आधुनिक निर्माण के क्षेत्र में, दक्षता, सटीकता और लागत-प्रभावशीलता सर्वोपरि हैं। इन मांगों को पूरा करने के लिए, नवीन मशीनरी और विनिर्माण तकनीकों अनिवार्य हो गई हैं। एक ऐसी क्रांतिकारी आविष्कार फरिंग चैनल रोल फॉर्मिंग मशीन, एक बहुमुखी उपकरण जो विभिन्न निर्माण परियोजनाओं में महत्वपूर्ण घटक फरिंग चैनलों के उत्पादन को बदल चुका है। इस लेख में, हम फरिंग चैनल रोल फॉर्मिंग मशीनों की जटिलताओं में गहराई से उतरेंगे, उनके कार्यों, लाभों, स्थापना प्रक्रिया और बहुत कुछ का अन्वेषण करेंगे।

फरिंग चैनलों को समझना

फरिंग चैनल रोल फॉर्मिंग मशीन के कार्यप्रणाली में उतरने से पहले, यह समझना आवश्यक है कि फरिंग चैनल क्या हैं और निर्माण में उनकी महत्वपूर्णता। फरिंग चैनल, जिन्हें अक्सर हैट चैनल या रेजिलिएंट चैनल कहा जाता है, लंबे, संकरे धातु पट्टे होते हैं जो दीवारों, छतों और अन्य सतहों को सहारा देने और समतल करने में महत्वपूर्ण भूमिका निभाते हैं। ये चैनल सतह सामग्री और संरचना के बीच एक गुहा बनाते हैं, जो इन्सुलेशन, ध्वनि-रोधीकरण और प्लंबिंग स्थापना के लिए स्थान प्रदान करते हैं।

फरिंग चैनलों के प्रकार

फरिंग चैनल विभिन्न प्रकारों में आते हैं, प्रत्येक विशिष्ट निर्माण आवश्यकताओं को पूरा करने के लिए डिज़ाइन किया गया है। सामान्य प्रकारों में शामिल हैं:

- धातु फरिंग चैनल: ये आमतौर पर गैल्वेनाइज्ड स्टील से बने होते हैं, जो असाधारण मजबूती, टिकाऊपन और जंग प्रतिरोध प्रदान करते हैं।

- लकड़ी फरिंग चैनल: उपचारित लकड़ी से बने लकड़ी फरिंग चैनल, उन अनुप्रयोगों के लिए एक विकल्प प्रदान करते हैं जहां धातु चैनल उपयुक्त न हों।

- रेजिलिएंट फरिंग चैनल: इन चैनलों में कंपन को प्रभावी ढंग से दबाने और ध्वनि संचरण को कम करने के लिए रेजिलिएंट डिज़ाइन होता है, जो उन्हें ध्वनि-रोधीकरण अनुप्रयोगों के लिए आदर्श बनाता है।

फरिंग चैनलों के लाभ और अनुप्रयोग

निर्माण परियोजनाओं में फरिंग चैनलों का उपयोग अनेक लाभ प्रदान करता है। कुछ प्रमुख लाभों में शामिल हैं:

- समतलीकरण और संरचनात्मक सहायता: फरिंग चैनल एक समतल और समान सतह बनाते हैं, जो वॉलबोर्ड, ड्राईवॉल और अन्य क्लैडिंग सामग्रियों की उचित स्थापना सुनिश्चित करते हैं। वे सतह सामग्री के वजन को सहन करने के लिए संरचनात्मक सहायता भी प्रदान करते हैं।

- तापीय और ध्वनिक इन्सुलेशन: फरिंग चैनलों द्वारा बनाई गई गुहा इन्सुलेशन सामग्रियों की स्थापना की अनुमति देती है, जो भवन की ऊर्जा दक्षता और ध्वनि-रोधी क्षमताओं को बढ़ाती है।

- प्लंबिंग और वायरिंग छिपाव: फरिंग चैनलों के पीछे का स्थान प्लंबिंग पाइपों, विद्युत वायरिंग और अन्य उपयोगिताओं के लिए एक छिपा हुआ मार्ग प्रदान करता है।

