La industria automotriz es un semillero de innovación, que evoluciona constantemente para satisfacer demandas de vehículos más livianos, resistentes y eficientes. En el corazón de esta evolución está el rol de la fabricación de precisión, y Máquinas perfiladoras de piezas de automóviles lideran la carga. Estas máquinas permiten la producción de componentes de alta calidad, duraderos y diseñados a medida que son críticos para los automóviles modernos.

En este artículo, nos sumergiremos en qué son las máquinas formadoras de rodillos para autopartes, sus aplicaciones, ventajas, precios, capacidades de automatización, beneficios ambientales y por qué Wuxi Sunway Machinery es un nombre confiable en la industria. Si es un fabricante que busca optimizar sus procesos de producción o un proveedor que apunta al próximo gran avance en tecnología automotriz, esta guía le proporcionará las perspectivas que necesita.

¿Qué son las máquinas formadoras de rodillos para autopartes?

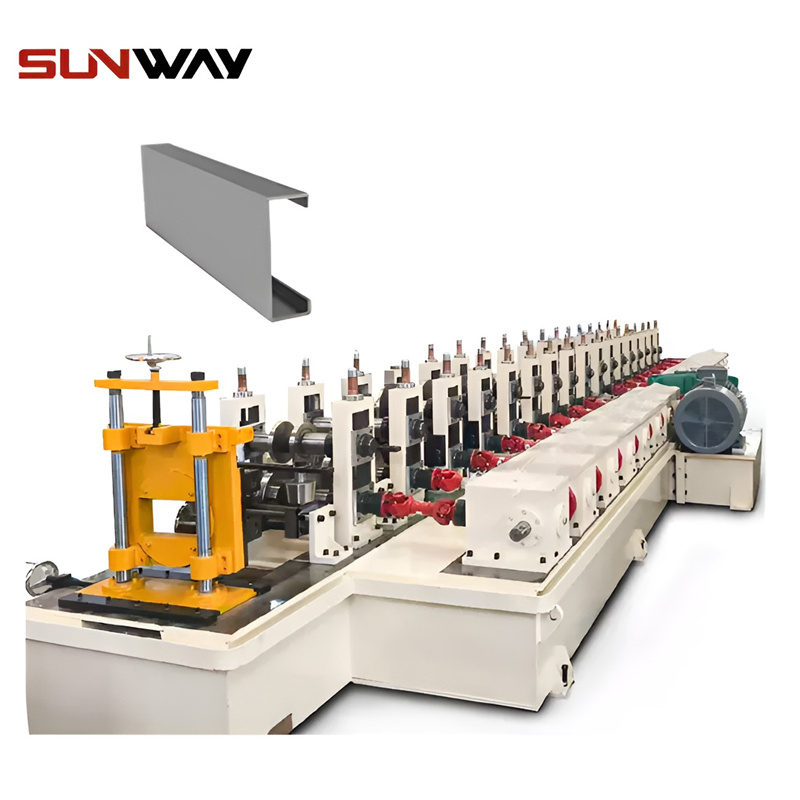

Máquinas perfiladoras de piezas de automóviles son sistemas industriales especializados diseñados para dar forma a láminas o bobinas de metal en perfiles específicos utilizados en la fabricación automotriz. Estas máquinas aprovechan un proceso de plegado continuo para crear componentes con precisión y eficiencia, permitiendo la producción en masa sin comprometer la calidad.

Características principales

- Alta precisión: Produce componentes con especificaciones exactas, asegurando compatibilidad con diseños de vehículos.

- Flexibilidad del material: Procesa materiales livianos pero resistentes como aluminio, acero de alta resistencia y acero galvanizado.

- Perfiles personalizados: Admite diseños diversos adaptados a diferentes modelos y aplicaciones de vehículos.

- Producción a alta velocidad: Satisface las demandas de la fabricación automotriz a gran escala.

- Prácticas respetuosas con el medio ambiente: Minimiza el desperdicio y el uso de energía, alineándose con objetivos de sostenibilidad.

Aplicaciones de las máquinas formadoras de rodillos para autopartes

Las máquinas formadoras de rodillos para autopartes son esenciales para producir una amplia gama de componentes que se incorporan en la construcción de autos, camiones y otros vehículos modernos. Estas son las principales aplicaciones:

1. Componentes estructurales automotrices

- Caso práctico: Fabricación de refuerzos estructurales como vigas de impacto lateral, rieles de techo y pilares B.

