উপলব্ধ সকল বিকল্পের মধ্যে, শীট মেটাল রোল ফর্মিং মেশিন খোঁজার সময় কোথা থেকে শুরু করবেন তা জানা কঠিন। এই ব্লগ পোস্টে আপনি চারটি টিপস পাবেন যা আপনাকে সাহায্য করবে সঠিক মেটাল রোল ফর্মিং মেশিন নির্বাচন করতে যা আপনার প্রয়োজনের জন্য উপযুক্ত।

শীট মেটাল রোল ফর্মিং মেশিন কী?

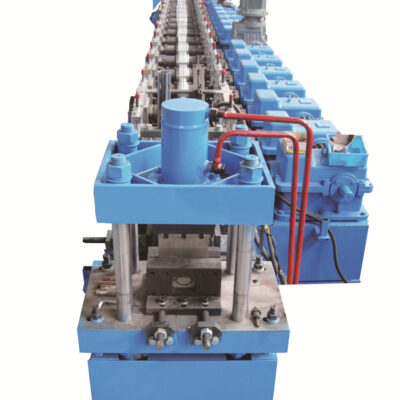

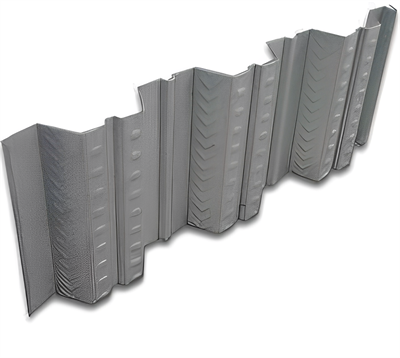

ক রোল গঠন মেশিনটি ধাতুর কয়েল থেকে দীর্ঘ, অবিচ্ছিন্ন ধাতু শীট তৈরি করার জন্য ব্যবহৃত এক ধরনের মেশিন। এই মেশিনগুলি বিভিন্ন আকার এবং সাইজ তৈরি করতে পারে এবং নির্মাণ শিল্পে ছাদ, সাইডিং এবং অন্যান্য ভবন উপকরণ তৈরির জন্য প্রায়শই ব্যবহৃত হয়।

অধিকাংশ মেশিন পাতলা গেজ বা মোটা গেজ উপাদানের সাথে কাজ করার জন্য ডিজাইন করা হয়, কিন্তু কিছু মেশিন উভয়ই সামলাতে পারে। এছাড়া, কিছু মেশিন অ্যালুমিনিয়াম বা স্টিলের মতো নির্দিষ্ট ধাতুর জন্য ডিজাইন করা হয়, যেখানে অন্যরা একাধিক ধাতুর সাথে কাজ করতে পারে।

শীট মেটাল রোল ফর্মিং মেশিনের উপকারিতা

শীট মেটাল রোল ফর্মিং মেশিনের শীট ধাতু রোল গঠন মেশিন. প্রথমত, এই মেশিনগুলি অত্যন্ত দ্রুত এবং উচ্চ নির্ভুলতার সাথে প্রচুর পরিমাণে অংশ উৎপাদন করতে সক্ষম। এছাড়া, এগুলি অত্যন্ত বহুমুখী এবং বিভিন্ন আকার ও মাত্রার জিনিস তৈরি করতে ব্যবহারযোগ্য।

আরেকটি দুর্দান্ত সুবিধা হলো এগুলো খুব কম সেটআপ সময়ের প্রয়োজন করে এবং প্রায় যে কেউ সহজেই এগুলো চালাতে পারে। এটি ছোট ব্যবসা বা উৎপাদন সরঞ্জাম নিয়ে অভিজ্ঞতার অভাবীদের জন্য আদর্শ করে তোলে।

অবশেষে, শীট মেটাল রোল ফর্মিং মেশিন ক্রয় এবং রক্ষণাবেক্ষণের জন্য তুলনামূলকভাবে সস্তা, যা যেকোনো ব্যবসার জন্য একটি চমৎকার বিনিয়োগ।

-

দ্রাক্ষাক্ষেত্র পোস্ট রোল ফর্মিং মেশিন

দ্রাক্ষাক্ষেত্র পোস্ট রোল ফর্মিং মেশিন -

হালকা গেজ ইস্পাত রোল গঠন মেশিন

হালকা গেজ ইস্পাত রোল গঠন মেশিন -

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য সিগমা Purlin রোল ফর্মিং মেশিন

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য সিগমা Purlin রোল ফর্মিং মেশিন -

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য Z Purlin রোল তৈরির মেশিন

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য Z Purlin রোল তৈরির মেশিন -