- नमी सुरक्षा: सतह सामग्री और संरचना के बीच हवा की खाई बनाकर, फरिंग चैनल नमी संचय और संभावित क्षति को रोकने में मदद करते हैं।

उनकी बहुमुखी प्रतिभा के कारण, फरिंग चैनल आवासीय भवनों, व्यावसायिक स्थानों, अस्पतालों, होटलों और अधिक में विभिन्न निर्माण परियोजनाओं में उपयोग पाते हैं।

रोल फॉर्मिंग प्रक्रिया

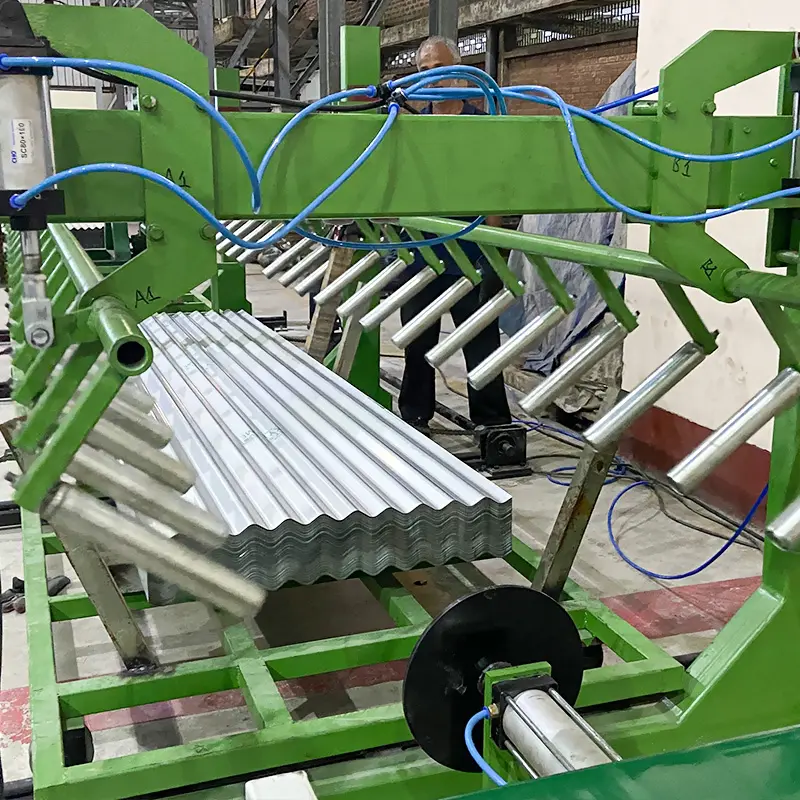

फरिंग चैनलों के कुशल उत्पादन के केंद्र में रोल फॉर्मिंग प्रक्रिया स्थित है। रोल फॉर्मिंग एक सतत झुकाव संचालन है जो सपाट धातु शीटों या पट्टियों को सुसंगत क्रॉस-सेक्शनों के साथ वांछित प्रोफाइल में परिवर्तित करता है। फरिंग चैनल रोल फॉर्मिंग मशीन इस प्रक्रिया को स्वचालित करने के लिए विशेष रूप से डिज़ाइन की गई है, जो उच्च सटीकता और उत्पादकता सुनिश्चित करती है।

फरिंग चैनल रोल फॉर्मिंग मशीन कैसे कार्य करती है

फरिंग चैनल रोल फॉर्मिंग मशीन में कई प्रमुख घटक होते हैं जो सद्भाव में कार्य करके फरिंग चैनल उत्पन्न करते हैं। प्राथमिक घटकों में शामिल हैं:

- Decoiler: यह घटक धातु कॉइल को अनवाइंड करता है और रोल फॉर्मिंग मशीन में खिलाता है, जो सामग्री की सतत आपूर्ति सुनिश्चित करता है।

- रोल फॉर्मिंग स्टेशन: रोल फॉर्मिंग स्टेशन में एक विशिष्ट कॉन्फ़िगरेशन में व्यवस्थित रोलर्स की एक श्रृंखला होती है। जैसे ही धातु पट्टी इन रोलर्स से गुजरती है, यह धीरे-धीरे वांछित आकार और प्रोफाइल ग्रहण करती है।

