La demanda de perfiles de aluminio ligeros, duraderos y versátiles se está disparando en sectores como la construcción, la automoción, la electrónica y las energías renovables. Desde elegantes diseños arquitectónicos hasta robustas estructuras industriales, los perfiles de aluminio son componentes esenciales de la infraestructura y la tecnología modernas. Pero, ¿cómo se fabrican estos intrincados perfiles con tanta precisión y escala? La respuesta está en Perfiladoras de aluminio-una tecnología innovadora que permite una producción de alta velocidad, rentable y respetuosa con el medio ambiente.

En esta completa guía, profundizaremos en los características, aplicaciones, precios, tendencias mundiales, innovaciones y por qué Wuxi Sunway Machinery es líder mundial en soluciones de perfilado de aluminio.. Tanto si es usted un profesional del sector como si está explorando lo último en tecnología de fabricación, este artículo le proporcionará información práctica.

¿Qué son las máquinas perfiladoras de perfiles de aluminio?

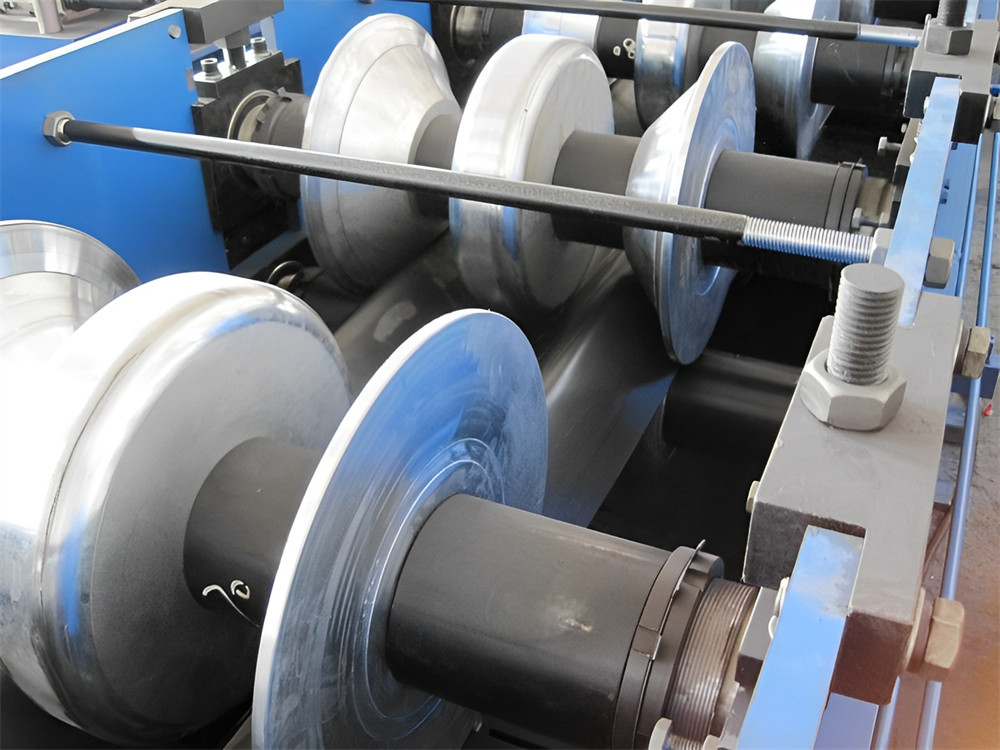

Un Máquina Perfiladora de Aluminio es un equipo especializado diseñado para fabricar perfiles de aluminio precisos y personalizados alimentando láminas o bobinas de aluminio a través de una serie de rodillos. Estos rodillos moldean gradualmente el material en el perfil de sección transversal deseado, garantizando la consistencia, precisión y durabilidad.

Características principales

- Versatilidad de materiales: Las máquinas están optimizadas para procesar diversos grados de aluminio, incluido el aluminio revestido, anodizado y en bruto.

- Producción a alta velocidad: Capaz de producir perfiles complejos a velocidades de hasta 100 metros por minuto.

- Ingeniería de precisión: Mantiene tolerancias estrictas para garantizar que cada perfil se adapte perfectamente a la aplicación prevista.

- Diseños personalizables: Admite la creación de perfiles únicos para satisfacer requisitos específicos del proyecto.

- Operaciones respetuosas con el medio ambiente: Reduce el desperdicio de material y el consumo de energía, en línea con los objetivos de sostenibilidad.

