Overview of Heavy-Duty Roll Forming Machines

ए heavy-duty roll forming machine is an advanced industrial machine designed to process thick and high-strength metal sheets, such as galvanized steel, 不锈钢, aluminum, and structural steel. These machines are used to manufacture heavy-gauge structural components, industrial beams, highway guardrails, solar mounting systems, and storage racks.

Unlike standard roll forming machines, heavy-duty roll forming machines are built with reinforced rollers, powerful hydraulic systems, and precision CNC controls to handle high-tensile materials with ease.

Key Features of Heavy-Duty Roll Forming Machines

✅ Capable of processing thick materials – Up to 8mm thickness for ultra-strong structural components.

✅ High-speed production – Produces 10-40 meters per minute, depending on material strength.

✅ Heavy-duty rollers & hydraulic systems – Designed for continuous, high-load operations.

✅ Fully automated operation – CNC-controlled for precision and efficiency.

✅ Energy-efficient servo motors – Improves power consumption and operational efficiency.

In this guide, we’ll cover:

✅ Types of heavy-duty roll forming machines

✅ How the roll forming process works

✅ Best materials for heavy-duty roll forming

✅ Cost analysis & pricing guide

✅ Top manufacturers & why Sunway Machine is a trusted choice

Let’s get started!

Types of Heavy-Duty Roll Forming Machines

Different heavy-duty roll forming machines are designed for specific industrial applications and material thicknesses.

1. Heavy-Duty Structural Beam Roll Forming Machine

- Produces I-beams, C-channels, and heavy-gauge profiles used in construction and industrial applications.

- Ideal for bridges, steel structures, and load-bearing elements.

2. Heavy-Duty Storage Rack Roll Forming Machine

- Manufactures high-strength racking and shelving components for warehouses and logistics centers.

- Ensures precision, strength, and durability.

3. Heavy-Duty Guardrail Roll Forming Machine

- Used to produce highway safety barriers and crash guardrails.

- Capable of handling high-tensile steel for impact resistance.

4. Fully Automatic Heavy-Duty Roll Forming Machine

- विशेषताएँ CNC automation for quick profile adjustments and high-precision outputs.

- Best for large-scale, high-efficiency production.

Sunway Machine provides customized heavy-duty roll forming machines with advanced automation features.

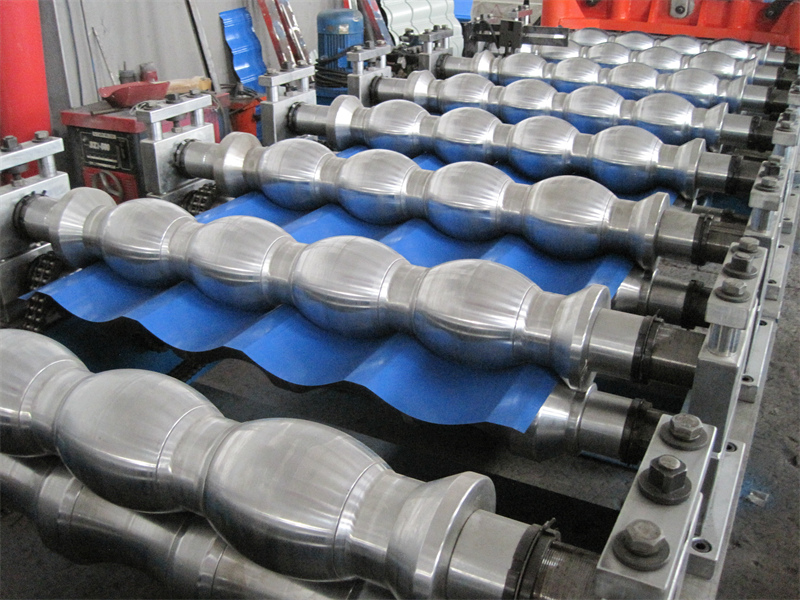

How Heavy-Duty Roll Forming Works

The roll forming process for heavy-duty applications involves gradually shaping thick and high-strength metal sheets into heavy-gauge profiles using reinforced rollers and high-pressure hydraulic systems.