- कट-ऑफ सिस्टम: एक बार वांछित लंबाई प्राप्त हो जाने पर, कट-ऑफ सिस्टम चैनल को आवश्यक आकार में सटीक रूप से काटता है।

- 控制系统: नियंत्रण प्रणाली मशीन के विभिन्न घटकों को संचालित करती है, रोल फॉर्मिंग प्रक्रिया की गति, लंबाई और अन्य पैरामीटर्स को नियंत्रित करती है।

धातु पट्टी को रोल फॉर्मिंग मशीन में खिलाकर, फरिंग चैनल को सटीक विनिर्देशों के अनुसार आकार दिया जाता है और काटा जाता है, जो सुसंगत गुणवत्ता और सटीकता सुनिश्चित करता है।

फरिंग चैनल रोल फॉर्मिंग मशीन का उपयोग करने के लाभ

फरिंग चैनल रोल फॉर्मिंग मशीन का उपयोग निर्माण व्यवसायों और ठेकेदारों के लिए अनेक लाभ प्रदान करता है। आइए इनमें से कुछ लाभों का अन्वेषण करें:

High speed for volume.

पारंपरिक विनिर्माण विधियों के साथ, फरिंग चैनलों का उत्पादन श्रम-गहन और समय लेने वाला हो सकता है। हालांकि, फरिंग चैनल रोल फॉर्मिंग मशीन प्रक्रिया को स्वचालित करती है, मैनुअल श्रम आवश्यकताओं को काफी कम करती है और उत्पादन गति को बढ़ाती है। यह स्वचालन लागत बचत का परिणाम देता है, क्योंकि व्यवसाय कम संसाधनों के साथ बड़ी मात्रा में फरिंग चैनल उत्पन्न कर सकते हैं।

定制选项

फरिंग चैनल रोल फॉर्मिंग मशीनें अनुकूलन के संदर्भ में लचीलापन प्रदान करती हैं। मशीन सेटिंग्स को समायोजित करके, निर्माता विभिन्न आयामों, प्रोफाइलों और सामग्री मोट

高速生产

找平龙骨辊压成型机的自动化特性实现了高速生产。这些机器能够以稳定的速度连续辊压成型找平龙骨,从而确保高效的制造流程和建筑项目的准时完工。

一致的质量与精度

找平龙骨辊压成型机提供的精确控制,确保了所生产龙骨的一致质量与精度。龙骨的均匀性提升了其结构完整性,并便于无缝安装,最终带来卓越的成品效果。

选购找平龙骨辊压成型机时需考虑的因素

为建筑企业选购找平龙骨辊压成型机时,必须综合考量多项因素,以确保最佳性能与长期可靠性。这些因素包括:

Machine Specifications

评估辊压成型机的规格,例如其可处理的的最大卷材宽度与厚度。确保机器能适应特定找平龙骨型材所需的尺寸与材料厚度。

सामग्री संगतता

不同找平龙骨采用多种材料,包括钢材、铝材和木材。请确认辊压成型机与您计划使用的材料兼容,从而实现高效精确的成型过程。

自动化功能

寻找能提升生产力和减少人工需求的自动化功能,例如自动卷材进料、长度测量和切割系统,这些功能可显著简化制造流程。

售后支持

考量制造商提供的售后支持和技术援助可用性。可靠的客户服务能及时处理任何问题或维护需求,最大限度减少停机时间并优化机器性能。

找平龙骨辊压成型机的安装与操作

安装与操作找平龙骨辊压成型机需注重细节,以确保平稳运行与安全。请遵循以下关键步骤:

准备机器运行

- 确保机器置于稳定平整的表面,提供坚固的基础。

- 将机器连接至可靠电源,并验证所有电气连接正确无误。

- 熟悉机器控制面板与设置,确保了解如何根据需求调整参数。

सुरक्षा सावधानियां

- 操作机器时始终佩戴适当的个人防护装备(PPE),包括手套、安全眼镜和耳罩。

- 熟悉机器的紧急停止按钮及其位置,以便在突发情况下快速访问。

- 遵循制造商提供的所有安全指南,以最大限度降低事故或伤害风险。

分步安装流程

- 首先安装开卷机,并将其与辊压成型机精确对齐。

- 调整开卷机以适应所用卷材,确保辊压过程中平稳展开。

- 将金属带料送入辊压成型站,确保其与辊轮对齐并顺畅通过。

- 调整机器设置,以实现所需的找平龙骨尺寸与型材。

- 启动机器并监控成型过程,确保龙骨精确生产且质量一致。

维护提示

定期维护对找平龙骨辊压成型机的最佳性能与使用寿命至关重要。请遵循以下维护建议:

- 定期清洁机器,清除辊压过程中积聚的碎屑或金属屑。

- 按照制造商推荐润滑机器运动部件,以减少摩擦并确保顺畅运行。

- 定期检查并紧固所有螺栓与紧固件,防止因机器振动而松动。

- 安排合格技术人员定期检查,以及早识别潜在问题并及时处理。

通过遵循这些安装与操作指南并坚持正确维护实践,您可最大化找平龙骨辊压成型机的效率与使用寿命。

案例研究与成功故事

实际案例展示了找平龙骨辊压成型机在各类建筑项目中的卓越成效。以下是几则突出企业与承包商所获益处的案例研究:

案例研究1:住宅建筑施工

一家专注于住宅建筑项目的建筑公司将其制造流程中引入找平龙骨辊压成型机。通过使用该机器,他们相较传统方法实现了显著的时间节省与成本降低。机器生产定制化且质量一致的找平龙骨,确保了顺畅高效的安装过程,并带来高度客户满意度。

案例研究2:商业空间翻新

在一项大规模商业空间翻新项目中,承包商采用找平龙骨辊压成型机以满足紧迫截止期限并确保精确安装。机器的高速生产实现了快速龙骨制造,而其定制选项使承包商能适应各种设计需求,最终在规定时间内成功完工。

这些案例研究生动说明,将找平龙骨辊压成型机融入建筑流程如何简化操作、降低成本并提升整体项目成果。

找平龙骨辊压成型领域的未来趋势与创新

找平龙骨辊压成型领域持续演进,新兴趋势与创新正塑造行业未来。一些值得关注的趋势包括:

प्रौद्योगिकीय प्रगति

自动化、机器控制系统与数据分析的进步正革新辊压成型过程。这些技术实现了更精确控制、实时监控与数据驱动决策,提升效率与质量。

可持续制造实践

建筑行业日益注重可持续性。找平龙骨辊压成型机正被设计为最小化材料浪费、能耗与环境影响。融入环保材料与回收功能正成为现代辊压成型机的关键特性。

与其他建筑流程的整合

找平龙骨辊压成型机正与其他建筑流程整合,如框架系统与面板生产线。这种整合优化了工作流程、减少生产瓶颈并提升整体生产力。

找平龙骨辊压成型的未来将带来更高效率、可持续性以及与先进建筑实践的深度整合,推动行业迈向更具创新性与环保性的解决方案。

常见问题解答

常见问题1:找平龙骨与帽形龙骨有何区别? 找平龙骨与帽形龙骨常被互换使用,指代同一产品。两者均描述建筑中用于找平、支撑与隔热的金属条。

常见问题2:找平龙骨辊压成型机能否生产不同尺寸的龙骨? 是的,找平龙骨辊压成型机可调节以生产各种尺寸的龙骨,实现根据项目需求的定制化。

常见问题3:设置并操作找平龙骨辊压成型机需要多长时间? 找平龙骨辊压成型机的设置时间因具体机型与安装复杂度而异。但在适当指导与准备下,通常可在几小时内完成。一旦设置完成,机器即可连续运行,以高速生产龙骨。

常见问题4:找平龙骨适用于住宅与商业建筑吗? 是的,找平龙骨广泛应用于住宅与商业建筑。它提供结构支撑、找平与隔热优势,适用于各类建筑项目。

常见问题5:找平龙骨辊压成型机能否用于其他型材? 虽然找平龙骨辊压成型机专为生产找平龙骨设计,但它可调整以制造形状与尺寸相似的其他型材。然而,机器能力取决于其具体设计与功能。