La industria de defensa opera en las condiciones más exigentes y requiere equipos que combinen resistencia, durabilidad y fiabilidad. Desde componentes para vehículos blindados hasta perfiles estructurales para bases militares, la producción de piezas de alto rendimiento es fundamental para la seguridad nacional. Entre en Máquinas perfiladoras de material militarla tecnología de vanguardia que hay detrás de muchos de los componentes duraderos y precisos que se utilizan en aplicaciones militares. Estas máquinas cumplen las estrictas normas de la fabricación para defensa, lo que permite producir perfiles que soportan entornos extremos y condiciones rigurosas.

En esta guía, exploraremos aplicaciones, características, precios, tendencias del mercadoy cómo Maquinaria Wuxi Sunway está desarrollando soluciones de perfilado para la industria de defensa. Si usted es contratista de defensa, ingeniero militar o simplemente siente curiosidad por la tecnología que impulsa la infraestructura militar moderna, este artículo le ayudará.

¿Qué es una perfiladora de material militar?

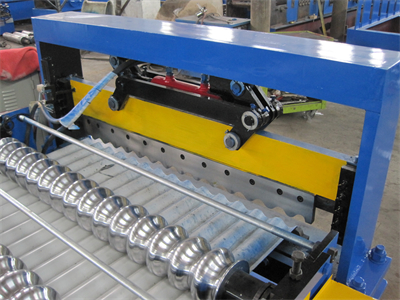

A Máquina perfiladora de material militar es un equipo especializado diseñado para producir perfiles duraderos y de alto rendimiento utilizados en la construcción de vehículos, infraestructuras y equipos militares. Estas máquinas procesan chapas o bobinas planas de metal -típicamente fabricadas con acero de alta resistencia, aleaciones balísticas o materiales resistentes a la corrosión-en formas precisas que satisfagan las rigurosas exigencias de las operaciones militares.

Componentes clave producidos

- Paneles para vehículos blindados: Perfiles utilizados en tanques, vehículos blindados de transporte de tropas (APC) y otros vehículos militares.

- Soportes para armas: Componentes para el montaje de armas en plataformas terrestres, aéreas o navales.

- Armazones de refugios portátiles: Perfiles ligeros pero duraderos para tiendas militares y refugios de campaña.

- Perfiles de la infraestructura de base: Vigas, canales y soportes para la construcción de bases y puestos militares.

- Sistemas de almacenamiento de munición: Perfiles para bastidores y contenedores utilizados en el almacenamiento seguro de armas y municiones.

- Perfiles personalizados: Diseños exclusivos para aplicaciones militares especializadas, como sistemas de radar, plataformas de vehículos aéreos no tripulados y torres de comunicaciones.

Estas máquinas destacan en la automatización de la producción de componentes militares, garantizando la precisión, la coherencia y el cumplimiento de las estrictas normas de defensa.

Aplicaciones de las perfiladoras de equipos militares

La versatilidad de Máquinas perfiladoras de material militar los hace indispensables para una amplia gama de aplicaciones relacionadas con la defensa. A continuación se exponen algunos casos de uso clave:

1. Fabricación de vehículos blindados

- Caso práctico: Fabricación de paneles y perfiles estructurales para tanques, vehículos blindados de transporte de tropas (APC) y vehículos protegidos contra emboscadas y resistentes a las minas (MRAP).

- Por qué es esencial: Garantiza la supervivencia del personal y los equipos en las zonas de combate.

2. Componentes del sistema de armas

- Caso práctico: Fabricación de soportes, abrazaderas y armazones para sistemas de armas en vehículos, aviones y barcos.

- Por qué es importante: Proporciona la integridad estructural necesaria para un funcionamiento preciso y fiable del arma.

3. Refugios de campaña portátiles

- Caso práctico: Fabricación de estructuras ligeras para tiendas, refugios y centros de mando móviles.

- Por qué es valioso: Permite un despliegue y montaje rápidos en entornos remotos u hostiles.

4. Construcción de bases militares

- Caso práctico: Fabricación de vigas, pilares y soportes para cuarteles, hangares y otras infraestructuras de la base.

- Por qué es relevante: Mejora la durabilidad y la seguridad de las instalaciones militares.

5. Almacenamiento de municiones y armas

- Caso práctico: Creación de perfiles seguros para bastidores, taquillas y contenedores utilizados para almacenar armas y munición.

- Por qué es fundamental: Evita daños y garantiza la manipulación y el transporte seguros de materiales delicados.