- Por qué es esencial: Mejora la seguridad del vehículo al crear componentes que absorben impactos y mejoran la integridad estructural.

2. Partes de chasis y bastidor

- Caso práctico: Producción de componentes de chasis, incluyendo travesaños, paneles de umbral y refuerzos de piso.

- Por qué es beneficioso: Asegura una base liviana pero resistente para los vehículos, mejorando el rendimiento y la eficiencia de combustible.

3. Marcos de puertas y ventanas

- Caso práctico: Creación de marcos de puertas de precisión, canales de ventanas y perfiles de sellado.

- Por qué es necesario: Garantiza un ajuste perfecto y durabilidad, contribuyendo a la estética y funcionalidad general del vehículo.

4. Bandejas de baterías para vehículos eléctricos

- Caso práctico: Fabricación de bandejas y carcasas para sistemas de baterías de VE.

- Por qué es único: Apoya el creciente mercado de vehículos eléctricos al proporcionar componentes livianos y resistentes a la corrosión.

5. Piezas de acabado y decorativas personalizadas

- Caso práctico: Producción de elementos de acabado personalizados, como molduras, burletes y perfiles de acento.

- Por qué es relevante: Realza el atractivo visual del vehículo manteniendo durabilidad y precisión.

6. Partes de suspensión y soporte

- Caso práctico: Fabricación de refuerzos de suspensión, soportes y soportes.

- Por qué es fundamental: Mejora la calidad de conducción y la estabilidad del vehículo al asegurar componentes de suspensión robustos y confiables.

Por qué las máquinas formadoras de rodillos para autopartes son indispensables

El sector automotriz está bajo presión constante para innovar, reducir costos y cumplir objetivos de sostenibilidad. Por eso Máquinas perfiladoras de piezas de automóviles son críticas para lograr estos objetivos:

1. Ingeniería de precisión

- Por qué es vital: Asegura que cada componente cumpla tolerancias de diseño estrictas, crucial para la seguridad y el rendimiento del vehículo.

2. Personalización para modelos diversos

- Por qué es beneficioso: Permite a los fabricantes producir piezas adaptadas a diseños de vehículos específicos, acomodando tanto modelos estándar como autos de lujo.

3. Escalabilidad

- Por qué es práctico: Habilita la producción a alta velocidad para satisfacer la creciente demanda de componentes automotrices en mercados globales.

4. Eficiencia de materiales

- Por qué es económico: Reduce el desperdicio de material mediante corte y conformado precisos, bajando los costos de producción generales.

5. Diseño liviano

- Por qué es relevante: Facilita la producción de componentes livianos que mejoran la eficiencia de combustible y reducen emisiones, alineándose con tendencias de la industria.

6. Sostenibilidad

- Por qué es importante: Apoya la fabricación ecológica al minimizar el consumo de energía y permitir el uso de materiales reciclables.

Características clave de las máquinas formadoras de rodillos para autopartes de Wuxi Sunway

Cuando se trata de tecnología de perfilado, Maquinaria Wuxi Sunway es un líder global. Sus Máquinas perfiladoras de piezas de automóviles están diseñadas para cumplir los más altos estándares de precisión, eficiencia e innovación. Esto es lo que las distingue:

1. Manipulación avanzada de materiales

- Materiales de apoyo:

- Acero de alta resistencia

- Acero galvanizado

- Aluminio

- Acero inoxidable

- Por qué es beneficioso: Asegura compatibilidad con materiales livianos y duraderos esenciales para la fabricación de vehículos modernos.

2. Sistemas modulares de utillaje

- Qué ofrece: Herramientas intercambiables para producir múltiples diseños de componentes en una sola máquina.

- Por qué es versátil: Admite diversas necesidades de fabricación sin requerir equipo adicional.

3. Corte y punzonado integrados

- Qué incluye: Sistemas integrados para corte de precisión, punzonado y entallado durante el proceso de perfilado.

- Por qué es eficaz: Reduce el tiempo de producción y asegura componentes listos para ensamblar.

4. Integración de IoT y automatización

- Qué permite: Supervisión en tiempo real, ajustes automatizados y mantenimiento predictivo mediante sistemas IoT.

- Por qué es revolucionario:

- Mejora la eficacia operativa.

- Minimiza el tiempo de inactividad y los costos de mantenimiento.