Aplicaciones de las maquinas perfiladoras de aluminio

Estas máquinas son indispensables para fabricar componentes de aluminio que se utilizan en infinidad de industrias. He aquí un desglose de sus principales aplicaciones:

1. Construcción y arquitectura

- Caso práctico: Producción de perfiles de aluminio para muros cortina, marcos de ventanas, marcos de puertas y marcos estructurales.

- Por qué es esencial: Garantiza componentes ligeros, resistentes a la corrosión y fáciles de instalar y mantener.

2. Industria del automóvil

- Caso práctico: Fabricación de componentes como barras de techo, quitamiedos y perfiles embellecedores.

- Por qué es fundamental: Proporciona piezas ligeras pero duraderas que mejoran el rendimiento del vehículo y la eficiencia del combustible.

3. Energía renovable

- Caso práctico: Fabricación de sistemas de montaje y soportes para paneles solares y turbinas eólicas.

- Por qué es relevante: Apoya el sector de las energías renovables con componentes duraderos y resistentes a la intemperie.

4. Electrónica y electrodomésticos

- Caso práctico: Fabricación de disipadores térmicos, carcasas y componentes estructurales para dispositivos eléctricos.

- Por qué es beneficioso: Garantiza perfiles precisos y de alta calidad para aplicaciones electrónicas sensibles.

5. Mobiliario y diseño de interiores

- Caso práctico: Creación de perfiles para muebles modulares, molduras decorativas y sistemas de tabiques.

- Por qué es único: Diseños estéticos y funcionales para interiores modernos.

6. Infraestructuras de transporte

- Caso práctico: Fabricación de perfiles para vías de ferrocarril, pasarelas de aeropuertos y puentes peatonales.

- Por qué es valioso: Ofrece soluciones ligeras que reducen el tiempo y los costes de instalación.

Por qué las perfiladoras de aluminio están ganando popularidad

La versatilidad y eficacia del aluminio lo convierten en el material preferido en todos los sectores, y Perfiladoras de aluminio se adaptan perfectamente a la creciente demanda. He aquí por qué son indispensables:

1. Ligero y duradero

- Por qué es importante: Los perfiles de aluminio son resistentes a la vez que ligeros, lo que los hace ideales para aplicaciones en las que la reducción de peso es crucial, como en las industrias automovilística y aeroespacial.

2. Resistencia a la corrosión

- Por qué es fundamental: Los perfiles de aluminio resisten condiciones ambientales adversas, por lo que son perfectos para aplicaciones exteriores como la construcción y los sistemas de energías renovables.

3. Personalización

- Por qué es beneficioso: Las perfiladoras pueden producir perfiles de distintas formas, tamaños y acabados, atendiendo a diversas necesidades de la industria.

4. Fabricación respetuosa con el medio ambiente

- Por qué es esencial: El aluminio es altamente reciclable, y las máquinas de perfilado minimizan los residuos, apoyando prácticas de producción sostenibles.

5. Alta eficiencia de producción

- Por qué es necesario: Las perfiladoras están diseñadas para funcionar en continuo, lo que permite a los fabricantes satisfacer las demandas de grandes volúmenes sin comprometer la calidad.

Características principales de las maquinas perfiladoras de aluminio Wuxi Sunway

Maquinaria Wuxi Sunway es un nombre de confianza en la industria del perfilado, que ofrece soluciones de vanguardia para la fabricación de perfiles de aluminio. He aquí por qué destacan sus máquinas:

1. Manipulación avanzada de materiales

- Materiales de apoyo:

- Aluminio bruto

- Aluminio anodizado

- Aluminio revestido

- Por qué es beneficioso: Garantiza la compatibilidad con diversos materiales para aplicaciones versátiles.

2. Ingeniería de precisión

- Rendimiento: Alcanza tolerancias tan bajas como ±0,02 mm, lo que garantiza unas dimensiones exactas.

- Por qué es importante: Garantiza un montaje perfecto y la compatibilidad con otros componentes.

3. Sistemas modulares de utillaje

- Qué ofrece: Herramientas intercambiables para producir varios perfiles en una sola máquina.

- Por qué es valioso: Reduce el tiempo de inactividad durante los cambios de utillaje y aumenta la flexibilidad de la producción.

4. Integración de IoT y automatización

- Qué permite: Supervisión en tiempo real, ajustes automatizados y mantenimiento predictivo mediante sistemas IoT.

- Por qué es revolucionario:

- Mejora la eficacia de la producción.

- Reduce los costes operativos.

5. Funcionamiento a alta velocidad

- Rendimiento: Produce perfiles a velocidades de hasta 100 metros por minuto.

- Por qué es necesario: Satisface las demandas de gran volumen de industrias como la construcción y la automoción.

