विशेषताएँ

- 全自动 C 檩条辊压成型机专为通过两个机架自由调节实现自动规格变换而设计。

- 配备西门子触摸屏的 PLC 控制系统,所有调节均由电机驱动完成。

- 如需,可配备冲孔和剪切装置。

- 自动 C 机型具有高效、操作简便、快速换型和安全可靠的特点。

全自动 C 檩条辊压成型机型材参数:

- 厚度:1.5-3.0mm

- 腹板宽度范围:80-300mm

- 法兰高度范围:40-80mm

全自动 C 檩条辊压成型机应用:

तैयार उत्पादों का व्यापक रूप से बड़े पैमाने पर और मध्य-स्तर के निर्माण में छत और दीवार के समर्थक के रूप में उपयोग किया जाता है, जैसे कि कारखाने, गोदाम, गेराज, प्रदर्शनी केंद्र, सिनेमा, थिएटर, उद्यान और इतने पर।

工艺流程:

अनकॉइलर - फीडिंग - स्ट्रेटनिंग - प्री-पंचिंग - रोल फॉर्मिंग - कटिंग - एग्जिट रैक

मशीन विन्यास

| 1. Hydraulic Uncoiler |

2. फीडिंग डिवाइस

|

| 3. सीधा करना |

4. 预冲孔

|

| 5. रोल बनाने की मशीन |

6. Post-Cutting

|

| 7. पीएलसी नियंत्रण प्रणाली | 8. रैक से बाहर निकलें |

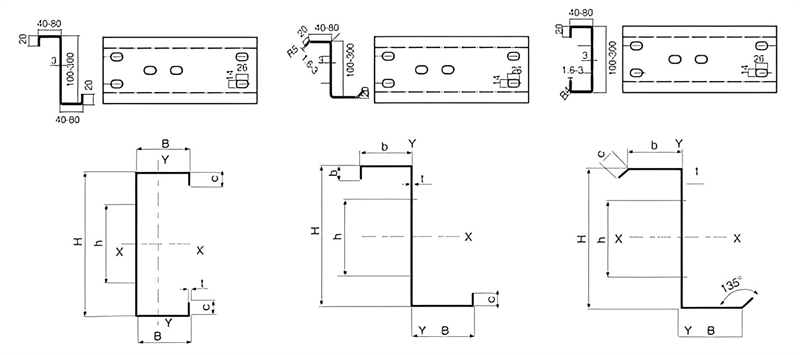

संदर्भ के लिए प्रोफाइल ड्राइंग्स

| C Purlin Section Dimensions | |||||||

|

नमूना

|

Section Dimensions (mm) | 孔距 |

备注

|

||||

| H | B | B | C | t | h | ||

| C100 | 100 | 40 | 40 | 15 | 2.0~3.0 | 无冲孔 |

可根据客户要求设计机器(带中间孔冲孔)

|

| C120 | 120 | 50 | 50 | 20 | 2.0-3.0 | 40 | |

| C140 | 140 | 50 | 50 | 20 | 2.0-3.0 |

可调节孔距

|

|

| C160 | 160 | 60 | 60 | 20 | 2.0-3.0 | ||

| C180 | 180 | 60 | 60 | 20 | 2.0-3.0 | ||

| C200 | 200 | 60 | 60 | 20 | 2.0-3.0 | ||

| C220 | 220 | 70 | 70 | 20 | 2.0-3.0 | ||

| C250 | 250 | 70 | 70 | 20 | 2.0-3.0 | ||

| C300 | 300 | 80 | 80 | 20 | 2.0-3.0 | ||

| Z 檩条截面尺寸 | |||||||

|

नमूना

|

Section Dimensions (mm) | 孔距 |

备注

|

||||

| H | B | b | C | t | h | ||

| Z100 | 100 | 55 | 50 | 20 | 2.0-3.0 | 40 |

可根据客户要求设计机器(带中间孔冲孔或法兰冲孔)

|

| Z120 | 120 | 55 | 50 | 20 | 2.0-3.0 |

可调节孔距

|

|

| Z140 | 140 | 55 | 50 | 20 | 2.0-3.0 | ||

| 2150 | 160 | 67 | 61 | 20 | 2.0-3.0 | ||

| Z160 | 180 | 67 | 61 | 20 | 2.0-3.0 | ||

| 2180 | 200 | 67 | 61 | 20 | 2.0-3.0 | ||

| 2200 | 220 | 67 | 61 | 20 | 2.0-3.0 | ||

| Z250 | 250 | 78 | 72 | 20 | 2.0.3.0 | ||

| Z280 | 280 | 78 | 72 | 20 | 2.0-3.0 | ||

| 2300 | 300 | 78 | 72 | 20 | 2.0-3.0 | ||

How is automation achieved in a fully automated roll forming machine?

Automation in a fully automated roll forming machine is realized through integrated components and technologies that streamline the production process. Key elements include:

- Control System: At the core is a sophisticated control system featuring programmable logic controllers (PLCs) or computer numerical control (CNC) systems. It manages operations by receiving sensor inputs and directing components for seamless automation.

- Sensors: These detect parameters like material position, dimensions, speed, and alignment, delivering real-time feedback to the control system for precise adjustments.

- Automatic Feeding System: Equipped with motorized or hydraulic decoilers, this system unwinds and feeds metal coils into the line without manual input, using sensors for optimal tension and alignment.

- Roll Forming Stations: Comprising multiple rollers and tools, these stations progressively shape the material. Motor- or actuator-driven adjustments ensure accurate positioning and forming.

- Cutting Mechanism: An automated system, often a flying cutoff, shears profiles to length without halting production, synchronized with the control system for consistency.

- Length Measurement and Control: Encoders or laser sensors measure profile lengths accurately, enabling the control system to trigger precise cuts.

- Stacking or Discharge Systems: Conveyor belts, robotic arms, or mechanical devices automate collection, stacking, and organization of finished profiles for downstream processes.

This integration ensures coordinated control across production stages, reducing manual intervention, boosting efficiency, enhancing accuracy, and maintaining consistent quality.

Advantages of OEM C Purlin Roll Forming Machine

- Customization: Tailored to customer specifications, it accommodates various C purlin sizes, shapes, and dimensions for flexible production.

- Quality and Precision: Built with premium materials and advanced technology, it delivers precise, consistent C purlin forming for superior results.

- Efficiency and Productivity: High-speed design with automation and advanced controls maximizes output while minimizing labor.

- Cost Savings: Long-term savings from high-speed production, reduced waste, and efficient resource use improve profitability.

- Reliability and Durability: Robust construction and quality components ensure dependable operation with minimal downtime and maintenance.

- Technical Support: Comprehensive services include installation, training, troubleshooting, and spare parts for optimal machine performance and longevity.

- Competitive Edge: Efficient production of high-quality C purlins sets manufacturers apart, expanding market share and customer loyalty.

निर्माण परियोजनाओं में उपयोग की जाने वाली शीर्ष 6 सी पर्लिन रोल फॉर्मिंग मशीनें

कैसे एसी शहतीर रोल बनाने की मशीन आपके व्यवसाय को सुचारू रूप से चलाने में मदद कर सकती है?

समीक्षा

अभी तक कोई समीक्षा नहीं।