What is a China Door Frame Roll Forming Machine?

A door frame roll forming machine is an industrial machine specifically designed to produce metal door frames. These machines transform a flat sheet of metal, commonly steel, into the desired profile of a door frame. When we talk about the China Door Frame Roll Forming Machine, we refer to these machines that are manufactured in China, which has grown to be a major producer of these devices due to the country’s robust manufacturing infrastructure.

History and Evolution

The roll forming process has been used for centuries, with evidence of its basic principle being employed in ancient times. However, modern roll forming machines, including the door frame variants, have been largely influenced by advancements in technology and automation. Chinese manufacturers have played a crucial role in these advancements, capitalizing on the rising demand for construction materials in both domestic and global markets.

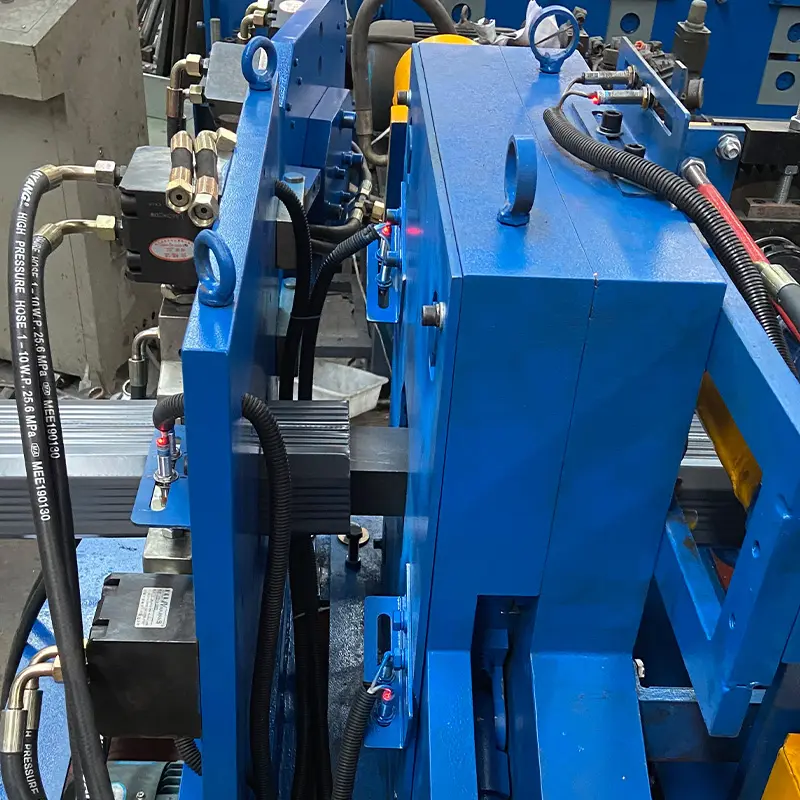

Components and Working

A typical China Door Frame Roll Forming Machine comprises several components:

- Uncoiler: This holds and feeds the metal sheet to the machine.

- Feeding Guide: Ensures the metal sheet is aligned correctly.

- Roll Forming Unit: This contains several sets of rollers that shape the metal sheet into the desired profile.

- Cutting Unit: Cuts the formed profile to the desired length.

- Control Unit: Manages the machine’s operations and settings.

The metal sheet is fed through the machine, getting shaped as it passes through the various sets of rollers, and is finally cut into door frames at the end.

Materials Used

While steel is the most common material used with these machines due to its durability and strength, other metals can also be used, such as aluminum or copper. Chinese manufacturers often offer machines that can handle multiple types of materials, providing flexibility to their customers.

Technical Specifications

| Feature | Typical Range |

|---|---|

| Thickness of the input sheet | 0.3 – 2.0 mm |

| Working Speed | 8 – 15 m/min |

| Total Power | 5 – 20 kW |

| Dimensions | Varies based on capacity and design |

| Weight | 2 – 10 tons |

Importance in Construction

The China Door Frame Roll Forming Machine holds great importance in the construction sector. Door frames are an essential component in building construction, and having the capability to produce them quickly and in bulk can greatly expedite construction projects. The precision and consistency of the frames produced by these machines also ensure a high standard of quality, which is crucial for safety and aesthetics.

