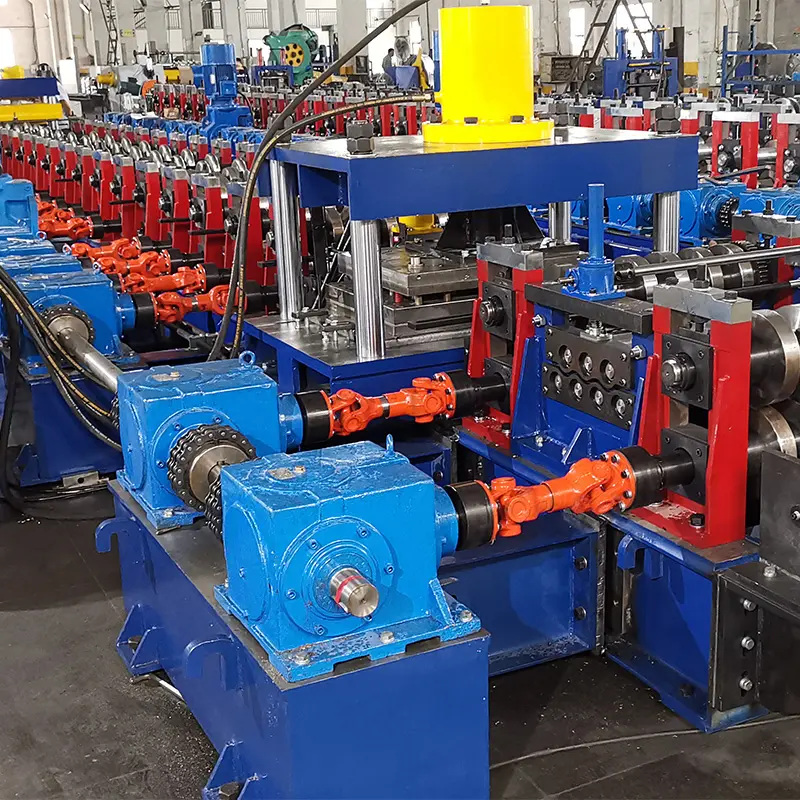

Overview of Highway Guardrail Roll Forming Machines

ए Highway guardrail roll forming machine is an advanced piece of equipment designed to manufacture steel guardrails used for road safety barriers. These machines are essential for producing W-beam, thrie-beam, and custom guardrails, ensuring high-strength, durable roadside protection.

Key Features of Highway Guardrail Roll Forming Machines

✅ High-speed production – Capable of producing 10-30 meters per minute.

✅ Fully automatic operation – PLC-controlled for precision and efficiency.

✅ Customizable profiles – Produces W-beam, thrie-beam, and special designs.

✅ Heavy-duty construction – Built with high-strength steel rollers and hydraulic cutting systems.

✅ Hot-dip galvanization compatibility – Ensures long-lasting corrosion resistance.

In this guide, we’ll cover:

✅ Types of highway guardrail roll forming machines

✅ How the roll forming process works

✅ Best materials for highway guardrails

✅ Cost analysis & pricing guide

✅ Top manufacturers & why Sunway Machine is a trusted choice

Let’s dive in!

Types of Highway Guardrail Roll Forming Machines

Different guardrail roll forming machines cater to various production needs and automation levels.

1. W-Beam Guardrail Roll Forming Machine

- Produces standard W-beam guardrails (most commonly used worldwide).

- Ideal for highway and road safety applications.

2. Thrie-Beam Guardrail Roll Forming Machine

- Creates stronger, wider thrie-beam guardrails for high-risk areas.

- Suitable for high-speed highways and crash-prone zones.

3. Custom Guardrail Roll Forming Machine

- Designed to manufacture customized guardrail profiles.

- Ideal for specialized safety projects and non-standard road applications.

4. Fully Automatic Highway Guardrail Roll Forming Machine

- विशेषताएँ CNC automation for quick profile adjustments.

- Best for large-scale, high-efficiency production.

Sunway Machine provides customized highway guardrail roll forming machines with advanced automation features.

How Highway Guardrail Roll Forming Works

The roll forming process for guardrails involves gradually shaping a flat steel coil into a high-strength guardrail profile.

