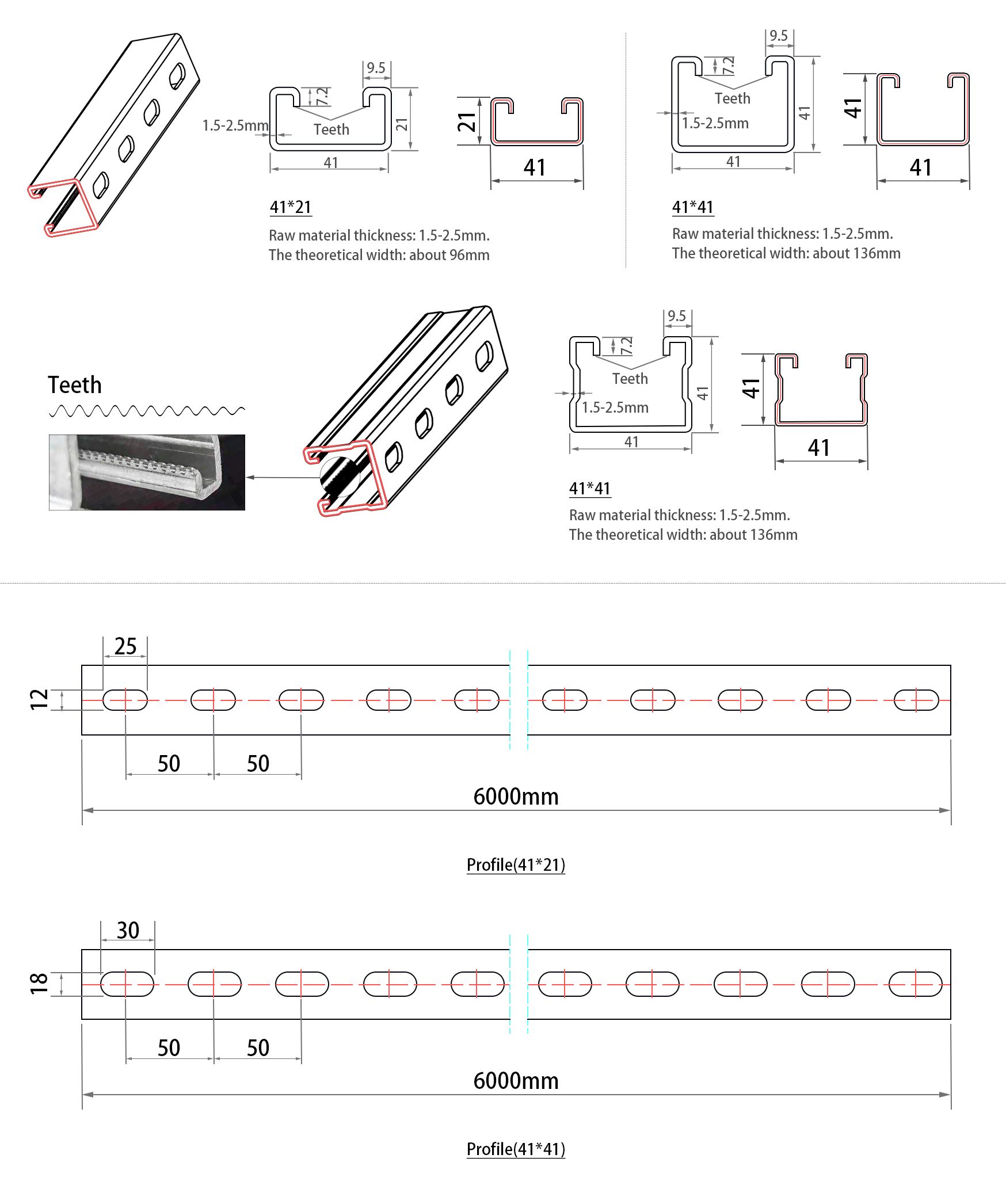

अकड़ चैनल रोल बनाने की मशीन प्रोफ़ाइल चित्र

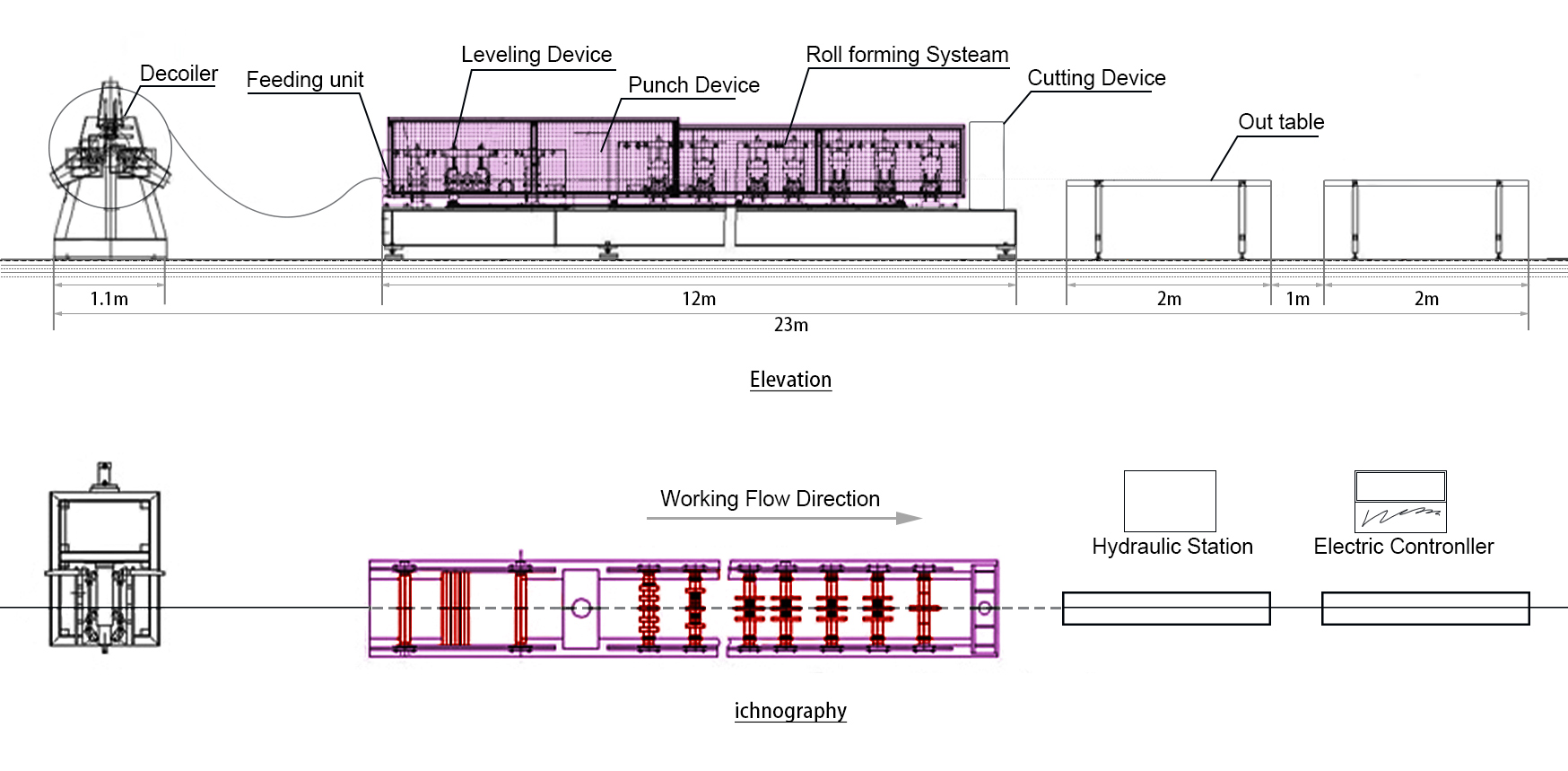

अकड़ चैनल रोल बनाने की मशीन उत्पादन लाइन

उत्पाद विवरण

अकड़ चैनल रोल बनाने की मशीन पैरामीटर

| अकड़ चैनल रोल बनाने की मशीन (नियमित संस्करण) | ||

|

मशीन योग्य सामग्री

|

ए) हॉट रोल्ड और कोल्ड रोल्ड स्टील |

मोटाई (एमएम): 1.5-2.0, 2.0-2.5 मिमी

|

| बी) गर्म-डुबकी जस्ती शीट | ||

| सी) पूर्व-जस्ती स्टील | ||

| डी) मिल (सादा/काला) स्टील | ||

| नम्य होने की क्षमता | 235 - 345 एमपीए | |

| तन्य तनाव | G250 एमपीए-G350 एमपीए | |

| डेकोइलर | मैनुअल डेकोइलर |

* हाइड्रोलिक डेकोइलर (वैकल्पिक)