6. Plataformas de equipos especializados

- Caso práctico: Perfiles de fabricación de sistemas de radar, plataformas de lanzamiento de UAV y torres de comunicación.

- Por qué es beneficioso: Apoya las tecnologías militares avanzadas y mejora las capacidades operativas.

Características principales de las Máquinas Perfiladoras de Equipos Militares Wuxi Sunway

Maquinaria Wuxi Sunwaylíder mundial en tecnología de perfilado, ofrece máquinas adaptadas a las exigencias específicas del sector de defensa. Estas son las características más destacadas que hacen que sus máquinas sean ideales para la fabricación militar:

1. Procesamiento de materiales de alta resistencia

- Materiales de apoyo:

- Acero de calidad balística

- Aleaciones de aluminio

- Metales resistentes a la corrosión

- Titanio

- Por qué es importante: Garantiza la producción de componentes duraderos capaces de soportar condiciones extremas.

2. Precisión y coherencia

- Rendimiento: Tolerancias dimensionales tan bajas como ±0,05 mm, que garantizan la uniformidad en aplicaciones críticas.

- Por qué es fundamental: Reduce los errores de montaje y garantiza la compatibilidad con otros equipos.

3. Herramientas personalizables para diseños especializados

- Qué aporta: Sistemas modulares de utillaje para crear perfiles únicos adaptados a las especificaciones militares.

- Por qué es esencial: Apoya la producción de componentes a medida para aplicaciones de defensa especializadas.

4. Sistemas integrados de corte y punzonado

- Qué incluye: Sistemas de corte de precisión, perforación y troquelado durante la producción.

- Por qué es valioso: Simplifica el montaje y reduce los procesos de postproducción.

5. Producción a alta velocidad

- Rendimiento: Capaz de producir hasta 20-100 metros de perfiles por minutosegún el material y la complejidad.

- Por qué es beneficioso: Satisface las exigencias de gran volumen de los proyectos de defensa a gran escala.

6. Integración de IoT y automatización

- Qué permite: Supervisión en tiempo real, ajustes automatizados y mantenimiento predictivo mediante sistemas IoT.

- Por qué cambia el juego:

- Mejora la eficacia de la producción.

- Reduce el tiempo de inactividad y los costes de mantenimiento.

- Proporciona información práctica para la mejora continua.

7. Tratamientos superficiales mejorados

- El reportaje: Máquinas diseñadas para tratar revestimientos como anticorrosión, antioxidante y acabados reflectantes.

- Por qué es significativo: Prolonga la vida útil de los componentes expuestos a entornos agresivos.

Flujo de trabajo de producción de una perfiladora de equipos militares

El proceso de fabricación de componentes militares está optimizado para ofrecer durabilidad, precisión y eficacia. A continuación se muestra un resumen del flujo de trabajo típico:

1. Carga de material

- Las láminas o bobinas de materiales balísticos se cargan en un desbobinadorgarantizando un suministro continuo.

2. Enderezado y nivelación

- Una unidad de nivelación garantiza que el material esté plano y libre de defectos antes de que comience el perfilado.

3. Perfilado

- El material pasa por una serie de rodillos que le van dando forma hasta obtener el perfil deseado, manteniendo estrictas tolerancias.

4. Punzonado y corte

- Los sistemas integrados añaden orificios de precisión para fijaciones o conectores y cortan los perfiles a longitudes personalizadas.

5. Aplicación del revestimiento

- Los sistemas opcionales aplican revestimientos protectores, como acabados anticorrosión o balísticos, durante o después de la producción.

6. Inspección de calidad

- Los perfiles acabados se inspeccionan para comprobar su precisión dimensional, resistencia y cumplimiento de las normas militares.

7. Embalaje y entrega

- Los componentes terminados se agrupan, etiquetan y preparan para su transporte seguro a contratistas de defensa o instalaciones militares.

Precios de las perfiladoras de material militar

El coste de un Máquina perfiladora de material militar depende de sus características, compatibilidad de materiales y opciones de personalización. A continuación se ofrece una guía general de precios para 2025:

| Tipo de máquina | Capacidades | Gama de precios (USD) |

|---|---|---|

| Máquinas estándar | Producción de perfiles básicos para aplicaciones de defensa | 500,000–500,000–500,000–1,200,000 |

| Máquinas avanzadas | Sistemas integrados de corte y punzonado de alta velocidad | 1,200,000–1,200,000–1,200,000–2,800,000 |

| Máquinas totalmente personalizables | IoT, herramientas modulares y manipulación avanzada de materiales | 2,800,000–2,800,000–2,800,000–5,000,000 |

Para obtener información detallada sobre precios y opciones de financiación, póngase en contacto con Maquinaria Wuxi Sunway.

