Roll forming is a metal forming process used to form metal sheets, strips, coils or blanks into various profiles or shapes. Tishken is a leading manufacturer of high quality roll forming machines used for production of metal components with complex cross-sections. This guide provides a detailed overview of Tishken roll forming machines, their types, technical specifications, applications, advantages, installation and operation.

Overview of Tishken Roll Forming Machines

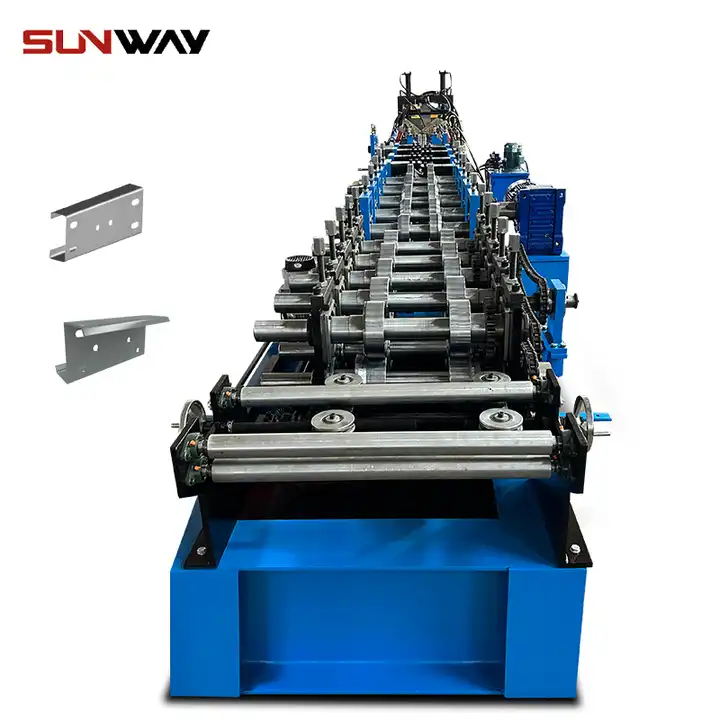

Tishken roll forming machines are engineered for efficient and precise forming of metal into custom profiles for various applications. Here is a quick look at key details:

- Product – Roll forming machine

- Manufacturer – Tishken, USA

- Main Components – Uncoiler, feeder, pre-cut station, rolling mill, cutoff press

- Drive Types – Mechanical, Servo, Hybrid

- Speed – Up to 400 feet/min

- Metal Thickness – 22 ga to 1 in

- Metal Type – Carbon steel, stainless steel, aluminum

- Profile Types – Simple C, Z, U, L profiles, complex profiles

- End Uses – Solar panel frames, door frames, roofing, cladding, racking, enclosures

Tishken uses advanced technology and robust construction to maximize productivity, efficiency, precision and flexibility for high volume roll forming production.

Roll Forming Technology by Tishken

Tishken rollers and tooling are engineered for superior performance and durability. Key technologies include:

- High speed precision planetary drives for smooth operation

- Helical gearing for reduced noise and vibration

- Hardened rollers with polished finish for reduced friction

- Quick change roller box design for fast roller changeovers

- Precision machinedComponents – No uncoiler, feeder, pre-cut station, rolling mill, cutoff press and other components

Construction and Design

Tishken roll formers feature all-welded steel construction and a modular frame design for strength and rigidity. Machines are designed for:

- Heavy duty industrial operation

- Quick and easy maintenance

- Operator safety

- Minimum downtime

They utilize robust mechanical drives and industrial electric motors to handle large material load. Control panels feature customer friendly touchscreen HMI for easy monitoring. Precisely engineered components allow tight tolerances and consistent output.