5. Producción a alta velocidad

- Lo que ofrece: Máquinas capaces de producir hasta 120 metros de componentes por minuto.

- Por qué es esencial: Sigue el ritmo de las demandas de alto volumen de la fabricación automotriz.

6. Diseño respetuoso con el medio ambiente

- Qué incluye: Motores energéticamente eficientes, flujos de trabajo optimizados y sistemas de reducción de residuos.

- Por qué es sostenible: Reduce el impacto ambiental de la fabricación de autopartes.

Precios de las máquinas formadoras de rodillos para autopartes

El coste de un Máquina formadora de rodillos para autopartes depende de factores como personalización, características avanzadas y capacidad de producción. A continuación, una guía general de precios para 2025:

| Tipo de máquina | Capacidades | Gama de precios (USD) |

|---|---|---|

| Máquinas estándar | Perfiles automotrices básicos | 150,000–150,000–150,000–400,000 |

| Máquinas avanzadas | Sistemas integrados de corte y punzonado de alta velocidad | 400.000–400.000–400.000–900.000 |

| Máquinas totalmente personalizables | Herramientas modulares compatibles con IoT y ecológicas | 900,000–900,000–900,000–2,500,000 |

Para precios específicos y opciones de financiamiento, conéctese con Maquinaria Wuxi Sunway.

Automatización en máquinas formadoras de rodillos para autopartes

La automatización está revolucionando la industria de fabricación automotriz, y las máquinas formadoras de rodillos para autopartes están a la vanguardia de esta transformación. Al aprovechar tecnología de última generación, estas máquinas entregan eficiencia y calidad superiores.

1. Control de la producción en tiempo real

- Lo que rastrea: Métricas clave como velocidad de producción, uso de material y tasas de defectos.

- Por qué es valioso: Ayuda a los fabricantes a optimizar los flujos de trabajo e identificar ineficiencias.

2. Mantenimiento predictivo

- Qué permite: Los sensores IoT controlan el desgaste de los componentes y predicen las necesidades de mantenimiento.

- Por qué es revolucionario:

- Evita averías inesperadas.

- Prolonga la vida útil de la máquina.

3. Ajustes automatizados

- Qué ofrece: Ajusta automáticamente rodillos, cortadores y punzonadoras para diferentes materiales o diseños.

- Por qué es eficaz: Reduce el tiempo de preparación y garantiza una calidad constante.

4. Control de calidad basado en IA

- Lo que detecta: Identifica los defectos en tiempo real y realiza los ajustes necesarios para mantener la calidad.

- Por qué es eficaz: Reduce los residuos y aumenta la satisfacción del cliente.

5. Control remoto y diagnóstico

- Qué incluye: Sistemas basados en la nube para supervisión, solución de problemas y control remotos.

- Por qué es conveniente: Permite a los operarios supervisar la producción y resolver problemas desde cualquier lugar.

Beneficios ambientales de las máquinas formadoras de rodillos para piezas de automóvil

La sostenibilidad es un enfoque central para la industria automotriz, y Máquinas perfiladoras de piezas de automóviles están diseñadas para respaldar prácticas ecológicas.

1. Reducción del desperdicio de material

- Cómo se consigue: La ingeniería de precisión minimiza el desperdicio de material durante el proceso de fabricación.

- Impacto: Conserva recursos y reduce los residuos en vertederos.

2. Eficiencia energética

- Cómo funciona: Equipadas con motores eficientes en energía y flujos de trabajo optimizados para reducir el consumo eléctrico.

- Impacto: Reduce la huella de carbono de la fabricación automotriz.

3. Uso de materiales reciclables

- En qué consiste: Procesa metales reciclables como el aluminio y el acero galvanizado.

- Impacto: Promueve una economía circular y reduce la extracción de recursos.

4. Componentes duraderos

- Por qué es importante: Produce componentes de alta calidad diseñados para durar, reduciendo la necesidad de reemplazos frecuentes.

- Impacto: Apoya la producción sostenible de vehículos al extender la vida útil de las piezas.

