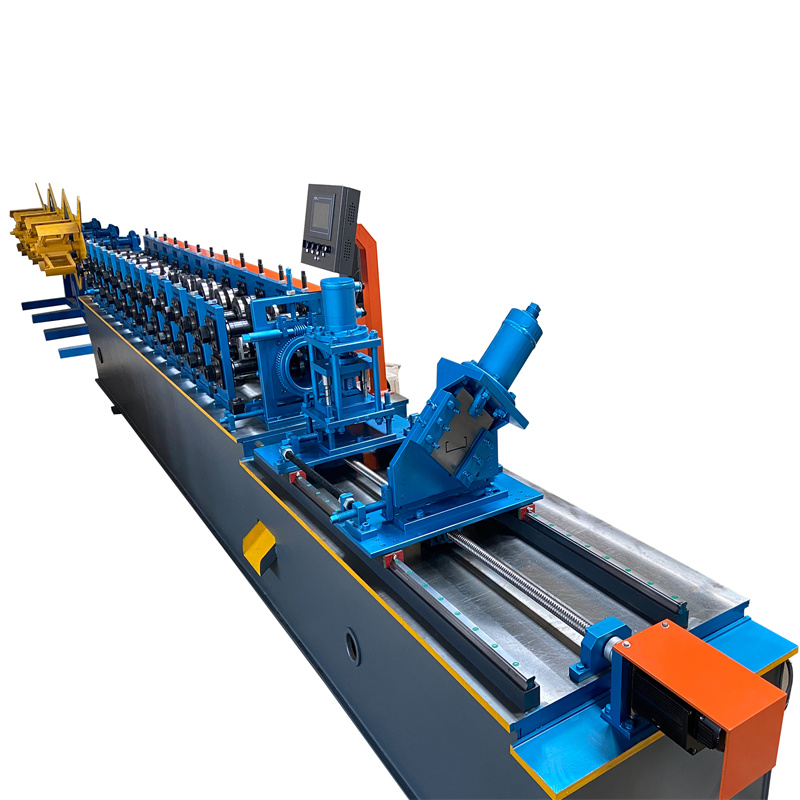

There are many reasons to use a light steel keel roll forming machine, so read on to learn more! Light steel keel rolls are used in a variety of industries, such as automotive, marine, and appliances. They are essential for producing strong, flexible components.

What is a light steel keel roll forming machine?

ए लाइट स्टील कील रोल बनाने की मशीन It is an excellent tool for crafting custom keels for boats and other watercraft. The machine employs a rotating die to form the desired shape and is user-friendly, ensuring precise results every time. Additionally, its die-cast aluminum construction offers durability and lightness, making it ideal for small workshops or home setups.

The Benefits of Using a Light Steel Keel Roll Forming Machine

Light steel keel roll forming machines offer numerous advantages. They produce high-quality parts rapidly with minimal labor, making them ideal for small businesses and production lines. Key benefits include:

- Quick Production: A light steel keel roll forming machine enables rapid creation of high-quality parts. It shapes metal sheets precisely without excessive pressure or heat.

- Durable Parts: These machines apply less force than alternatives, resulting in more resilient components that resist wear and last longer.

- Precise Shapes: With a light steel keel रोल बनाना roll forming machine, you can effortlessly produce exact shapes in metal sheets. This facilitates components tailored to specific aesthetic or functional requirements.

- Increased Productivity: A light steel keel roll forming machine can boost productivity by up to 50%, allowing faster work with reduced strain and superior outcomes.