সম্পূর্ণ স্বয়ংক্রিয় দ্রুত পরিবর্তন CZ purlin রোল গঠন মেশিন

সম্পূর্ণ স্বয়ংক্রিয় দ্রুত পরিবর্তন CZ purlin রোল গঠন মেশিন -

দ্রাক্ষাক্ষেত্র পোস্ট রোল ফর্মিং মেশিন

দ্রাক্ষাক্ষেত্র পোস্ট রোল ফর্মিং মেশিন -

ওমেগা পুরলিন রোল ফর্মিং মেশিন

ওমেগা পুরলিন রোল ফর্মিং মেশিন -

L কোণ রোল মেশিন গঠন

L কোণ রোল মেশিন গঠন -

Keel ইস্পাত রোল গঠন মেশিন

Keel ইস্পাত রোল গঠন মেশিন

শীট মেটাল রোল ফর্মিং মেশিন কেনার জন্য ৪টি টিপস

নতুন শীট মেটাল রোল ফর্মিং মেশিন ক্রয়ের ক্ষেত্রে অনেক বিকল্প উপলব্ধ। আপনার ব্যবসার জন্য সঠিকটি বেছে নেওয়ার জন্য এখানে কয়েকটি টিপস দেওয়া হলো:

- আপনার বাজেট নির্ধারণ করুন

প্রথম ধাপ হলো আপনার বাজেট নির্ধারণ করা। এটি আপনার বিকল্পগুলো সংকুচিত করতে এবং আপনার মূল্য পরিসরের মধ্যে যুক্তিসঙ্গত একটি মেশিন খুঁজে পেতে সাহায্য করবে। মনে রাখবেন যে আপনাকে অতিরিক্ত সরঞ্জাম বা আনুষঙ্গিক কেনার প্রয়োজন হতে পারে, তাই এটিকেও আপনার বাজেটে অন্তর্ভুক্ত করুন।

- আপনার প্রয়োজনীয়তা বিবেচনা করুন

পরবর্তীতে, চিন্তা করুন আপনি মেশিনটি কীসের জন্য ব্যবহার করবেন। আপনার কি হালকা কাজের জন্য সাধারণ মেশিন দরকার নাকি ভারী কাজের জন্য আরও শক্তিশালী কিছু? আপনার ব্যবসার প্রয়োজনীয়তা বিবেচনা করে ক্রয় সিদ্ধান্ত নেওয়ার নির্দেশনা পান।

- বৈশিষ্ট্য এবং সুবিধাগুলো তুলনা করুন

একবার আপনার বাজেট এবং প্রয়োজনীয়তা নির্ধারণ করার পর, বিভিন্ন মেশিন তুলনা শুরু করার সময়। প্রত্যেক বিকল্পের বৈশিষ্ট্য এবং সুবিধা পরীক্ষা করে আপনার ব্যবসার জন্য সেরাটি খুঁজুন। অনলাইন রিভিউ পড়ে অন্যান্য গ্রাহকদের ক্রয় সন্তুষ্টির ধারণা নিন।

- একাধিক সরবরাহকারীর কাছ থেকে দাম নিন

অবশেষে, আপনার ব্যবসার জন্য নিখুঁত মেশিন নির্ধারণ করার পর, চূড়ান্ত ক্রয় সিদ্ধান্ত নেওয়ার আগে একাধিক সরবরাহকারীর কাছ থেকে দাম নিন। এটি নিশ্চিত করবে যে আপনি বাজারে সেরা সম্ভাব্য মূল্য পাচ্ছেন।

শীট মেটাল রোল ফর্মিং মেশিনের প্রকারভেদ

শীট মেটাল রোল ফর্মিং মেশিনের তিনটি মৌলিক প্রকার রয়েছে:

- ম্যানুয়াল মেশিন – এগুলো সবচেয়ে সস্তা এবং বহুমুখী। বিভিন্ন প্রকল্পে ব্যবহার করা যায়, কিন্তু অন্য দুই প্রকারের চেয়ে বেশি অপারেটরের সম্পৃক্ততা প্রয়োজন।

- সিএনসি মেশিন – এগুলো কম্পিউটার নিয়ন্ত্রিত এবং নির্দিষ্ট কাজের জন্য প্রোগ্রাম করা যায়। ম্যানুয়াল মেশিনের চেয়ে দ্রুত এবং নির্ভুল, কিন্তু বেশি দামি।

- হাইব্রিড মেশিন – এগুলো ম্যানুয়াল এবং সিএনসি মেশিনের বৈশিষ্ট্যের সমন্বয় করে। উভয়ের সেরা সুবিধা প্রদান করে, কিন্তু একক প্রকারের চেয়ে বেশি দামি।

