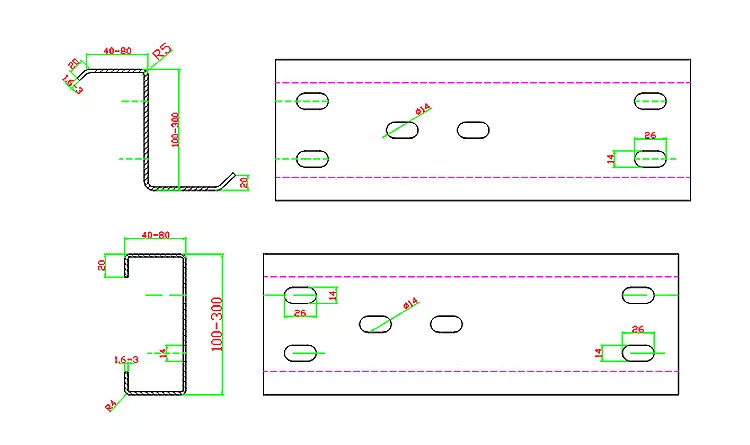

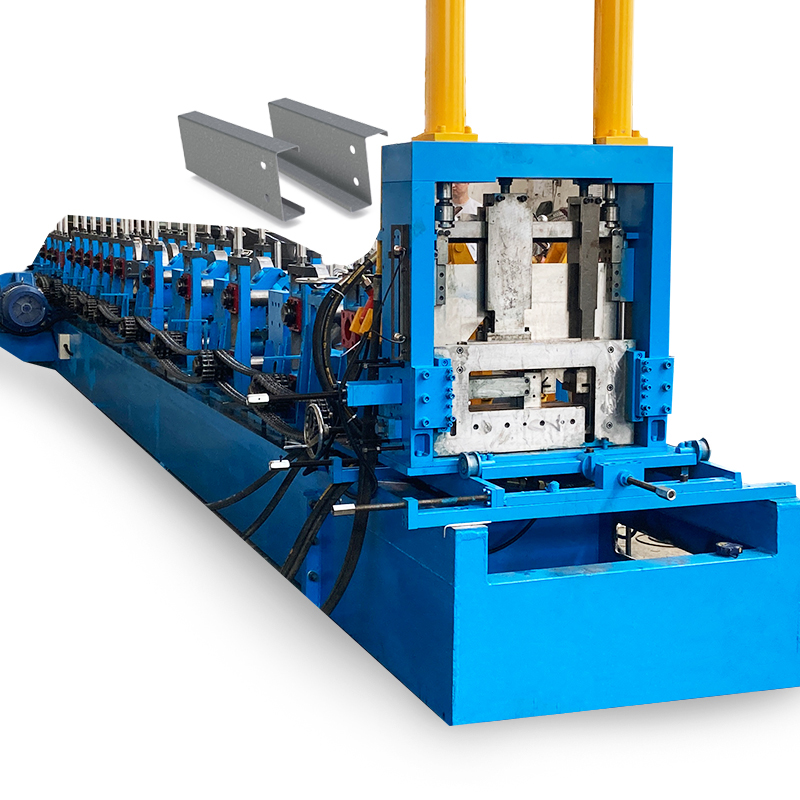

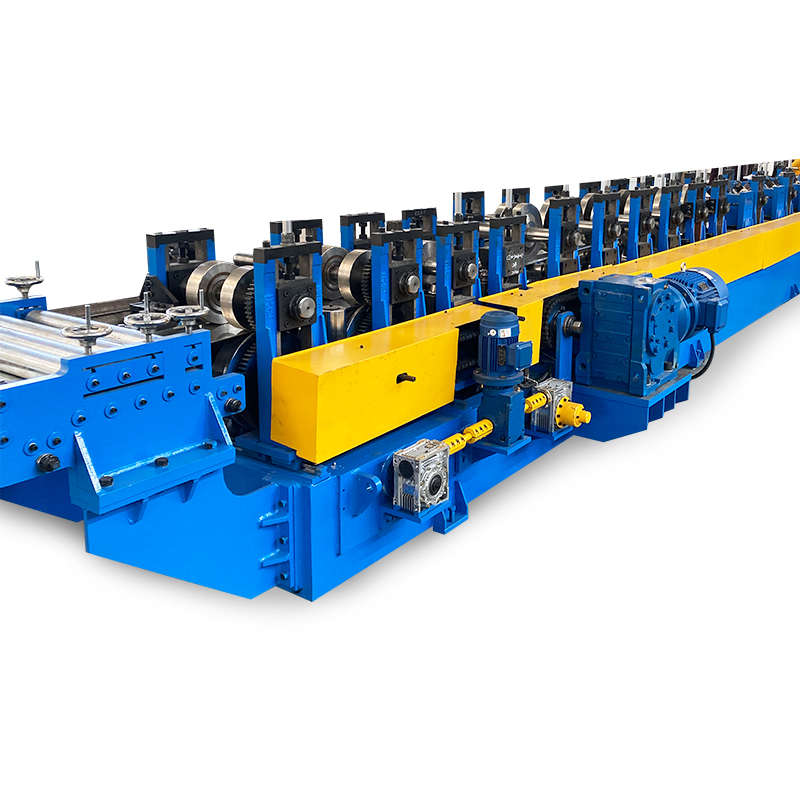

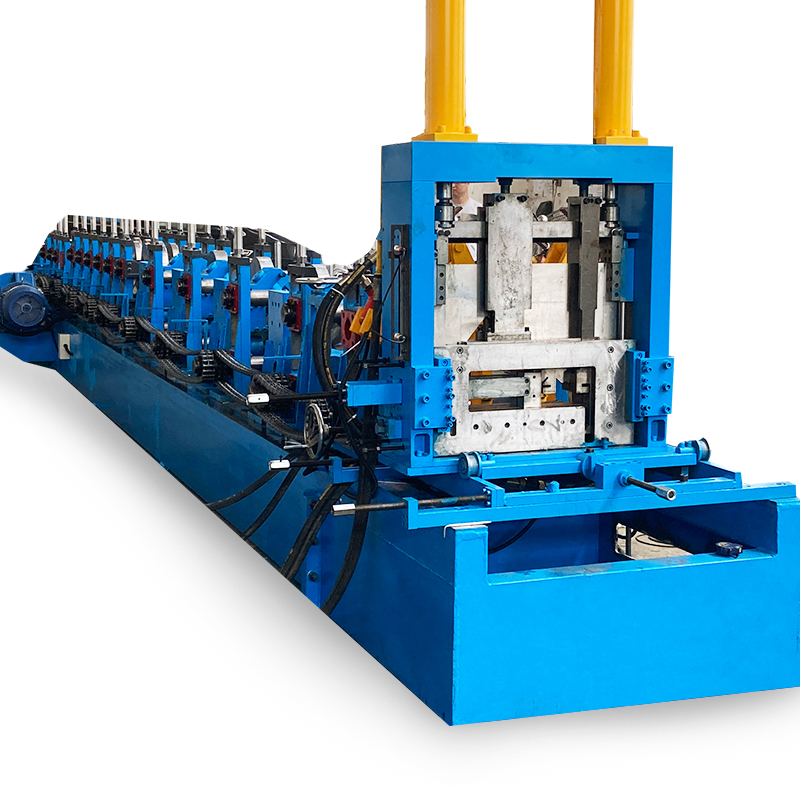

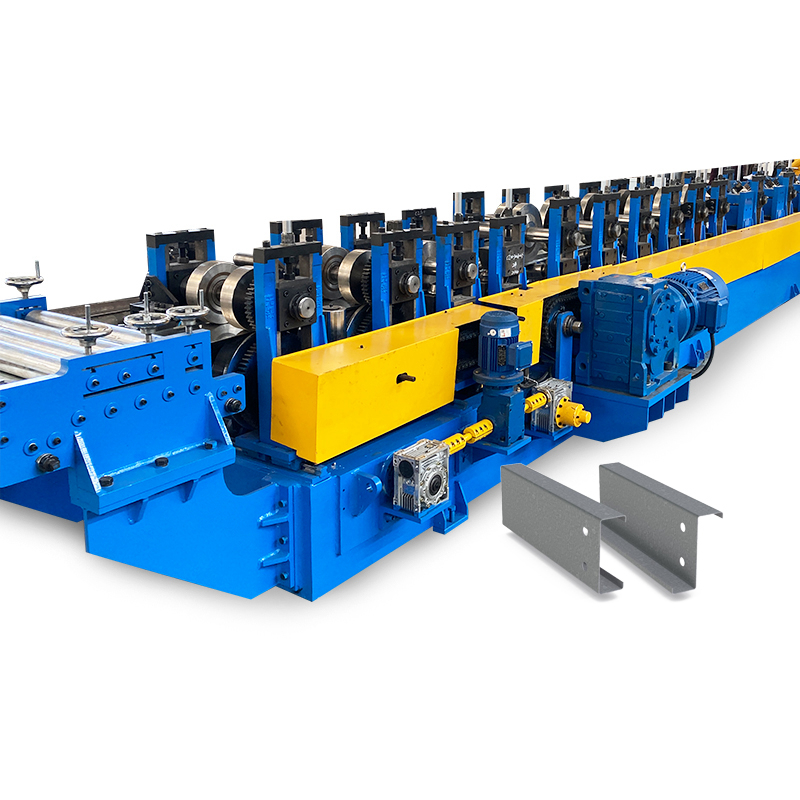

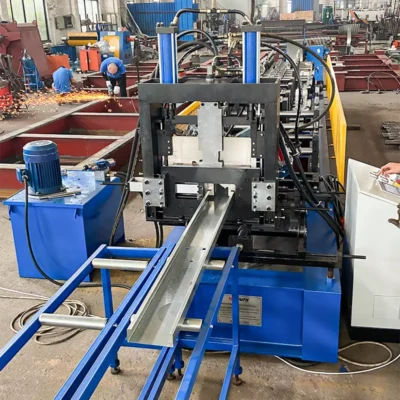

पूरी तरह से स्वचालित सी एंड जेड शहतीर त्वरित विनिमेय रोल बनाने की मशीन, सी और जेड शहतीर बनाने के लिए एक विशेष संरचना को गोद लेती है। सी और जेड के लिए रोलर्स