Architectural design is no longer just about functionality; aesthetics now play an equally important role in modern construction. From intricate wall panels to decorative ceilings and facades, decorative structures are redefining the visual appeal of residential, commercial, and industrial spaces. The production of these decorative components relies heavily on the precision, efficiency, and versatility of Декоративные структуры рулонные формовочные машины.

These machines are designed to produce a wide range of aesthetically appealing and structurally sound profiles, including wall panels, ceilings, facades, trims, and moldings. Whether it’s for high-rise buildings, luxury interiors, or industrial facilities, Декоративные структуры рулонные формовочные машины enable manufacturers to meet the growing demand for functional yet visually stunning architectural components.

В этом подробном руководстве мы рассмотрим what these machines are, their applications, key features, pricing, troubleshooting tips, and future trendsи почему Уси Sunway машины is the industry leader in roll-forming technology for decorative structures.

What Are Decorative Structure Roll Forming Machines?

Декоративные структуры рулонные формовочные машины are specialized industrial machines that shape metal sheets or coils into intricate profiles used in architectural and interior design. These machines can produce a variety of decorative elements, such as corrugated panels, false ceilings, facade claddings, trims, and moldings, with high precision and consistency.

The demand for decorative structures is on the rise as architects and designers strive to create unique and visually appealing spaces. These machines not only cater to aesthetic requirements but also ensure the structural integrity and durability of the components.

Key Features of Decorative Structure Roll Forming Machines

- Intricate Design Capabilities: Produces complex and detailed profiles for decorative applications.

- Универсальность материалов: Processes an array of materials, including aluminum, galvanized steel, stainless steel, and pre-coated metals.

- Настраиваемые профили: Supports bespoke designs tailored to specific architectural projects.

- High-Quality Finishing: Ensures smooth and flawless surfaces for enhanced visual appeal.

- Высокоскоростное производство: Facilitates mass production without compromising quality.

- Интеграция автоматизации: Reduces labor costs and ensures uniformity in every batch.

Applications of Decorative Structure Roll Forming Machines

Универсальность Декоративные структуры рулонные формовочные машины makes them indispensable in various sectors, including construction, interior design, and infrastructure development. Below are some key applications:

1. Wall Panels

- Пример использования: Producing corrugated or flat wall panels for exterior and interior walls.

- Почему это необходимо: Enhances both the aesthetic and functional aspects of buildings, offering durability and weather resistance.

2. Ceiling Systems

- Пример использования: Manufacturing decorative false ceilings and acoustic panels for offices, airports, and auditoriums.

- Почему это полезно: Improves the visual appeal and acoustic performance of indoor spaces.

3. Facade Cladding

- Пример использования: Creating facade systems for high-rise buildings, shopping malls, and public infrastructure.

- Почему это важно: Provides an attractive exterior while protecting the building from environmental factors.

4. Trims and Moldings

- Пример использования: Crafting decorative trims, moldings, and corner beads for architectural detailing.

- Почему это актуально: Adds elegance and refinement to both interiors and exteriors.

5. Decorative Roofing

- Пример использования: Producing panels and profiles for decorative roofing systems.

- Почему это необходимо: Combines aesthetic appeal with long-lasting protection against the elements.

6. Partition Systems

- Пример использования: Manufacturing panels for modular partitions in commercial and industrial spaces.

- Почему это инновация: Offers flexibility in space management while maintaining a modern and professional look.

