Producing custom doors begins with crafting the perfect door frame—a task ideally suited to a door frame roll forming machine . Partnering with China's premier machine manufacturers brings these concepts to life efficiently, cost-effectively, and with cutting-edge quality suitable for commercial properties or homes alike. रोल बनाना machine manufacturers in China will help bring those great ideas to life in a powerful manner. Plus, you get to save money, while also delivering state of the art doors for any type of establishment. They can be suitable for a commercial property, but also for a home as well.

Why is a Door Frame Roll Forming Machine Important?

A door frame must be functional, durable, and of superior quality to ensure longevity. A reliable metal door frame roll forming machine eliminates issues, streamlines the process, and delivers flawless results every time.

Furthermore, it prevents manufacturing defects common in manual methods. Partnering with top roll forming machine manufacturers in China optimizes and automates production for exceptional outcomes.

How Does the Roll Forming Process Work?

Roll forming excels in producing window and door frames. A door frame roll forming machine accelerates this with multiple precision rolls that shape the material strip as it advances.

Renowned for its precision, efficiency, high material utilization, and low initial investment, roll forming is invaluable, particularly for door frame production.

What Components Make Up a Door Frame Roll Forming Machine?

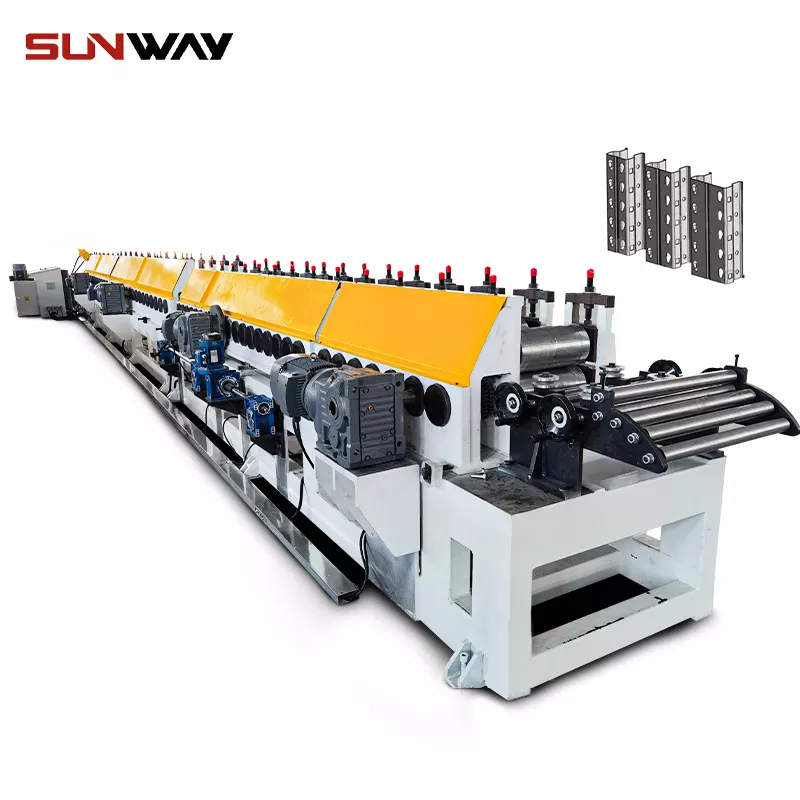

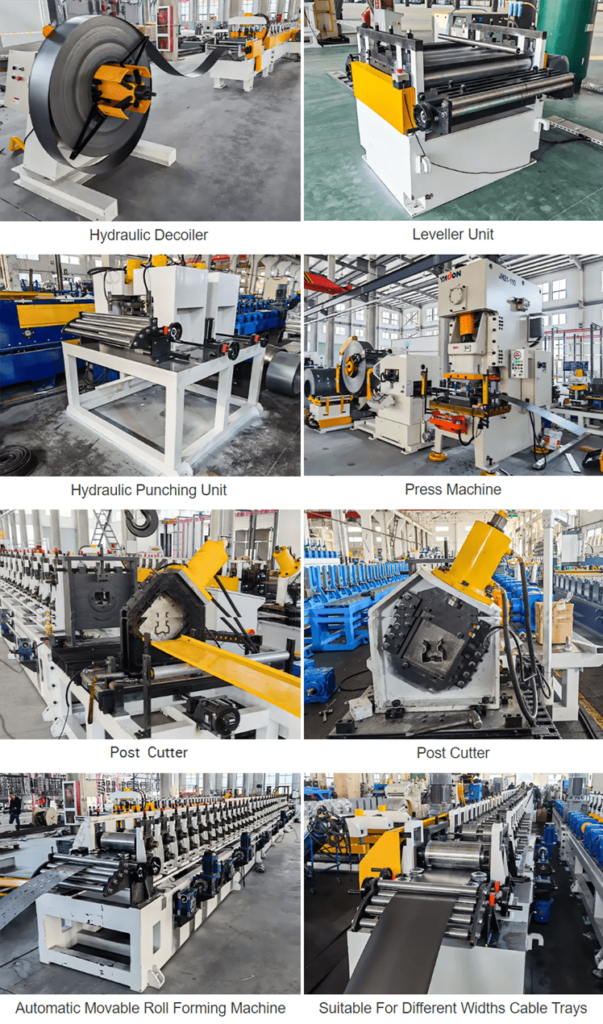

This sophisticated equipment features numerous moving parts, including key components of the metal door frame roll forming machine:

- The manual decoiler is designed to control inner bore shrinkage of the steel coil and prevent excessive material feeding.