Step-by-Step Highway Guardrail Roll Forming Process

| Step | 描述 |

|---|---|

| 1. Decoiling | The steel coil is placed on the decoiler to feed the material. |

| 2. Leveling & Feeding | The sheet is straightened and guided into the forming stations. |

| 3. Punching & Cutting | The hydraulic system performs hole punching for guardrail installation. |

| 4. Roll Forming | The sheet passes through multiple roller stations, forming the guardrail shape. |

| 5. Final Cutting & Output | The formed guardrail is cut to the required length and stacked. |

👉 Pro Tip: ए fully automated guardrail roll forming machine ensures high precision, minimal waste, and faster production speeds.

Best Materials for Highway Guardrails

Choosing the right material ensures strength, durability, and corrosion resistance.

Comparison of Materials for Highway Guardrails

| सामग्री | Properties | Best For |

|---|---|---|

| Hot-Dip Galvanized Steel | Corrosion-resistant, long lifespan | Standard highways & roads |

| Cold-Rolled Steel | High strength, smooth finish | Urban roads & bridges |

| Stainless Steel | Rust-proof, durable | High-end infrastructure projects |

| Aluminum Alloy | Lightweight, corrosion-resistant | Low-traffic zones and decorative applications |

Sunway Machine manufactures guardrail roll forming machines compatible with all major highway guardrail materials.

Highway Guardrail Roll Forming Machine Price Guide

The cost of a Highway guardrail roll forming machine depends on factors like automation level, production speed, and profile range.

Estimated Price Ranges for Highway Guardrail Roll Forming Machines

| Machine Type | Price Range (USD) | विशेषताएँ |

|---|---|---|

| Manual Machine | 30,000–30,000 – 30,000–60,000 | Manual adjustments, low-speed production |

| Semi-Automatic Machine | 60,000–60,000 – 60,000–120,000 | PLC-controlled, requires manual profile adjustments |

| Fully Automatic Machine | 120,000–120,000 – 120,000–250,000 | CNC-controlled, quick profile switching |

| High-Speed Machine | 250,000–250,000 – 250,000–500,000 | Advanced automation, high-speed production |

Looking for a custom quotation? Contact Sunway Machine today!

Top Highway Guardrail Roll Forming Machine Manufacturers

Choosing a reliable manufacturer ensures high-quality machines, long-term support, and global service.

Comparison of Leading Highway Guardrail Roll Forming Machine Manufacturers

| Manufacturer | Country | Specialization | Key Features |

|---|---|---|---|

| वूशी सनवे मशीनरी कं, लिमिटेड | China | Highway guardrail roll forming machines | Custom designs, high-speed automation, IoT-enabled machines |

| Dreistern GmbH | Germany | Precision metal forming | CNC-controlled machines, strong R&D |

| सैमको मशीनरी | Canada | Roll forming for construction | Custom engineering, automation |

| Bradbury Group | USA | Heavy-duty roll forming systems | Robust machines, automation-focused |

Verdict: If you’re looking for a cost-effective, high-speed highway guardrail roll forming machine, Sunway Machine is a top choice for global buyers.

Common Problems & Solutions in Highway Guardrail Roll Forming Machines

Even with high-quality highway guardrail roll forming machines, certain operational challenges may arise, such as roller misalignment, material warping, and inaccurate hole punching. Identifying and resolving these problems quickly is essential for maintaining efficient production and high-quality guardrails.

Troubleshooting Guide for Highway Guardrail Roll Forming Machines

| Issue | Possible Cause | Solution |

|---|---|---|

| Misaligned or Twisted Guardrails | Roller misalignment, uneven pressure distribution | Check and adjust roller alignment and pressure settings |

| Inaccurate Hole Punching | Faulty hydraulic system or misaligned punching dies | Inspect hydraulic pressure and realign punching dies |

| Material Slippage During Forming | Loose feeder rollers or incorrect tension settings | Tighten feeder rollers and adjust material tension |

| Excessive Machine Vibration | Loose bolts, unstable machine foundation | Secure machine components and ensure a stable installation |

| Cutting Inaccuracy | Worn-out cutting blades or misaligned cutters | Replace dull blades and align cutters properly |

Pro Tip: Routine roller realignment and servo-driven adjustments can improve guardrail accuracy by up to 30%.

Future Trends in Highway Guardrail Roll Forming Machines

As technology advances, highway guardrail roll forming machines are becoming smarter, faster, and more efficient. Manufacturers are integrating AI, IoT, and automation to enhance productivity and quality control.