শীট মেটাল রোল ফর্মিং মেশিনের গুরুত্বপূর্ণ কারণসমূহ

- খরচ: মেশিনের প্রাথমিক খরচ গুরুত্বপূর্ণ বিবেচনা, যেমন রক্ষণাবেক্ষণ এবং চালানোর খরচ।

- ক্ষমতা: প্রয়োজনীয় সময়ের মধ্যে প্রয়োজনীয় পরিমাণ পণ্য উৎপাদনের ক্ষমতা বিবেচনা করার গুরুত্বপূর্ণ কারণ।

- গুণমান: উচ্চমানের পণ্য উৎপাদনের ক্ষমতা গুরুত্বপূর্ণ বিবেচনা।

- নমনীয়তা: বিভিন্ন পণ্য উৎপাদনের ক্ষমতা বা নতুন পণ্য উৎপাদনের জন্য সহজে পরিবর্তনযোগ্যতা গুরুত্বপূর্ণ বিবেচনা।

- সেবা এবং সহায়তা: প্রস্তুতকারক বা বিতরণকারীর কাছ থেকে সেবা এবং সহায়তার উপলব্ধতা গুরুত্বপূর্ণ বিবেচনা।

উপসংহার

যদি আপনি নির্ভরযোগ্য এবং সাশ্রয়ী শীট মেটাল রোল ফর্মিং মেশিন খুঁজছেন, তাহলে এই টিপসগুলো অনুসরণ করে আপনার প্রয়োজনের উপযুক্তটি খুঁজে পাবেন। বাজারে এত বিভিন্ন মেশিন থাকায় সঠিকটি নির্ধারণ করা কঠিন। কিন্তু গবেষণা করে এবং বাজেট ও নির্দিষ্ট প্রয়োজনীয়তা বিবেচনা করে আপনি সঠিক কাজ সম্পাদনকারী মেশিন খুঁজে পাবেন।

FAQ

শীট মেটাল রোলারকে কী বলা হয়?

মেটাল রোলার প্রত্যেক মেশিন শপের গুরুত্বপূর্ণ অংশ। মেটাল রোলারকে শীট মেটাল রোলার বা মেটাল রোলার বেন্ডারও বলা হয়, যা বিভিন্ন ধনু, বাঁক, সিলিন্ডার এবং বৃত্তাকার বস্তু তৈরি করতে পারে। এই সরঞ্জাম কাস্টম উপকরণ তৈরির গুরুত্বপূর্ণ অংশ।

Frequently Asked Questions (FAQ)

1) How do I size Sheet Metal Roll Forming Machines for my production volume?

- Match line speed (m/min) and changeover time to your batch sizes. For 500–1,500 m/day mixed SKUs, prioritize quick-change cassettes and recipe presets over maximum speed. For 5,000+ m/day single SKU, seek 80–120 m/min with flying shear.

2) What tolerances are realistic for roofing/siding profiles?

- With encoder feedback and servo flying shear: cut length ±0.7–1.0 mm at 60–100 m/min; hole position ±0.5–0.8 mm with servo-electric punching; profile straightness ≤1.5 mm per 1,000 mm.

3) Which materials and thicknesses run best?

- GI/GL (zinc or zinc-aluminum coated steel) 0.3–1.2 mm are common; aluminum 0.5–1.0 mm; stainless requires dedicated roll materials and pass design. Pre-painted coils benefit from polyurethane or hard-chrome roll surfaces.

4) What should be included in the Factory Acceptance Test (FAT)?

- Verify cut-length tolerance at target speed, burr height limit, hole location CpK, panel straightness, energy intensity (kWh/ton), noise level at 1 m, recipe recall accuracy, and safety compliance (ISO 12100, IEC 60204-1).

5) How do I compare total cost of ownership (TCO) between machines?

- Combine capex with consumables, energy (kWh/ton), scrap rate, planned downtime, changeover labor, and spare parts lead times. A 1% scrap reduction on GI coils often offsets a higher purchase price within 12–18 months.

2025 Industry Trends for Sheet Metal Roll Forming Machines

- Quick-change ecosystems: Cassette tooling and auto-width adjustment shorten changeovers to under 10–15 minutes.

- Servo-electric punching: Lower noise, cleaner holes, and tighter positional tolerance; hydraulic units phased out in light-gauge lines.

- Inline vision and laser metrology: Real-time checks for cut length, hole offset, and edge burr height to cut rework.

- Energy and ESG metrics: Buyers track kWh/ton and scrap rate; regenerative drives and high-efficiency motors adopted as standard.