How much does a China Door Frame Roll Forming Machine cost?

When considering the purchase of a China Door Frame Roll Forming Machine, one of the foremost concerns is the cost. These machines are significant investments, but their prices can vary widely based on several factors.

Factors Influencing Cost

- Capacity and Size: Larger machines with higher production capacities tend to cost more.

- Technology and Automation: Machines with advanced features, automation, and computerized controls might have a higher price tag.

- Brand and Reputation: Established manufacturers with a reputation for quality and reliability might charge a premium.

- Material Compatibility: Machines designed to work with multiple materials or specially treated metals can be pricier.

- Additional Features: Some machines come with extra features like touch screen controls, remote monitoring, or integrated quality checks, which can increase the cost.

Price Range

To provide a clearer understanding, here’s a breakdown of the cost based on different categories:

| Machine Type | Price Range (USD) |

|---|---|

| Basic, Manual Machines | $20,000 – $50,000 |

| Mid-Range, Semi-Automated Machines | $50,000 – $100,000 |

| High-End, Fully Automated Machines | $100,000 – $200,000 |

Brands to Consider

Several Chinese brands have gained prominence in the manufacturing of door frame roll forming machines. Some of these include:

- Jinggong: Known for their reliability and advanced technology.

- Zhongtuo: Offers a wide range of machines with varying capacities.

- YingYee: Renowned for their efficient customer service and durable machines.

- Liming Stamping: Offers high-speed machines with top-notch accuracy.

When considering a purchase, it’s essential to not just look at the initial cost but also consider after-sales service, warranty, and the availability of replacement parts. This ensures that the machine remains operational and provides a good return on investment.

Considerations for Import

If you’re considering importing a machine from China, remember there will be additional costs such as shipping, customs duties, and potential installation or training fees. It’s essential to factor in these costs to get a complete picture of the investment.

Cost vs. Benefit

While the initial cost can be high, the return on investment (ROI) for a China Door Frame Roll Forming Machine can be significant, especially if you’re involved in large-scale construction or door frame production. Over time, the ability to produce high-quality door frames efficiently can lead to significant savings and increased profits.

Given the vast range of options and the varying costs, potential buyers should conduct thorough research, get multiple quotes, and potentially visit manufacturers or trade shows to get a hands-on understanding before making a purchase.

What are the types of China Door Frame Roll Forming Machines?

China, as a leading manufacturer of industrial machinery, has diversified its offerings in the door frame roll forming machine market. Different types cater to varying needs, ensuring that businesses can find the most suitable machinery for their specific requirements.

- Manual Machines: These are the most basic types and require manual intervention at multiple steps of the roll forming process. Typically, these are used by businesses that have limited production needs or are just starting out.

- Semi-Automated Machines: As the name suggests, these machines automate several aspects of the roll forming process but might still require manual input for tasks like material feeding or product removal.

- Fully Automated Machines: These are the top-tier machines that can handle almost the entire roll forming process without manual intervention. Ideal for large-scale production, they offer the highest efficiency and consistency in output.

- Custom Machines: Some manufacturers offer custom-built machines tailored to unique requirements. This can include special dimensions, material compatibility, or unique door frame designs.

Price Range by Type

| Type of Machine | Price Range (USD) |

|---|---|

| Manual Machines | $15,000 – $40,000 |

| Semi-Automated Machines | $40,000 – $90,000 |

| Fully Automated Machines | $90,000 – $200,000 |

| Custom Machines | Varies based on requirements |

Understanding the types of China Door Frame Roll Forming Machines is essential for potential buyers. This knowledge allows for a more informed decision, ensuring that the chosen machine aligns well with production needs and budget constraints.

Functions of China Door Frame Roll Forming Machine

The China Door Frame Roll Forming Machine, given its specialized nature, performs a set of specific functions. Each function ensures the transformation of a flat metal sheet into a precision-formed door frame. Here are the core functions:

- Metal Sheet Uncoiling: The machine starts the process by uncoiling the metal sheet from a large roll. This prepares the metal for the roll forming process.