Key Innovations in Highway Guardrail Roll Forming Machines for 2025

1. AI-Powered Quality Inspection

- AI-powered sensors detect defects in real-time, minimizing waste.

- Improves accuracy and consistency of guardrail production.

2. IoT & Smart Factory Integration

- Machines now feature cloud connectivity, enabling remote diagnostics and predictive maintenance.

- Enhances real-time monitoring and operational efficiency.

3. Servo-Driven Roll Forming Technology

- Improves speed control, energy efficiency, and precision.

- Reduces wear and tear on mechanical components, extending machine lifespan.

4. Fully Automated Profile Adjustments

- Eliminates manual adjustments when switching between different guardrail profiles.

- CNC-controlled automatic profile changes reduce downtime and improve efficiency.

Upgrading to AI-powered guardrail roll forming machines can increase production efficiency by up to 50%!

Roll Forming vs. Press Braking for Highway Guardrails

When choosing between रोल बनाना and press braking, manufacturers must consider speed, material waste, and cost efficiency.

Comparison Between Roll Forming and Press Braking for Guardrails

| विशेषता | रोल बनाना | Press Braking |

|---|---|---|

| उत्पादन गति | Faster for long, continuous profiles | Slower for custom bends |

| Material Waste | Minimal waste | Higher material scrap |

| Tooling Costs | Higher initial investment, lower long-term cost | Lower upfront cost, higher operational cost |

| Best For | High-volume, industrial production | Custom, low-volume metal components |

Verdict: If you require high-speed, continuous production with minimal waste, highway guardrail roll forming is the better choice.

Automation in Highway Guardrail Roll Forming Machines

Automation is transforming the manufacturing process, making roll forming machines smarter, faster, and more cost-efficient.

Key Benefits of Automated Highway Guardrail Roll Forming Machines

| विशेषता | Benefit |

|---|---|

| PLC & CNC Control Systems | Ensures precise measurements and minimizes human error |

| AI-Based Defect Detection | Identifies issues in real-time, reducing material waste |

| IoT & Remote Monitoring | Allows operators to track machine performance from anywhere |

| Automated Profile Changeover | Reduces downtime when switching between profiles |

| Energy-Efficient Servo Motors | Lowers operational costs and improves sustainability |

Fully automated highway guardrail roll forming machines from Sunway Machine improve production efficiency by up to 40%!

Essential Maintenance Tips for Highway Guardrail Roll Forming Machines

Proper maintenance ensures longer machine lifespan and uninterrupted production.

Maintenance Checklist for Highway Guardrail Roll Forming Machines

| Task | Frequency | Purpose |

|---|---|---|

| Lubricate Rollers & Bearings | Weekly | Prevents wear and tear |

| Check Roller Alignment | Monthly | Ensures accurate profile production |

| Inspect Cutting Mechanism | Quarterly | Prevents defective cuts and misalignment |

| Clean Machine Components | Daily | Removes dust and debris that can affect performance |

| Update Software & Calibration | Semi-Annually | Keeps automation functions optimized |

Pro Tip: Scheduled maintenance can extend machine lifespan by 50% and reduce failures by 70%.

FAQ: Highway Guardrail Roll Forming Machines

1. How fast can a highway guardrail roll forming machine produce guardrails?

High-speed models can produce up to 30 meters per minute, depending on the profile.

2. What guardrail profiles can be produced?

Most machines can produce W-beam, thrie-beam, and custom guardrail profiles.

3. How much does a highway guardrail roll forming machine cost?

The price ranges from 30,000forbasicmodels∗∗to∗∗30,000 for basic models** to **30,000forbasicmodels∗∗to∗∗500,000 for fully automated systems.

4. What materials can be used in highway guardrail roll forming machines?

Common materials include hot-dip galvanized steel, cold-rolled steel, stainless steel, and aluminum alloys.

5. Where can I buy a high-quality highway guardrail roll forming machine?

对于 custom-built, high-speed highway guardrail roll forming machines, visit वूशी सनवे मशीनरी कं, लिमिटेड.

结语

Investing in a Highway guardrail roll forming machine is essential for efficient, high-quality guardrail production. Whether you need a standard or fully automated system, choosing a trusted manufacturer ensures long-term reliability and profitability.

वूशी सनवे मशीनरी कं, लिमिटेड is a leading global manufacturer of custom-built highway guardrail roll forming machines, offering advanced technology, expert support, and competitive pricing.

Want a custom highway guardrail roll forming machine? Contact us today!