6. Diseño respetuoso con el medio ambiente

- Qué incluye: Motores energéticamente eficientes, reducción de los residuos de material y apoyo al aluminio reciclable.

- Por qué es esencial: Se ajusta a los objetivos mundiales de sostenibilidad y reduce la huella de carbono de la fabricación.

7. Corte y punzonado integrados

- Qué ofrece: Sistemas integrados para cortar y perforar chapas de aluminio durante el proceso de perfilado.

- Por qué es eficaz: Acelera la producción y garantiza componentes listos para usar.

Precios de Máquinas Perfiladoras de Aluminio

El coste de un Máquina Perfiladora de Aluminio depende de sus características, capacidad y nivel de personalización. A continuación se ofrece una guía general de precios para 2025:

| Tipo de máquina | Capacidades | Gama de precios (USD) |

|---|---|---|

| Máquinas estándar | Producción básica de perfiles de aluminio | 150,000–150,000–150,000–400,000 |

| Máquinas avanzadas | Sistemas integrados de corte y punzonado de alta velocidad | 400,000–400,000–400,000–1,000,000 |

| Máquinas totalmente personalizables | IoT, herramientas modulares y funciones ecológicas | 1,000,000–1,000,000–1,000,000–2,500,000 |

Para obtener información detallada sobre precios y opciones de financiación, póngase en contacto con Maquinaria Wuxi Sunway.

Innovaciones en la tecnología de perfilado de aluminio

La industria del perfilado evoluciona rápidamente, con nuevas tecnologías que mejoran las capacidades de Perfiladoras de aluminio. He aquí las últimas innovaciones:

1. Tecnología Digital Twin

- Lo que simula: Modelos virtuales del proceso de perfilado para optimizar los ajustes de la máquina.

- Por qué es revolucionario:

- Reduce el tiempo de configuración y los ajustes de prueba y error.

- Garantiza una calidad constante desde la primera tirada de producción.

2. Control de calidad basado en IA

- Qué hace: Supervisa las dimensiones, la calidad de la superficie y el grosor del material en tiempo real.

- Por qué cambia el juego:

- Detecta los defectos a tiempo, reduciendo los residuos.

- Mejora la calidad general del producto.

3. Capacidad multiperfil

- Qué permite: Produce varios perfiles en un solo ciclo de producción.

- Por qué es beneficioso:

- Aumenta la velocidad de producción.

- Admite diversas necesidades de fabricación.

4. Integración de IoT

- Qué ofrece: Recogida de datos en tiempo real, mantenimiento predictivo y ajustes automatizados.

- Por qué es fundamental:

- Mejora el tiempo de actividad de la máquina.

- Reduce los costes de mantenimiento.

5. Sistemas de revestimiento ecológicos

- Qué incluye: Sistemas de aplicación de revestimientos protectores o decorativos durante el proceso de perfilado.

- Por qué es sostenible:

- Elimina los procesos de revestimiento adicionales.

- Reduce el consumo de energía.

Preguntas frecuentes acerca de las maquinas perfiladoras de aluminio

| Pregunta | Respuesta |

|---|---|

| ¿Qué materiales pueden procesar estas máquinas? | Aluminio (bruto, anodizado, revestido) y otros metales ligeros. |

| ¿Cuál es la velocidad de producción? | Hasta 100 metros por minutoen función de la complejidad del perfil. |

| ¿Son ecológicas estas máquinas? | Sí, incluyen motores de bajo consumo y minimizan el desperdicio de material. |

| ¿Pueden estas máquinas realizar diseños personalizados? | Por supuesto. El utillaje modular admite perfiles a medida para diversas aplicaciones. |

| ¿Cumplen estas máquinas las normas de seguridad? | Sí, cumplen las certificaciones CE, ISO y OSHA de seguridad y fiabilidad. |

| ¿Pueden estas máquinas integrarse con los sistemas IoT? | Sí, las funciones habilitadas para IoT permiten la supervisión en tiempo real y el mantenimiento predictivo. |

Casos de éxito reales: Perfiladoras de aluminio en acción

La versatilidad y eficacia de Perfiladoras de aluminio son evidentes en su aplicación en diversos sectores. He aquí algunos ejemplos reales que ilustran su impacto transformador:

1. Estudio de caso: Infraestructura de energía solar

- Cliente: Empresa de energía solar que gestiona grandes parques solares en Norteamérica.

- Desafío: La empresa necesitaba sistemas de montaje ligeros pero duraderos para los paneles solares que pudieran soportar condiciones meteorológicas extremas.

