Introducción

¿Alguna vez se ha preguntado cómo se fabrican perfiles metálicos largos y uniformes como chapas para techos, perlins C y Z, y barreras de carretera? La respuesta radica en el proceso de perfiladoproceso de formado por rodillos, un método eficiente y de alta velocidad para dar forma al metal utilizado en múltiples industrias.

A máquina formadora de rollos La máquina formadora por rodillos está diseñada para dar forma progresivamente a las chapas metálicas al pasarlas por una serie de rodillos de precisiónrodillos. A diferencia de los métodos tradicionales de plegado de metal, el formado por rodillos minimiza el desperdicio de material, reduce los costos laborales y mejora la eficiencia de producción..

En esta guía trataremos:

✅ Cómo funciona una máquina formadora por rodillos

✅ Componentes clave de un sistema de formado por rodillos

✅ Proceso de formado por rodillos paso a paso

✅ Tipos de máquinas perfiladoras

✅ Ventajas del formado por rodillos frente a otros métodos de conformado de metales

Sumergámonos en la mecánica detrás de ¡uno de los procesos de conformado de metales más eficientes en la fabricación moderna!

¿Cómo funciona una máquina formadora de rollos?

A máquina formadora de rollos opera mediante el plegado gradual de una banda metálica hasta una forma específica a través de múltiples estaciones secuenciales de rodillos. En lugar de plegar el metal de una sola vez (como en el plegado por prensa), el formado por rodillos aplica plegados incrementales a lo largo de varias etapas de rodillos, garantizando un conformado suave y preciso.

Principio de funcionamiento básico

1️⃣ Alimentación de material – Se desenrolla una bobina metálica y se introduce en la máquina.

2️⃣ Formación gradual – El metal pasa por una serie de estaciones de rodillosrodillos, cada uno realizando pequeños plegados incrementales.

3️⃣ Procesamiento en línea (opcional) – Se pueden integrar punzonado, entallado, grabado en relieve o soldadura en el proceso.

4️⃣ Corte a medida – El perfil conformado se corta al tamaño requerido.

5️⃣ Salida del producto final – La pieza terminada se envía para inspección y empaquetado.

Consejo profesional: El proceso de plegado incremental garantiza una tensión mínima en el material, lo que resulta en perfiles de alta resistencia y precisión.

Componentes clave

A perfiladora de alta calidad consta de múltiples componentes esenciales que trabajan juntos para crear perfiles metálicos complejos con precisión y eficiencia.

Componentes principales y sus funciones

| Componente | Función |

|---|---|

| desbobinador | Sostiene y desenrolla la bobina metálica para alimentarla a la máquina. |

| Sistema de guías de alimentación | Alinea y dirige la chapa hacia los rodillos. |

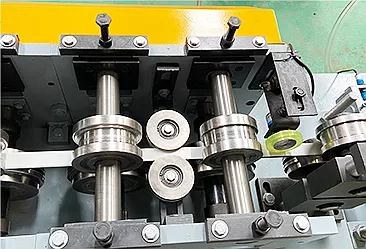

| Estaciones de rodillos | Múltiples rodillos conforman progresivamente la chapa metálica. |

| Unidad de punzonado/entallado (opcional) | Agrega orificios, ranuras o indentaciones en el metal antes del conformado final. |

| Sistema de Corte | Corta el perfil conformado a la longitud requerida. |

| Accionamiento hidráulico o por motor servo | Acciona los rodillos, asegurando un movimiento suave del material. |

| Sistema de control (PLC/CNC) | Automatiza y supervisa todo el proceso de formado por rodillos. |

| Mesa de salida de productos | Recoge las piezas terminadas para inspección y empaquetado. |

Máquina Sunway proporciona perfiladoras a medida con automatización avanzada y controles de precisión.

Proceso de perfilado paso a paso

los proceso de perfilado está diseñada para conformado metálico continuo y de alta velocidad, lo que lo hace ideal para producción en masa de perfiles uniformes.

