Metalworking has been an essential part of manufacturing for centuries. Over the years, various methods have been developed to create metal components, from stamping and welding to extrusion and casting. However, in recent times, a new method has emerged that has revolutionized metalworking— सी चैनल रोल फॉर्मिंग मशीनें. इन मशीनों ने धातु घटकों के उत्पादन के तरीके को बदल दिया है, विनिर्माण प्रक्रिया में स्वचालन, दक्षता और सटीकता लाकर। इस पोस्ट में, हम चर्चा करेंगे कि सी चैनल रोल फॉर्मिंग मशीनें धातु कार्य को कैसे क्रांतिकारी बना रही हैं, वे कौन से लाभ प्रदान करती हैं, और वे विनिर्माण के भविष्य को कैसे आकार दे रही हैं।

सी चैनल रोल फॉर्मिंग मशीनों का परिचय

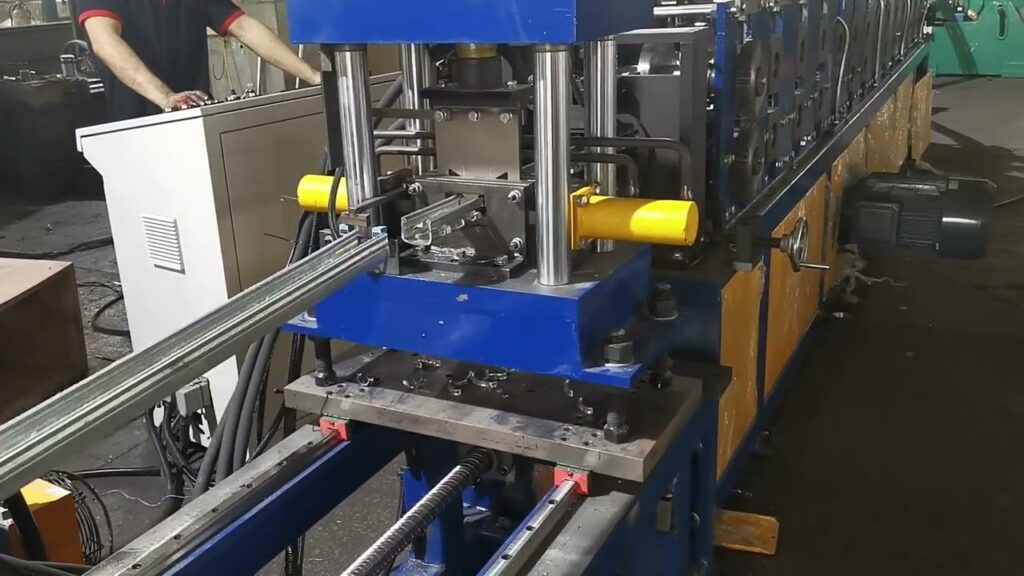

सी चैनल रोल फॉर्मिंग मशीनें धातु कार्य में उपयोग की जाने वाली ऐसी मशीनें हैं जो विभिन्न आकारों और शक्लों की सी चैनलें उत्पन्न करती हैं। रोल फॉर्मिंग एक विनिर्माण प्रक्रिया है जिसमें धातु कॉइलों को एक श्रृंखला के रोलर्स और डाइज का उपयोग करके वांछित प्रोफाइल या क्रॉस-सेक्शन में मोड़ा और आकार दिया जाता है। यह प्रक्रिया कई वर्षों से उपयोग में है, और समय के साथ यह एक अत्यधिक कुशल और स्वचालित विनिर्माण प्रक्रिया में विकसित हो गई है।

रोल फॉर्मिंग का इतिहास 17वीं शताब्दी तक जाता है जब शिल्पकारों ने धातु शीटों को आकार देने के लिए मैनुअल रोलर्स का उपयोग किया। 19वीं शताब्दी में, भाप-संचालित रोलर्स वाली रोल फॉर्मिंग मशीनें पेश की गईं जो धातु घटकों का उत्पादन करती थीं। इन मशीनों का उपयोग छत प्रणालियों और गटर सिस्टम से लेकर कार बॉडी और हवाई जहाज के पुर्जों तक विभिन्न धातु उत्पादों के उत्पादन के लिए किया गया।