Preguntas frecuentes sobre las máquinas formadoras de rodillos para piezas de automóvil

| Pregunta | Respuesta |

|---|---|

| ¿Qué materiales pueden procesar estas máquinas? | Acero de alta resistencia, aluminio, acero galvanizado y acero inoxidable. |

| ¿Cuál es la velocidad de producción? | Hasta 120 metros por minutosegún el material y la complejidad del perfil. |

| ¿Son ecológicas estas máquinas? | Sí, incluyen motores de bajo consumo y minimizan el desperdicio de material. |

| ¿Pueden estas máquinas realizar diseños personalizados? | ¡Absolutamente! Las herramientas modulares permiten perfiles personalizados para diversas aplicaciones automotrices. |

| ¿Cuál es el precio de estas máquinas? | Los precios oscilan entre 150.000a150.000a150.000a2.500.000en función de las características y la personalización. |

| ¿Se integran estas máquinas con los sistemas IoT? | Sí, las funciones habilitadas para IoT permiten la supervisión en tiempo real y el mantenimiento predictivo. |

Historias de éxito reales: Máquinas formadoras de rodillos para piezas de automóvil en acción

Las capacidades transformadoras de Máquinas perfiladoras de piezas de automóviles han permitido a fabricantes de todo el mundo innovar y escalar sus líneas de producción automotriz. A continuación, se presentan algunos ejemplos reales de cómo estas máquinas han revolucionado las operaciones.

1. Bandejas de baterías para vehículos eléctricos de un fabricante líder

Cliente: Una marca global de vehículos eléctricos (EV).

Desafío: El fabricante requería bandejas de baterías ligeras y resistentes a la corrosión para su próxima línea de EV.

Solución: Wuxi Sunway suministró una máquina formadora de rodillos diseñada para procesar aluminio y acero galvanizado con punzonado integrado para ranuras y orificios.

Resultado:

- Redujo el peso de las bandejas de baterías en un 20 %, mejorando el alcance del vehículo.

- Aumentó la velocidad de producción en un 30 %, cumpliendo con plazos ajustados para el lanzamiento del vehículo eléctrico.

- Mejoró la reputación de la empresa como pionera en soluciones automovilísticas sostenibles.

2. Componentes estructurales para un fabricante de camiones comerciales en Norteamérica

Cliente: Un fabricante líder de camiones.

Desafío: La empresa necesitaba componentes de chasis de alta resistencia capaces de soportar cargas elevadas y condiciones adversas.

Solución: Wuxi Sunway suministró una máquina formadora de rodillos de acero de alta resistencia con herramientas avanzadas para perfiles reforzados.

Resultado:

- Entregó componentes de chasis con una resistencia y durabilidad superiores.

- Redujo el desperdicio de material en un 18 %, disminuyendo los costos de producción.

- Mejoró el rendimiento y la fiabilidad del camión, incrementando la satisfacción del cliente.

3. Perfiles de molduras personalizados para una marca de automóviles de lujo en Europa

Cliente: Un fabricante de automóviles de lujo especializado en vehículos a medida.

Desafío: El fabricante requería elementos de moldura diseñados a medida para realzar la estética de sus vehículos premium.

Solución: Wuxi Sunway suministró una máquina formadora de rodillos con herramientas modulares para diseños intrincados y acabados decorativos.

Resultado:

- Permitió la creación de perfiles de molduras únicos y de alta calidad.

- Aumentó la capacidad del fabricante de automóviles para ofrecer opciones de diseño personalizadas a sus clientes.

- Elevó el posicionamiento de la marca en el segmento de automóviles de lujo.

4. Componentes de suspensión ligeros para un proveedor automotriz asiático

Cliente: Un proveedor de nivel 1 para múltiples fabricantes de automóviles globales.

Desafío: El proveedor necesitaba componentes de suspensión ligeros pero duraderos para mejorar la eficiencia de combustible del vehículo.

Solución: Wuxi Sunway entregó una máquina adaptada para procesar acero de alta resistencia con funciones integradas de corte y punzonado.

Resultado:

- Redujo el peso de los componentes en un 15 %, contribuyendo a una mejor eficiencia de combustible.

- Aumentó la capacidad de producción en un 40 %, permitiendo al proveedor satisfacer la creciente demanda.

- Fortaleció la asociación del proveedor con los principales fabricantes de automóviles.

Solución de problemas comunes en las máquinas formadoras de rodillos para piezas de automóvil

Incluso los más avanzados Máquinas perfiladoras de piezas de automóviles pueden enfrentar desafíos operativos. A continuación, se presentan algunos problemas comunes y sus soluciones para mantener su línea de producción funcionando sin interrupciones.

1. Perfiles inconsistentes

- Síntomas: Los componentes producidos tienen dimensiones desiguales o no cumplen con las especificaciones de diseño.