Flujo detallado del proceso de formado por rodillos

| Paso | Descripción |

|---|---|

| 1. Carga de material | Se coloca una bobina de metal en el desbobinador, y la chapa se introduce en la máquina. |

| 2. Alimentación inicial y alineación | La hoja pasa por guías de alineación para asegurar una entrada recta. |

| 3. Formado por rodillos progresivo | La chapa metálica pasa por múltiples estaciones de rodillosmúltiples estaciones de rodillos, cada una aplicando plegados graduales. |

| 4. Punzonado y entallado en línea (si se requiere) | Unidades de punzonado accionadas por servo crean orificios, ranuras o grabados en relieve según sea necesario. |

| 5. 5. Corte a medida | A sistema de corte hidráulico o por cizalla volante corta el perfil conformado a la longitud requerida. |

| 6. Salida del producto final | La pieza terminada sale hacia la tabla de salida mesa para inspección de calidad. |

Consejo profesional: Sistemas de corte controlados por servo garantizar cortes precisos, sin rebabas y con mínimo desperdicio.

Tipos

Las diferentes aplicaciones requieren diferentes tipos de perfiladoras, cada una ofreciendo ventajas únicas en función de complejidad del perfil, velocidad de producción y nivel de automatización.

Comparación

| Tipo de máquina | Lo mejor para | Características principales |

|---|---|---|

| Máquina perfiladora de un perfil | Producción de perfiles fijos (p. ej., chapas para techos) | Diseño rentable y compacto |

| Máquina perfiladora multiperfil | Producción de múltiples perfiles con herramientas de cambio rápido | Reduce el tiempo de inactividad, aumenta la flexibilidad |

| Máquina perfiladora ajustable | Ajustes personalizables de ancho y forma | Ideal para la producción de perlines C y Z |

| Máquina perfiladora de alta velocidad | Producción en masa de perfiles uniformes | Hasta 50 metros por minuto |

| Máquina formadora de rodillos totalmente automatizada | Operaciones de alta precisión controladas por CNC | Detección de defectos impulsada por IA, integración IoT |

¿Busca una solución personalizada de formado por rodillos? Máquina Sunway ofrece máquinas formadoras de rodillos de alta velocidad y precisión para fabricantes globales.

Ventajas del formado por rodillos frente a otros métodos de conformado de metales

El formado por rodillos es ampliamente preferido sobre plegado por prensa, estampado y extrusión gracias a su eficiencia, precisión y rentabilidad.

¿Por qué elegir el formado por rodillos?

| Ventaja | Perfilado | Plegado por prensa / Estampado |

|---|---|---|

| Velocidad de producción | Proceso continuo (hasta 50 m/min) | Producción más lenta y por lotes |

| Residuos materiales | Mínimo desperdicio gracias al plegado incremental | Más desperdicio debido a ajustes por ensayo y error |

| Costo de mano de obra | Bajo: proceso totalmente automatizado | Alto: requiere ajustes manuales |

| Consistencia de las piezas | Alta uniformidad para perfiles largos y repetidos | Posibles variaciones en la producción por lotes |

| Coste de utillaje | Costo inicial más alto, pero menor costo por unidad | Costo inicial más bajo, pero mayor costo por unidad |

Veredicto: El formado por rodillos es la mejor opción para fabricación de alto volumen, eficiente en costos y precisa.

Problemas comunes y soluciones

Incluso con máquinas perfiladoras de última generaciónLos operadores pueden encontrarse con desafíos como distorsión del material, desalineación y desgaste de rodillos. Identificar y solucionar estos problemas principios de garantiza producción fluida y alta calidad.

Guía de resolución de problemas

| Edición | Posible causa | Solución |

|---|---|---|

| Desalineación del perfil | Posicionamiento incorrecto de rodillos, alimentación suelta del material | Recalibrar los rodillos y ajustar las guías de material |

| Deslizamiento del material en los rodillos | Rodillos de alimentación sueltos, ajustes incorrectos de tensión | Apriete los rodillos del alimentador y ajuste la tensión del material |

| Rayones o deformaciones en la superficie | Rodillos sucios, presión de formado excesiva | Limpiar los rodillos regularmente y ajustar la presión de formado |

| Longitudes de corte incoherentes | Sistema de corte defectuoso, cuchillas desalineadas | Inspeccionar y recalibrar el mecanismo de corte |

| Desgaste de rodillos por alta fricción | Falta de lubricación, presión excesiva | Aplicar lubricación adecuada y usar rodillos endurecidos |

Consejo profesional: Regular calibración y lubricación de rodillos puede prolongar la vida útil de la máquina en 40% y reduce significativamente los defectos de los perfiles.

Tendencias futuras en la tecnología de perfilado

los industria de perfilado evoluciona rápidamente con IA, IoT y automatizaciónmejorando eficiencia, precisión y sostenibilidad.

