La creciente demanda de energía renovable ha colocado a las turbinas eólicas a la vanguardia de la generación de energía sostenible. A medida que evoluciona la tecnología de las turbinas eólicas, también aumenta la necesidad de precisión, escalabilidad y eficiencia en la fabricación de componentes como soportes estructurales, secciones de torres y refuerzos de palas. Entran en escena Máquinas formadoras de rodillos para turbinas eólicassistemas avanzados diseñados para producir componentes de alta resistencia y duraderos esenciales para la construcción de turbinas eólicas.

En este artículo exploraremos qué son las máquinas formadoras de rodillos para turbinas eólicas, sus aplicaciones, precios, características de automatización, beneficios ambientales y por qué Wuxi Sunway Machinery se destaca como líder global en este campo. Ya sea que sea un fabricante que escala la producción o un desarrollador de energía renovable que explora soluciones rentables, esta guía proporcionará información valiosa.

¿Qué son las máquinas formadoras de rodillos para turbinas eólicas?

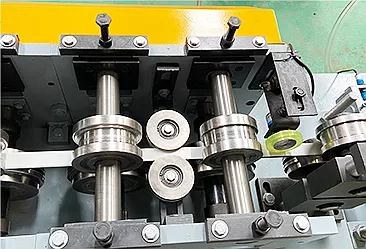

Máquinas formadoras de rodillos para turbinas eólicas son sistemas especializados que utilizan tecnología de formación por rodillos para fabricar componentes metálicos requeridos en la construcción de turbinas eólicas. Estas máquinas dan forma a láminas o bobinas de metal plano en perfiles precisos, asegurando alta resistencia, durabilidad y cumplimiento de estándares industriales rigurosos.

Dado el enorme tamaño de las turbinas eólicas modernas, estas máquinas formadoras de rodillos están diseñadas para manejar materiales grandes manteniendo precisión y eficiencia. Desde la producción de secciones de torres hasta la creación de refuerzos para palas, estas máquinas son integrales para la industria de la energía eólica.

Características principales

- Alta precisión: Garantiza dimensiones exactas, cumpliendo con los rigurosos estándares de construcción de turbinas eólicas.

- Versatilidad de materiales: Procesa acero de alta resistencia, acero galvanizado y aluminio.

- Perfiles personalizados: Capaz de producir formas únicas adaptadas a diseños específicos de turbinas eólicas.

- Durabilidad: Genera componentes que resisten condiciones ambientales extremas.

- Escalabilidad: Soporta producción a gran escala para satisfacer la creciente demanda de proyectos de energía renovable.

Aplicaciones de las máquinas formadoras de rodillos para turbinas eólicas

Los componentes de una turbina eólica deben diseñarse para cumplir con estándares rigurosos de seguridad, rendimiento y durabilidad. Las máquinas formadoras de rodillos juegan un papel crítico en la fabricación de estos componentes con precisión y eficiencia.

1. Secciones de torres

- Caso práctico: Producción de secciones cilíndricas o cónicas de torres de turbinas eólicas.

- Por qué es esencial: Proporciona la integridad estructural requerida para soportar la turbina a gran altura.

2. Refuerzos de palas

- Caso práctico: Conformado de refuerzos metálicos para palas de turbinas para mejorar su resistencia a las fuerzas del viento.

- Por qué es beneficioso: Asegura que las palas resistan velocidades de viento extremas y estrés operativo prolongado.

3. Estructuras de marco y base

- Caso práctico: Fabricación de marcos y placas base que anclan las turbinas al suelo o al lecho marino.

- Por qué es necesario: Garantiza estabilidad y seguridad, incluso en condiciones ambientales adversas.

4. Componentes de góndola

- Caso práctico: Manufactura de unidades de carcasa que protegen componentes críticos de la turbina como generadores y cajas de engranajes.

- Por qué es único: Ofrece durabilidad y precisión, protegiendo equipos sensibles de los elementos.

5. Vigas de soporte y contravientos

- Caso práctico: Producción de contravientos y vigas que mejoran la integridad estructural de la turbina.

- Por qué es fundamental: Previene deformaciones estructurales causadas por presión continua del viento y movimiento del rotor.