|

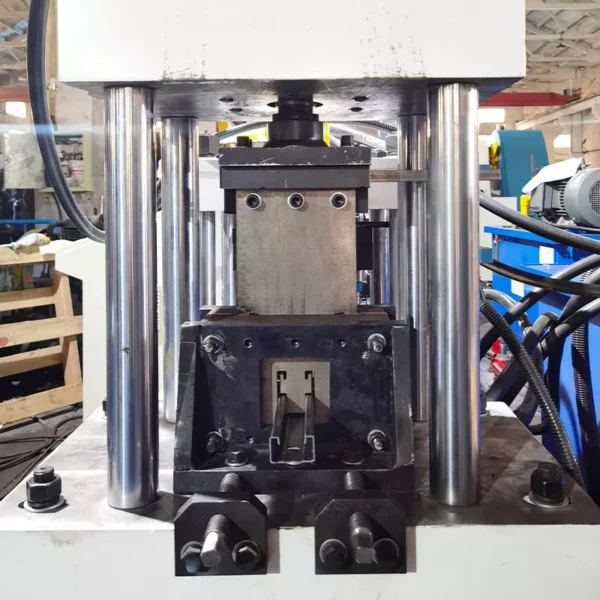

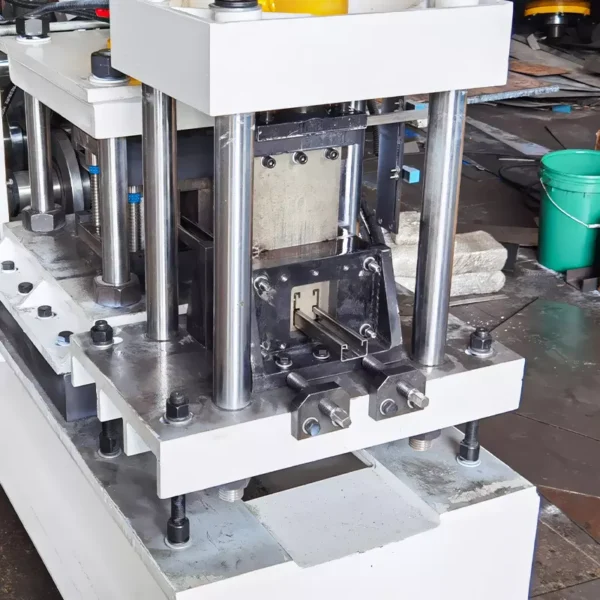

| पंचिंग सिस्टम: | हाइड्रोलिक पंचिंग स्टेशन |

* पोस्ट पंचिंग या प्री-पंचिंग विकल्प

|

| फॉर्मिंग स्टेशन | 19-22 |

* आपके प्रोफाइल ड्रॉइंग के अनुसार

|

| मुख्य मशीन मोटर ब्रांड | रेड्यूसर + मोटर |

* सर्वो मोटर (वैकल्पिक)

|

| ड्राइविंग सिस्टम | चेन ड्राइव |

* गियरबॉक्स ड्राइव (वैकल्पिक)

|

| मशीन संरचना | दिवार का पैनल |

* जाली लोहा स्टेशन (वैकल्पिक)

|

| लाइन बनाने की गति | 4-6 (एम/मिन) |

* अंतिम विन्यास के अनुसार

|

| रोलर्स की सामग्री | जीसीआर15 |

* Cr12 (वैकल्पिक)

|

| कटिंग सिस्टम | पोस्ट-कटिंग, मशीन स्टॉप टू कट |

* ट्रैकिंग कटर (वैकल्पिक)

|

| आवृत्ति परिवर्तक ब्रांड | यास्कावा | |

| पीएलसी ब्रांड | पैनासोनिक | |

| बिजली की आपूर्ति | 380V 50Hz 3ph |

* या आपकी आवश्यकता के अनुसार

|

| मशीन का रंग | औद्योगिक नीला |

* या आपकी आवश्यकता के अनुसार

|

आवेदन

हरे, ठोस, किफायती, टिकाऊ, तेजी से स्थापित करने में आसान और अच्छी दिखने वाली सुविधाओं के साथ, रोल सी-आकार वाले स्टील फोटोवोल्टिक ब्रैकेट और अन्य स्टील निर्माण सामग्री में अधिक से अधिक व्यापक रूप से उपयोग किया जाता है। यह विभिन्न प्रकाश इस्पात संरचना निर्माण, अलमारियों, छत के फ्रेम आदि के लिए उपयुक्त है।

application of strut channel roll forming machine

A strut channel roll forming machine is used to manufacture strut channels, also known as C-channels or U-channels. These channels are commonly used in various industries, including construction, electrical, and HVAC (heating, ventilation, and air conditioning). Here are some applications of strut channels and their roll forming machines:

- Construction Industry: Strut channels are widely used in the construction industry to provide structural support for electrical conduit, plumbing pipes, and HVAC ducts. They are used to create a framework for mounting and supporting these systems within buildings. The roll forming machine produces custom strut channels with precise dimensions, hole patterns, and lengths to meet the specific requirements of construction projects.

- Electrical Industry: Strut channels play a crucial role in electrical installations. They are used to mount and support electrical panels, conduits, cable trays, and wiring systems. The roll forming machine produces strut channels with slots or holes at regular intervals, allowing easy installation and adjustment of electrical components. This helps in organizing and routing electrical wiring, improving safety and efficiency.