Types of Tishken Roll Forming Machines

Tishken offers a wide range of roll forming machines and customized configurations to suit specific production needs:

Roll Former Types by Drive

| Roll Former Type | विवरण |

|---|---|

| Mechanical Drive | Geared AC motors and chain drives |

| Servo Drive | Servo motors for each roller station |

| Hybrid Drive | Servo motors for key stations, geared for others |

Roll Former Types by Configuration

| Type | 描述 |

|---|---|

| Compact | Basic roll former with 10-12 stations |

| High Speed | Higher speeds up to 400 ft/min |

| Heavy Duty | For thick material up to 1 inch |

| Double Head | Dual lanes for high volume |

| Custom | Fully customized for special profiles |

Specialty Roll Forming Machines

| Machine | 描述 |

|---|---|

| Folder | Folds profile edges |

| Rotary Punch | Punches holes inline |

| Hydraulic Press | Cutoff and end finishing |

| Auto Stacker | Automatically stacks finished parts |

Tishken engineers analyze product design requirements and recommend the right equipment configuration for optimal productivity.

Roll Forming Machine Specifications

Tishken roll forming machines are available in different specifications based on speed, size, material thickness, drive type and other parameters as highlighted below:

Size and Speed

| Spec | विवरण |

|---|---|

| उत्पादन गति | Up to 400 feet/min |

| Roller Size | 6 in to 26 in diameter |

| Forming Length | 10 ft to 60 ft |

| Material Width | 18 in to 80 in |

Material Thickness Capacity

| मोटाई | 描述 |

|---|---|

| 22 gauge to 16 gauge | Typical for flashing and panels |

| 16 gauge to 7 gauge | Standard for door frames, racks |

| 7 gauge to 1 inch | Heavy duty range |

Driveline Components

| Component | विवरण |

|---|---|

| Motors | 5 HP to 20 HP AC motors |

| Gearbox | Helical or planetary type |

| Chains | ANSI roller chain drives |

| Bearings | Heavy duty tapered or spherical roller |

Electrical Specifications

| विशेषता | 描述 |

|---|---|

| Control Voltage | 24 VDC for servo/VFD drives |

| System Bus | Ethernet/IP or DeviceNET |

| Motor Control | VFD or servo drives |

| Fitur Keselamatan | E-stop, guarding, alarms |

Customized configurations outside standard specs are available. Engineering team analyzes requirements and recommends optimal machine design.

Applications of Tishken Roll Forming Machines

Tishken roll forming machines are versatile and can produce components for wide range of applications:

By Industry

| Industry | Typical Applications |

|---|---|

| Solar | Solar panel frames, mounting structures |

| Construction | Roofing, siding, door frames |

| 汽车工业 | Racks, brackets, chassis parts |

| Appliances | Washing machine tubs, housings |

| Aerospace | Aircraft interiors, enclosures |

| Agriculture | Greenhouse frames, livestock equipment |

By Product

| उत्पादों | 描述 |

|---|---|

| Door frames | Roll formed door jambs |

| Roofing | Standing seam panels |

| Pelapisan | Insulated metal panels |

| Racking | Pallet rack uprights |

| Enclosure | Electrical or equipment housings |

From simple profiles like angles and rails to complex custom shapes, Tishken roll formers can produce components for virtually any application.

Roll Forming Process Basics

Understanding the roll forming process helps appreciate machine design and productivity parameters:

- Coiled metal sheet or strip is fed into the roll former

- The strip passes through consecutive rolling stations

- Each station progressively forms the material through a series of rolling dies

- Stations can perform processes like punching, notching, cutting

- The fully formed profile is cut off at the end

- Material is formed gradually without extremes of stress/strain

Benefits of roll forming:

- Highly productive continuous process

- Consistent quality and tolerance

- Efficient material utilization with low waste

- Flexibility to change profiles with quick roll change

- Allows complex custom shapes

A key metric is feet of material produced per minute. Robust machine design by Tishken allows maximizing production speeds.