6. Componentes para turbinas eólicas offshore

- Caso práctico: Fabricación de componentes especializados diseñados para turbinas instaladas en entornos marinos.

- Por qué es relevante: Proporciona resistencia a la corrosión y durabilidad estructural en condiciones de alta salinidad.

Ventajas de usar máquinas formadoras de rodillos para turbinas eólicas

El sector de energía renovable exige soluciones de fabricación que ofrezcan precisión, eficiencia y escalabilidad. Por eso Máquinas formadoras de rodillos para turbinas eólicas son indispensables para proyectos de energía eólica:

1. Ingeniería de precisión

- Por qué es crucial: Cumple con las tolerancias estrictas requeridas para componentes que deben operar eficientemente en condiciones extremas.

2. Producción a alta velocidad

- Por qué es beneficioso: Permite a los fabricantes satisfacer la creciente demanda global de turbinas eólicas sin comprometer la calidad.

3. Personalización

- Por qué es esencial: Soporta la producción de perfiles únicos adaptados a diseños y requisitos específicos de sitios de turbinas.

4. Coste-eficacia

- Por qué es práctico: Reduce el desperdicio de material y costos laborales, haciendo que los proyectos de energía renovable sean más viables financieramente.

5. Durabilidad

- Por qué es relevante: Produce componentes capaces de resistir exposición prolongada a viento, lluvia y fluctuaciones de temperatura.

6. Fabricación respetuosa con el medio ambiente

- Por qué es importante: Minimiza el desperdicio y soporta el uso de materiales reciclables, alineándose con los objetivos de sostenibilidad de la energía eólica.

Características clave de las máquinas formadoras de rodillos para turbinas eólicas de Wuxi Sunway

Maquinaria Wuxi Sunway está a la vanguardia de la tecnología de formación por rodillos, ofreciendo máquinas específicamente adaptadas para el sector de energía eólica. Aquí está lo que distingue a sus máquinas:

1. Manipulación avanzada de materiales

- Materiales de apoyo:

- Acero de alta resistencia

- Acero galvanizado

- Aluminio

- Por qué es beneficioso: Garantiza compatibilidad con materiales que proporcionan la resistencia y durabilidad requeridas para componentes de turbinas eólicas.

2. Sistemas modulares de utillaje

- Qué ofrece: Herramientas intercambiables para producir varios perfiles en una sola máquina.

- Por qué es versátil: Admite diversas necesidades de fabricación sin requerir equipo adicional.

3. Corte, punzonado y soldadura integrados

- Qué incluye: Sistemas integrados para corte, punzonado y soldadura de precisión durante el proceso de formación por rodillos.

- Por qué es eficaz: Reduce el tiempo de producción y garantiza componentes listos para instalar.

4. Integración de IoT y automatización

- Qué permite: Supervisión en tiempo real, ajustes automatizados y mantenimiento predictivo mediante sistemas IoT.

- Por qué es revolucionario:

- Mejora la eficacia de la producción.

- Minimiza el tiempo de inactividad y los costes operativos.

5. Producción de alta capacidad

- Lo que ofrece: Máquinas capaces de producir componentes a gran escala para satisfacer las demandas de parques eólicos a escala utility.

- Por qué es esencial: Mantiene el ritmo con el rápido crecimiento del mercado de energía renovable.

6. Diseño respetuoso con el medio ambiente

- Qué incluye: Motores energéticamente eficientes, flujos de trabajo optimizados y sistemas de reducción de residuos.

- Por qué es sostenible: Apoya los esfuerzos globales para reducir la huella de carbono de la fabricación.

Precios de las máquinas formadoras de rodillos para turbinas eólicas

El coste de un Máquina formadora de rodillos para turbinas eólicas depende de sus características, capacidad de producción y opciones de personalización. A continuación se ofrece una guía general de precios para 2025:

| Tipo de máquina | Capacidades | Gama de precios (USD) |

|---|---|---|

| Máquinas estándar | Perfiles básicos para torres y soportes | 500,000–500,000–500,000–1,200,000 |

| Máquinas avanzadas | Sistemas de corte y soldadura integrados de alta velocidad | 1,200,000–1,200,000–1,200,000–2,500,000 |

| Máquinas totalmente personalizables | Herramientas modulares compatibles con IoT y ecológicas | 2.500.000–2.500.000–2.500.000–5.000.000 |

Para obtener información detallada sobre precios y opciones de financiación, póngase en contacto con Maquinaria Wuxi Sunway.