- HVAC Industry: In the HVAC industry, strut channels are utilized for installing ductwork, supporting air handling units, and mounting other HVAC equipment. The roll forming machine produces strut channels that can withstand the weight of heavy ducts and equipment while maintaining stability and reliability. These channels are designed to provide flexibility in configuring HVAC systems and making adjustments as needed.

- Retail Fixtures and Displays: Strut channels find applications in retail settings as well. They are used to create versatile display systems, shelving units, and signage supports in stores. The roll forming machine produces customized strut channels that can be easily assembled and disassembled, allowing retailers to create dynamic displays and adapt to changing merchandise requirements.

- Solar Panel Mounting Systems: Strut channels are widely employed in solar panel mounting structures. They provide a robust framework for supporting solar panels on rooftops or ground-mounted installations. The roll forming machine produces strut channels with specific profiles and hole patterns to facilitate easy and secure attachment of solar panels, ensuring optimal positioning and maximum energy generation.

Overall, a strut channel roll forming machine is essential for manufacturing high-quality and customized strut channels used in a wide range of industries. It enables efficient production, precise customization, and cost-effective solutions for various applications.

Application Fields of C Channel Roll Forming Machine

A C channel roll forming machine is used to produce C-shaped channels from various materials such as steel, aluminum, or galvanized steel. These channels, also known as C channels or U channels, have a wide range of applications across different industries. Here are some of the common application fields of C channel roll forming machines:

- Construction Industry: C channels are extensively used in the construction industry for structural framing, support, and installation purposes. They are employed in building frameworks, roof structures, wall partitions, and ceiling systems. C channel roll forming machines produce precise and consistent channels with standardized dimensions and profiles, making them ideal for construction projects.

- Electrical and Wiring Systems: C channels are used in electrical installations to provide a secure and organized pathway for electrical wiring, conduit, and cables. The roll-formed C channels can be mounted on walls, ceilings, or floors to create a framework for routing electrical components, such as switches, outlets, and lighting fixtures. The channels facilitate easy installation and maintenance of electrical systems.

- Automotive Industry: C channels find applications in the automotive industry for various purposes,

- 存储和货架系统:C型槽钢常用于存储架、货架单元和仓库系统的设计与建设。滚压成型的C型槽钢提供坚固多功能支撑,便于组装、定制和调整以适应不同尺寸和重量的物品。

- Material Handling and Conveyor Systems: C channels are essential components in material handling equipment, conveyor systems, and industrial automation. They form frameworks for conveyors, guide rails, support structures, and product handling systems. Roll-formed C channels deliver the strength and rigidity needed to support heavy loads while ensuring smooth material flow.

- Greenhouse and Agricultural Applications: C channels are widely used in greenhouse structures and agricultural settings. They support greenhouse glazing, provide frameworks for crop support systems, and serve as mounting structures for irrigation. Roll-formed C channels offer the corrosion resistance and structural stability essential for outdoor and farming environments.

- Furniture Manufacturing: C channels are applied in furniture production, particularly metal furniture. They create frames, supports, and structural elements for chairs, tables, cabinets, and other items. Roll-formed C channels provide design flexibility, strength, and stability for furniture construction.

These represent only a few application areas for C channel roll forming machines. Their versatility and customization options make them ideal for industries needing high-quality, standardized C channels.

How to Choose a Gypsum Channel Roll Forming Machine?

Selecting a gypsum channel roll forming machine requires careful consideration of key factors to match your specific needs. Here are the main points:

- Production Capacity: Assess your output requirements, such as the volume of gypsum channels needed over a given period. This determines the machine's required speed and capacity. Select a model that efficiently meets your production volume.

- Channel Specifications: Evaluate the dimensions and profiles of your gypsum channels, including width, height, flange size, lip size, and custom features. Ensure the machine accommodates these specs with adjustable settings.

- Material Compatibility: Verify the machine handles your gypsum material's type and thickness. It should feature suitable rollers, forming stations, and cutting tools for the material's properties.

- Machine Durability and Reliability: Choose a machine built with premium materials and components for long-term performance. Opt for a reputable manufacturer known for robust, dependable equipment.

- Customization Options: If you need features like hole patterns, embossing, or specials, confirm the machine supports them with easy adjustments.

- Automation and Efficiency: Look for advanced automation, such as auto-feeding, PLC controls, and quick changeovers, to boost productivity and minimize downtime.

- After-Sales Support: Select a manufacturer offering comprehensive service, including technical help, spare parts, and maintenance, to resolve issues promptly.

- Cost and Return on Investment: Weigh the total cost—purchase, installation, and upkeep—against production needs and market demand for gypsum channels.

Consult reputable suppliers or manufacturers, share your requirements, and request quotes. Attend trade shows for roll forming machinery to observe machines and explore options.

समीक्षा

अभी तक कोई समीक्षा नहीं।