Step-by-Step Heavy-Duty Roll Forming Process

| Step | 描述 |

|---|---|

| 1. Decoiling | The high-strength metal coil is placed on a heavy-duty decoiler, feeding material into the machine. |

| 2. Leveling & Feeding | The sheet is straightened and guided into the forming stations. |

| 3. Pre-Punching (If Required) | Hydraulic or servo-driven punching units create holes or slots in the material. |

| 4. Roll Forming | The sheet passes through multiple reinforced roller stations, forming the desired profile. |

| 5. Cutting & Stacking | The formed profile is cut using hydraulic or servo-driven systems and stacked for shipment. |

Pro Tip: ए fully automated heavy-duty roll forming machine ensures high precision, minimal waste, and faster production speeds.

Best Materials for Heavy-Duty Roll Forming

Choosing the right metal grade ensures optimal strength, durability, and corrosion resistance.

Comparison of Materials for Heavy-Duty Roll Forming

| सामग्री | Properties | Best For |

|---|---|---|

| High-Tensile Galvanized Steel | Excellent strength, corrosion resistance | Guardrails, structural beams, heavy-duty storage racks |

| Stainless Steel 304/316 | High corrosion resistance, long lifespan | Marine structures, industrial frames |

| Aluminum 6061/7075 | Lightweight, strong, and corrosion-resistant | Aerospace, automotive, solar mounting systems |

| Structural Steel S355/S460 | Exceptional load-bearing capacity, impact resistance | Bridges, heavy construction, industrial support beams |

Sunway Machine manufactures roll forming machines compatible with all major heavy-duty metal grades.

Heavy-Duty Roll Forming Machine Price Guide

The cost of a heavy-duty roll forming machine depends on factors like automation level, material thickness capacity, and profile range.

Estimated Price Ranges for Heavy-Duty Roll Forming Machines

| Machine Type | Price Range (USD) | विशेषताएँ |

|---|---|---|

| Manual Machine | 50,000–50,000 – 50,000–100,000 | Manual adjustments, low-speed production |

| Semi-Automatic Machine | 100,000–100,000 – 100,000–200,000 | PLC-controlled, requires manual profile adjustments |

| Fully Automatic Machine | 200,000–200,000 – 200,000–500,000 | CNC-controlled, quick profile switching |

| High-Speed Precision Machine | 500,000–500,000 – 500,000–1,000,000 | Advanced automation, high-speed production |

Looking for a custom quotation? Contact Sunway Machine today!

Top Heavy-Duty Roll Forming Machine Manufacturers

Choosing a reliable manufacturer ensures high-quality machines, long-term support, and global service.

Comparison of Leading Heavy-Duty Roll Forming Machine Manufacturers

| Manufacturer | Country | Specialization | Key Features |

|---|---|---|---|

| वूशी सनवे मशीनरी कं, लिमिटेड | China | Heavy-duty roll forming machines | Custom designs, high-speed automation, IoT-enabled machines |

| Dreistern GmbH | Germany | Precision metal forming | CNC-controlled machines, strong R&D |

| सैमको मशीनरी | Canada | Roll forming for construction | Custom engineering, automation |

| Bradbury Group | USA | Heavy-duty roll forming systems | Robust machines, automation-focused |

Verdict: If you’re looking for a cost-effective, high-speed heavy-duty roll forming machine, Sunway Machine is a top choice for global buyers.

Common Problems & Solutions in Heavy-Duty Roll Forming Machines

Even with high-quality heavy-duty roll forming machines, certain operational challenges can arise, such as roller misalignment, machine vibration, and inaccurate cutting. Identifying and troubleshooting these issues early ensures smooth production and high-quality heavy-gauge profiles.

Troubleshooting Guide

| Issue | Possible Cause | Solution |

|---|---|---|

| Bent or Twisted Profiles | Roller misalignment, improper pressure settings | Adjust roller alignment and optimize pressure settings |

| Material Slipping During Forming | Loose feeder rollers, incorrect tension settings | Tighten feeder rollers and adjust material tension |

| Excessive Machine Vibration | Loose bolts, unstable installation | Secure machine components and ensure a stable foundation |

| Inconsistent Cutting Lengths | Faulty cutting system, misaligned blades | Inspect and recalibrate the cutting mechanism |

| Roller Wear and Tear | High friction, improper material handling | Use hardened rollers and apply anti-wear coatings |

Pro Tip: Routine roller realignment and lubrication can extend machine lifespan by 40% and improve profile accuracy.