Automatización en máquinas formadoras de rodillos para turbinas eólicas

La automatización está transformando el panorama de la fabricación, y Máquinas formadoras de rodillos para turbinas eólicas no son una excepción. Aquí hay un vistazo a algunas características avanzadas de automatización:

1. Detección de defectos en tiempo real

- Qué incluye: Sistemas impulsados por IA que identifican defectos superficiales, desalineaciones o fallos estructurales en tiempo real.

- Por qué es valioso: Asegura que solo componentes impecables se utilicen, reduciendo desperdicios y retrabajos.

2. Mantenimiento predictivo

- Lo que rastrea: Sensores IoT monitorean el desgaste de componentes y predicen necesidades de mantenimiento antes de que ocurran fallos.

- Por qué es revolucionario: Evita paradas imprevistas y prolonga la vida útil de la máquina.

3. Ajuste adaptativo del rodillo

- Qué hace: Ajusta automáticamente las posiciones de los rodillos según el espesor del material y diseños de perfiles.

- Por qué es beneficioso: Elimina la calibración manual, mejorando la eficiencia y precisión.

4. Monitoreo y control basado en la nube

- Qué incluye: Acceso remoto a datos operativos, diagnósticos y controles a través de sistemas basados en la nube.

- Por qué es conveniente: Permite a los operadores supervisar la producción desde cualquier lugar, asegurando el máximo tiempo de actividad.

5. Producción multiperfil

- Qué permite: Cambia sin problemas entre varios perfiles en una sola corrida de producción.

- Por qué es conveniente: Admite diversas necesidades de fabricación sin tiempo de configuración adicional.

Beneficios ambientales de las máquinas formadoras de rodillos para turbinas eólicas

A medida que el mundo se desplaza hacia la energía renovable, los procesos de fabricación detrás de estas tecnologías también deben alinearse con objetivos ambientales. Así es como Máquinas formadoras de rodillos para turbinas eólicas contribuir a la sostenibilidad:

1. Reducción del desperdicio de material

- Cómo se consigue: La ingeniería de precisión minimiza el material de desecho durante la producción.

- Impacto: Conserva recursos y reduce costos de disposición.

2. Eficiencia energética

- Cómo funciona: Las máquinas están equipadas con motores de bajo consumo y flujos de trabajo optimizados.

- Impacto: Reduce el consumo de energía y la huella de carbono de la fabricación.

3. Uso de materiales reciclables

- En qué consiste: Procesa materiales como aluminio y acero, que son completamente reciclables.

- Impacto: Fomenta las prácticas sostenibles y promueve una economía circular.

4. Salidas de larga duración

- Por qué es importante: Produce componentes duraderos que reducen la necesidad de reemplazos frecuentes.

- Impacto: Soporta la longevidad y confiabilidad de las turbinas eólicas.

Preguntas frecuentes sobre máquinas formadoras de rodillos para turbinas eólicas

| Pregunta | Respuesta |

|---|---|

| ¿Qué materiales pueden procesar estas máquinas? | Acero de alta resistencia, acero galvanizado y aluminio. |

| ¿Cuál es la velocidad de producción? | Hasta 100 metros por minutosegún el material y la complejidad del perfil. |

| ¿Son ecológicas estas máquinas? | Sí, incluyen motores de bajo consumo y minimizan el desperdicio de material. |

| ¿Pueden estas máquinas realizar diseños personalizados? | ¡Absolutamente! Las herramientas modulares soportan perfiles personalizados para diversos componentes de turbinas eólicas. |

| ¿Cuál es el precio de estas máquinas? | Los precios oscilan entre 500.000a500.000a500.000a5.000.000en función de las características y la personalización. |

| ¿Se integran estas máquinas con los sistemas IoT? | Sí, las funciones habilitadas para IoT permiten la supervisión en tiempo real y el mantenimiento predictivo. |

Historias de éxito en el mundo real: Máquinas formadoras de rodillos para turbinas eólicas en acción

La eficiencia y fiabilidad de Máquinas formadoras de rodillos para turbinas eólicas han permitido a fabricantes de todo el mundo satisfacer la creciente demanda de infraestructura para energía eólica. A continuación, se presentan algunas historias de éxito clave que demuestran cómo estas máquinas han transformado el panorama de la producción.

