आज बाजार में डोर फ्रेम रोल फॉर्मिंग मशीनों के अनेक प्रकार उपलब्ध हैं। एक घर मालिक या व्यवसायी के रूप में, आप सोच रहे होंगे कि समय और श्रम लागत बचाने के लिए एक खरीदना उचित है या नहीं। इस लेख में जानें कि क्या आपके लिए डोर फ्रेम रोल फॉर्मिंग मशीन सही है!

डोर फ्रेम रोल फॉर्मिंग मशीन क्या है?

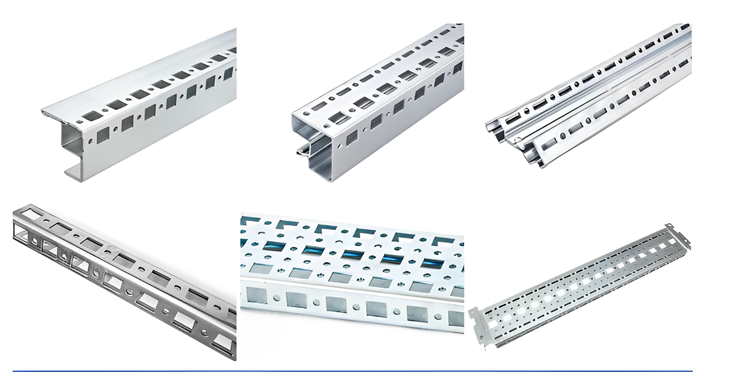

ए door frame roll forming machine यह धातु से बने डोर फ्रेम बनाने के लिए उपयोग की जाने वाली एक विशेष मशीन है। ये मशीनें धातु के मानक और कस्टम डोर फ्रेम बनाने के लिए डिज़ाइन की गई हैं।

डोर फ्रेम रोल फॉर्मिंग मशीनों के प्रकार

बाजार में डोर फ्रेम रोल फॉर्मिंग मशीनों के अनेक भिन्न प्रकार उपलब्ध हैं, जो अपनी क्षमताओं और विशेषताओं में भिन्न हैं। कुछ लोकप्रिय प्रकारों में सीएनसी मशीनें, हाइड्रोलिक मशीनें और न्यूमेटिक मशीनें शामिल हैं।

सीएनसी मशीनें डोर फ्रेम रोल फॉर्मिंग मशीनों का सबसे लोकप्रिय प्रकार हैं, क्योंकि ये उच्चतम स्तर की सटीकता और शुद्धता प्रदान करती हैं। हाइड्रोलिक मशीनें भी बहुत लोकप्रिय हैं, क्योंकि ये प्रक्रिया पर उच्च नियंत्रण प्रदान करती हैं। न्यूमेटिक मशीनें कम लोकप्रिय हैं, लेकिन इनकी स्वामित्व लागत कम होती है।

डोर फ्रेम रोल फॉर्मिंग मशीन चुनते समय, अपनी विशिष्ट आवश्यकताओं और जरूरतों पर विचार करना महत्वपूर्ण है। इन मशीनों के लिए कोई एक आकार-सभी समाधान नहीं है, इसलिए अपनी विशेष अनुप्रयोग के लिए सबसे उपयुक्त मशीन चुनें।

डोर फ्रेम के प्रकार

तीन प्रकार के डोर फ्रेम होते हैं: लकड़ी, धातु और कम्पोजिट।

लकड़ी के डोर फ्रेम सबसे पारंपरिक प्रकार के फ्रेम हैं। ये ठोस लकड़ी से बने होते हैं और सामान्यतः इनमें लकड़ी या धातु का दरवाजा लगा होता है। धातु के डोर फ्रेम एल्यूमीनियम या स्टील से बने होते हैं और ये खोखले या ठोस हो सकते हैं। कम्पोजिट डोर फ्रेम लकड़ी, प्लास्टिक और धातु सहित विभिन्न सामग्रियों के संयोजन से बने होते हैं।

-

Multi Profiles Roll Forming Machine

Multi Profiles Roll Forming Machine -

Auto Changeable C Z Purline Machine

Auto Changeable C Z Purline Machine -

Semi Auto Size Changeable CZ Purlin Roll Forming Machine

Semi Auto Size Changeable CZ Purlin Roll Forming Machine -

Laser Welding Square Pipe Roll Forming Machine

Laser Welding Square Pipe Roll Forming Machine -

वाइनयार्ड पोस्ट रोल बनाने की मशीन

वाइनयार्ड पोस्ट रोल बनाने की मशीन -

मचान तख़्त रोल बनाने की मशीन

मचान तख़्त रोल बनाने की मशीन -

लाइट गेज स्टील रोल बनाने की मशीन

लाइट गेज स्टील रोल बनाने की मशीन -

ऑटो आकार बदलने योग्य सिग्मा शहतीर रोल बनाने की मशीन

ऑटो आकार बदलने योग्य सिग्मा शहतीर रोल बनाने की मशीन -

ऑटो आकार बदलने योग्य CZ शहतीर रोल बनाने की मशीन

ऑटो आकार बदलने योग्य CZ शहतीर रोल बनाने की मशीन

डोर फ्रेम रोल फॉर्मिंग मशीन के फायदे और नुकसान क्या हैं?