Future Trends in Heavy-Duty Roll Forming Machines

The heavy-duty metal manufacturing industry is evolving, and रोल फॉर्मिंग मशीनें are integrating AI, IoT, and automation to improve efficiency, precision, and sustainability.

Key Innovations

1. AI-Based Quality Control

- AI-powered sensors detect defects in real time, reducing material waste.

- Improves accuracy and consistency of heavy-duty profiles.

2. IoT & Smart Factory Integration

- Machines now feature cloud-based monitoring, enabling real-time diagnostics and predictive maintenance.

- Enhances production tracking and operational efficiency.

3. Servo-Driven Roll Forming Technology

- Enhances speed control, accuracy, and energy efficiency.

- Reduces wear and tear on mechanical components, increasing machine lifespan.

4. Fully Automated Profile Adjustments

- Eliminates manual adjustments when switching between different profiles.

- CNC-controlled automatic profile changes reduce downtime and improve efficiency.

Upgrading to AI-powered heavy-duty roll forming machines can increase production efficiency by up to 50%!

Automation in Heavy-Duty Roll Forming Machines

Automation is revolutionizing heavy-gauge profile manufacturing, making roll forming machines smarter, faster, and more cost-efficient.

Key Benefits

| विशेषता | Benefit |

|---|---|

| PLC & CNC Control Systems | Ensures precise measurements and minimizes human error |

| AI-Based Defect Detection | Identifies issues in real time, reducing material waste |

| IoT & Remote Monitoring | Allows operators to track machine performance from anywhere |

| Automated Profile Changeover | Reduces downtime when switching between profiles |

| Energy-Efficient Servo Motors | Lowers operational costs and improves sustainability |

Fully automated heavy-duty roll forming machines from Sunway Machine improve production efficiency by up to 40%!

Essential Maintenance Tips for Heavy-Duty Roll Forming Machines

उचित maintenance ensures longer machine lifespan and consistent production quality.

Maintenance Checklist

| Task | Frequency | Purpose |

|---|---|---|

| Lubricate Rollers & Bearings | Weekly | Prevents wear and tear |

| Check Roller Alignment | Monthly | Ensures accurate profile production |

| Inspect Cutting Mechanism | Quarterly | Prevents defective cuts and misalignment |

| Clean Machine Components | Daily | Removes dust and debris that can affect performance |

| Update Software & Calibration | Semi-Annually | Keeps automation functions optimized |

Pro Tip: Scheduled maintenance can extend machine lifespan by 50% and reduce failures by 70%.

सामान्य प्रश्न

1. How fast can a heavy-duty roll forming machine produce profiles?

High-speed models can produce up to 40 meters per minute, depending on material thickness.

2. What materials can be processed?

Heavy-duty roll forming machines can handle high-tensile steel, stainless steel, aluminum, and structural steel.

3. How much does a heavy-duty roll forming machine cost?

The price ranges from 50,000forbasicmodels∗∗to∗∗50,000 for basic models** to **50,000forbasicmodels∗∗to∗∗1,000,000 for fully automated systems.

4. What industries use heavy-duty roll forming machines?

Common applications include construction, infrastructure, automotive, aerospace, and industrial storage systems.

5. Where can I buy a high-quality heavy-duty roll forming machine?

对于 custom-built, high-speed heavy-duty roll forming machines, visit वूशी सनवे मशीनरी कं, लिमिटेड.

结语

Investing in a heavy-duty roll forming machine is essential for efficient, high-quality structural component production. Whether you need a standard or fully automated system, choosing a trusted manufacturer ensures long-term reliability and profitability.

वूशी सनवे मशीनरी कं, लिमिटेड is a leading global manufacturer of custom-built heavy-duty roll forming machines, offering advanced technology, expert support, and competitive pricing.

Want a custom heavy-duty roll forming machine? Contact us today!