1. Parque eólico marino en Europa

Cliente: Un destacado desarrollador de energías renovables especializado en parques eólicos marinos.

Desafío: El cliente necesitaba secciones de torre resistentes a la corrosión y estructuras base para turbinas ubicadas en entornos marinos de alta salinidad.

Solución: Wuxi Sunway suministró una máquina formadora de rodillos capaz de procesar acero galvanizado con recubrimientos anticorrosivos aplicados durante la producción.

Resultado:

- Produjo secciones de torre con una resistencia superior a la corrosión, prolongando la vida operativa de las turbinas en 20 años.

- Aumentó la capacidad de producción en un 35 %, permitiendo que el parque eólico entrara en funcionamiento antes del plazo previsto.

- Redujo el desperdicio de material en un 15 %, disminuyendo los costos generales del proyecto.

2. Proyecto de turbinas eólicas terrestres en Norteamérica

Cliente: Un fabricante que suministra componentes para instalaciones de turbinas eólicas terrestres en áreas remotas.

Desafío: El cliente requería soportes ligeros pero duraderos que pudieran transportarse y ensamblarse fácilmente en el sitio.

Solución: Wuxi Sunway proporcionó una máquina formadora de rodillos optimizada para acero de alta resistencia con funciones integradas de corte y soldadura.

Resultado:

- Entregó componentes que redujeron el peso total de la turbina, mejorando la eficiencia del transporte.

- Mejoró la estabilidad estructural de las turbinas, garantizando seguridad en condiciones de fuertes vientos.

- Logró una reducción del 25 % en el tiempo de producción, cumpliendo con plazos ajustados.

3. Proyecto híbrido de energía eólica-solar en Asia

Cliente: Un contratista de energía renovable que desarrolla una planta de energía híbrida eólica-solar.

Desafío: El proyecto requería componentes de turbina diseñados a medida compatibles con sistemas de energía híbrida.

Solución: Wuxi Sunway suministró una máquina formadora de rodillos con herramientas modulares para producir perfiles personalizados adaptados a las especificaciones del sistema híbrido.

Resultado:

- Permitió la creación de componentes innovadores y multifuncionales.

- Fortaleció la posición del contratista como líder en soluciones de energía híbrida.

- Logró una reducción de costos del 20 % en comparación con métodos de fabricación tradicionales.

4. Turbinas eólicas a pequeña escala para la electrificación rural en África

Cliente: Una organización sin fines de lucro enfocada en proporcionar energía renovable a comunidades rurales.

Desafío: La organización necesitaba soluciones rentables y escalables para la fabricación de componentes de turbinas eólicas a pequeña escala.

Solución: Wuxi Sunway entregó una máquina formadora de rodillos compacta diseñada para materiales ligeros como el aluminio.

Resultado:

- Produjo componentes asequibles adecuados para aplicaciones a pequeña escala.

- Empoderó a las comunidades rurales con acceso a energía sostenible.

- Redujo la huella de carbono del proceso de fabricación, alineándose con la misión de la organización sin fines de lucro.

Solución de problemas comunes en máquinas formadoras de rodillos para turbinas eólicas

Incluso los más avanzados Máquinas formadoras de rodillos para turbinas eólicas pueden enfrentar desafíos operativos. Aquí hay una guía para solucionar problemas comunes y mantener una producción fluida.

1. Perfiles de componentes inconsistentes

- Síntomas: Los componentes producidos varían en dimensiones o no cumplen con las especificaciones de diseño.

- Posibles causas:

- Rodillos desalineados o herramientas desgastadas.