- A feed guidance device is essential as it adjusts material feeding and ensures proper management. Generally, the guiding position can also be adjusted for this component.

- In addition, the main machine includes the body frame, side walls, rollers, shafts, and main motor.

- A door frame roll forming machine also features a hydraulic post-punching and cutting device. This component cuts and punches holes, incorporating a robust cutting blade design.

- You will also need a PLC control system, which manages cutting length and ensures overall cutting quality.

- Finally, your metal door frame roll forming machine requires an exit rack, essential for efficient processing and prompt inspection of the produced door frames.

Can the door frame roll forming machine accommodate multiple door sizes?

Generally, consult roll forming machine manufacturers in China to determine if they offer such solutions. Multi-size door frame roll forming machines are available, enabling the production of durable, reliable door frames that can be easily adjusted to meet your specifications. These solutions are highly dependable and adaptable to various requirements.

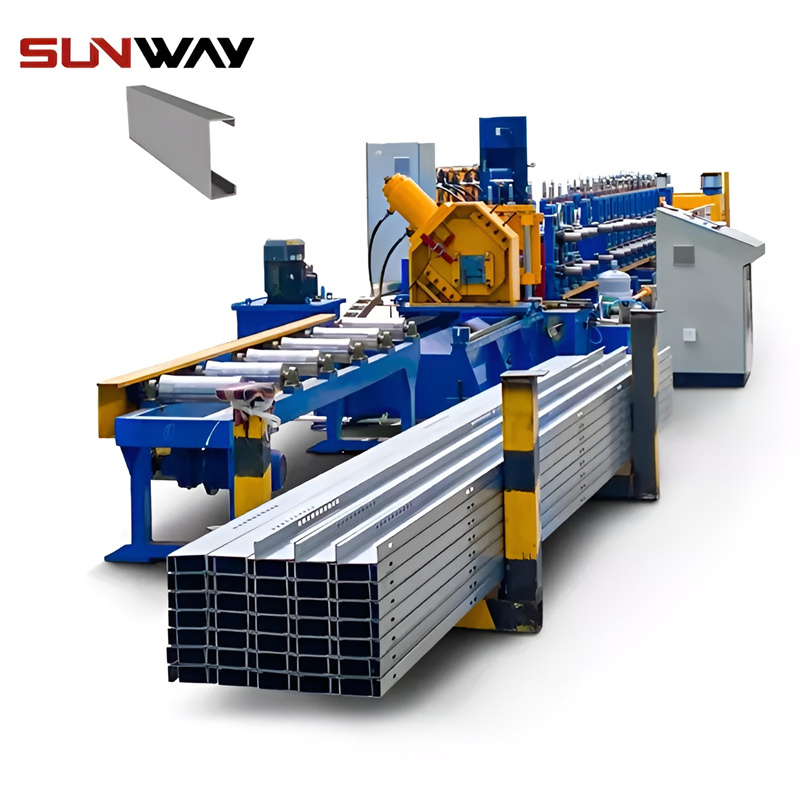

Products like the door frame roll forming machine are highly sought after because they power the motor and gearbox effectively, handling even the thickest materials. This allows for the creation of diverse door frames, not limited to standard sizes—you can produce larger frames, split jambs, robe doors, or metro door frames. Their adjustability and versatility set these machines apart.

How fast can a door frame roll forming machine operate?

Speed depends on the specific metal door frame roll forming machine. Typically, production speeds reach around 30 meters per minute with standard, fully automatic, non-stop configurations. While achieving this may be challenging, the potential exists and warrants consideration.

Additionally, you can incorporate overground or ground-pit accumulation units, as well as flying tracking cutting or hole-punching units. Stacking and optimizing these enhances efficiency and speed. Ultimately, it requires experimentation to find the optimal approach, but a door frame roll forming machine offers significant potential for accelerating production and delivering excellent results.

Can a door frame roll forming machine truly save time and money?

The primary goal when purchasing a metal door frame roll forming machine is to boost production speed. It automates the process with a customizable, fully integrated solution. This delivers substantial benefits and merits careful consideration.

When producing door frames, customization to your exact needs is key. A door frame roll forming machine is an excellent investment, enabling precise hinge placement, hole punching, and flawless execution. It exceeds expectations, providing an exceptional experience.

Acquire your door frame roll forming machine today.

Selecting the best metal door frame roll forming machine is crucial for efficient, high-quality door frame production. Sussman Machinery, a leading roll forming machine manufacturer in China, offers reliable, powerful, and efficient equipment. Committed to excellence and professionalism, we continually innovate to deliver superior results and quality.

For a dependable door frame roll forming machine, contact us today without hesitation. We provide cutting-edge, reliable solutions—reach out now for the finest metal door frame roll forming machine!