- Solución: Wuxi Sunway Machinery proporcionó una perfiladora capaz de procesar aluminio anodizado e integrar perfiles personalizados para los soportes de montaje.

- Resultados:

- Aumento de la producción en 35%, lo que permite una instalación más rápida de los parques solares.

- Componentes resistentes a la corrosión con dimensiones precisas.

- Reducción de los residuos de material en 20%, en línea con los objetivos de sostenibilidad de la empresa.

2. Estudio de caso: Proveedor de componentes de automoción

- Cliente: Proveedor líder de piezas de aluminio para vehículos eléctricos (VE) en Europa.

- Desafío: El cliente necesitaba perfiles de aluminio ligeros y de alta resistencia para las carcasas de las baterías de los vehículos eléctricos y los quitamiedos.

- Solución: Wuxi Sunway ha desarrollado una perfiladora con capacidades integradas de corte y punzonado para aleaciones de alta resistencia.

- Resultados:

- Reducción de los plazos de producción en 40%.

- Suministró componentes que mejoraron la eficiencia energética y la seguridad de los vehículos.

- Permitió al cliente ampliar su cartera de productos y conseguir nuevos contratos.

3. Estudio de caso: Estudio de arquitectura

- Cliente: Empresa constructora especializada en diseños arquitectónicos modernos en Oriente Medio.

- Desafío: La empresa necesitaba perfiles de aluminio a medida para muros cortina y molduras decorativas que pudieran soportar altas temperaturas y la exposición a la arena.

- Solución: Wuxi Sunway suministró una perfiladora optimizada para aluminio prerrevestido con acabados superficiales avanzados.

- Resultados:

- Produjo perfiles elegantes y resistentes a la intemperie que cumplían los requisitos estéticos y funcionales del proyecto.

- Reducción de los costes de producción en 25% en comparación con los métodos de fabricación tradicionales.

- Aumento de la reputación de la empresa por sus proyectos arquitectónicos de alta calidad.

4. Estudio de caso: Fabricante de muebles modulares

- Cliente: Fabricante de muebles especializado en diseños modulares y personalizables.

- Desafío: La empresa necesitaba perfiles de aluminio ligeros y fáciles de montar para sus sistemas de mobiliario.

- Solución: Wuxi Sunway suministró una perfiladora con utillaje modular para crear diversos diseños de perfiles.

- Resultados:

- Mayor flexibilidad de producción, lo que permite a la empresa adaptarse a la evolución de las preferencias de los clientes.

- Componentes entregados con un acabado impecable, lo que aumenta el atractivo del producto en el mercado.

- Reducción de los residuos de producción, apoyando las iniciativas ecológicas de la empresa.

Prácticas sostenibles en la fabricación de perfiles de aluminio

La sostenibilidad es un aspecto clave en la fabricación moderna, y Perfiladoras de aluminio están diseñados para apoyar las prácticas respetuosas con el medio ambiente. He aquí cómo contribuyen a un futuro más verde:

1. Operaciones energéticamente eficientes

- Cómo se consigue: Los motores avanzados y los flujos de trabajo optimizados reducen el consumo eléctrico.

- Impacto: Reduce la huella de carbono de los procesos de fabricación, en consonancia con los objetivos mundiales de sostenibilidad.

2. Reducción del desperdicio de material

- Cómo se consigue: Los sistemas de corte y conformado de precisión minimizan los desechos durante la producción.

- Impacto: Conserva las materias primas y reduce los costes de producción.

3. Apoyo a los materiales reciclables

- Cómo se consigue: Las máquinas están diseñadas para procesar materiales de aluminio reciclables.

- Impacto: Promueve la reutilización de materiales, la reducción de residuos y el apoyo a las prácticas de economía circular.

4. Componentes duraderos

- Por qué es importante: Los duraderos perfiles de aluminio requieren sustituciones menos frecuentes, lo que reduce el consumo total de material.

- Impacto: Prolonga el ciclo de vida de los productos, minimizando el impacto medioambiental.

5. Integración del revestimiento

- Cómo se consigue: Las máquinas admiten revestimientos ecológicos que mejoran la durabilidad y la estética de los perfiles de aluminio.

- Impacto: Elimina la necesidad de procesos de revestimiento adicionales, reduciendo el consumo de energía.

Normas de seguridad para perfiladoras de aluminio

La seguridad es primordial en la fabricación, y Perfiladoras de aluminio están equipados con funciones avanzadas para proteger a los operadores y garantizar el cumplimiento de las normas mundiales.

1. Sistemas de parada de emergencia

- Qué hace: Permite a los operarios detener el funcionamiento de la máquina al instante en caso de emergencia.