- Feeding and Alignment: The uncoiled metal sheet is then fed into the machine. An alignment or guiding system ensures that the sheet enters the rollers correctly.

- रोल बनाना: This is the heart of the machine. Several sets of rollers sequentially shape the metal sheet as it passes through them. Each roller set shapes the metal a bit more, gradually forming the desired door frame profile.

- Cutting and Shearing: After the metal is shaped, it needs to be cut to produce individual door frames. Machines have cutting mechanisms that slice the continuous metal form into the desired lengths.

- Stacking or Collection: Once the door frames are cut, they need to be collected or stacked for further processing or packaging. Some advanced machines have automated collection systems that neatly organize the finished frames.

- Control and Monitoring: Modern machines come with a control unit, often computerized, that allows operators to set parameters, monitor the production process, and ensure quality control.

The functions of a China Door Frame Roll Forming Machine highlight the intricacies involved in creating a seemingly simple product like a door frame. Each function plays a crucial role in ensuring that the end product is of high quality and meets the desired specifications.

Applications of China Door Frame Roll Forming Machine

The China Door Frame Roll Forming Machine, with its capability to produce high-quality metal door frames, finds application in a myriad of sectors. The machine’s versatility and efficiency have made it indispensable in the modern construction and manufacturing landscape. Here’s a deep dive into its various applications:

1. Residential Construction

With urbanization on the rise, the demand for residential buildings is continually growing. The China Door Frame Roll Forming Machine aids in constructing homes, apartments, and other residential structures by providing sturdy and consistent door frames.

2. Commercial Construction

Whether it’s office buildings, shopping malls, or hotels, commercial spaces require door frames in large quantities. The efficiency of these machines ensures timely delivery for large-scale projects.

3. Industrial Construction

Factories, warehouses, and other industrial structures often require specialized door frames that can withstand heavy usage and environmental stresses. The China Door Frame Roll Forming Machine can be calibrated to produce such robust frames.

4. Infrastructure Projects

Major projects like airports, train stations, and bus terminals require thousands of door frames. The capacity and consistency of the China Door Frame Roll Forming Machine make it apt for such large-scale applications.

5. Specialized Spaces

Hospitals, laboratories, and research facilities often have unique requirements for door frames, like radiation shielding or airtight seals. Customized machines from China can cater to these specific needs.

6. Retrofitting and Renovation

As older buildings undergo renovation, there’s often a need to replace old door frames. These machines play a pivotal role in such projects, supplying new frames that fit seamlessly into the renovated structure.

7. Exports

Given China’s prowess in manufacturing, many door frames produced by these machines are exported worldwide, catering to the global demand in construction and infrastructure sectors.

8. Door Manufacturing Units

Several businesses focus solely on door manufacturing. For them, the China Door Frame Roll Forming Machine is at the core of their production process, churning out frames around which the rest of the door components are assembled.

To comprehend the significance of the China Door Frame Roll Forming Machine, one only needs to consider its wide-ranging applications. From shaping the skylines with new buildings to ensuring the modernization of old structures, these machines are truly reshaping the world around us.

How Can a China Door Frame Roll Forming Machine Benefit You?

In an ever-evolving construction industry, efficiency, consistency, and cost-effectiveness are paramount. The China Door Frame Roll Forming Machine offers all these advantages and more. Here’s a deep dive into the numerous benefits one can reap by incorporating this machinery into their operations:

- Efficiency and Speed: One of the primary advantages of the machine is its capacity to produce door frames at a rapid pace. Unlike manual or semi-automated processes, a fully automated roll forming machine can churn out door frames continuously, ensuring that large orders are completed in a shorter timeframe.

- Consistency and Precision: With computerized controls and precision engineering, these machines produce door frames that are consistent in size, shape, and quality. This uniformity is crucial for construction projects where standardized components are essential.

- Cost Savings: In the long run, the machine offers significant cost savings. Automated production reduces labor costs, and the efficient use of raw materials ensures minimal wastage. Moreover, the speed of production means more orders can be completed, leading to increased revenue.

