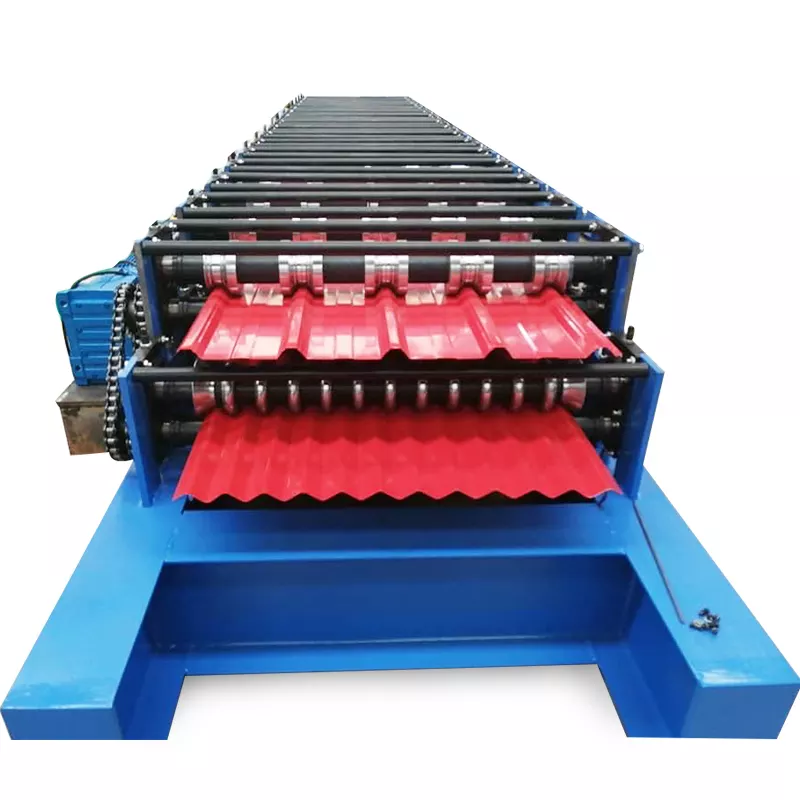

Are you looking for a machine that can help you make products quickly and efficiently? If so, you’ll want to check out a double layer roll forming machine! This machine is perfect for making products such as cups, plates, bowls, and other small items. It works by taking a sheet of material and rolling it into a precise shape. This is a great machine for businesses that need to make large quantities of products quickly.

What is a double layer roll forming machine?

ए डबल परत रोल बनाने की मशीन is a specialized machine that is used to form two sheets of metal into a desired shape. The machine uses two rolls to create the required shape, and it can be used for things like car bodies, aircraft parts, and medical devices.

How a Double Layer Roll Forming Machine Works?

The double layer roll forming machine is a highly advanced equipment that is widely used in the manufacturing of various types of products. This machine has the ability to create two layers of product simultaneously, which makes it ideal for a variety of applications.

This machine works by first depositing afilm of material onto a rotating drum. The film is then cut into desired shapes using either manual or automatic cutting devices and then transferred to a conveyor belt. The conveyor belt then carries the cut film through the machine where it is forced into two parallel rolls formers. These rolls are heated to temperatures high enough to create a thermo-polymerization reaction between the polymer and the heat from the roll formers. As a result, these rolls form two sheets of product that are then separated by the extruder.