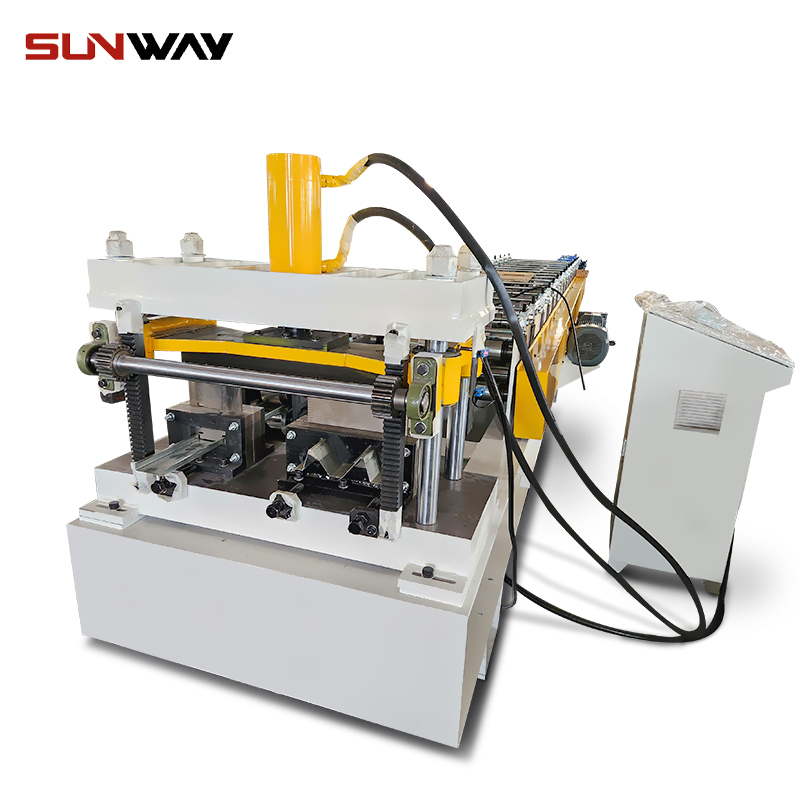

Key Features of Wuxi Sunway Decorative Structure Roll Forming Machines

When it comes to precision, reliability, and innovation, Уси Sunway машины stands out as a global leader in roll-forming technology. Here are the key features that make their decorative structure roll forming machines the preferred choice for manufacturers:

1. Advanced Design Capabilities

- Что он предлагает: Machines equipped with advanced tooling for producing intricate designs and patterns.

- Почему это важно: Meets the growing demand for unique and customized decorative profiles.

2. Гибкость материала

- Что он обрабатывает:

- Алюминий

- Нержавеющая сталь

- Оцинкованная сталь

- Металлы с предварительным покрытием

- Почему он универсален: Supports a range of materials to cater to various architectural applications.

3. Superior Finishing

- Что он обеспечивает: Profiles with smooth surfaces and flawless finishes, ready for installation without additional processing.

- Почему это полезно: Reduces the need for secondary finishing operations, saving time and costs.

4. Modular Tooling

- Что он поддерживает: Quick-change tooling systems for producing different profiles with minimal downtime.

- Почему он гибкий: Enables manufacturers to switch between projects efficiently.

5. High-Speed and High-Precision Production

- Что это дает: Processes up to 40 meters of material per minute with minimal deviations.

- Почему это необходимо: Keeps pace with the high demand for decorative construction components.

6. Интеграция IoT и автоматизации

- Что в него входит: IoT-enabled systems for real-time monitoring, remote control, and predictive maintenance.

- Почему это инновация: Enhances operational efficiency and minimizes machine downtime.

7. Durability and Reliability

- Что она гарантирует: Machines built to handle continuous production while maintaining consistent quality.

- Почему это важно: Ensures long-term value and reliability for manufacturers.

Pricing of Decorative Structure Roll Forming Machines

Стоимость Decorative Structure Roll Forming Machine варьируется в зависимости от его характеристик, производственной мощности и возможностей настройки. Ниже приведены общие цены для 2025 года:

| Тип машины | Возможности | Диапазон цен (USD) |

|---|---|---|

| Стандартные машины | Basic decorative profile production | 200,000–200,000–200,000–400,000 |

| Передовые машины | High-speed production with integrated finishing | 400,000–400,000–400,000–800,000 |

| Настраиваемые машины | Tailored for unique designs and high complexity | 800,000–800,000–800,000–1,500,000 |

Для получения подробной информации о ценах и возможностях финансирования обращайтесь Уси Sunway машины.

Advantages of Using Decorative Structure Roll Forming Machines

Декоративные структуры рулонные формовочные машины offer numerous advantages that make them invaluable for manufacturers and architects alike:

1. Enhanced Aesthetic Appeal

- Почему это важно: Produces intricate designs and smooth finishes that elevate the visual appeal of structures.

2. Высокая эффективность производства

- Почему это полезно: Enables the mass production of decorative profiles, reducing lead times and meeting tight project deadlines.

3. Customization Capabilities

- Почему это ценно: Supports bespoke designs, allowing manufacturers to cater to unique architectural requirements.

4. Экономическая эффективность

- Почему это практично: Minimizes material waste and reduces the need for secondary processing, lowering overall production costs.

5. Долговечность

- Почему это важно: Produces components that are resistant to corrosion, weather, and wear, ensuring long-lasting performance.

6. Устойчивое развитие

- Почему это актуально: Processes recyclable materials and aligns with eco-friendly construction practices.

Troubleshooting Common Issues with Decorative Structure Roll Forming Machines

Even advanced machines can face occasional challenges. Here are common issues and their solutions:

1. Неравномерные размеры профиля

- Симптомы: Profiles do not match design specifications, causing assembly issues.

- Возможные причины: Неправильное выравнивание роликов или неправильная калибровка машины.

- Решение:

- Повторно откалибруйте машину и обеспечьте правильное выравнивание роликов.

- Проводите регулярные проверки качества в процессе производства.

2. Поверхностные дефекты

- Симптомы: Profiles have scratches, dents, or inconsistent finishes.