Benefits of Tishken Roll Forming Machines

Tishken roll forming equipment offers significant benefits to profile manufacturers:

Maximized Productivity

- High speed production up to 400 feet/min

- Quick roll changes in 45 minutes

- Easy operator control through touchscreen HMI

- Low maintenance due to quality components

- Minimum downtime for changeovers or maintenance

Superior Part Quality

- Advanced roller box design for precision forming

- Consistent tolerances within +/- 0.005 in

- Excellent surface finish

- Uniform mechanical properties by gradual forming

- No scratches or defects from material handling

Flexible and Versatile

- Produce simple or complex custom profiles

- Easy programming of different profiles through HMI

- Various configurations from 10 ft to 60 ft long

- Handles 22 ga to 1 in material thickness

- Suit different production volumes

Cost Effective Solution

- Compact footprint saves factory space

- Energy efficient drives reduce operating costs

- Streamlined material utilization with low waste

- High productivity lowers cost per piece

- Made in USA quality with total support

When choosing a roll forming machine, Tishken offers productivity, quality, flexibility and cost effectiveness all in one robust, reliable system.

How to Choose a Roll Forming Machine Supplier?

Choosing the right roll forming machine supplier is critical for production efficiency and end product quality. Here are key factors to consider:

Company Overview

- Many years of roll forming experience

- Full in-house manufacturing capabilities

- Strong reputation in metal forming industry

- Financially stable long-term partner

Machine Design and Construction

- Rugged all-welded steel frame construction

- Brand name industrial components

- Precision engineered for quality and tolerance

- Designed for high productivity

- Safety integrated into design

Range of Equipment Offered

- Standard and custom roll formers

- Specialty machines like folder, punch, etc.

- Line integration capabilities

- Entry level to heavy duty machines

Technical Expertise

- In-house engineering department

- Assist with tooling design

- Experience with various profiles and metals

- Provide design and product development support

Customer Service and Support

- Responsive sales and service team

- Programming support and training

- Timely technical support and maintenance

- Readily available spare parts

- Installation and start-up assistance

As an industry leader, Tishken excels in all above parameters providing a complete production solution.

Comparing Tishken with Competitors

Tishken faces competition from other established roll forming manufacturers along with some smaller regional players. Here is how Tishken compares on key criteria:

| Criteria | Tishken | Competitor A | Competitor B |

|---|---|---|---|

| Years in Business | 60+ | 40+ | 25+ |

| Manufacturing Facility | 130,000 sq ft | 100,000 sq ft | 60,000 sq ft |

| Product Range | Standard + Custom | Mainly Standard | Only Standard |

| Max Speed | 400 ft/min | 300 ft/min | 250 ft/min |

| Max Thickness | 1 inch | 0.5 inch | 0.75 inch |

| Construction | All-welded steel | Some fabricated | Mostly fabricated |

| Driveline | Helical gearing | Some chain drives | Chain drives |

| Design Experience | All profiles | Mainly standard shapes | Standard shapes |

| Technical Support | Full engineering team | Limited | Limited |

| Spare Parts | Large inventory | Average inventory | Long lead times |

Tishken clearly leads competitors on parameters like speed, thickness capacity, construction quality, design experience and customer support. Tishken’s all-welded heavy duty construction also ensures longer equipment life versus fabricated machines.

While Competitor A also has good capability, their max thickness capacity is lower at 0.5 inches only. Competitor B has lower maximum speed of 250 ft/min and limited design experience beyond standard profiles.

Roll Forming Machine Pricing

Cost of a roll forming machine depends on its size, configuration, speed, material capacity and other features. Here is an overview of price range:

Standard Roll Forming Machines

| Machine Type | Price Range |

|---|---|

| Compact Mechanical | $75,000 to $150,000 |

| Servo Hybrid | $150,000 to $250,000 |

| Heavy Duty | $200,000 to $400,000 |

कस्टम रोल फॉर्मिंग मशीनें

- Prices start from $250,000

- Can exceed $500,000 for large custom machines

- Geometric complexity, size, material thickness, speed determine price

- Per piece price reduces with higher production volume

- Return on investment from productivity and operational savings

Additional Equipment

| Item | Price Range |

|---|---|

| Tooling | $10,000 to $50,000 |

| Hydraulic Press | $30,000 to $100,000 |

| डेकोइलर | $10,000 to $50,000 |

| Stacker | $5,000 to $15,000 |

Key Price Factors

- Type of drive: Servo > Mechanical

- Size: Line length, roller diameter

- Speed: 300+ fpm costs more

- Material thickness capacity

- Complexity of profile shape

- Additional secondary operations

Tishken provides customized quotations based on client production needs and budget. Their team analyzes the application and recommends the optimal equipment specification.