-

Multi Profiles Roll Forming Machine

Multi Profiles Roll Forming Machine -

Auto Changeable C Z Purline Machine

Auto Changeable C Z Purline Machine -

Semi Auto Size Changeable CZ Purlin Roll Forming Machine

Semi Auto Size Changeable CZ Purlin Roll Forming Machine -

Laser Welding Square Pipe Roll Forming Machine

Laser Welding Square Pipe Roll Forming Machine -

वाइनयार्ड पोस्ट रोल बनाने की मशीन

वाइनयार्ड पोस्ट रोल बनाने की मशीन -

मचान तख़्त रोल बनाने की मशीन

मचान तख़्त रोल बनाने की मशीन -

लाइट गेज स्टील रोल बनाने की मशीन

लाइट गेज स्टील रोल बनाने की मशीन -

ऑटो आकार बदलने योग्य सिग्मा शहतीर रोल बनाने की मशीन

ऑटो आकार बदलने योग्य सिग्मा शहतीर रोल बनाने की मशीन -

ऑटो आकार बदलने योग्य CZ शहतीर रोल बनाने की मशीन

ऑटो आकार बदलने योग्य CZ शहतीर रोल बनाने की मशीन

Common Applications for a Light Steel Keel Roll Forming Machine

One key application is manufacturing boat hulls, typically from lightweight yet rigid materials like fiberglass and carbon fiber. Improper forming can cause sagging due to weight; a light steel keel roll forming machine ensures strong, lightweight hulls.

Another frequent use is producing automotive body panels, which require precise alignment of layered materials for a seamless finish. This machine delivers uniformly thick, accurately shaped panels.

The Reasons To Use a Light Steel Keel Roll Forming Machine

Light steel keel forms are crafted from a single metal piece shaped via a stamping die and pressure plate for precision with minimal effort.

This machine is also easy to transport and set up without specialized tools, and robust enough for demanding processes.

In summary, a light steel keel roll forming machine offers an efficient, cost-effective solution for custom boat shapes. It delivers quality results affordably.

Limitations of a Light Steel Keel Roll Forming Machine

A light steel keel roll forming machine excels at producing wire EDM sheets from round or square bar stock, surpassing traditional methods with faster production and reduced machining time.

Traditional wire EDM struggles with long, narrow items of consistent dimensions. This machine’s revolving die ensures even, uniform sheets in any shape, including curves, without die changes.

Overall, it is ideal for high-quality wire EDM sheets from bar stock, offering speed and efficiency advantages.

निष्कर्ष

When selecting a light steel roll forming machine, consider these ten compelling reasons. Whether for complex shapes or waste reduction, it is indispensable for manufacturing. Thank you for reading!

Frequently Asked Questions (FAQ)

1) What profiles can a light steel keel roll forming machine produce for drywall framing?

- Typical profiles include C studs, U tracks, ceiling channels, furring channels, and corner beads in thicknesses 0.4–1.0 mm (GI/GL). Changeover cassettes can switch between stud and track within minutes.

2) What tolerances are realistic for light gauge keel profiles in 2025?

- Length: ±0.5–1.0 mm with encoder control; web/flange width: ±0.3–0.5 mm; hole location: ±0.5 mm with servo punching and vision verification, assuming 30–60 m/min.

3) Which steels work best for light keel roll forming?

- Galvanized steel per EN 10346 (S220GD–S350GD, Z120–Z275 coatings) and ASTM A653 (Commercial/Structural Quality). For coastal projects, AZ (aluzinc) coated or prepainted coils per EN 10169 improve corrosion resistance.

4) How do I reduce scrap during frequent SKU changes (stud lengths)?

- Use recipe-driven flying cutoff, coil-end optimization, and nesting by length mix. Quick-change cassettes and auto-stand positioning reduce mis-setup scrap.

5) Is servo-electric punching worth it for drywall stud lines?

- Yes. For ≤1.2 mm thickness, servo-electric units cut oil use, simplify maintenance, and hold tighter hole tolerances at higher speeds than hydraulics.

2025 Industry Trends

- Fast changeovers for multi-profile lines: Auto stand positioning and quick cassettes reduce changeover to 5–10 minutes.

- Inline QC becomes standard: Low-cost laser width gauges and camera-based hole inspection drive first-pass yield to 98–99%.

- Energy optimization: IE4/IE5 motors and regenerative drives lower energy to 55–75 kWh/ton on best-in-class light gauge lines.

- Digital thread for traceability: OPC UA/MQTT connectivity to MES/ERP enables coil-to-room tracking for large drywall projects.

- Sustainability and compliance: EPD-backed coils, ISO 14001 facilities, and low-VOC lubricants are increasingly specified by contractors.