- Flexibility in Production: The machine can be calibrated to produce different types of door frames. Whether the need is for residential, commercial, or industrial door frames, the machine can be adjusted to meet specific requirements. This flexibility allows manufacturers to cater to a broader market.

- Durability and Quality: Door frames produced by these machines are known for their durability. The precision roll forming process ensures that the metal is shaped without any imperfections, leading to a stronger and more resilient end product.

- Ease of Operation: Modern China Door Frame Roll Forming Machines come equipped with user-friendly interfaces. Operators can easily set parameters, monitor the production process, and manage outputs, ensuring smooth operations with minimal hiccups.

- Environmental Benefits: These machines are designed to be efficient in their consumption of raw materials, leading to reduced wastage. This not only translates to cost savings but also has a positive environmental impact by reducing scrap metal and conserving resources.

How to Choose a China Door Frame Roll Forming Machine?

In a market flooded with options, selecting the right China Door Frame Roll Forming Machine can be a daunting task. However, with a structured approach and understanding of individual needs, one can make an informed decision. Here are some crucial pointers to consider:

- Assess Your Needs: Begin by evaluating your production requirements. How many door frames do you intend to produce daily, weekly, or monthly? Your choice should align with your production goals.

- Check Material Compatibility: Different machines can handle different types of metals. Ensure that the machine you’re considering is compatible with the material you intend to use, be it steel, aluminum, or any other metal.

- Automation Level: Depending on your budget and production needs, decide on the level of automation you require. While fully automated machines are pricier, they offer higher production speeds and require less manual intervention.

- Brand Reputation: Research various manufacturers and brands. Some Chinese manufacturers are renowned for their quality, after-sales service, and technology. Referrals, online reviews, and industry recommendations can provide insights.

- Technical Specifications: Dive deep into the machine’s technical aspects. Factors such as working speed, power requirements, weight, and dimensions can influence your choice.

- Budget and ROI: Have a clear budget in mind. While cost shouldn’t be the only deciding factor, understanding the return on investment (ROI) can provide clarity. A pricier machine with advanced features might offer better long-term value.

Features to Consider

| Feature | Description |

|---|---|

| Speed | The machine’s production rate. Higher speeds are beneficial for large-scale operations. |

| अनुकूलन | The machine’s ability to produce different types of door frames. |

| Safety Features | Look for machines with safety mechanisms to protect operators. |

| Warranty & Support | A robust warranty and strong after-sales support are crucial for long-term operations. |

Making an informed decision ensures that the chosen China Door Frame Roll Forming Machine aligns well with business objectives, provides value for money, and serves as a reliable asset for years to come.

Best 10 China Door Frame Roll Forming Machine Manufacturers

China’s status as a manufacturing powerhouse is reflected in its wide range of door frame roll forming machine manufacturers. With each offering its strengths, it can be challenging to navigate and identify the best. Here’s a curated list of the top 10 manufacturers, ensuring quality, innovation, and reliability:

- वूशी सनवे मशीनरी कं, लिमिटेड: is a professional manufacturer and exporter that are concerned with the design, development and production of cold roll forming machines.

- Zhongtuo: With a wide range of products, Zhongtuo caters to both small-scale and large-scale production needs. Their machines are known for efficiency and robustness.

- YingYee: Focusing on customer-centric solutions, YingYee offers machines that are easy to operate and maintain. Their after-sales service is particularly commendable.

- Liming Stamping: A leader in high-speed roll forming machines, Liming offers solutions that can drastically reduce production times without compromising on quality.

- BOTOU KEXINDA: Kexinda is recognized for its machines that offer flexibility in production. Their machines can be easily adjusted for different types of door frames.

- BOHAI: Specializing in custom solutions, BOHAI can provide machines tailored to unique production needs, making them a favorite among specialized manufacturers.

- Hebei Feixiang: Known for their heavy-duty machines, Feixiang offers solutions that are ideal for continuous, large-scale production.

- Haixing: With an emphasis on research and development, Haixing continually innovates, ensuring their machines are equipped with the latest technology.

