परिचय

No matter how advanced your रोल बनाने की मशीन is, problems can still arise. A small issue—if left unresolved—can lead to misaligned profiles, production slowdowns, or even complete machine failure.

So, how do you quickly diagnose and fix roll forming machine issues?

In this guide, we’ll cover:

✅ Common roll forming machine problems and how to fix them

✅ Step-by-step troubleshooting guide for operators

✅ Preventive measures to reduce downtime

✅ How to optimize machine efficiency and performance

Let’s dive into the most frequent roll forming machine issues and expert solutions!

Common Roll Forming Machine Issues & Solutions

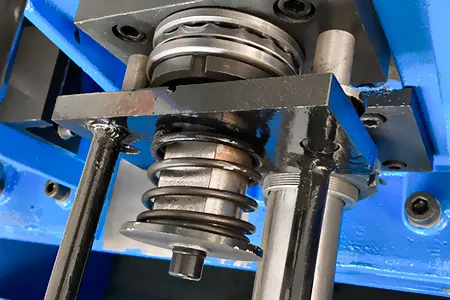

Even well-maintained machines can experience misalignment, material jamming, or roller wear. Below are the most frequent roll forming machine issues and how to fix them.

Troubleshooting Guide for Common Roll Forming Problems

| Issue | Possible Causes | Solution |

|---|---|---|

| Profile Misalignment | Roller positioning errors, worn bearings, loose guiding system | Re-calibrate roller stations, tighten guide rails, replace worn bearings |

| Material Jamming in Rollers | Poor material feeding, incorrect thickness, misaligned rolls | Adjust material feeder, check material specs, realign rollers |

| Uneven Forming or Profile Distortion | Incorrect roller spacing, varying material thickness | Adjust roller spacing, use high-quality material |

| Excessive Roller Wear | Lack of lubrication, high-friction material | Apply proper lubrication, use wear-resistant rollers |

| Surface Scratches on Formed Profiles | Dirty rollers, excessive forming pressure | Clean rollers, adjust forming pressure |

| हाइड्रोलिक Cutting System Malfunctions | Low hydraulic fluid levels, clogged filters | Refill hydraulic fluid, clean filters |

| Inconsistent Cutting Lengths | Faulty sensor calibration, worn cutting blades | Recalibrate sensors, replace worn blades |

| Machine Overheating | Excessive friction, poor cooling system | Ensure proper lubrication, inspect cooling fans |

Pro Tip: 80% of roll forming failures are due to improper lubrication and roller misalignment—regular inspections prevent costly downtime!

Step-by-Step Roll Forming Machine Troubleshooting Guide

If your roll forming machine is not producing precise, high-quality profiles, follow this structured troubleshooting approach.

Step 1: Identify the Problem

✅ Observe the machine while running. Listen for unusual sounds or vibrations.

✅ Inspect formed profiles for bends, distortions, or scratches.

✅ Check the feeding system for jams or misalignment.

Step 2: Inspect the Rollers & Alignment

✅ Look for misaligned rollers or uneven pressure application.

✅ Ensure roller gaps are correctly adjusted for material thickness.

✅ Clean dirty rollers that may cause surface defects.

Step 3: Check Lubrication & Bearings

✅ Inspect bearings and chains for adequate lubrication.

✅ Apply high-quality lubricants to prevent roller wear and excessive friction.

Step 4: Verify Cutting & Punching Systems

✅ Check hydraulic fluid levels in cutting and punching systems.

✅ Ensure sensors are calibrated for accurate cutting lengths.

✅ Inspect wear and tear on cutting blades.

Step 5: Test the Electrical System & PLC Controls

✅ Look for faulty sensors, wiring, or PLC programming errors.

✅ Reset CNC or PLC controls to factory settings if needed.

Pro Tip: Systematically troubleshooting your roll forming machine can reduce repair time by 50%!

Preventive Measures to Reduce Downtime

The best way to avoid troubleshooting is to prevent issues before they happen. Follow these best practices to keep your roll forming machine running efficiently.

1. Perform Regular Machine Inspections

- Check rollers, bearings, and cutting mechanisms weekly.

- Look for loose bolts, misalignment, or worn-out parts.

2. Maintain a Strict Lubrication Schedule

- Apply high-quality industrial lubricants to rollers and bearings weekly.

- Prevents overheating, excessive friction, and premature roller wear.

3. Keep Rollers Clean and Well-Aligned

- Dirt and debris on rollers cause surface scratches and profile defects.

- Regular cleaning improves product quality and extends roller lifespan.

4. Use High-Quality Raw Materials

- Poor-quality metal sheets increase roller wear and cause misalignment.

- Choose uniform-thickness, rust-free materials for optimal performance.

5. Train Operators on Proper Machine Handling

- Many roll forming problems are caused by operator errors.

- Ensure staff understands machine controls, troubleshooting, and maintenance procedures.