- Por qué es fundamental: Evita accidentes y minimiza los daños en los equipos durante incidentes imprevistos.

2. Protecciones y escudos de seguridad

- Qué incluye: Barreras protectoras alrededor de las piezas móviles para evitar el contacto accidental.

- Por qué es importante: Reduce el riesgo de lesiones causadas por errores humanos o fallos mecánicos.

3. Cortinas de luz

- Lo que detecta: Identifica objetos o personal en zonas peligrosas y detiene automáticamente las operaciones de la máquina.

- Por qué es eficaz: Mejora la seguridad sin interrumpir los flujos de trabajo de producción.

4. Reducción de ruidos y vibraciones

- Lo que reduce: Minimiza los niveles de ruido y las vibraciones durante el funcionamiento.

- Por qué es beneficioso: Crea un entorno de trabajo más seguro y cómodo para los operarios.

5. Cumplimiento de las normas mundiales

- Certificaciones: Las máquinas cumplen las normas CE, ISO 45001 y OSHA de seguridad y protección medioambiental.

- Por qué es esencial: Garantiza la fiabilidad y la seguridad en diversos mercados mundiales.

Tendencias del mercado mundial de perfiladoras de aluminio en 2025

A medida que las industrias se adaptan a las demandas cambiantes y a los avances tecnológicos, el mercado de Perfiladoras de aluminio sigue creciendo. He aquí las principales tendencias que impulsan el crecimiento:

1. Aumento de la adopción de energías renovables

- Tendencia: El crecimiento del sector de las energías renovables está impulsando la demanda de perfiles de aluminio ligeros y resistentes a la corrosión.

- Impacto: Las perfiladoras capaces de producir sistemas de montaje de paneles solares y componentes de aerogeneradores están muy solicitadas.

2. Expansión de la industria del automóvil

- Tendencia: El auge de los vehículos eléctricos está impulsando la necesidad de componentes ligeros de aluminio.

- Impacto: Los fabricantes necesitan perfiladoras de gran capacidad para cumplir sus objetivos de producción.

3. Crecimiento de la urbanización y desarrollo de infraestructuras

- Tendencia: La rápida urbanización está aumentando la demanda de materiales de construcción como marcos, puertas y ventanas de aluminio.

- Impacto: Las perfiladoras diseñadas para aplicaciones arquitectónicas son cada vez más esenciales.

4. Hacia una fabricación sostenible

- Tendencia: Las empresas están adoptando prácticas ecológicas para satisfacer las expectativas de los consumidores y los requisitos normativos.

- Impacto: Las máquinas optimizadas para la eficiencia energética y los materiales reciclables están ganando terreno.

5. Integración con la industria 4.0

- Tendencia: La adopción de IoT y AI en la fabricación está impulsando la demanda de máquinas inteligentes de perfilado.

- Impacto: Las máquinas con funciones de supervisión en tiempo real y mantenimiento predictivo se están convirtiendo en estándares del sector.

¿Por qué elegir Maquinaria Wuxi Sunway para Máquinas Perfiladoras de Aluminio?

Maquinaria Wuxi Sunway es un líder mundial en tecnología de perfilado en el que confían fabricantes de todos los sectores. A continuación le explicamos por qué es el socio de referencia para la producción de perfiles de aluminio:

- Experiencia demostrada: Décadas de experiencia en el diseño de perfiladoras de alto rendimiento.

- Alcance mundial: Las máquinas se utilizan con éxito en Asia, Europa, América y otros continentes.

- Impulsada por la innovación: Características como la integración de IoT, las herramientas modulares y el control de calidad basado en IA distinguen a sus máquinas.

- Compromiso de sostenibilidad: Las máquinas están optimizadas para una producción respetuosa con el medio ambiente, apoyando los objetivos de sostenibilidad global.

- Apoyo integral: Desde la consulta hasta el servicio posventa, Wuxi Sunway garantiza una experiencia sin fisuras.

Conclusiones: Perfilar el futuro de la fabricación con perfiles de aluminio

Perfiladoras de aluminio están revolucionando la fabricación moderna al combinar precisión, eficiencia y sostenibilidad. Su versatilidad las hace indispensables para sectores que van desde la construcción y la automoción hasta las energías renovables y la electrónica.

¿Está listo para transformar sus procesos de fabricación? Asóciese con Maquinaria Wuxi Sunway y explore sus innovadoras soluciones de perfilado adaptadas a sus necesidades. Juntos, daremos forma a un futuro más inteligente y sostenible, perfil a perfil.