If you're seeking a metal roof panel roll forming machine that delivers value for money, identify the ideal type for your needs. These machines vary in size, speed, and cost. Discover how to choose the perfect one in this article.

What is a metal roof panel roll forming machine?

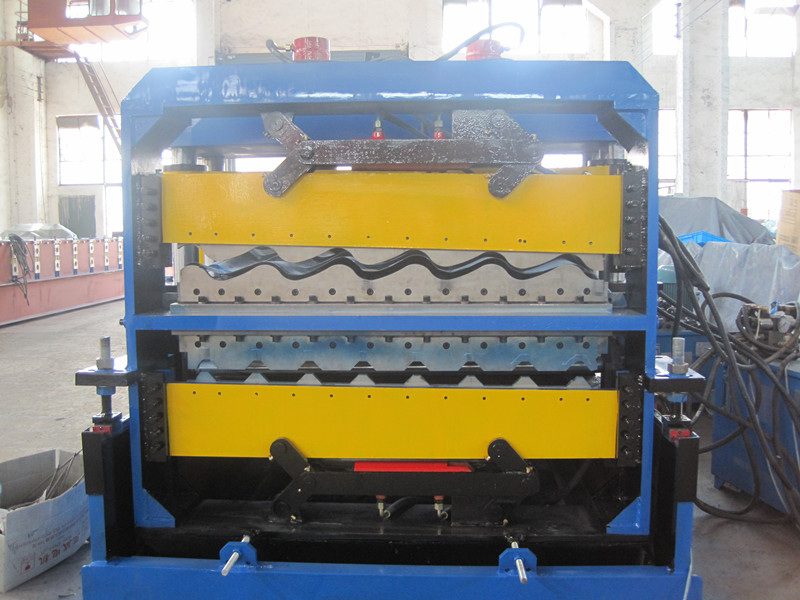

ए Metal roof panel roll forming machine is a production-line tool for creating custom metal roof panels. These panels are vital in modern construction, with quality hinging on the precision of the roll forming process.

Metal roof panel roll forming machines employ techniques like die rolling, which uses pressure and heat to shape sheets. Other methods include bend rolling and cold rolling.

मेटल रूफ पैनल रोल बनाने की मशीन कैसे खरीदें?

When purchasing a metal roof panel roll forming machine, consider panel size compatibility first. Next, evaluate the forming type: hydraulic (pressurized fluid), pneumatic (air pressure), or manual (hand-operated).

The final consideration when buying a metal roof panel रोल बनाना machine is price. Most range from $5,000 to $10,000. Once aligned with your needs and budget, seek a reputable dealer or online retailer.

Benefits and Drawbacks of a Metal Roof Panel Roll Forming Machine

A metal roof panel roll forming machine excels in producing high-quality, precision-formed panels rapidly. However, it has limitations. Key pros and cons include:

Benefits of a Metal Roof Panel Roll Forming Machine:

- It efficiently yields high-quality, precise metal panels.

- It produces large volumes swiftly, ideal for urgent production.

- Operation is straightforward with minimal setup.

- Results are consistent, ensuring uniform shape and size.

- Affordability makes it economical versus alternatives.

Drawbacks of a Metal Roof Panel Roll Forming Machine:

- New or poorly maintained units may produce noise.

- Precise dimensions can complicate installation.

Common Problems Associated with Using a Metal Roof Panel Roll Forming Machine

Key issues include: improper die alignment/calibration, rough die surfaces causing material adhesion, inadequate maintenance leading to wear, and mishandling of finished products.

निष्कर्ष

Metal roof panel roll forming machines are ideal for high-volume production. They swiftly form panels to any shape or size, benefiting manufacturers and individuals alike. Explore our selection for the perfect fit.

सामान्य प्रश्न

लुढ़का धातु छत क्या है?

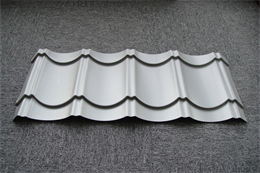

Metal roofing: A system of metal panels or tiles known for wind/storm resistance, impermeability, and durability. Metal coils/sheets: The starting material, rolled, cut, and formed into installable panels.