- Возможные причины: Worn-out rollers or improper material handling.

- Решение:

- Replace damaged rollers.

- Ensure proper handling and storage of raw materials.

3. Вопросы подачи материала

- Симптомы: Material jams or feeds unevenly, disrupting production.

- Возможные причины: Poor-quality material or misaligned feeding system.

- Решение:

- Используйте высококачественные материалы с равномерной толщиной.

- Adjust the feeding system for smooth operation.

FAQs About Decorative Structure Roll Forming Machines

| Вопрос | Ответ |

|---|---|

| Какие материалы могут обрабатывать эти машины? | Aluminum, stainless steel, galvanized steel, and pre-coated metals. |

| Какова скорость производства? | До 40 метров в минуту, в зависимости от сложности профиля. |

| Могут ли эти машины работать с индивидуальными проектами? | Yes, modular tooling supports bespoke and intricate decorative profiles. |

| Экологичны ли эти машины? | Yes, they minimize material waste and support recyclable materials. |

| Каков диапазон цен на эти машины? | Цены варьируются от 200,000to200,000 to 200,000to1,500,000В зависимости от возможностей и настроек. |

| Поддерживают ли эти машины интеграцию IoT? | Да, функции с поддержкой IoT позволяют осуществлять мониторинг в режиме реального времени и прогнозировать техническое обслуживание. |

Real-World Success Stories: How Decorative Structure Roll Forming Machines Are Shaping Iconic Projects

Декоративные структуры рулонные формовочные машины have been instrumental in creating some of the most iconic architectural landmarks worldwide. Below are examples of how these machines have delivered exceptional results in real-world applications:

1. Transforming Urban Skylines in the Middle East

Клиент: A leading construction firm in Dubai specializing in high-rise buildings.

Вызов: The firm required custom-designed facade panels for a luxury skyscraper, combining modern aesthetics with durability to withstand extreme weather conditions.

Решение: Wuxi Sunway Machinery provided a roll-forming machine with advanced tooling for producing unique aluminum facade profiles with intricate patterns.

Результат:

- Produced over 50,000 square meters of decorative facade panels in less than six months.

- Reduced project costs by 20% through efficient material usage and high-speed production.

- Delivered a visually stunning exterior that has become a landmark in Dubai’s skyline.

2. Sustainable Office Cladding in Europe

Клиент: An architectural firm in Germany focused on sustainable building designs.

Вызов: The project required environmentally friendly wall cladding panels for a corporate office building, aligning with EU sustainability standards.

Решение: Wuxi Sunway supplied a machine capable of processing recycled aluminum and steel, ensuring precision and eco-friendly production.

Результат:

- Produced 30,000 square meters of cladding panels using 100% recyclable materials.

- Helped the project achieve LEED Gold Certification for sustainable construction.

- Enhanced the building’s energy efficiency by integrating thermal insulation layers into the panels.

3. Luxury Interior Ceilings for a Hotel in Asia

Клиент: A luxury hotel chain in Singapore.

Вызов: The chain needed decorative false ceilings with intricate designs for a five-star hotel, ensuring an upscale and luxurious ambiance.

Решение: Wuxi Sunway delivered a specialized roll-forming machine for producing detailed ceiling panels with smooth finishes.

Результат:

- Produced over 15,000 decorative ceiling panels in three months, meeting the tight project timeline.

- Improved the hotel’s interior aesthetics, earning praise from guests and industry experts.

- Reduced installation time by 25% through precision-engineered profiles.

4. Modular Wall Systems for Public Infrastructure in North America

Клиент: A government contractor in Canada working on public transit stations.

Вызов: The contractor required modular wall panels for metro stations, combining durability with a modern design aesthetic.

Решение: Wuxi Sunway provided a roll-forming machine optimized for producing modular panels with integrated mounting systems.

Результат:

- Produced modular panels that reduced installation time by 40%, accelerating project completion.

- Enhanced station durability, ensuring a lifespan of over 25 years.

- Delivered a clean, modern look that improved the commuter experience.

Future Trends in Decorative Structure Manufacturing for 2025

The decorative structure manufacturing industry is rapidly evolving, driven by technological advancements, environmental concerns, and changing aesthetic preferences. Here are the key trends shaping the future of Декоративные структуры рулонные формовочные машины:

1. Sustainability and Green Manufacturing

- Тренд: Architects and builders increasingly demand eco-friendly decorative components that align with global sustainability goals.

- Воздействие на машины: Roll-forming machines optimized for processing recyclable materials like aluminum and coated steel will dominate the market.

2. Advanced Customization for Unique Structures

- Тренд: Personalized designs are becoming more popular, with architects seeking bespoke decorative profiles for iconic structures.

- Воздействие на машины: Machines with modular tooling and CAD compatibility will enable the production of highly customized profiles.