- Posibles causas:

- Rodillos desalineados o herramientas desgastadas.

- Alimentación incorrecta de material.

- Solución:

- Inspeccione y realinee los rodillos regularmente.

- Asegure una alimentación adecuada del material calibrando guías y alimentadores.

2. Atasco de material

- Síntomas: El material se atasca en los rodillos, deteniendo la producción.

- Posibles causas:

- El grosor del material excede la capacidad de la máquina.

- Residuos o cuerpos extraños en el área de conformado.

- Solución:

- Verifique que los materiales cumplan con las especificaciones de la máquina.

- Limpie los rodillos y guías antes de cada corrida de producción.

3. Desgaste excesivo de herramientas

- Síntomas: Las herramientas de corte y punzonado se desgastan rápidamente, afectando la calidad de producción.

- Posibles causas:

- Materias primas de baja calidad.

- Lubricación inadecuada de las partes móviles.

- Solución:

- Utilice materiales de alta calidad para minimizar el desgaste de las herramientas.

- Implemente un programa de mantenimiento regular para limpiar y lubricar los componentes.

4. Vibraciones de la máquina

- Síntomas: Ruido y vibraciones excesivas durante la operación.

- Posibles causas:

- Componentes sueltos o rodillos desequilibrados.

- Operar la máquina más allá de su capacidad recomendada.

- Solución:

- Apriete todos los componentes y equilibre los rodillos.

- Opere la máquina dentro de los límites especificados.

5. Mal funcionamiento del software

- Síntomas: El sistema de control se congela o no ejecuta comandos.

- Posibles causas:

- Software o firmware obsoletos.

- Averías eléctricas en el panel de control.

- Solución:

- Actualice el software a la versión más reciente.

- Inspeccione y repare cualquier cableado o componentes defectuosos en el panel de control.

Tendencias globales de la industria para máquinas formadoras de rodillos de piezas de automóvil en 2025

La industria automotriz está experimentando un cambio de paradigma impulsado por avances en tecnología, sostenibilidad y preferencias del consumidor. Estas son las tendencias clave que están moldeando el mercado para Máquinas perfiladoras de piezas de automóviles:

1. Transición a vehículos eléctricos (VE)

- Tendencia: El cambio global hacia los VE está impulsando la demanda de componentes ligeros y resistentes a la corrosión.

- Impacto: Las máquinas formadoras de rodillos diseñadas para aluminio y otros materiales ligeros están en alta demanda.

2. Énfasis en la sostenibilidad

- Tendencia: Los fabricantes de automóviles están adoptando prácticas ecológicas para cumplir con estrictos estándares globales de emisiones.

- Impacto: Las máquinas que minimizan los residuos y permiten el uso de materiales reciclables se están convirtiendo en estándares de la industria.

3. Auge de la personalización

- Tendencia: Los consumidores buscan diseños de vehículos personalizados, lo que impulsa la demanda de componentes a medida.

- Impacto: Las máquinas formadoras de rodillos modulares capaces de producir perfiles personalizados están ganando terreno.

4. Integración en fábricas inteligentes

- Tendencia: La adopción de tecnologías de la Industria 4.0 está reconfigurando la fabricación automotriz.

- Impacto: Las máquinas formadoras de rodillos habilitadas para IoT con monitoreo en tiempo real y mantenimiento predictivo lideran el cambio.

5. Crecimiento en materiales ligeros

- Tendencia: El uso de acero de alta resistencia, aluminio y compuestos está aumentando para mejorar la eficiencia de combustible.

- Impacto: Las máquinas optimizadas para estos materiales son esenciales para satisfacer las necesidades automotrices futuras.

Capacidades avanzadas de automatización en máquinas formadoras de rodillos para piezas de automóvil

La automatización es la base de la fabricación moderna, y Máquinas perfiladoras de piezas de automóviles no son una excepción. He aquí algunas funciones de automatización de vanguardia:

1. Manejo adaptativo de materiales

- Qué hace: Ajusta automáticamente la configuración según el material que se procesa.

- Por qué es revolucionario: Reduce el tiempo de configuración y asegura una calidad consistente en diferentes materiales.

2. Detección inteligente de defectos

- Qué incluye: Sistemas impulsados por IA que detectan defectos superficiales, desalineaciones o errores dimensionales en tiempo real.