Tendencias del mercado de las perfiladoras para equipamiento militar en 2025

La industria de defensa evoluciona rápidamente, impulsada por los avances tecnológicos y los factores geopolíticos. Estas son las tendencias que configuran el mercado:

1. Materiales avanzados

- La tendencia: Uso creciente de metales balísticos y aleaciones ligeras en equipos militares.

- Papel de la máquina:

- Permiten el conformado preciso de materiales avanzados.

- Reduzca el desperdicio de material mediante ingeniería de precisión.

2. Sistemas militares autónomos

- El crecimiento: Aumento de la demanda de UAV, drones y vehículos autónomos en operaciones de defensa.

- Contribución de la máquina:

- Producir perfiles ligeros y duraderos para plataformas autónomas.

- Apoyar diseños innovadores para tecnologías militares avanzadas.

3. Soluciones de implantación rápida

- El foco: Desarrollo de infraestructuras militares portátiles y modulares de despliegue rápido.

- Impacto de la máquina:

- Permitir la producción en serie de armazones y estructuras de soporte de refugios portátiles.

- Facilite el montaje in situ con perfiles prefabricados.

4. Crecimiento del gasto en defensa

- El crecimiento: El aumento de los presupuestos mundiales de defensa impulsa la demanda de equipos militares avanzados.

- Impacto de la máquina:

- Apoyar la producción a gran escala de componentes militares.

- Aumentar la eficacia de la producción para cumplir plazos ajustados.

Preguntas frecuentes sobre las perfiladoras de equipos militares

| Pregunta | Respuesta |

|---|---|

| ¿Qué materiales pueden procesar estas máquinas? | Acero de calidad balística, aleaciones de aluminio, titanio y metales resistentes a la corrosión. |

| ¿Cuál es la velocidad de producción de estas máquinas? | Las máquinas pueden producir hasta 20-100 metros de perfiles por minutosegún el material y la complejidad. |

| ¿Pueden estas máquinas realizar diseños personalizados? | Sí, el utillaje modular permite crear perfiles militares a medida. |

| ¿Son eficientes desde el punto de vista energético? | Sí, incluyen motores de bajo consumo y flujos de trabajo optimizados para reducir costes. |

| ¿Qué industrias se benefician de estas máquinas? | Sectores de defensa, seguridad nacional e infraestructuras pesadas. |

| ¿Cumplen estas máquinas las normas de seguridad? | Sí, cumplen las normas de calidad ISO, CE y específicas para el sector militar. |

| ¿Cuál es la vida útil de estas máquinas? | Con un mantenimiento adecuado, estas máquinas pueden durar 20-30 años o más. |

| ¿Se proporciona formación con la compra? | Sí, Wuxi Sunway ofrece formación completa y asistencia posventa a todos los clientes. |

| ¿Cuál es el precio de estas máquinas? | Los precios oscilan entre 500.000a500.000a500.000a5.000.000en función de las características y opciones de personalización. |

| ¿Pueden estas máquinas apoyar una producción sostenible? | Sí, están optimizados para minimizar los residuos y favorecer los materiales reciclables. |

Historias de éxito reales: Las perfiladoras de equipos militares en acción

El uso de Máquinas perfiladoras de material militar es fundamental para abordar algunos de los retos más complejos a los que se enfrentan los fabricantes del sector de defensa. A continuación se muestran ejemplos reales de cómo estas máquinas han transformado la producción militar.

1. Estudio de caso: Paneles de vehículos blindados de transporte de tropas (APC)

- Cliente: Contratista mundial de defensa especializado en vehículos terrestres tácticos.

- Desafío: Se necesitan paneles de acero de alta resistencia para APC capaces de soportar amenazas balísticas e impactos explosivos.

- Solución: Wuxi Sunway Machinery suministró una perfiladora diseñada para procesar acero balístico con sistemas integrados de corte y punzonado para los orificios de los cierres.

- Resultados:

- Reducción del tiempo de producción en 40%, lo que permite una entrega más rápida de los vehículos.

- Mayor durabilidad del panel, que cumple las normas balísticas de la OTAN.

- Reducción del desperdicio de material en 15%, optimizando los costes de los insumos.

2. Estudio de caso: Infraestructura de despliegue rápido

- Cliente: Proveedor de refugios militares portátiles y hospitales de campaña.

