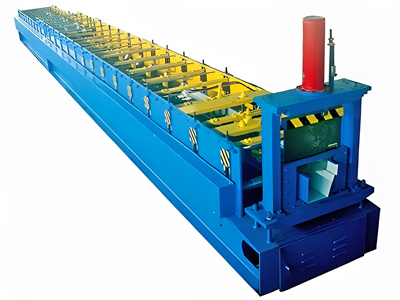

Gutter Roll Forming Machine Features:

We not only provide customers with an exceptional gutter roll forming machine but also extensive experience, precision manufacturing, stable automated production powered by hydraulics, advanced control systems, and dedicated service.

अनुप्रयोग

Products from the gutter roll forming machine are widely used in factories, workshops, garages, warehouses, locomotive sheds, hangars, exhibition buildings, cinemas, theaters, stadiums, gardens, and more.

प्रक्रिया प्रवाह

Uncoiler — Feeding — Roll Forming — Cutting — Exit Rack

मशीन विन्यास

| 1. Uncoiler |

2. फीडिंग डिवाइस

|

| 3. Roll Forming Machine |

4. Hydraulic Cutting

|

| 5. पीएलसी नियंत्रण प्रणाली | 6. एक्जिट रैक |

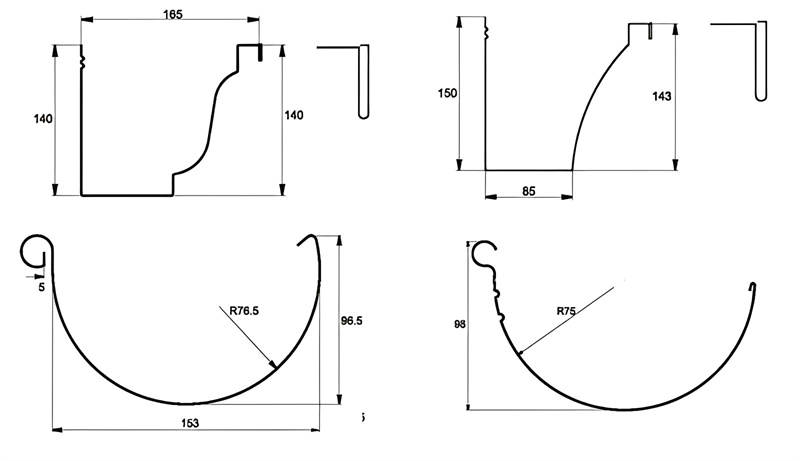

संदर्भ के लिए प्रोफाइल ड्राइंग्स

Types of Gutter Roll Forming Machines

Several types of gutter roll forming machines are used in the manufacturing industry. The choice of machine depends on the desired gutter shape and size, as well as production requirements. Here are some common types:

- K-Style Gutter Roll Forming Machine: This machine produces K-style gutters, popular in residential and commercial buildings. K-style gutters feature a flat bottom and a decorative front profile.

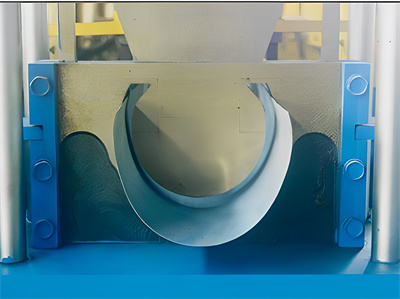

- Half-Round Gutter Roll Forming Machine: Designed for half-round gutters with a semicircular cross-section, this machine is ideal for historical or architectural applications.

- Box Gutter Roll Forming Machine: Used for industrial or commercial buildings with large roof areas, this machine creates rectangular or square gutters for greater water capacity.

- Fascia Gutter Roll Forming Machine: This produces fascia gutters that integrate seamlessly into the roofline, typically concealed behind the fascia board.

- Custom Gutter Roll Forming Machines: Tailored to specific needs, these machines are designed and built to produce gutters with unique shapes or profiles.

These examples represent just a few gutter roll forming machines. The exact type varies by manufacturer, region, and industry requirements.

What are the main applications of rain gutter roll forming machines?

Rain gutter roll forming machines are primarily used in construction and building materials to produce essential components for effective water drainage in residential and commercial buildings.

Here are the primary fields of application:

- Construction Industry: Essential for managing rainwater and preventing water damage, these machines produce gutters in various sizes, shapes, and materials like aluminum, steel, or PVC.

- Roofing Contractors: These machines enable on-site fabrication of custom gutters to match specific roofing projects, ensuring optimal water management.

- Building Material Manufacturers: Metal fabrication companies use them for large-scale production, supplying gutters to contractors or the market as finished products.

- Home Improvement and Renovation: They support custom installations or replacements, offering efficiency and flexibility for contractors and homeowners.

- Sheet Metal Fabrication: Ideal for precise production of gutters with specific dimensions, shapes, and profiles to meet architectural and engineering needs.

Overall, these machines are vital in construction and related sectors for producing rain gutters that ensure effective water management and building protection.

How to Choose a Water Gutter Roll Forming Machine?

Selecting a water gutter roll forming machine requires careful consideration of several factors to ensure it meets your needs. Key points include:

- Gutter Profile: Identify the required profile, such as K-style, half-round, box, or custom. Ensure the machine produces it accurately and consistently.

- Material Compatibility: Verify compatibility with materials like aluminum, steel, or copper, including appropriate thickness and width handling.

- Production Capacity: Evaluate output needs in terms of volume and speed to match your production timeline.

- Machine Flexibility: Opt for machines that easily adjust dimensions for various sizes and profiles to accommodate diverse requirements.

- Quality and Accuracy: Choose machines with robust construction, precision components, and advanced controls for consistent, high-quality output.

- Customization Options: Check for adaptability to unique profiles, including additional tooling from the manufacturer.

- After-Sales Support and Service: Select suppliers with strong reputations for technical support, training, spare parts, and warranties.

- Cost and Return on Investment: Balance price with features, quality, and support, considering production output and market demand.

Thorough evaluation of these factors will help you select a water gutter roll forming machine that delivers long-term value.

गटर रोल बनाने की मशीन कैसे काम करती है और इसके क्या फायदे हैं?

समीक्षा

अभी तक कोई समीक्षा नहीं।