20वीं शताब्दी में, रोल फॉर्मिंग मशीनें अधिक उन्नत हो गईं, जिसमें इलेक्ट्रिक मोटर्स का परिचय हुआ, हाइड्रॉलिक्स, और कंप्यूटर नियंत्रण। इन प्रगतियों ने रोल फॉर्मिंग को एक अत्यधिक कुशल और स्वचालित विनिर्माण प्रक्रिया बना दिया, जिससे मैनुअल श्रम की आवश्यकता कम हुई और अंतिम उत्पाद की सटीकता और शुद्धता बढ़ी।

आज, सी चैनल रोल फॉर्मिंग मशीनों का उपयोग निर्माण, परिवहन, ऑटोमोटिव और मशीनरी सहित विभिन्न उद्योगों में व्यापक रूप से किया जाता है। इन मशीनों ने विनिर्माण प्रक्रिया में स्वचालन, दक्षता और सटीकता लाकर धातु कार्य में क्रांति ला दी है, जिससे व्यवसाय उच्च गुणवत्ता वाले धातु घटकों को तेजी से और कम संसाधनों के साथ उत्पादित कर सकें।

निष्कर्ष में, सी चैनल रोल फॉर्मिंग मशीनें आधुनिक धातु कार्य का एक आवश्यक उपकरण हैं, जो विभिन्न आकारों और शक्लों के उच्च गुणवत्ता वाले धातु घटकों का उत्पादन करने वाली एक अत्यधिक कुशल और स्वचालित विनिर्माण प्रक्रिया प्रदान करती हैं। रोल फॉर्मिंग का इतिहास दर्शाता है कि यह प्रक्रिया समय के साथ कैसे विकसित हुई है, एक अत्यधिक उन्नत और बहुमुखी विनिर्माण विधि बनकर जो धातु कार्य में क्रांति लाई है।

धातु कार्य में सी चैनल रोल फॉर्मिंग मशीनों द्वारा हुई क्रांति

सी चैनल रोल फॉर्मिंग मशीनों ने धातु कार्य पर महत्वपूर्ण प्रभाव डाला है, धातु घटकों के निर्माण की प्रक्रिया में क्रांति ला दी है। यहां कुछ संभावित विषयों पर विचार करने योग्य हैं:

- स्वचालन: सी चैनल रोल फॉर्मिंग मशीनों ने धातु कार्य में उच्च स्तर का स्वचालन ला दिया है। ये मशीनें न्यूनतम मानवीय हस्तक्षेप के साथ धातु घटक उत्पन्न कर सकती हैं, जिससे त्रुटियों या दोषों का जोखिम कम हो जाता है। वास्तविक समय में उत्पादन प्रक्रिया की निगरानी करने वाले स्वचालित नियंत्रण और सेंसरों के साथ, रोल फॉर्मिंग मशीनें सेटिंग्स और पैरामीटर्स को समायोजित कर सुगम और सुसंगत संचालन सुनिश्चित करती हैं। इस स्वचालन ने धातु कार्य की दक्षता बढ़ाई है, जिससे व्यवसाय उच्च गुणवत्ता वाले धातु घटकों को तेजी से और कम संसाधनों के साथ उत्पादित कर सकें।

- दक्षता: सी चैनल रोल फॉर्मिंग मशीनों ने बहुविध संचालनों और सेटअप की आवश्यकता कम करके धातु कार्य की दक्षता बढ़ाई है। रोल फॉर्मिंग मशीनों के साथ, धातु घटकों को एक ही चरण में उत्पादित किया जा सकता है, बिना अतिरिक्त कटाई, मुद्रण या वेल्डिंग की आवश्यकता के। इसका अर्थ है कि निर्माण प्रक्रिया तेज और अधिक सुव्यवस्थित होती है, जिसमें कम संसाधन और सामग्री बर्बाद होती है। परिणामस्वरूप प्रति भाग कम लागत और तेजी से पूरा होने वाला समय मिलता है।