- BELIEVE Industry Company: Prioritizing sustainability, BELIEVE’s machines are energy efficient and produce minimal wastage. Their green approach sets them apart.

- Wuxi Zhengchuang: With a legacy spanning over two decades, Wuxi Zhengchuang combines experience with innovation. Their machines are known for precision and longevity.

Comparison Table

| Manufacturer | Key Strength | Average Price Range (USD) |

|---|---|---|

| Jinggong | Technological Innovation | $50,000 – $180,000 |

| Zhongtuo | Product Range | $45,000 – $150,000 |

| YingYee | ग्राहक सहेयता | $40,000 – $130,000 |

| Liming Stamping | High-Speed Machines | $60,000 – $200,000 |

| BOTOU KEXINDA | Flexibility | $45,000 – $160,000 |

| BOHAI | Custom Solutions | $55,000 – $190,000 |

| Hebei Feixiang | Heavy-Duty Machines | $50,000 – $175,000 |

| Haixing | R&D Focus | $48,000 – $170,000 |

| BELIEVE | Sustainability | $42,000 – $140,000 |

| Wuxi Zhengchuang | Experience & Innovation | $40,000 – $155,000 |

Given the plethora of choices, this list provides a starting point for those looking to invest in a China Door Frame Roll Forming Machine. While the above manufacturers are among the best, always conduct thorough research, consider individual requirements, and seek referrals before making a decision.

Where to Buy a China Door Frame Roll Forming Machine?

When it comes to procuring a China Door Frame Roll Forming Machine, one must be well-informed to ensure they obtain a reliable, efficient, and high-quality machine. China is a vast country with numerous manufacturers specializing in these machines, and finding the right vendor can be a challenge. Here’s a guide to help prospective buyers navigate this landscape:

- Online B2B Platforms: Websites like Alibaba, Made-in-China, and Global Sources serve as massive directories where one can find multiple manufacturers and suppliers. These platforms provide detailed product specifications, customer reviews, and allow for direct communication with suppliers.

- Industry Trade Shows: China hosts numerous trade shows dedicated to the construction and manufacturing sectors. Attending these events offers the advantage of face-to-face interactions, product demonstrations, and direct negotiations. Examples of such trade shows include the Canton Fair and the China International Building Technologies Building Materials & Construction Equipment Exposition.

- Direct Manufacturer Visits: If you’re looking for a long-term association or a large order, consider visiting the manufacturer’s facility. This approach provides insights into their production capabilities, quality control measures, and overall reliability.

- Referrals and Recommendations: Sometimes, the best insights come from industry peers. Asking for referrals or recommendations can lead you to trusted and proven suppliers who have delivered satisfactory results in the past.

- Dealer Networks: Some manufacturers, due to their international reputation, have established dealer networks in various countries. These dealers are authorized to sell and sometimes service the machines, ensuring genuine products and after-sales support.

- Research and Due Diligence: Regardless of the source, always conduct thorough research on the manufacturer or supplier. Check for certifications, customer testimonials, and any red flags that might indicate subpar products or unreliable service.

Product Advantages of Chinese Door Frame Roll Forming Machines

China, over the years, has become a hub for manufacturing and exporting machinery, and the door frame roll forming machines are no exception. These machines from China come with several notable advantages that have made them favorites among global buyers:

- Competitive Pricing: Due to large-scale production, efficient supply chains, and labor cost advantages, Chinese machines often come at a more competitive price point without compromising on quality.

- Technological Advancements: Chinese manufacturers have heavily invested in R&D, ensuring their machines are at par, if not better, than their global counterparts in terms of technology and features.

- Quality Standards: With the rise in global demand, many Chinese manufacturers have adopted international quality standards. Machines undergo rigorous testing and quality checks before being shipped.

- Customization Capabilities: Chinese manufacturers are known for their flexibility in catering to specific customer requirements. Whether it’s a unique size, shape, or functionality, these manufacturers can tailor machines accordingly.

- Vast Supplier Network: Given the plethora of manufacturers, buyers have a wide variety of choices, allowing them to find the perfect match for their requirements.