3. Lightweight and High-Strength Materials

- Тренд: Lightweight materials such as aluminum alloys are being widely used to reduce structural load and improve transportation efficiency.

- Воздействие на машины: Machines capable of processing lightweight yet high-strength materials will see higher demand.

4. Integration of Functional Features

- Тренд: Decorative components are now expected to include functional features such as insulation, soundproofing, or integrated lighting.

- Воздействие на машины: Roll-forming machines with multi-layer processing capabilities will become essential.

5. Экспансия на развивающиеся рынки

- Тренд: Rapid urbanization in Asia, Africa, and South America is driving demand for affordable decorative structures.

- Воздействие на машины: Cost-efficient machines with high production rates will cater to the needs of emerging markets.

6. AI and Automation Integration

- Тренд: The adoption of AI and IoT in manufacturing processes is improving efficiency and reducing errors.

- Воздействие на машины: IoT-enabled roll-forming machines with AI-driven quality control systems will become industry standards.

Innovations in Decorative Structure Roll Forming Machines for 2025

Следующее поколение Декоративные структуры рулонные формовочные машины is set to revolutionize the production of architectural components. Here are the cutting-edge innovations to watch for:

1. Real-Time Design Adjustments

- Что это дает: Machines equipped with AI-driven systems to adjust designs and specifications in real-time during production.

- Почему это ценно: Reduces downtime and ensures quick adaptation to project changes.

2. Multi-Layer Processing

- Что он предлагает: Machines capable of producing multi-layer panels with integrated insulation or soundproofing materials.

- Почему это революционно: Meets the growing demand for decorative components with functional benefits.

3. Advanced Coating Systems

- Что он объединяет: In-line systems for applying anti-corrosion, fire-resistant, or decorative finishes during production.

- Почему это изменит игру: Reduces post-production steps and ensures consistent quality.

4. Modular and Portable Machines

- Что это дает: Machines designed for easy transportation and quick setup, ideal for on-site production.

- Почему это удобно: Enables manufacturers to produce components closer to the construction site, saving time and costs.

5. Интеллектуальный мониторинг и предиктивное обслуживание

- Что в него входит: IoT-enabled systems for monitoring machine performance and predicting maintenance needs.

- Почему это необходимо: Minimizes downtime and extends the machine’s lifespan, ensuring consistent production.

Why Wuxi Sunway Machinery Leads the Decorative Roll-Forming Industry

Уси Sunway машины has earned its reputation as a global leader in roll-forming technology. Here’s why they are the preferred choice for decorative structure manufacturers:

1. Decades of Experience

With years of expertise in designing roll-forming solutions, Wuxi Sunway has a proven track record of delivering excellence.

2. Передовые технологии

Incorporates advanced features like IoT, AI, and multi-layer processing into their machines.

3. Превосходство персонализации

Offers tailored solutions for producing unique decorative profiles that meet specific project requirements.

4. Глобальный охват

Trusted by clients across Asia, Europe, the Americas, and Africa, making Wuxi Sunway a truly international brand.

5. Обязательства по устойчивому развитию

Designs machines that support eco-friendly manufacturing, aligning with global sustainability goals.

6. Всесторонняя поддержка

Provides end-to-end services, including consultation, installation, training, and after-sales support.

Посетите их официальный сайт to learn more about their offerings or request a customized solution for your decorative structure production needs.

FAQs About Decorative Structure Roll Forming Machines

| Вопрос | Ответ |

|---|---|

| Какие материалы могут обрабатывать эти машины? | Aluminum, stainless steel, galvanized steel, and pre-coated metals. |

| Какова скорость производства? | До 40 метров в минутув зависимости от материала и сложности профиля. |

| Могут ли эти машины изготавливать нестандартные конструкции? | Yes, modular tooling supports bespoke designs for unique architectural projects. |

| Экологичны ли эти машины? | Yes, they minimize material waste and support recyclable and sustainable materials. |

| Каков диапазон цен на эти машины? | Цены варьируются от 200,000to200,000 to 200,000to1,500,000В зависимости от возможностей и настроек. |

| Поддерживают ли эти машины интеграцию IoT? | Да, функции с поддержкой IoT позволяют осуществлять мониторинг в режиме реального времени и прогнозировать техническое обслуживание. |

Conclusion: Building Aesthetic and Functional Structures with Advanced Roll-Forming Technology

The future of architecture lies in combining beauty with functionality, and Декоративные структуры рулонные формовочные машины are at the heart of this transformation. From creating visually stunning facades to producing multi-functional panels, these machines empower manufacturers to redefine modern construction.

Ready to revolutionize your decorative structure production? Partner with Уси Sunway машины and discover how their state-of-the-art roll-forming solutions can help you achieve your architectural vision. Together, let’s shape the world of tomorrow—one profile at a time.