Floor deck roll forming machine, sometimes also named deck floor or metal deck roll forming machine, which is used to produce floor deck panel. It is used to support concrete or insulating membrane of a roof and developed to provide a structurally efficient product for use in roof and floor systems.

Its design and fabrication maximizes the properties of the steel in order to create a high strength-to-weight ratio, which lowers the material handling and erection costs but maintains the durability that has

尽管它是结构构件,但其均匀的质量可营造出迷人的外观,尤其是在采用规范指定的车间及现场涂层时。钢楼承板同时也是众多经UL和ULC认证的防火组合构件的重要组成部分。

निर्माण उद्योगों में, हम मुख्य चैनल रोल बनाने की मशीन, शहतीर रोल बनाने की मशीन, ड्राईवॉल रोल बनाने की मशीन, स्टड रोल बनाने की मशीन, ट्रैक रोल बनाने की मशीन, शीर्ष टोपी रोल बनाने की मशीन, क्लिप रोल बनाने की मशीन, धातु जैसी अधिक मशीनों का निर्माण करने में सक्षम हैं। डेक (फ्लोर डेक) रोल बनाने की मशीन, छत / दीवार पैनल रोल बनाने की मशीन, छत टाइल रोल बनाने की मशीन, नालीदार रोल बनाने की मशीन, रिज कैप रोल बनाने की मशीन, डाउनस्पॉट रोल बनाने की मशीन इत्यादि।

हम ग्राहकों की ड्राइंग, सहिष्णुता और बजट के अनुसार अलग-अलग समाधान करते हैं, पेशेवर एक-से-एक सेवा प्रदान करते हैं, जो आपकी सभी आवश्यकताओं के अनुकूल है। आप जो भी लाइन चुनते हैं, सनवे मशीनरी की गुणवत्ता सुनिश्चित करेगी कि आप पूरी तरह कार्यात्मक प्रोफाइल प्राप्त करें।