- Global Presence: Many leading Chinese manufacturers, due to their quality and reliability, have established a robust global presence. Their machines are now operational in various continents, from Asia and Europe to Africa and the Americas.

- Eco-Friendly Options: As sustainability becomes a global concern, many Chinese manufacturers have incorporated eco-friendly features in their machines, ensuring energy efficiency and minimal wastage.

- After-sales Service: Recognizing the importance of post-purchase support, many manufacturers offer comprehensive after-sales service, ensuring smooth operations and addressing any potential issues.

Key Advantages in a Snapshot

| Advantage | Description |

|---|---|

| Price | Affordable without compromising quality |

| Technology | Cutting-edge features and functionalities |

| अनुकूलन | Tailored as per specific requirements |

| Global Presence | Used and trusted worldwide |

Best Chinese Door Frame Roll Forming Machine Supplier: WUXI SUNWAY MACHINERY CO., LTD

Selecting the best supplier for a door frame roll forming machine can be challenging, given the myriad of options available. However, certain companies, due to their exceptional products and services, stand out. One such prominent name is WUXI SUNWAY MACHINERY CO., LTD.

- Company Profile: WUXI SUNWAY MACHINERY CO., LTD is a leading professional manufacturer and exporter. Their focus is on the design, development, and production of cold roll forming machines. With a commitment to excellence, their products adhere to international quality standards, making them favorites in diverse markets across the globe, including Asia, Africa, Europe, South America, and Australia.

- गुणवत्ता आश्वासन: Their emphasis on quality is evident in every product they release. By complying with global quality standards, they ensure each machine’s efficiency, durability, and precision.

- Global Reach: WUXI SUNWAY’s reach is not limited to China. Their products are appreciated and employed in multiple markets worldwide. This vast presence is a testament to their product quality, reliability, and the trust they’ve built over the years.

- Continuous Innovation: The company is dedicated to innovation. Their research and development initiatives ensure that they remain at the forefront of technology, offering machines that cater to modern manufacturing challenges.

- Customer-Centric Approach: At the heart of WUXI SUNWAY’s operations is a commitment to customer satisfaction. They not only provide top-notch products but also ensure excellent after-sales support, helping clients navigate any challenges they might face.

सामान्य प्रश्न

1. What is a China Door Frame Roll Forming Machine?

A China Door Frame Roll Forming Machine is a specialized machine, primarily manufactured in China, designed to shape metal sheets into door frames. The machine uses a series of rollers to progressively shape the metal into the desired door frame profile.

2. Are Chinese Roll Forming Machines comparable in quality to Western machines?

Absolutely. Many Chinese manufacturers, including WUXI SUNWAY MACHINERY CO., LTD, have adopted international quality standards, ensuring their machines are on par with, or even exceed, the quality of Western counterparts.

3. How do I maintain my Door Frame Roll Forming Machine?

Regularly check the alignment of rollers, lubricate moving parts, and ensure that the machine is kept clean. It’s also essential to follow the manufacturer’s maintenance guidelines, which are typically provided in the user manual.

4. What materials can the Roll Forming Machine handle?

Most roll forming machines can handle a variety of metals such as steel, stainless steel, aluminum, and more. However, the specific material compatibility depends on the machine model and manufacturer.

5. Is it possible to get a customized Roll Forming Machine from China?

Yes, many Chinese manufacturers offer customization options. They can tailor machines based on specific requirements, be it in terms of size, shape, or functionality.

6. How long is the typical lifespan of a Door Frame Roll Forming Machine?

With proper maintenance and care, a Door Frame Roll Forming Machine can last for many years, often exceeding a decade. The lifespan, however, also depends on the machine’s usage frequency and the quality of its construction.

7. Can I get after-sales support for my machine if I buy it from a Chinese manufacturer?

Most reputable Chinese manufacturers, like WUXI SUNWAY MACHINERY CO., LTD, offer comprehensive after-sales service. This includes troubleshooting, parts replacement, and even on-site support in some cases. Always inquire about after-sales support before finalizing a purchase.