- Digital workflows: BIM/ERP-driven recipes and barcode job tickets reduce setup errors and speed line starts.

2025 Benchmark Snapshot

| KPI | 2023 Typical | 2025 Best-in-Class | Why It Matters | Source |

|---|---|---|---|---|

| Changeover time (profile/cassette) | 25–40 min | 8–12 min | Higher OEE for high-mix production | OEM demo data; user case notes |

| Cut-length accuracy at 80 m/min | ±১.৫ মিমি | ±0.7–1.0 mm | Fewer field fit-up issues | EN 1090 practices; OEM specs |

| Hole position tolerance | ±1.0–1.5 mm | ±0.5–0.8 mm | Faster MEP install alignment | Inline vision vendor apps |

| Scrap rate (GI 0.5–0.8 mm) | 2.0–3.5% | 0.8–1.5% | Material cost and ESG gains | Keyence/Micro‑Epsilon notes |

| Energy intensity (kWh/ton) | 150–190 | 110–140 | Lower OpEx, sustainability | ABB/Siemens efficiency guides |

| Inline QA adoption | ~20–30% | 45–60% | Real-time defect prevention | Vendor adoption surveys |

Authoritative references:

- ISO 12100 Risk Assessment: https://www.iso.org

- IEC 60204-1 Electrical Safety: https://webstore.iec.ch

- EU Machinery Regulation overview: https://ec.europa.eu

- ABB Drives energy optimization: https://new.abb.com/drives

- Siemens motion/automation efficiency: https://new.siemens.com

- Keyence inline inspection systems: https://www.keyence.com

- Micro‑Epsilon displacement/laser sensors: https://www.micro-epsilon.com

Latest Research Cases

Case Study 1: Reducing Changeover Losses in High-Mix Roofing Profiles (2025)

Background: A regional fabricator ran 6 roof/siding profiles with small batches, losing >18% availability to changeovers.

Solution: Implemented cassette tooling, barcode-triggered HMI recipes, and servo flying shear; added inline camera to verify cut length and hole position automatically.

Results: Changeover time dropped from 32 to 11 minutes; OEE improved by 12.7%; scrap reduced from 2.8% to 1.4%; ROI in 14 months.

Case Study 2: Energy and Noise Improvements via Servo Punching (2024)

Background: Hydraulic punching caused high noise and rising energy consumption on a light-gauge line.

Solution: Replaced hydraulic unit with servo-electric punch and regenerative drive package; optimized pass progression for 0.55–0.9 mm GI.

Results: Noise reduced by 6–8 dBA; energy intensity cut by 16%; maintenance interventions down 28% due to elimination of leaks/valves.

Expert Opinions

- Priya Natarajan, Plant Manager, Building Envelope Fabricator

“For buyers of Sheet Metal Roll Forming Machines, sub-12-minute changeovers matter more than headline speed. That’s where daily capacity is won.” - Marco Santori, Technical Director, Roofing Systems Integrator

“Servo-electric punching plus encoder-based shears have become table stakes. Without them, you’ll struggle to hit ±1 mm cut length and tight hole tolerances at speed.” - Dr. Lin Qiu, Associate Professor, Advanced Manufacturing

“Inline metrology closes the loop on quality. When vision verifies hole offset and burr height in real time, scrap falls and installers stop fighting fit-up issues.”

Practical Tools/Resources

- Roll design and simulation: COPRA RF (https://www.datam.de), UBECO PROFIL (https://www.ubeco.com), Altair Inspire/Form (https://www.altair.com)

- Standards and compliance: ISO 12100 (https://www.iso.org), IEC 60204-1 (https://webstore.iec.ch), EU Machinery Regulation (https://ec.europa.eu)

- Inline QA and measurement: Keyence vision/laser (https://www.keyence.com), Micro‑Epsilon sensors (https://www.micro-epsilon.com)

- Maintenance/OEE: UpKeep CMMS (https://www.onupkeep.com), Fiix CMMS (https://www.fiixsoftware.com)

Implementation tip: In your RFQ and FAT, specify cut length ±1.0 mm at target speed, hole position ±0.8 mm, burr height ≤0.05 mm, changeover ≤12 minutes, energy intensity reporting (kWh/ton), and max noise ≤80 dBA at 1 m.

Last updated: 2025-10-23

Changelog: Added 5 FAQs, 2025 trend table with benchmarks and sources, two recent case studies, three expert viewpoints, and curated tools/resources with an actionable RFQ/FAT tip.

Next review date & triggers: 2026-05-20 or earlier if new CE/Machinery Regulation updates, major OEM releases on cassette tooling/servo punching, or updated benchmarks for energy and scrap are published.