2025 Benchmarks for Light Steel Keel Roll Forming Machines

| Metric | 2023 Typical | 2025 Best-in-class | What improves it |

|---|---|---|---|

| Changeover (stud ↔ track) | 20–30 min | 5–10 min | Quick cassettes, auto-stand presets |

| Line speed (≤1.0 mm GI) | 25–40 m/min | 50–70 m/min | Servo punching, optimized cutoff |

| First-pass yield | 95–97% | 98–99% | Inline laser/vision, closed-loop offsets |

| Energy use (kWh/ton) | 80–100 | 55–75 | IE4/IE5 + regenerative drives |

| Scrap rate | 3–5% | 1–2% | Nesting, coil-end optimization, AI anomaly detection |

Sources:

- U.S. DOE Advanced Manufacturing: https://www.energy.gov/amo

- ISO 14001 Environmental Management Systems: https://www.iso.org/iso-14001-environmental-management.html

- OPC Foundation (OPC UA): https://opcfoundation.org

- Keyence inline inspection resources: https://www.keyence.com

- ASTM A653 / EN 10346 material references: https://www.astm.org / https://standards.cen.eu

Latest Research Cases

Case Study 1: Rapid Changeover for Mixed C-Stud/U-Track Production (2025)

Background: A drywall framing supplier needed to run short batches (2–5 m lengths) across five stud/track sizes, suffering 25-minute changeovers and high trim scrap.

Solution: Implemented quick-change cassette roll tooling, auto-stand positioning, and recipe-driven flying cutoff with nesting by length mix.

Results: Changeover time dropped to 7 minutes; scrap reduced from 4.1% to 1.6%; throughput increased 18% at peak while maintaining length tolerance ±0.7 mm.

Case Study 2: Servo-Electric Punching Improves Hole Quality in Perforated Studs (2024)

Background: A manufacturer of MEP-ready studs struggled with ovalized service holes at speeds >40 m/min using hydraulics.

Solution: Replaced hydraulic punching with servo-electric module, added camera-based hole inspection, and synchronized with the feed encoder.

Results: Hole roundness improved by 30% and location tolerance tightened to ±0.5 mm; unplanned downtime fell 22%; measured energy per ton decreased 14%.

Expert Opinions

- Dr. Elena Morales, Head of Advanced Forming, University of Sheffield AMRC

Key viewpoint: “For light steel keel lines, the biggest ROI comes from linking low-cost inline gauges to automatic stand offsets—precision at speed without adding operators.” - Jason Patel, Director of Manufacturing Engineering, Nucor Buildings Group

Key viewpoint: “Standard OPC UA data structures let drywall stud lines plug into plant MES for coil-to-bundle traceability, which contractors increasingly require.” - Priya Khanna, Senior Product Manager, Rockwell Automation

Key viewpoint: “Servo-electric punching on thin-gauge studs enables higher line speeds while tightening hole quality—plus it removes hydraulic headaches.”

Practical Tools/Resources

- AISI S100 Cold-Formed Steel Specification and framing design aids: https://www.awc.org/standards/aisi

- ASTM A653 and EN 10346 coated steel standards: https://www.astm.org and https://standards.cen.eu

- DOE Better Plants energy benchmarking tools: https://www.energy.gov/better-plants

- SSAB coil yield and nesting calculators: https://www.ssab.com/en/tools-and-services

- Keyence application notes for width and hole inspection: https://www.keyence.com

- OPC UA and MQTT best practices for machine connectivity: https://opcfoundation.org and https://mqtt.org

- OSHA machine guarding and lockout/tagout: https://www.osha.gov/machine-guarding and https://www.osha.gov/control-hazardous-energy

Last updated: 2025-10-20

Changelog: Added targeted 5-item FAQ, 2025 trends with benchmark table and sources, two recent case studies, expert viewpoints, and curated tools/resources for light steel keel roll forming machines

Next review date & triggers: 2026-03-31 or earlier if ASTM/EN standards update, major vendor releases on servo-electric punching/inline QC, or new DOE energy benchmarks are published