- Desafío: Se necesitan estructuras ligeras y modulares para construir refugios que puedan desplegarse rápidamente en zonas de conflicto o en operaciones de socorro en caso de catástrofe.

- Solución: Wuxi Sunway suministró una perfiladora capaz de producir perfiles de aluminio de alta resistencia con utillaje modular para diversos diseños.

- Resultados:

- Permitió fabricar refugios que podían montarse en menos de 30 minutos.

- Peso reducido en 25% en comparación con los bastidores de acero tradicionales, lo que facilita la logística del transporte.

- Mayor durabilidad de la cubierta, lo que garantiza la fiabilidad en entornos difíciles.

3. Estudio de caso: Estanterías de almacenamiento de munición

- Cliente: Empresa de logística que gestiona el almacenamiento de municiones y armas para bases militares.

- Desafío: Se necesitaban perfiles resistentes a la corrosión para bastidores de municiones que pudieran soportar temperaturas y humedad extremas.

- Solución: Wuxi Sunway suministró una máquina diseñada para procesar acero galvanizado con revestimientos anticorrosión aplicados durante la producción.

- Resultados:

- Fabricamos bastidores que cumplían los requisitos militares de seguridad y longevidad.

- Reducción de los costes de mantenimiento en 30% gracias a su mayor resistencia a la corrosión.

- Permitió una producción en masa eficiente para satisfacer las crecientes necesidades de almacenamiento.

4. Estudio de casos: Bastidores de UAV (vehículos aéreos no tripulados)

- Cliente: Fabricante de drones que suministra al ejército UAV tácticos para reconocimiento y logística.

- Desafío: Se necesitan estructuras ultraligeras y duraderas para mejorar los tiempos de vuelo y la capacidad de carga de los UAV.

- Solución: Wuxi Sunway ha desarrollado una laminadora capaz de procesar materiales compuestos avanzados para fabricar perfiles personalizados para vehículos aéreos no tripulados.

- Resultados:

- Aumento de la duración de los vuelos de los UAV en 20%, mejorando las capacidades operativas.

- Reducción de los plazos de producción en 35%, lo que permite una entrega más rápida a los clientes militares.

- Diseños modulares compatibles con vehículos aéreos no tripulados, que permiten una rápida personalización sobre el terreno.

Personalización: La ventaja clave de las perfiladoras de equipos militares

En la industria de defensa, no hay una talla única. Las aplicaciones militares suelen requerir perfiles personalizados para satisfacer requisitos operativos únicos. Máquinas perfiladoras de Maquinaria Wuxi Sunway ofrecen una flexibilidad inigualable para crear estas soluciones a medida.

1. Herramientas modulares

- Qué ofrece: Sistemas de utillaje fácilmente intercambiables que permiten a los fabricantes cambiar rápidamente entre distintos diseños de perfil.

- Por qué es valioso:

- Admite diversas necesidades de producción, desde paneles blindados hasta armazones de refugios.

- Reduce el tiempo de inactividad asociado a los cambios de herramientas.

- Permite la producción de lotes pequeños para prototipos o componentes especializados.

2. Versatilidad de los materiales

- Materiales de apoyo:

- Acero de calidad balística

- Aleaciones de aluminio

- Titanio

- Materiales compuestos (por ejemplo, fibra de carbono)

- Por qué es fundamental:

- Proporciona la flexibilidad necesaria para fabricar componentes optimizados en cuanto a resistencia, peso o resistencia a la corrosión.

- Apoya la innovación en el diseño de equipos de defensa.

3. Diversidad de perfiles

- Capacidades: Las máquinas pueden producir una amplia gama de perfiles:

- Canales en U

- Perfiles Z

- Vigas de caja

- Geometrías personalizadas

- Por qué es importante:

- Permite a los fabricantes satisfacer las necesidades específicas de diversas aplicaciones militares.

- Admite la integración con otros componentes para un montaje sin fisuras.

4. Integración avanzada de revestimientos

- Qué incluye: Sistemas para aplicar revestimientos como acabados anticorrosión, reflectantes o de camuflaje durante la producción.

- Por qué es beneficioso:

- Mejora la durabilidad y funcionalidad de los componentes.

- Reduce los pasos de postproducción, ahorrando tiempo y costes.