बिना किसी हिस्से को अलग किए बहुत जल्दी बदल दिए जाते हैं। कटर सार्वभौमिक हाइड्रोलिक कटिंग डिवाइस को अपनाता है, विभिन्न आकारों के साथ अलग-अलग प्रोफाइल का निर्माण करते समय कटर ब्लेड को बदलने की आवश्यकता नहीं होती है जो श्रम लागत को बचाती है और उत्पादन क्षमता में सुधार करती है।

सीजेड शहतीर चैनल कोल्ड रोल बनाने की मशीन का विवरण

स्टैंड बेस

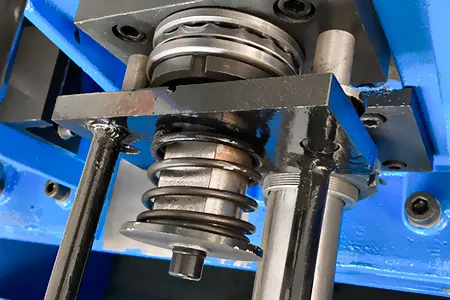

रोल स्टैंड कास्ट आयरन सिंगल स्टेशन को अपनाते हैं जो सबसे भारी और मजबूत होता है।

विनिमय करने योग्य

रोलर्स या स्पेसर्स को बदले बिना विभिन्न शहतीर आकार का उत्पादन करें।

केवल रोलर्स को 180 डिग्री पलटने की जरूरत है, लागत और समय बचाएं।

यूनिवर्सल कट

यूनिवर्सल पोस्ट कटर। विभिन्न आकारों के लिए कटर ब्लेड बदलने की आवश्यकता नहीं है।

अनुकूलन

वरिष्ठ और अनुभवी इंजीनियर आपके अनुकूलित करने के लिए पूरी प्रक्रिया को नियंत्रित करते हैं।