- Por qué es eficaz: Minimiza los residuos y reduce la necesidad de inspecciones manuales.

3. Producción multiperfil

- Qué permite: Cambio fluido entre diferentes perfiles de componentes en una sola corrida de producción.

- Por qué es conveniente: Mejora la flexibilidad y soporta diversos requisitos de fabricación.

4. Análisis en la nube

- Lo que rastrea: Métricas de producción, rendimiento de las máquinas y programas de mantenimiento.

- Por qué es valioso: Proporciona información práctica para optimizar las operaciones y evitar tiempos de inactividad.

Impacto ambiental de las máquinas formadoras de rodillos para piezas de automóvil

La sostenibilidad es un enfoque creciente en la industria automotriz, y Máquinas perfiladoras de piezas de automóviles están diseñadas para alinearse con estos objetivos. Así es como contribuyen a una fabricación ecológica:

1. Uso eficiente de materiales

- Cómo se consigue: La ingeniería de precisión reduce los desechos y asegura un uso óptimo de las materias primas.

- Impacto: Conserva los recursos y reduce los costes de producción.

2. Eficiencia energética

- Cómo funciona: Las máquinas están equipadas con motores eficientes en energía y funciones de ahorro de potencia.

- Impacto: Reduce el consumo de energía y la huella de carbono de la fabricación.

3. Apoyo a los materiales reciclables

- Qué permite: Procesa materiales como aluminio y acero galvanizado, que son fácilmente reciclables.

- Impacto: Fomenta las prácticas sostenibles y promueve una economía circular.

4. Salidas de larga duración

- Por qué es importante: Produce componentes automotrices duraderos que reducen la necesidad de reemplazos frecuentes.

- Impacto: Apoya la fabricación sostenible de vehículos al extender la vida útil de las piezas.

Por qué Wuxi Sunway Machinery lidera la industria de formadoras de rodillos

Con décadas de experiencia y un compromiso con la innovación, Maquinaria Wuxi Sunway se ha establecido como líder global en tecnología de formadoras de rodillos. Estas son las razones por las que siguen estableciendo el estándar:

- Experiencia global: Fabricantes de Asia, Europa, América y otros continentes confían en nosotros.

- Soluciones personalizables: Ofrece máquinas adaptadas a necesidades de producción específicas.

- Enfoque de sostenibilidad: Diseña máquinas ecológicas alineadas con objetivos ambientales globales.

- Apoyo integral: Proporciona servicios integrales, desde la consulta hasta el soporte postventa.

- Innovación probada: Incorpora tecnologías de vanguardia como IoT, IA y herramientas modulares en sus máquinas.

Descubra más sobre sus productos en el sitio web oficial.

Preguntas frecuentes sobre las máquinas formadoras de rodillos para piezas de automóvil

| Pregunta | Respuesta |

|---|---|

| ¿Qué materiales pueden procesar estas máquinas? | Acero de alta resistencia, aluminio, acero galvanizado y acero inoxidable. |

| ¿Cuál es la velocidad de producción? | Hasta 120 metros por minutosegún el material y la complejidad del perfil. |

| ¿Son ecológicas estas máquinas? | Sí, incluyen motores de bajo consumo y minimizan el desperdicio de material. |

| ¿Pueden estas máquinas realizar diseños personalizados? | ¡Absolutamente! Las herramientas modulares permiten perfiles personalizados para diversas aplicaciones automotrices. |

| ¿Cuál es el precio de estas máquinas? | Los precios oscilan entre 150.000a150.000a150.000a2.500.000en función de las características y la personalización. |

| ¿Se integran estas máquinas con los sistemas IoT? | Sí, las funciones habilitadas para IoT permiten la supervisión en tiempo real y el mantenimiento predictivo. |

Conclusión: Acelerando la industria automotriz con tecnología de formadoras de rodillos

Máquinas perfiladoras de piezas de automóviles están moldeando el futuro de la fabricación automotriz al habilitar precisión, eficiencia y sostenibilidad. Desde componentes ligeros para VE hasta molduras de lujo personalizadas, estas máquinas son esenciales para satisfacer las demandas de una industria en rápida evolución.

¿Está listo para impulsar la innovación en su línea de producción? Aliéntese con Maquinaria Wuxi Sunway y explore sus soluciones de formadoras de rodillos de última generación para el sector automotriz. Juntos, aceleremos el futuro del transporte: una pieza a la vez.