- Alimentación de material irregular.

- Solución:

- Inspeccione y recalibre regularmente los rodillos para garantizar una alineación adecuada.

- Utilice materias primas uniformes y de alta calidad para evitar incoherencias.

2. Atascos de material durante la alimentación

- Síntomas: El material se detiene o se atasca durante el proceso de alimentación.

- Posibles causas:

- Tensión o alineación incorrecta del alimentador.

- Escombros u objetos extraños en la trayectoria de alimentación.

- Solución:

- Ajuste la configuración del alimentador para que coincida con las especificaciones del material.

- Limpie el recorrido de alimentación e inspeccione si hay obstrucciones antes de iniciar la producción.

3. Desgaste rápido de la herramienta

- Síntomas: Las herramientas de corte y soldadura requieren reemplazos frecuentes, lo que genera tiempos de inactividad.

- Posibles causas:

- Materiales de baja calidad que causan un desgaste excesivo.

- Lubricación insuficiente de las partes móviles.

- Solución:

- Opte por materiales de alta calidad diseñados para formado de rodillos.

- Implemente un programa de mantenimiento para lubricar y limpiar las herramientas regularmente.

4. Sobrecalentamiento de la máquina

- Síntomas: La máquina opera de manera ineficiente o se apaga inesperadamente.

- Posibles causas:

- Motores sobrecargados o funcionamiento prolongado a máxima capacidad.

- Rejillas de refrigeración bloqueadas o flujo de aire insuficiente.

- Solución:

- Utilice la máquina dentro de su capacidad recomendada.

- Asegure una ventilación adecuada y limpie los sistemas de refrigeración regularmente.

5. Fallos en el software o panel de control

- Síntomas: El sistema de control de la máquina se vuelve no receptivo o no ejecuta comandos.

- Posibles causas:

- Software o firmware obsoletos.

- Conexiones eléctricas defectuosas.

- Solución:

- Actualice el software de la máquina a la última versión.

- Inspeccione y repare las conexiones eléctricas para garantizar un funcionamiento adecuado.

Tendencias del mercado global para máquinas formadoras de rodillos de turbinas eólicas en 2025

La demanda de energía eólica está aumentando a nivel global, impulsada por avances tecnológicos, incentivos gubernamentales y objetivos de sostenibilidad. Aquí hay algunas tendencias clave que moldean el mercado para Máquinas formadoras de rodillos para turbinas eólicas:

1. Expansión de parques eólicos marinos

- Tendencia: Los países están invirtiendo fuertemente en proyectos eólicos marinos para aprovechar recursos eólicos más fuertes y consistentes.

- Impacto: Las máquinas capaces de producir componentes resistentes a la corrosión y a gran escala están en alta demanda.

2. Crecimiento en los mercados emergentes

- Tendencia: Los países en desarrollo en África, Asia y Sudamérica están adoptando la energía eólica para satisfacer la creciente demanda de electricidad.

- Impacto: Las soluciones de formado de rodillos rentables y escalables son esenciales para estos mercados.

3. Enfoque en sistemas de energía híbrida

- Tendencia: La integración de la energía eólica con solar y almacenamiento en baterías está ganando terreno.

- Impacto: Las máquinas que pueden producir componentes multifuncionales están volviéndose cada vez más valiosas.

4. Avances en el diseño de palas

- Tendencia: Los nuevos diseños de palas buscan mejorar la eficiencia y reducir el ruido.

- Impacto: Las máquinas formadoras de rodillos con herramientas avanzadas para refuerzos de palas son cruciales.

5. Compromiso con la sostenibilidad

- Tendencia: Los fabricantes están adoptando prácticas ecológicas para alinearse con objetivos globales de sostenibilidad.

- Impacto: Las máquinas diseñadas para minimizar el desperdicio y usar materiales reciclables están estableciendo estándares en la industria.

Características avanzadas de automatización en máquinas formadoras de rodillos para turbinas eólicas

La automatización está revolucionando el proceso de fabricación, permitiendo mayor eficiencia y precisión en la producción de componentes de turbinas eólicas. Aquí hay algunas de las características de automatización más avanzadas disponibles en Máquinas formadoras de rodillos para turbinas eólicas:

1. Detección de defectos impulsada por IA

- Qué incluye: Sistemas de inteligencia artificial que identifican defectos en tiempo real.