CZ शहतीर चैनल कोल्ड रोल बनाने की मशीन पैरामीटर

| उत्पाद |

सी एंड जेड शहतीर त्वरित विनिमेय रोल बनाने की मशीन

|

| नमूना |

सी चैनल प्रोफ़ाइल / जेड आकार प्रोफ़ाइल (अनुकूलन योग्य)

|

| मूलभूत सामग्री |

जस्ती स्टील हॉट एंड कोल्ड रोल्ड स्टील

|

| मोटाई |

1.5-3.0 मिमी (अनुकूलन योग्य)

|

| प्रभावी चौड़ाई |

प्रोफ़ाइल आकार के अनुसार

|

| रोलर स्टेशन |

लगभग 16 स्टेशन

|

| रोलर सामग्री |

असर स्टील / Cr12Mov

|

| रोलर चालित प्रकार |

चेन / गियरबॉक्स द्वारा

|

| रंग |

ग्राहक आवश्यकताओं / अनुकूलन के अनुसार

|

| ब्रैंड | सनवे |

| नियंत्रण प्रणाली |

दुनिया भर में प्रसिद्ध ब्रांड पीएलसी (पैनासोनिक, सीमेंस, डेल्टा, आदि)

|

| शक्ति | 15KW-18KW |

| चौखटा |

350 एच स्टील / 400 एच स्टील

|

| कटिंग ड्राइव | हाइड्रोलिक ड्राइव |

| काटना और हाइड्रोलिक प्रकार |

प्रकार: पोस्ट यूनिवर्सल कटर

हाइड्रोलिक पंप स्टेशन: 11kw ब्लेड: Cr12mov HRC: 58-62 |

What is cold roll forming machine?

A cold roll forming machine is a type of manufacturing equipment used to shape metal sheets or strips into desired profiles or shapes. It is called “cold” roll forming because the process takes place at room temperature, without the use of heat.

The machine consists of a series of rollers arranged in a specific sequence, through which the metal material is fed. As the material passes through the rollers, it gradually takes on the shape of the profile designed for the final product. The rollers are usually adjustable, allowing for precise control over the dimensions and shape of the formed product.

Cold roll forming machines are commonly used in various industries, such as construction, automotive, and manufacturing. They are often employed to produce components with consistent cross-sections, such as channels, angles, tubes, and other complex shapes. The process is known for its high efficiency, accuracy, and the ability to produce long lengths of continuous profiles.

Compared to other metal forming processes, cold roll forming offers several advantages. It eliminates the need for additional machining or welding operations, reduces material waste, and provides better dimensional control. Additionally, it can work with a wide range of metals, including steel, aluminum, copper, and stainless steel, making it a versatile solution for different applications.

How about cold roll forming machine price?

The price of a cold roll forming machine can vary significantly depending on several factors, including the machine’s specifications, complexity, size, and the manufacturer or supplier. Additionally, prices may also vary based on the geographical location and market conditions.

Generally, cold roll forming machines can range in price from several thousand dollars for simpler, entry-level machines, to hundreds of thousands of dollars for more advanced, high-capacity machines with complex features.

It’s important to note that the price of the machine is not the only consideration when purchasing a cold roll forming machine. Other factors to consider include the machine’s quality, reliability, after-sales support, and the reputation of the manufacturer.