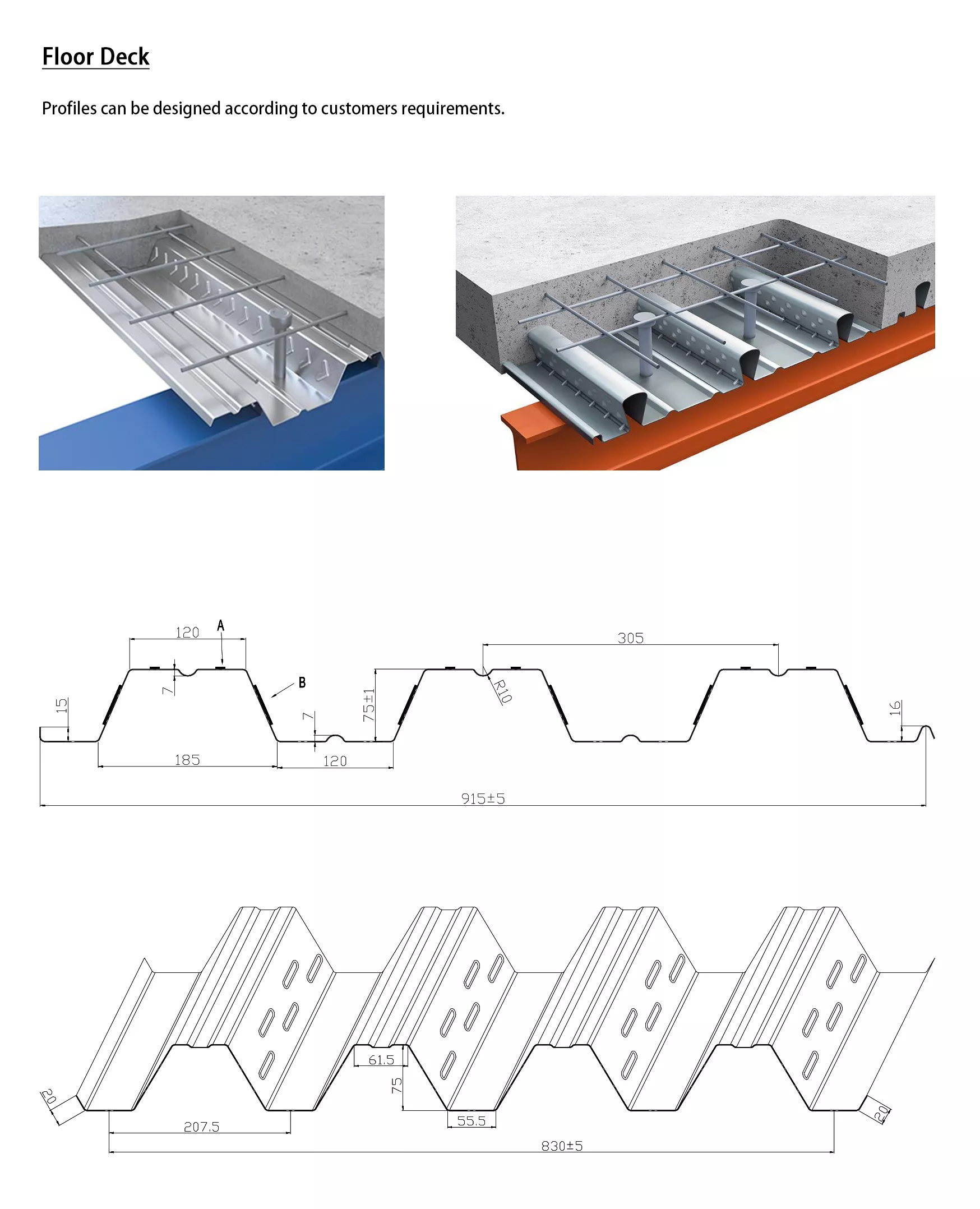

प्रोफ़ाइल चित्र

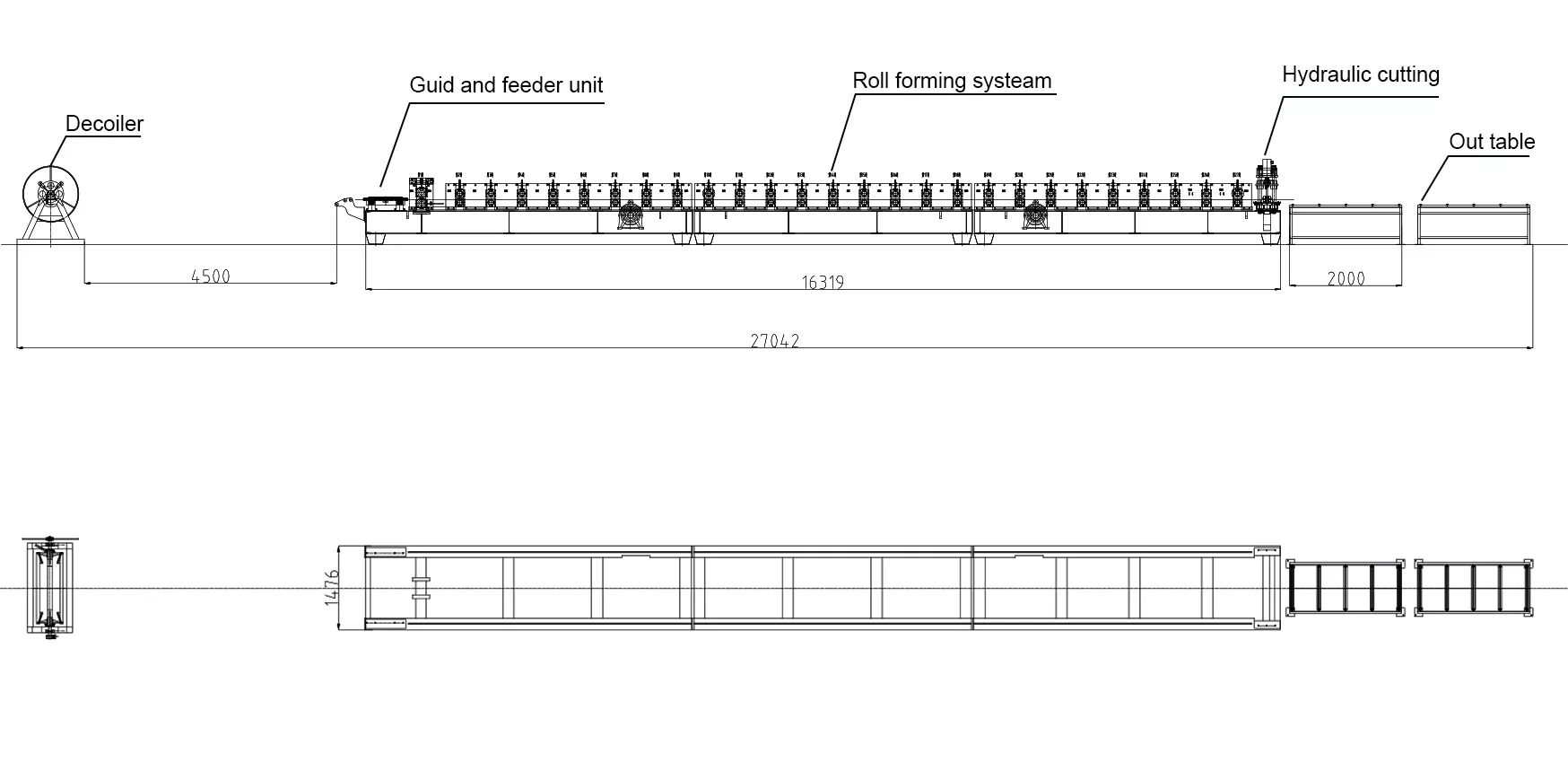

उत्पादन लाइन

उत्पाद विवरण

उत्पाद पैरामीटर

| तल डेक रोल बनाने की मशीन | ||

|

मशीन योग्य सामग्री

|

ए) जस्ती कॉइल |

厚度(mm):0.7-1.2,根据客户需求甚至可达1.5

|

| बी) पीपीजीआई, पीपीजीएल | ||

| नम्य होने की क्षमता | 250–350 MPa | |

| तन्य तनाव | 350–500 MPa | |

| कुंडल चौड़ाई | 914 मिमी, 1000 मिमी, 1200 मिमी, 1220 मिमी, 1250 मिमी आदि | |

| Nominal Forming Speed (m/min) | 10-15 | * या आपकी आवश्यकता के अनुसार |

| फॉर्मिंग स्टेशन | 约24-32 | * आपके प्रोफाइल ड्रॉइंग के अनुसार |

| डेकोइलर | मैनुअल डेकोइलर | * हाइड्रोलिक डेकोइलर (वैकल्पिक) |

| ड्राइविंग सिस्टम | चेन ड्राइव | * गियरबॉक्स ड्राइव (वैकल्पिक) |

| मशीन संरचना | स्टील प्लेट्स वेल्डेड | * कच्चा लोहा स्टैंड (वैकल्पिक) |

| रोलर्स की सामग्री | जीसीआर 15 | * Cr12Mov (वैकल्पिक) |

| कटिंग सिस्टम | हाइड्रोलिक पोस्ट कट | |

| आवृत्ति परिवर्तक ब्रांड | यास्कावा | * सीमेंस (वैकल्पिक) |

| बिजली की आपूर्ति | 380 वी 50 हर्ट्ज | * या आपकी आवश्यकता के अनुसार |

| मशीन का रंग | औद्योगिक नीला | * या आपकी आवश्यकता के अनुसार |

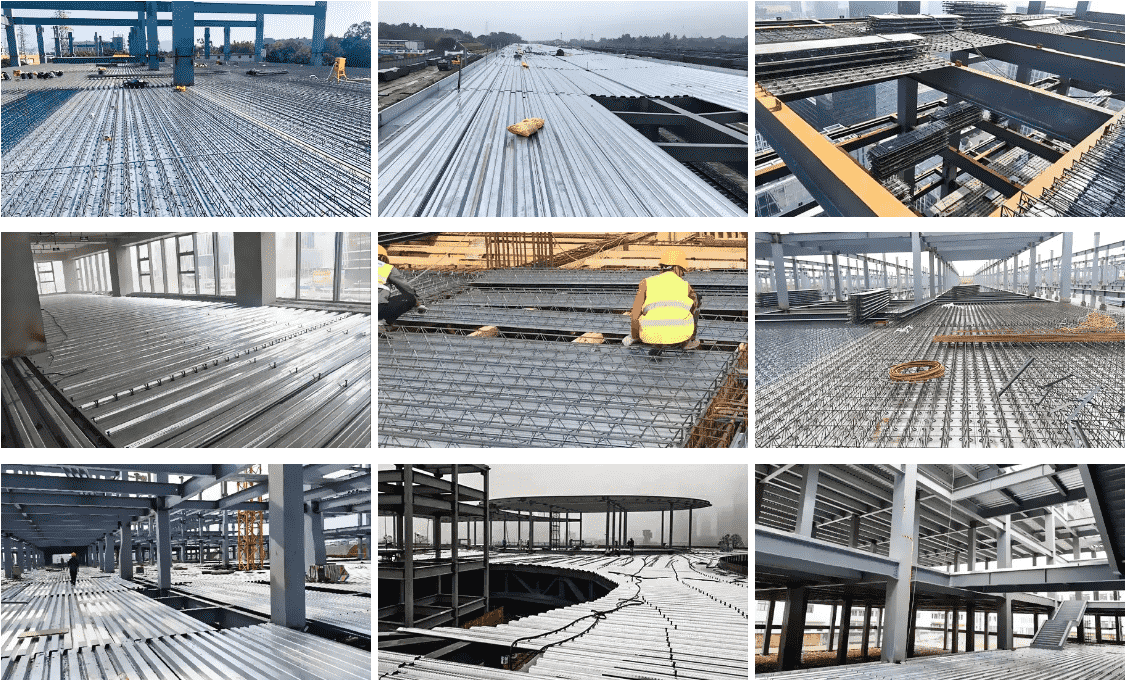

आवेदन

What is a floor deck roll forming machine?

A floor deck roll forming machine is specialized industrial equipment used to produce floor decking panels. These panels serve as essential structural components for floors in buildings and bridges within the construction industry.

The machine continuously processes metal coils, typically steel, into uniform floor deck panels. It feeds the coil through a series of rollers and dies that progressively shape the metal into the required profile and cut it to precise lengths.