How to Install a Roll Forming Machine

Proper installation is vital for smooth operation and maximum production. Here are key steps:

Site Preparation

- Prepare suitable foundation – concrete or steel structure

- Allow clearance around machine for material and maintenance access

- Have electric power supply available per machine requirements

- Set up proper grounding, separate from welding machines

- Ensure sufficient compressed air supply and piping

Receiving and Handling

- Unload components carefully using forklifts, cranes etc.

- Place machine components as per installation drawings

- Use appropriate chains, straps, lifting eyes for handling

Assembly

- Bolt machine frame, stands, and bases as marked

- Install drive motors, gearboxes, and chain drives

- Mount forming rollers and roller boxes

- Install electrical cabinets and wire system

- Connect hydraulics, air supply and other utilities

Commissioning

- Check all anchors, mounts and clearances

- Verify electrical, controls and drives

- Test run empty to confirm smooth operation

- Load initial tooling and material

- Debug any issues before production run

Taking time to properly install the roll former as per guidelines pays off through years of reliable production.

How to Operate a Roll Forming Machine

Operating a roll forming machine requires proper training and adherence to protocols for efficient, safe production. Key steps:

安全检查

- Ensure all guards and doors are in place

- Confirm E-stop, pull cords and other safety devices function

- Check electrical panel has no loose wires or issues

- Ensure no oil leaks

- Verify pneumatic pressure and air lines

- Inspect material feeding path for obstructions

- Use lockout procedures during maintenance

Startup

- Turn on main power and control power

- Set line speed through HMI panel

- Jog machine to verify correct rotation

- Set hydraulic pressure for cutoff

- Thread material through machine

Running Production

- Monitor strip feeding and tracking

- Listen for any abnormal sounds

- Watch formed profile for defects

- Periodically check roller wear

- Ensure smooth material flow to downstream processes

Changeovers

- Save existing production parameters

- Remove existing tooling safely

- Install new tooling for profile per drawings

- Adjust machine settings like speed, feed length etc.

- Run machine empty then re-thread material

- Verify first pieces meet specifications

Shutdown

- Stop feeding material into machine

- Allow running material to clear out

- Turn off main power and control power

- Clean machine and clear off cut pieces

- Close and lock electrical panel and doors

Proper operation procedures maximize output while minimizing safety risks, defects and downtime.

Maintenance of Roll Forming Machines

Regular preventive maintenance is key for trouble-free operation of a roll forming machine. Standard activities include:

Daily Maintenance

- Quick visual inspection of machine

- Check oil levels

- Verify pneumatic pressure

- Test emergency stop

- Ensure guides and stripper plates are tight

- Remove metal debris and dirt

- Lubricate chains, bearings and gears

Weekly Maintenance

- Thorough cleaning of machine

- Inspect electrical wiring and connections

- Check chain/gearbox alignment

- Verify drive key tightness

- Test coolant flow on gearboxes and motors

Monthly Maintenance

- Check roller wear and refinish contacting surfaces

- Inspect gear teeth for wear or cracks

- Verify alignment of shafts, sprockets and gears

- Grease bearings and sliding surfaces

- Check fluid quality and change if required

Annual Maintenance

- Disassemble gearboxes for inspection and re-lubrication

- Inspect and replace worn sprockets or chains

- Recondition or hard-chrome worn rollers

- Review safety devices, guards, E-stops

- Calibrate sensors, encoders and instrumentation

Proper maintenance improves safety, reduces downtime, and increases productivity. Tishken provides detailed preventive maintenance schedules for all equipment.

