced technology, these machines enhance productivity, minimize errors, and reduce operational costs. Here are some of the automation trends shaping the future of roll-forming machines for metal deck scaffolding in 2025:

1. IoT-Connected Machines

- What is IoT? দ্য Internet of Things (IoT) allows machines to communicate with each other and with operators via a network.

- Benefits for Roll Forming Machines:

- Real-time monitoring of production metrics.

- Remote troubleshooting and diagnostics.

- Data collection for performance analysis and optimization.

2. Predictive Maintenance

- Sensors embedded within the machine monitor components like rollers, hydraulic systems, and cutting units.

- How It Works: AI-powered algorithms analyze sensor data to predict when maintenance is required, preventing unexpected downtime.

- Benefit: Reduces repair costs and extends the machine’s lifespan.

3. Fully Automated Production Lines

- From material loading to stacking finished products, automation eliminates the need for manual intervention.

- Example: Sunway machines can integrate with robotic systems for seamless material handling.

4. Quick Profile Switching

- Advanced PLC systems allow manufacturers to switch between different scaffolding deck profiles with minimal downtime.

- Why It Matters: This flexibility is critical for manufacturers catering to diverse customer needs.

5. Digital Twin Technology

- What is a Digital Twin? A virtual replica of the machine used for testing and simulation.

- Benefits:

- Optimize production processes without halting actual operations.

- Test new scaffolding deck designs virtually before production.

6. AI-Driven Quality Control

- Automated inspection systems powered by Artificial Intelligence (AI) can detect defects in real-time, ensuring consistent product quality.

- Example: AI can identify discrepancies in anti-slip patterns or punching accuracy.

Automation isn’t just a trend—it’s the future of roll-forming technology. By investing in an automated Precision Roll Forming Machine, manufacturers can stay ahead of the competition and meet the increasing demand for high-quality scaffolding decks.

Global Market Trends for Metal Deck Scaffolding in 2025

The global demand for metal deck scaffolding and roll-forming machines is growing rapidly, driven by advancements in construction technology, infrastructure development, and safety standards. Here are some key trends shaping the market:

1. Surge in Construction Activities

- With urbanization accelerating, especially in Asia, Africa, and the Middle East, the demand for scaffolding is higher than ever.

- Scaffolding decks are indispensable for building high-rises, bridges, and industrial complexes.

2. Focus on Worker Safety

- Governments worldwide are enforcing stricter safety regulations for construction sites.

- Impact: Scaffolding decks with anti-slip patterns and drainage slots are becoming standard.

3. Growth of Pre-Engineered Buildings (PEBs)

- Pre-engineered buildings require extensive use of scaffolding decks during assembly.

- Market Impact: Increased demand for precision roll-forming machines catering to PEB projects.

4. Eco-Friendly Construction Practices

- Builders are increasingly opting for recyclable materials like steel and aluminum.

- Why It Matters: Roll-forming machines support the production of sustainable scaffolding components.

5. Technological Advancements

- Innovations like IoT, AI, and predictive maintenance are making roll-forming machines more efficient and cost-effective.

- Example: Sunway’s IoT-enabled machines are setting new standards in the industry.

6. Modular Construction Boom

- Modular construction methods require prefabricated scaffolding decks that can be quickly assembled on-site.

- Benefit: Precision roll-forming machines are ideal for producing consistent, modular scaffolding components.

7. Increased Investments in Infrastructure

- Governments are pouring billions into infrastructure projects, including bridges, airports, and highways.

- Impact: The need for durable scaffolding decks is driving demand for high-capacity roll-forming machines.

These trends highlight the growing importance of Precision Roll Forming Machines in the construction and manufacturing sectors. By adopting advanced roll-forming technology, manufacturers can capitalize on these opportunities and expand their market share.

Advanced Troubleshooting for Precision Roll Forming Machine for Metal Deck Scaffolding

Even with the most advanced machines, occasional issues can arise. Knowing how to troubleshoot these problems effectively can save time and money. Here are some advanced troubleshooting tips for Precision Roll Forming Machines:

1. Inconsistent Deck Dimensions

- Cause: Misaligned rollers or faulty PLC programming.

- Solution:

- Inspect and realign the rollers.

- Recalibrate the PLC system to ensure accurate dimensions.

2. Punching Errors

- Cause: Worn-out punching dies or synchronization issues.

- Solution:

- Replace the punching dies.

- Verify that the punching unit is correctly synchronized with the roll-forming process.

3. Material Jams

- Cause: Debris in the feeding system or improperly tensioned material.

- Solution:

- Clean the feeding system to remove obstructions.

- Adjust the tension settings in the material feeder.

4. Cutting Inaccuracies

- Cause: Calibration issues in the servo-driven cutting system.

- Solution:

- Recalibrate the cutting parameters using the PLC interface.

- Inspect the cutting blade for wear and replace it if necessary.

5. Overheating of Components

- Cause: Insufficient lubrication or extended high-speed operation.

- Solution:

- Regularly lubricate all moving parts.

- Allow the machine to cool periodically during long production runs.

6. Electrical Failures

- Cause: Power surges or damaged wiring.

- Solution:

- Use a stable power source with surge protection.

- Inspect and repair faulty wiring and connectors.

For persistent issues, contact Wuxi Sunway Machinery for expert technical support and maintenance services.

FAQs About Precision Roll Forming Machines for Metal Deck Scaffolding

| Question | Answer |

|---|---|

| Can the machine produce scaffolding decks with custom designs? | Yes, Sunway machines are fully customizable to produce various profiles, patterns, and sizes. |

| What is the maximum material thickness the machine can handle? | Sunway machines can process materials up to 2.5mm thick. |

| What is the expected lifespan of the machine? | With proper maintenance, Sunway machines are designed to last 10–15 years or more. |

| Can the machine be integrated into an automated production line? | Absolutely! Sunway machines are compatible with automated production setups. |

| What is the warranty period? | Sunway machines come with a 12-month warranty, with extended service options available. |

| Is on-site training provided? | Yes, comprehensive on-site training is included with every machine purchase. |

Why Choose Wuxi Sunway Machinery for Precision Roll Forming Machines?

Wuxi Sunway Machinery has earned its reputation as a global leader in roll-forming technology. Here’s why manufacturers trust Sunway:

- Unmatched Expertise: Decades of experience in designing and manufacturing precision roll-forming machines.

- Global Reach: Trusted by clients across Asia, Europe, Africa, and the Americas.

- Custom Solutions: Machines tailored to meet your unique production needs.

- Innovative Technology: Equipped with IoT, AI, and PLC systems for maximum efficiency.

- Sustainability Commitment: Designed to minimize waste and energy consumption.

- Comprehensive Support: From installation and training to troubleshooting and spare parts, Sunway has you covered.

Conclusion: Why Invest in a Precision Roll Forming Machine for Metal Deck Scaffolding?

দ্য Precision Roll Forming Machine for Metal Deck Scaffolding is more than just a piece of equipment—it’s a strategic investment in precision, efficiency, and sustainability. Whether you’re producing scaffolding decks for high-rises, bridges, or industrial projects, this machine ensures high-quality output that meets the demands of modern construction.

Ready to transform your manufacturing process? Contact Wuxi Sunway Machinery today to explore their cutting-edge roll-forming solutions. Together, let’s build safer, stronger, and smarter—one scaffolding deck at a time.