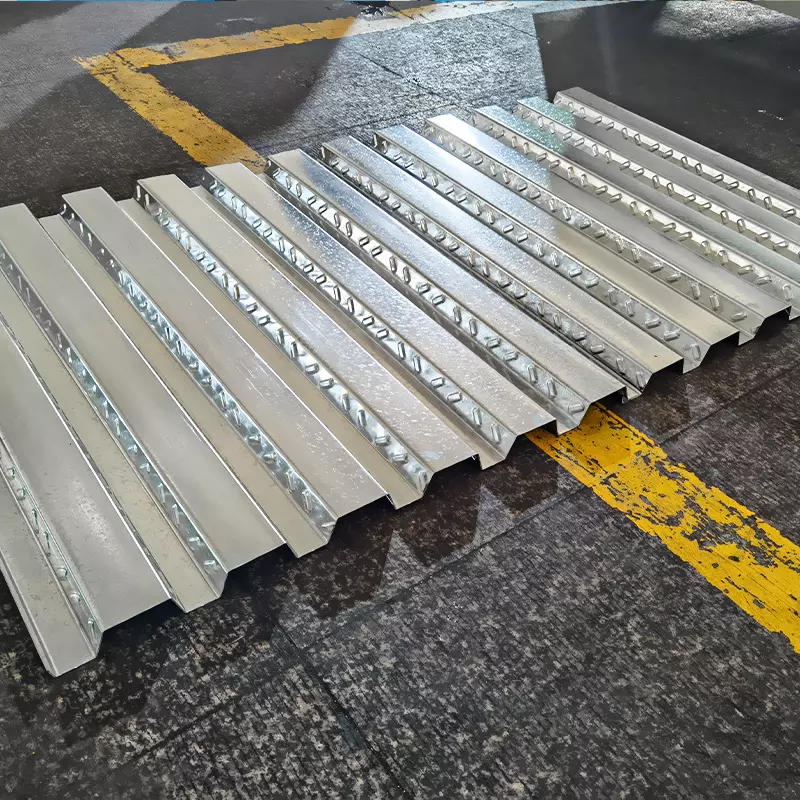

Benefits of Double Layer Roll Forming Machines

- The Double Layer Roll Forming Machine is one of the most efficient and reliable machines in the industry. It can produce high-quality products quickly and with little effort.

- The machine is equipped with sensors that regulate the temperature and pressure, ensuring that the products are consistently quality controlled.

- The Double Layer Roll Forming Machine is also Quick Change compatible, which means that it can easily switch between different types of materials without having to change any settings or tools.

- Lastly, the machine is easy to operate and maintenance free, making it a highly desirable choice for businesses of all sizes.

How to Choose the Right Machine For Your Business?

To start with, you’ll want to consider the type of product you’re going to be making. A double layer रोल बनाना machine can make products in a variety of shapes and sizes, from small parts for electronics to large sheets for fabricating cars and furniture.

Next, you’ll need to think about your production needs. Do you need to produce a lot of one-off items or do you need to roll out large quantities on a regular basis? If you have a steady flow of orders, then a double layer roll forming machine might not be the best option for you. On the other hand, if you’re looking for more flexibility in terms of production output and are able to produce several variations of the same product, then this type of machine is perfect for you.

Finally, consider your budget. Not all machines are created equal, and some will be more expensive than others. It’s important to get a sense of how much money you’re realistically willing to spend on a new tool before committing to anything. There are definitely exceptional machines out there that will justify their price tags, but don’t let that scare you off; it’s always worth doing your research first!

Why is it Important To Have a Double Layer Roll Forming Machine?

Roll forming machines are important for many reasons. They can create products with complex shapes that are difficult or impossible to make using other methods, such as injection molding. In addition, roll forming machines can produce parts with a variety of features and finishes.

One of the best brands in the industry when it comes to roll forming machines is Urethane Forming Machines (UFMs). UFMs have a reputation for producing high-quality parts with precise tolerances. They also have a wide range of features, including double layer Rolls-Royce technology and automatic shutoff systems. This makes them ideal for producing products that require intricate details and high levels of precision.

निष्कर्ष

In this article, we have looked at what a double layer roll forming machine is and how it works. We have also discussed some of the benefits that this type of machine can offer, including less waste and better quality products. If you are looking to produce high-quality products quickly and with minimal waste, then a double layer roll forming machine may be the perfect solution for you. Thanks for reading!

सामान्य प्रश्न

What are the 3 common forming processes?

Some of the more common processes are bending, stretching, deep drawing, and roll forming. Bending is a flexible metal forming process, bending utilizes a brake press or similar type of press machine. Stretching is another form of metal processing. Deep drawing is a common metal forming process.