Normas de cumplimiento para las perfiladoras de equipos militares

Los componentes militares deben cumplir estrictas normas internacionales para garantizar su seguridad, durabilidad y rendimiento. Maquinaria Wuxi Sunway diseña sus máquinas para producir perfiles que cumplan o superen estos requisitos:

| Estándar | Región | Requisito |

|---|---|---|

| Especificaciones MIL-STD | EE.UU. | Define los requisitos de calidad militar para materiales y componentes. |

| ISO 9001 | Global | Garantiza una gestión coherente de la calidad en los procesos de fabricación. |

| Normas STANAG de la OTAN | Países miembros de la OTAN | Especifica las normas de interoperabilidad y rendimiento de los equipos militares. |

| Marcado CE | Europa | Certifica el cumplimiento de las normas europeas de seguridad y calidad. |

| Conformidad RoHS | Europa | Restringe las sustancias peligrosas en los materiales de fabricación. |

| Cumplimiento del ITAR | EE.UU. | Garantiza el cumplimiento del Reglamento sobre Tráfico Internacional de Armas para la exportación. |

Cumpliendo estas normas, Maquinaria Wuxi Sunway garantiza que sus máquinas de perfilado suministran componentes seguros, duraderos y conformes a las normas internacionales.

Preguntas frecuentes sobre las perfiladoras de equipos militares

| Pregunta | Respuesta |

|---|---|

| ¿Qué materiales pueden procesar estas máquinas? | Acero de calidad balística, aleaciones de aluminio, titanio y materiales compuestos. |

| ¿Cuál es la velocidad de producción de estas máquinas? | Las máquinas pueden producir hasta 20-100 metros de perfiles por minutosegún el material y la complejidad. |

| ¿Pueden estas máquinas realizar diseños personalizados? | Sí, el utillaje modular permite crear perfiles militares a medida. |

| ¿Son eficientes desde el punto de vista energético? | Sí, incorporan motores de bajo consumo y flujos de trabajo optimizados para reducir los costes operativos. |

| ¿Qué industrias se benefician de estas máquinas? | Sectores de defensa, seguridad nacional y respuesta a emergencias. |

| ¿Cumplen estas máquinas las normas de seguridad? | Sí, cumplen las normas MIL-STD, STANAG de la OTAN y otras normas militares internacionales. |

| ¿Cuál es la vida útil de estas máquinas? | Con un mantenimiento adecuado, estas máquinas pueden durar 20-30 años o más. |

| ¿Se proporciona formación con la compra? | Sí, Wuxi Sunway ofrece formación completa y asistencia posventa a todos los clientes. |

| ¿Cuál es el precio de estas máquinas? | Los precios oscilan entre 500.000a500.000a500.000a5.000.000en función de las características y opciones de personalización. |

| ¿Pueden estas máquinas apoyar una producción sostenible? | Sí, están optimizados para minimizar los residuos y favorecer los materiales reciclables. |

¿Por qué elegir Maquinaria Wuxi Sunway para Máquinas Perfiladoras de Equipos Militares?

Maquinaria Wuxi Sunway se ha consolidado como un socio de confianza en la fabricación para defensa, ofreciendo soluciones innovadoras de perfilado adaptadas al sector militar. Estas son las razones por las que los contratistas de defensa eligen Sunway:

- Décadas de experiencia: Experiencia demostrada en el suministro de máquinas de alta calidad para aplicaciones militares.

- Alcance mundial: Fabricantes de defensa de Asia, Europa, Norteamérica y otros países confían en nosotros.

- Tecnología punta: Características como la integración de IoT, el utillaje modular y los sistemas de recubrimiento avanzados distinguen a sus máquinas.

- Compromiso de sostenibilidad: Máquinas diseñadas para minimizar el impacto medioambiental mediante la eficiencia energética y la manipulación de materiales reciclables.

- Apoyo integral: Desde el asesoramiento hasta la instalación y el servicio continuo, Wuxi Sunway garantiza a sus clientes un funcionamiento sin problemas.

Conclusiones: Construir defensas más sólidas con las perfiladoras

Máquinas perfiladoras de material militar están revolucionando la industria de defensa al permitir la producción de componentes de alto rendimiento, duraderos y fiables que satisfacen las exigencias de la guerra y la seguridad modernas. Estas máquinas desempeñan un papel fundamental en el refuerzo de las capacidades nacionales de defensa y el apoyo a escenarios de despliegue rápido.

¿Preparado para elevar su producción de equipos militares? Asóciese con Maquinaria Wuxi Sunway hoy mismo y explore sus soluciones de perfilado de vanguardia. Construyamos el futuro de la defensa, perfil a perfil.