Equipped with key components such as decoilers for holding and feeding coils, leveling devices for ensuring flat sheets, roll forming stations for shaping, cutting tools for length adjustment, and stacking mechanisms for finished panels, the floor deck roll forming machine delivers comprehensive production capabilities.

Operating continuously, the machine feeds the metal coil at a controlled speed through roll forming stations, where it assumes the floor deck profile. Cutting tools then shear the panels to specification, with finished products collected or stacked for subsequent handling or transport.

Renowned for their efficiency, these machines produce large volumes of precise, consistent floor decking panels, meeting the construction sector's demand for robust, reliable flooring solutions.

Applications of steel floor decking roll forming machines

Designed specifically for steel floor decking panels, these machines support diverse construction applications, including:

- Commercial and Industrial Buildings: These panels offer durable flooring capable of bearing heavy loads from machinery, equipment, and storage, ideal for floors, mezzanines, and roofs.

- High-Rise Buildings: Employed as temporary formwork during concrete pouring and curing, the panels integrate into the floor structure post-hardening, ensuring strength and stability.

- Composite Floor Systems: Paired with reinforced concrete, they function as formwork and tensile reinforcement, yielding lightweight, efficient, high-strength floors.

- Residential Construction: Utilized in houses, apartments, and condominiums for sturdy, dependable living surfaces.

- Bridge Construction: Serving as deck components, they provide durable surfaces tailored to load and design specifications.

In summary, steel floor decking roll forming machines enable efficient production of versatile panels essential for strength and durability across construction projects.

How to select a composite floor deck roll forming machine?

Selecting the ideal composite floor deck roll forming machine requires careful consideration of several factors to match your specific needs:

- Material and Specifications: Identify the material types and thicknesses required, ensuring the machine accommodates them effectively.

- Production Capacity: Assess output goals in terms of panels per hour or day, choosing a machine that meets or exceeds these targets.

- Profile and Dimensions: Confirm the machine's ability to produce exact widths, heights, and features like embossments with precision.

- Automation and Control: Opt for advanced systems such as touch screens, PLCs, and auto-adjustments to boost productivity and usability.

- Roll Forming Design: Prioritize robust construction, quality tooling, and adjustable components for reliable, long-term performance.

- After-Sales Support: Choose manufacturers offering robust technical assistance, training, and spare parts availability.

- Cost and ROI: Balance initial costs with long-term savings from efficiency, reduced waste, and performance gains.

Weighing these elements ensures a well-informed choice of a machine delivering efficiency, quality, and reliability.