- परिशुद्धता: सी चैनल रोल फॉर्मिंग मशीनों ने धातु कार्य में उच्च स्तर की परिशुद्धता और सटीकता ला दी है। रोल फॉर्मिंग मशीनें एक श्रृंखला के रोलरों और डाइज का उपयोग करती हैं जो धातु कॉइल को धीरे-धीरे वांछित प्रोफाइल में मोड़ती और आकार देती हैं, जिससे उत्पादन प्रक्रिया भर में सुसंगत आकार और आयाम सुनिश्चित होते हैं। यह परिशुद्धता अंतिम उत्पाद को उच्च गुणवत्ता वाला बनाती है, जो आवश्यक विनिर्देशों और मानकों को पूरा करता है। यह सटीकता उन उद्योगों में विशेष रूप से महत्वपूर्ण है जहां धातु घटकों का उपयोग महत्वपूर्ण अनुप्रयोगों में किया जाता है, जैसे एयरोस्पेस, ऑटोमोटिव या चिकित्सा उपकरण।

- बहुमुखी प्रतिभा: सी चैनल रोल फॉर्मिंग मशीनें बहुमुखी निर्माण उपकरण हैं जो विभिन्न आकारों और आकारों के धातु घटक उत्पन्न कर सकती हैं। इन्हें अनुकूलित और समायोजित किया जा सकता है ताकि विविध प्रोफाइल और ज्यामितियों का उत्पादन हो सके, जो विभिन्न अनुप्रयोगों और उद्योगों के लिए उपयुक्त बनाता है। यह बहुमुखी प्रतिभा व्यवसायों को बदलते बाजार मांगों के अनुरूप ढालने और ग्राहकों को अनुकूलित समाधान प्रदान करने में सक्षम बनाती है, बिना निर्माण प्रक्रिया की दक्षता या गुणवत्ता से समझौता किए।

निष्कर्ष में, सी चैनल रोल फॉर्मिंग मशीनों ने स्वचालन, दक्षता, परिशुद्धता और बहुमुखी प्रतिभा लाकर धातु कार्य में क्रांति ला दी है। इन मशीनों ने धातु घटकों के उत्पादन के तरीके को बदल दिया है, व्यवसायों को कम लागत पर उच्च गुणवत्ता वाले घटक तेजी से उत्पादित करने में सक्षम बनाया है। जैसे-जैसे प्रौद्योगिकी विकसित होती रहेगी, रोल फॉर्मिंग मशीनें धातु कार्य और निर्माण के भविष्य को आकार देने में महत्वपूर्ण भूमिका निभाती रहेंगी।

सी चैनल रोल फॉर्मिंग मशीनों के लाभ

-

विद्युत कैबिनेट फ्रेम रोल बनाने की मशीन

विद्युत कैबिनेट फ्रेम रोल बनाने की मशीन -

दीन रेल रोल बनाने की मशीन

दीन रेल रोल बनाने की मशीन -

केबल सीढ़ी रोल बनाने की मशीन

केबल सीढ़ी रोल बनाने की मशीन -

पीवी माउंटिंग ब्रैकेट सी शेप प्रोफाइल रोल बनाने की मशीन

पीवी माउंटिंग ब्रैकेट सी शेप प्रोफाइल रोल बनाने की मशीन -

केबल ट्रे रोल बनाने की मशीन

केबल ट्रे रोल बनाने की मशीन -

पीवी माउंटिंग ब्रैकेट रोल बनाने की मशीन (एचएटी / ओमेगा प्रोफाइल)

पीवी माउंटिंग ब्रैकेट रोल बनाने की मशीन (एचएटी / ओमेगा प्रोफाइल) -

पीवी माउंटिंग ब्रैकेट जेड शेप प्रोफाइल रोल बनाने की मशीन

पीवी माउंटिंग ब्रैकेट जेड शेप प्रोफाइल रोल बनाने की मशीन -

सौर बढ़ते अकड़ चैनल रोल बनाने की मशीन

सौर बढ़ते अकड़ चैनल रोल बनाने की मशीन -

स्ट्रट चैनल रोल बनाने की मशीन

स्ट्रट चैनल रोल बनाने की मशीन

सी चैनल रोल फॉर्मिंग मशीनें धातु कार्य के लिए कई लाभ प्रदान करती हैं, जो इन्हें उच्च गुणवत्ता वाले धातु घटकों को कुशलता और लागत-प्रभावी ढंग से उत्पादित करने वाले व्यवसायों के लिए आकर्षक विकल्प बनाती हैं। यहां धातु कार्य के लिए सी चैनल रोल फॉर्मिंग मशीनों के उपयोग के कुछ लाभ दिए गए हैं:

- लागत बचत: सी चैनल रोल फॉर्मिंग मशीनें अन्य निर्माण विधियों की तुलना में धातु घटकों को कम लागत पर उत्पादित कर सकती हैं। ये मशीनें कटाई, मुद्रण या वेल्डिंग जैसी द्वितीयक संचालनों की आवश्यकता समाप्त कर देती हैं, जिससे आवश्यक श्रम और सामग्री की लागत कम हो जाती है। इसके अतिरिक्त, रोल फॉर्मिंग मशीनें बड़ी मात्रा में धातु घटक उत्पन्न कर सकती हैं, जिससे प्रति भाग लागत कम होती है और लाभप्रदता बढ़ती है।

- उच्च गुणवत्ता: सी चैनल रोल फॉर्मिंग मशीनें उच्च परिशुद्धता और सटीकता के साथ धातु घटक उत्पन्न कर सकती हैं, सुनिश्चित करती हैं कि प्रत्येक भाग आवश्यक विनिर्देशों और मानकों को पूरा करे। यह उच्च गुणवत्ता वाला उत्पादन एयरोस्पेस, ऑटोमोटिव या चिकित्सा उपकरण जैसे उद्योगों में आवश्यक है, जहां आकार या आयाम में छोटे-से विचलन के गंभीर परिणाम हो सकते हैं।

- उत्पादन दक्षता: सी चैनल रोल फॉर्मिंग मशीनें उच्च गति पर धातु घटक उत्पन्न कर सकती हैं, जिससे पूरा होने का समय कम होता है और समग्र उत्पादन दक्षता बढ़ती है। इन्हें विभिन्न आकारों और आकारों के धातु घटकों के उत्पादन के लिए अनुकूलित और समायोजित किया जा सकता है, जो निर्माण प्रक्रिया में बहुमुखी प्रतिभा और लचीलापन प्रदान करता है।

- अपशिष्ट में कमी: सी चैनल रोल फॉर्मिंग मशीनें निर्माण प्रक्रिया के दौरान उत्पन्न होने वाले स्क्रैप धातु की मात्रा को काफी कम कर सकती हैं। ये मशीनें एक सतत प्रक्रिया का उपयोग करती हैं जो सामग्री अपव्यय को न्यूनतम करती है और सामग्री उपयोग को अधिकतम बनाती है। इससे न केवल पर्यावरणीय प्रभाव कम होता है बल्कि व्यवसाय के लिए लागत बचत भी होती है।

- अनुकूलन: सी चैनल रोल फॉर्मिंग मशीनों को विभिन्न आकारों, आकारों और प्रोफाइलों के धातु घटकों के उत्पादन के लिए अनुकूलित और समायोजित किया जा सकता है, जो इन्हें विविध अनुप्रयोगों और उद्योगों के लिए उपयुक्त बनाता है। यह अनुकूलन व्यवसायों को ग्राहकों की विशिष्ट आवश्यकताओं और मांगों को पूरा करने में सक्षम बनाता है, बाजार में प्रतिस्पर्धी लाभ प्रदान करता है।

संक्षेप में, सी चैनल रोल फॉर्मिंग मशीनें आधुनिक धातु कार्य का महत्वपूर्ण हिस्सा हैं, जो कुशल, लागत-प्रभावी और स्वचालित निर्माण प्रक्रिया प्रदान करती हैं जो विभिन्न आकारों और आकारों के उच्च गुणवत्ता वाले धातु घटक उत्पन्न कर सकती हैं। रोल फॉर्मिंग के इतिहास से पता चलता है कि यह प्रक्रिया समय के साथ विकसित हुई है, एक अत्यधिक उन्नत और बहुमुखी निर्माण विधि बन गई है जिसने धातु कार्य में क्रांति ला दी है। सी चैनल रोल फॉर्मिंग मशीनों ने निर्माण प्रक्रिया में स्वचालन, दक्षता और परिशुद्धता लाई है, व्यवसायों को कम संसाधनों के साथ तेजी से उच्च गुणवत्ता वाले धातु घटक उत्पादित करने में सक्षम बनाया है। जैसे-जैसे प्रौद्योगिकी विकसित होती रहेगी, रोल फॉर्मिंग मशीनें धातु कार्य और निर्माण के भविष्य को आकार देने में महत्वपूर्ण भूमिका निभाती रहेंगी।