Roll Forming Troubleshooting Guide

Some common issues that can arise with roll forming machines include:

| Issue | Possible Causes | Fixes |

|---|---|---|

| Material tracking off | Misaligned rolls, stripper plates | Realign/adjust guides, plates |

| Scratched material | Dirty/scratched rolls | Clean or refinish rollers |

| Roller marking | Worn rollers, roller overlap | Refinish or replace rollers |

| Flared profile | Improper roll alignment | Realign forming rolls |

| Dimensional deviation | Worn tooling, loose components | Replace worn tooling, tighten |

| Uneven material flow | Feed speed mismatch | Adjust feed vs line speed |

| Motor overload | Line jam, speed mismatch | Clear jam, align speeds |

| Hydraulic oil overheating | Low oil level, leaking valve | Top up oil, replace valve |

| Electrical fault | Loose connection, blown fuse | Check wiring, replace fuse |

Tishken field technicians are available for troubleshooting and repairs to minimize production downtime.

सामान्य प्रश्न

Q: How long does it take to change roller tooling on a roll former?

A: On a Tishken quick-change roll former, complete tooling changeovers can be accomplished in 30-45 minutes due to the easy access design.

Q: Can a roll forming machine make complex custom profiles?

A: Yes, an experienced supplier like Tishken can engineer roll formers to produce complex cross-sections based on customer product designs.

Q: What precision can be held on a roll formed part?

A: Tishken machines can routinely hold tolerances of +/- 0.005 in on critical dimensions through robust construction and precision components.

Frequently Asked Questions (FAQ)

1) What differentiates a Tishken Roll Forming Machine from generic roll formers?

- Tishken systems combine heavy all-welded frames, helical/planetary drivetrains, and quick-change roller boxes, enabling tight tolerances (+/- 0.005 in) at high speed (up to 400 fpm) with reduced vibration and noise.

2) Can Tishken lines handle both pre-cut and post-cut operations?

- Yes. Configurations support pre-cut feeding or post-cut with flying shear/cutoff press. Inline punching/notching modules (rotary or servo press) can be integrated for door frames, solar rails, or racking.

3) What materials and thicknesses are practical on Tishken equipment?

- Carbon/stainless steel and aluminum from 22 ga through 1 inch, depending on mill size and driveline. For >7 ga or high-strength steels, Tishken recommends heavy-duty stands, larger roll diameters, and higher horsepower.

4) How fast are changeovers on Tishken quick-change lines?

- With cassette tooling and recipe recall, 30–45 minutes is typical. Plants running 6+ profiles often standardize shims and spacers to reduce changeover to 20–30 minutes.

5) What maintenance practices extend roller life on Tishken machines?

- Keep rolls clean/polished, verify pass alignment monthly, use non-marring guides for coated stock, maintain lubrication, and apply SPC on critical passes to catch drift early. Refinish instead of replacing when profilometry shows minor wear.

2025 Industry Trends for Tishken Roll Forming Machine Users

- Digital twins and pass design optimization: More Tishken owners validate flower patterns with software (COPRA/PROFIL) before cutting steel, reducing first-article scrap.

- Servo-heavy hybrid drives: Select stations receive independent servo control for tighter flange and hem accuracy on complex door frames and solar rails.

- Inline quality automation: 2D/3D vision, laser length measurement, and torque-monitored stand adjustments tied to HMI recipes to hit +/- 0.005 in consistently at 250–400 fpm.

- ESG and energy visibility: Energy meters (kWh/meter) and regenerative VFDs lower energy intensity 15–25%, supporting corporate sustainability targets.

- Workforce upskilling: OEMs provide AR-assisted setup and video SOPs embedded in the HMI to offset skilled labor gaps.

2025 Benchmarks and Market Snapshot

| KPI / Market Stat (Roll Forming) | 2023 Baseline | 2025 Leading Users | Relevance to Tishken Lines | Source |

|---|---|---|---|---|

| Typical changeover time (cassette tooling) | 45–90 min | 20–35 min | Faster profile swaps on Tishken quick-change | The Fabricator, FMA |

| Pre-painted scrap rate | 3–5% | 1–2% | Non-marring guides + inline vision | The Fabricator |

| Energy intensity (kWh per meter formed) | 0.06–0.10 | 0.04–0.07 | VFD/servo hybrid drives, regen braking | U.S. DOE AMO |

| Global roll forming equipment CAGR (2024–2028) | 3–4% | 4–6% | Investment in high-mix, high-speed lines | Statista, MarketsandMarkets |

| Vision/QC inline adoption | ~30% | ~55% | Laser/2D cameras tied to HMI recipes | SME, FMA |