- Por qué es valioso: Reduce el desperdicio y asegura que solo componentes de alta calidad avancen al ensamblaje.

2. Mantenimiento predictivo

- Lo que rastrea: Sensores IoT que monitorean los componentes de la máquina y predicen necesidades de mantenimiento antes de que surjan problemas.

- Por qué es revolucionario: Minimiza los tiempos de inactividad y extiende la vida operativa de la máquina.

3. Ajuste adaptativo del rodillo

- Qué hace: Ajusta automáticamente las posiciones de los rodillos en función del grosor del material y los requisitos del perfil.

- Por qué es beneficioso: Mejora la precisión y reduce el tiempo de configuración.

4. Producción multiperfil

- Qué permite: Cambia sin problemas entre diferentes perfiles de componentes en una sola corrida de producción.

- Por qué es conveniente: Soporta diversas necesidades de fabricación sin cambios adicionales de herramientas.

5. Supervisión y control remotos

- Qué incluye: Sistemas basados en la nube para monitorear y controlar la máquina desde cualquier ubicación.

- Por qué es útil: Permite a los operadores supervisar la producción y solucionar problemas de forma remota, asegurando el máximo tiempo de actividad.

¿Por qué elegir Wuxi Sunway Machinery para máquinas formadoras de rodillos de turbinas eólicas?

Maquinaria Wuxi Sunway se ha establecido como líder global en tecnología de formado de rodillos, ofreciendo soluciones de vanguardia para el sector de energía renovable. Aquí está por qué los fabricantes recurren consistentemente a Wuxi Sunway:

- Experiencia demostrada: Décadas de experiencia en el diseño de máquinas formadoras de rodillos de alto rendimiento para aplicaciones energéticas.

- Alcance mundial: Clientes de Asia, Europa, América y otros continentes confían en nosotros.

- Impulsada por la innovación: Incorpora IoT, IA y herramientas modulares en sus máquinas para mejorar la eficiencia.

- Compromiso de sostenibilidad: Diseña máquinas que se alinean con el enfoque de la industria de energía renovable en reducir el impacto ambiental.

- Apoyo integral: Ofrece asesoramiento, instalación, formación y servicio posventa excepcionales.

Explore su gama de soluciones de perfilado en el sitio web oficial.

Preguntas frecuentes sobre máquinas formadoras de rodillos para turbinas eólicas

| Pregunta | Respuesta |

|---|---|

| ¿Qué materiales pueden procesar estas máquinas? | Acero de alta resistencia, acero galvanizado y aluminio. |

| ¿Cuál es la velocidad de producción? | Hasta 100 metros por minutosegún el material y la complejidad del perfil. |

| ¿Son ecológicas estas máquinas? | Sí, incluyen motores de bajo consumo y minimizan el desperdicio de material. |

| ¿Pueden estas máquinas realizar diseños personalizados? | ¡Absolutamente! Las herramientas modulares soportan perfiles personalizados para diversos componentes de turbinas eólicas. |

| ¿Cuál es el precio de estas máquinas? | Los precios oscilan entre 500.000a500.000a500.000a5.000.000en función de las características y la personalización. |

| ¿Se integran estas máquinas con los sistemas IoT? | Sí, las funciones habilitadas para IoT permiten la supervisión en tiempo real y el mantenimiento predictivo. |

Conclusión: Una nueva era en la fabricación de energía renovable

Máquinas formadoras de rodillos para turbinas eólicas están revolucionando el sector de energía renovable al permitir la producción eficiente de componentes críticos de turbinas eólicas. Con su precisión, escalabilidad y diseño ecológico, estas máquinas están allanando el camino para un futuro energético sostenible.

¿Listo para potenciar sus capacidades de fabricación? Aliéntese con Maquinaria Wuxi Sunway y explore sus soluciones de formado de rodillos de última generación para la industria eólica. Juntos, aprovechemos el poder del viento para construir un futuro más verde y brillante.