To get an accurate and up-to-date price for a specific cold roll forming machine, it is recommended to contact manufacturers, suppliers, or distributors directly. They can provide you with detailed information about the machine’s specifications and provide a customized quote based on your specific requirements.

top 5 cold roll forming machine manufacturers

- वूशी सनवे मशीनरी कं, लिमिटेड एक पेशेवर निर्माता और निर्यातक है जो कोल्ड रोल बनाने वाली मशीनों के डिजाइन, विकास और उत्पादन से संबंधित है। सभी उत्पाद अंतरराष्ट्रीय गुणवत्ता मानकों का अनुपालन करते हैं और दुनिया भर के विभिन्न बाजारों, जैसे एशिया, अफ्रीका, यूरोप, दक्षिण अमेरिका और ऑस्ट्रेलिया आदि में बहुत सराहना की जाती है। इसने वैश्विक बिक्री नेटवर्क हासिल किया है।

- Bradbury Group: Bradbury Group is a leading manufacturer of roll forming equipment, with a wide range of cold roll forming machines for various industries. They are known for their innovative designs, advanced technology, and reliable equipment.

- Formtek, Inc.: Formtek is a group of companies that specialize in metal forming and fabrication equipment, including cold roll forming machines. They offer a comprehensive range of roll forming solutions and have a strong reputation for their engineering expertise and customer support.

- Samco Machinery Ltd: Samco Machinery is a global leader in roll forming technology, providing high-quality cold roll forming machines for diverse applications. They have a wide product portfolio and are known for their commitment to innovation, precision, and reliability.

- Yoder Manufacturing: Yoder Manufacturing has been a prominent manufacturer of roll forming machines for over 100 years. They offer a range of cold roll forming equipment for various industries and are recognized for their durable machines and excellent customer service.

advantage of china cold roll forming machine

China has become a leading manufacturer and exporter of cold roll forming machines, and there are several advantages associated with choosing Chinese cold roll forming machines:

- Cost-Effective: Chinese cold roll forming machines are known for their competitive pricing. China’s manufacturing capabilities, economies of scale, and cost-effective labor force contribute to lower production costs, making Chinese machines more affordable compared to those from other countries.

- Wide Range of Options: China offers a wide range of cold roll forming machines to cater to various industries and applications. Whether you need a machine for roofing, construction, automotive, or any other sector, you can find a suitable option from Chinese manufacturers who often provide a diverse range of models.

- Quality Standards: Over the years, China has made significant improvements in terms of quality control and manufacturing standards. Many Chinese cold roll forming machine manufacturers adhere to internationally recognized quality management systems, ensuring that their machines meet or exceed industry standards.

- Customization and Flexibility: Chinese manufacturers often offer customization options to tailor the cold roll forming machines according to specific customer requirements. Whether it’s adjusting the machine dimensions, adding additional features, or incorporating specific software, Chinese manufacturers are often willing to accommodate customization requests.

- Timely Delivery: With efficient logistics networks and streamlined export processes, Chinese manufacturers are generally capable of delivering cold roll forming machines within reasonable timeframes. This is crucial for businesses that have tight production schedules and need machines delivered promptly.

- After-Sales Support: Chinese manufacturers have recognized the importance of after-sales support and have made efforts to enhance their customer service. Many companies offer technical assistance, training, and spare parts support to ensure the smooth operation and maintenance of their machines.

- Established Industry Cluster: China has developed several industrial clusters dedicated to manufacturing machinery, including cold roll forming machines. These clusters bring together suppliers, manufacturers, and research institutions, fostering innovation, collaboration, and the exchange of expertise. Being part of such clusters enables Chinese manufacturers to stay updated with the latest technological advancements.

It’s worth noting that while Chinese cold roll forming machines have these advantages, it’s essential to conduct thorough research, evaluate different manufacturers, and consider customer reviews and certifications to ensure you choose a reliable and reputable supplier.

बाजार में मौजूद 5 सर्वश्रेष्ठ शहतीर रोल बनाने वाली मशीन के ब्रांड

समीक्षा

अभी तक कोई समीक्षा नहीं।