Authoritative references:

- Fabricators & Manufacturers Association (FMA): https://www.fmamfg.org

- The Fabricator (Roll forming): https://www.thefabricator.com/topic/roll-forming

- U.S. DOE Advanced Manufacturing Office: https://www.energy.gov/eere/amo/advanced-manufacturing

- Society of Manufacturing Engineers (SME): https://www.sme.org

- Statista (market sizing): https://www.statista.com

Latest Research Cases

Case Study 1: Hybrid-Servo Upgrade on Tishken Mill for Door Jambs (2025)

- Background: A U.S. commercial door manufacturer running a legacy Tishken mechanical line struggled with tolerance drift on strike/hinge features at >250 fpm.

- Solution: Added servo drives to critical stands, integrated a rotary punch module and laser length measurement, and implemented recipe-based torque limits on the HMI.

- Results: First-pass yield improved from 95.0% to 98.6%; changeover time dropped from 52 to 28 minutes; scrap on pre-painted steel reduced from 3.8% to 1.9%; throughput increased 18%.

Case Study 2: Digital Pass Design and SPC for Solar Rail Profiles (2024)

- Background: An EU solar racking supplier needed to launch three new rail profiles on a Tishken high-speed line with minimal ramp-up waste.

- Solution: Simulated flower patterns in COPRA RF, standardized shims and spacers, added inline 2D cameras for hole position and flange angle checks; SPC limits tied to coil lot data.

- Results: Ramp-up scrap reduced by 42%; mechanical setup time decreased by 35%; maintained +/- 0.005 in on flange height at 320 fpm across three SKUs.

Expert Opinions

- Dr. Taylan Altan, Director (Emeritus), Center for Precision Forming, The Ohio State University

- Viewpoint: “For high-strength steels on roll forming mills, pass design that manages edge strain is critical to avoid longitudinal cracking—especially at hems and embossed features.”

- Source: https://cpf.osu.edu

- Kate Bachman, Senior Editor, The Fabricator

- Viewpoint: “Hybrid servo architectures on legacy roll formers deliver quick wins—tighter tolerance windows and faster changeovers without a full line replacement.”

- Source: https://www.thefabricator.com

- John Bradford, Applications Engineer, data M (COPRA RF)

- Viewpoint: “Validating Tishken pass designs with digital twins shortens commissioning and cuts first-article scrap, particularly on coated or laminated stock.”

- Source: https://www.datam.de/en/copra

Practical Tools/Resources

- Pass design and simulation: COPRA RF (data M) https://www.datam.de/en/copra; UBECO PROFIL https://www.ubeco.com

- Inline QC and metrology: Keyence 2D/3D vision systems https://www.keyence.com; Micro-Epsilon laser sensors https://www.micro-epsilon.com

- SPC/quality systems: InfinityQS https://www.infinityqs.com; NIST Engineering Statistics Handbook https://www.itl.nist.gov/div898/handbook

- Drives and control: Rockwell Automation Ethernet/IP knowledgebase https://rockwellautomation.custhelp.com; Siemens Drive & PLC resources https://support.industry.siemens.com

- Maintenance/CMMS: Limble CMMS https://limblecmms.com; Fluke vibration/thermal tools https://www.fluke.com

- Safety standards: ISO 14120, ISO 13849 https://www.iso.org; OSHA Machine Guarding eTool https://www.osha.gov/etools/machine-guarding

Last updated: 2025-10-27

Changelog: Added 5 Tishken-specific FAQs; included 2025 trends with KPI/statistics table and sources; provided two recent case studies; compiled expert viewpoints and practical tools/resources aligned to Tishken roll forming applications

Next review date & triggers: 2026-03-31 or earlier if tolerance nonconformance > 1.5% lots, changeover > 40 min, energy intensity > 0.08 kWh/m, or scrap on coated stock > 2.5%