डोर फ्रेम रोल फॉर्मिंग मशीन लेने का निर्णय लेते समय, कुछ बातों पर विचार करना चाहिए। एक ओर, ये मशीनें डोर फ्रेम को तेजी और कुशलता से बनाने में अत्यंत सहायक हो सकती हैं। दूसरी ओर, ये काफी महंगी भी हो सकती हैं और हर किसी के लिए आवश्यक नहीं।

डोर फ्रेम प्राप्त करने का मुख्य लाभ रोल बनाना मशीन यह है कि यह पारंपरिक डोर फ्रेम उत्पादन विधियों की तुलना में बहुत समय और प्रयास बचाती है। ये मशीनें आकार और साइज में सुसंगत डोर फ्रेम तेजी से बना सकती हैं, जो समग्र निर्माण प्रक्रिया को बहुत तेज कर देता है। इसके अलावा, चूंकि डोर फ्रेम रोल फॉर्मिंग मशीनें एक साथ बड़ी मात्रा में डोर फ्रेम उत्पन्न कर सकती हैं, ये कुल लागत भी कम कर सकती हैं।

हालांकि, डोर फ्रेम रोल फॉर्मिंग मशीनों से जुड़े कुछ संभावित नुकसान भी हैं। सबसे बड़ा दोष इनकी लागत है; ये मशीनें काफी महंगी हो सकती हैं, जो कुछ निर्माताओं के लिए असंभव हो सकती हैं। इसके अलावा, चूंकि इन मशीनों को उच्च सटीकता और शुद्धता की आवश्यकता होती है, ये सभी निर्माण वातावरणों के लिए उपयुक्त नहीं हो सकतीं। अंत में, भारी मशीनरी और जटिल प्रक्रियाओं पर निर्भर होने के कारण, इन्हें संचालित और रखरखाव करना कठिन हो सकता है।

क्या डोर फ्रेम रोल फॉर्मिंग मशीन का मूल्य है?

यदि आप डोर फ्रेम रोल फॉर्मिंग मशीन की बाजार में हैं, तो आप सोच रहे होंगे कि क्या यह निवेश के लायक है। निर्णय लेते समय कुछ बातों पर विचार करें।

सबसे पहले, आपका उत्पादन आयतन क्या है? यदि आप प्रति माह कुछ ही डोर फ्रेम बना रहे हैं, तो रोल फॉर्मिंग मशीन आवश्यक नहीं हो सकती। आप मैनुअल या अर्ध-स्वचालित प्रक्रिया से काम चला सकते हैं।

हालांकि, यदि आप बड़ी मात्रा में डोर फ्रेम बना रहे हैं, तो रोल फॉर्मिंग मशीन आपकी दक्षता और उत्पादन को बहुत बढ़ा सकती है। प्रारंभिक निवेश अधिक हो सकता है, लेकिन प्रतिफल महत्वपूर्ण होगा।

एक अन्य कारक है डोर फ्रेम का प्रकार जो आप बना रहे हैं। यदि आप केवल मानक आयताकार फ्रेम बना रहे हैं, तो रोल फॉर्मिंग मशीन अन्य विधियों पर अधिक लाभ नहीं देगी। लेकिन यदि आप कस्टम या जटिल आकार बना रहे हैं, तो यह अमूल्य होगी।

अंत में, आवश्यक डोर फ्रेम की गुणवत्ता पर विचार करें। यदि आपको न्यूनतम मानकों को पूरा करने वाले कार्यात्मक फ्रेम चाहिए, तो कम मूल्य की मशीन पर्याप्त हो सकती है। लेकिन यदि आपको घिसाव-टूट सहने वाले उच्च गुणवत्ता वाले फ्रेम चाहिए, तो औद्योगिक-ग्रेड रोल फॉर्मिंग मशीन निवेश के लायक होगी।

निष्कर्ष

डोर फ्रेम रोल फॉर्मिंग मशीन किसी भी व्यवसाय के लिए एक आवश्यक उपकरण है जो दरवाजे बनाता है। यह एक बहुमुखी मशीन है जिसका उपयोग सभी आकार और आकृतियों के दरवाजे बनाने के लिए किया जा सकता है, और इसे संचालित करना अपेक्षाकृत आसान है। यदि आप डोर फ्रेम रोल फॉर्मिंग मशीन लेने के बारे में सोच रहे हैं, तो हम इसे अत्यधिक अनुशंसित करते हैं।