Pro Tip: Preventive maintenance reduces unexpected breakdowns by up to 75%!

How to Optimize Roll Forming Machine Efficiency

ए highly efficient roll forming machine produces consistent, high-quality profiles with minimal waste and downtime.

Key Strategies to Improve Efficiency

✅ Upgrade to Servo-Driven Motors – Improves speed control, reduces energy consumption.

✅ Implement AI-Based Monitoring Systems – Detects defects in real-time, prevents material waste.

✅ Use IoT-Enabled Remote Monitoring – Tracks machine performance and schedules maintenance.

✅ Invest in High-Quality Tooling – Reduces roller wear and ensures precise profile shaping.

Upgrading to AI-powered defect detection can improve efficiency by 30% and reduce downtime by 50%!

Advanced Troubleshooting Techniques for Roll Forming Machines

Even with preventive maintenance, mechanical and operational problems can arise in roll forming machines. Advanced troubleshooting techniques can help diagnose complex issues before they cause major disruptions.

1. Diagnosing and Fixing Machine Vibration Issues

- Cause: Loose bolts, misaligned rollers, or worn-out bearings.

- Solution:

✅ Tighten all bolts and ensure the frame is stable.

✅ Check roller alignment and recalibrate if necessary.

✅ Replace worn-out bearings and lubricate moving parts.

2. Fixing Inconsistent Profile Dimensions

- Cause: Improper roller pressure, material stretching, or incorrect CNC settings.

- Solution:

✅ Adjust roller pressure to avoid excessive bending.

✅ Use high-quality, uniform-thickness materials.

✅ Verify and recalibrate CNC programs for accuracy.

3. Resolving Hydraulic System Failures

- Cause: Low hydraulic fluid, air bubbles in the system, or clogged filters.

- Solution:

✅ Refill hydraulic fluid and check for leaks.

✅ Bleed the system to remove air bubbles.

✅ Clean or replace clogged hydraulic filters.

Pro Tip: Hydraulic failures account for 30% of production downtime—regular fluid checks can prevent costly repairs!

How to Prevent Roll Forming Machine Overheating

Overheating can reduce machine efficiency, cause material defects, and shorten component lifespan.

Key Causes of Overheating & Solutions

| Cause | Solution |

|---|---|

| Lack of lubrication | Regularly apply high-quality lubricants to rollers and bearings. |

| Excessive friction due to misalignment | Recalibrate rollers and ensure smooth material feeding. |

| Blocked ventilation or cooling system failure | Clean cooling fans and ensure proper airflow. |

| Overworking the machine beyond its rated capacity | Reduce production speed and allow machine cooldown periods. |

Pro Tip: Proper lubrication and cooling system maintenance can extend machine lifespan by 40%!

How to Optimize Roll Forming Machine Performance

ए well-optimized roll forming machine ensures maximum efficiency, reduced waste, and consistent product quality.

1. Implement IoT-Based Machine Monitoring

- IoT sensors track real-time machine performance.

- Enables predictive maintenance, reducing unexpected failures.

2. Use AI-Powered Defect Detection

- AI cameras monitor profiles for real-time quality control.

- Prevents material waste by detecting defects early.

3. Upgrade to Servo-Driven Motors

- Provides precise speed control and reduces energy consumption.

- Extends roller and motor lifespan.

4. Automate Profile Adjustments

- CNC-controlled automatic profile changeovers reduce downtime.

- Enhances production flexibility.

Upgrading to AI and IoT-based systems can improve efficiency by 30% and reduce downtime by 50%!

FAQ: Roll Forming Machine Troubleshooting & Optimization

1. How can I prevent my roll forming machine from overheating?

- Ensure proper lubrication and clean ventilation systems.

- Reduce production load if the machine is being overworked.

2. Why is my roll forming machine making excessive noise?

- Loose components, worn-out bearings, or roller misalignment may be the cause.

- Solution: Tighten bolts, replace worn bearings, and realign rollers.

3. How do I fix irregular bending angles in my roll forming profiles?

- Check roller pressure settings and ensure uniform material thickness.

- Verify CNC programming for correct bending sequences.

4. Can automation improve roll forming machine performance?

- Yes! CNC automation, AI defect detection, and IoT monitoring significantly improve accuracy and efficiency.

5. Where can I buy reliable roll forming machines and replacement parts?

对于 custom-built roll forming machines and spare parts, visit वूशी सनवे मशीनरी कं, लिमिटेड.

结语

ए properly maintained and well-optimized roll forming machine ensures high efficiency, minimal downtime, and consistent product quality. By following structured troubleshooting techniques, you can quickly diagnose and resolve issues, keeping your production line running smoothly and profitably.

वूशी सनवे मशीनरी कं, लिमिटेड is a leading global manufacturer of custom-built roll forming machines, offering advanced technology, expert support, and competitive pricing.

Want a high-quality roll forming machine? Contact us today!