Innovaciones clave en máquinas formadoras de rodillos para 2025

1. Detección de defectos y autocorrección basadas en IA

- Inteligencia artificial cámaras y sensores detectan defectos en tiempo realreduciendo el desperdicio de material.

- Garantiza precisión consistente en los perfiles sin intervención del operador.

2. Supervisión remota habilitada para IoT

- Las máquinas disponen ahora de seguimiento basado en la nubepermitiendo permite a los operadores supervisar el rendimiento de forma remota.

- Activa diagnóstico en tiempo real y mantenimiento predictivo.

3. Tecnología de perfilado servoaccionada

- Mejora control de velocidad, precisión y eficiencia energética.

- Reduce desgaste de los componentes mecánicosaumentando la vida útil de la máquina.

4. Ajustes de perfil totalmente automatizados

- Elimina ajustes manuales al pasar de un perfil a otro.

- Controlado por CNC cambios automáticos de perfil reducir el tiempo de inactividad y mejorar la eficiencia.

La actualización a máquinas de perfilado con inteligencia artificial puede aumentar la eficiencia de la producción hasta 50%.

Automatización en máquinas formadoras por rodillos

La automatización es transformando conformado metálico de precisión, convirtiendo a las máquinas formadoras de rodillos en más inteligente, más rápido y más rentable.

Principales beneficios de las máquinas automatizadas de perfilado en rollo

| Característica | Beneficio |

|---|---|

| Sistemas de control PLC y CNC | Garantiza mediciones precisas y minimiza los errores humanos |

| Detección de defectos en tiempo real basada en IA | Identifica los problemas al instante, reduciendo el desperdicio de material |

| IoT y supervisión remota | Permite a los operarios controlar el rendimiento de la máquina desde cualquier lugar |

| Cambio automático de perfiles | Reduce el tiempo de inactividad al cambiar de perfil |

| Servomotores de bajo consumo | Reduce los costes operativos y mejora la sostenibilidad |

Máquinas perfiladoras totalmente automatizadas de Máquina Sunway mejorar la eficiencia de la producción hasta 40%!

Consejos esenciales de mantenimiento para máquinas formadoras de rodillos

Adecuado mantenimiento garantiza mayor vida útil de la máquina y calidad de producción constante.

Lista de verificación de mantenimiento para máquinas formadoras de rodillos

| Tarea | Frecuencia | Propósito |

|---|---|---|

| Lubricar rodillos y cojinetes | Semanal | Evita el desgaste |

| Comprobar la alineación de los rodillos | Mensualmente | Garantiza la producción de perfiles precisos |

| Inspeccionar el mecanismo de corte | Trimestral | Evita cortes defectuosos y desalineaciones |

| Componentes limpios de la máquina | Diario | Elimina el polvo y los residuos que pueden afectar al rendimiento |

| Actualización de software y calibración | Semestralmente | Mantiene optimizadas las funciones de automatización |

Consejo profesional: El mantenimiento programado puede prolongar la vida útil de la máquina en 50% y reducir los fallos en 70%.

Preguntas frecuentes: Principio de funcionamiento de la máquina formadora de rodillos

1. ¿Cómo funciona una máquina formadora de rodillos?

Una máquina formadora de rollos conforma gradualmente chapas metálicas al pasarlas por múltiples estaciones de rodillosuna serie de rodillos, cada uno aplicando plegados incrementales hasta formar el perfil final.

2. ¿Qué industrias utilizan máquinas formadoras de rodillos?

Industrias como:

✅ Construcción (paneles para techos, perlines C y Z)

✅ Automoción (componentes estructurales, vigas resistentes a impactos)

✅ Energía solar (estructuras de montaje solar)

✅ Estanterías y estanterías (bastidores de almacén, sistemas de almacenamiento)

3. ¿Qué materiales se pueden usar en el formado por rodillos?

Los materiales más comunes son:

✅ Acero galvanizado (G30-G90)

✅ Acero inoxidable (304/316)

✅ Aluminio (6061/7075)

✅ Acero de alta resistencia

4. ¿Cuánto cuesta una máquina formadora de rodillos?

El precio oscila entre 80,000forbasicmodels∗∗to∗∗80,000 para modelos básicos** hasta **80,000forbasicmodels∗∗to∗∗1,200,000 para máquinas totalmente automatizadas e impulsadas por IA.

5. ¿Dónde puedo comprar una máquina de formado en rodillo de alta calidad?

Para perfiladoras a medida de alta velocidadVisite WUXI SUNWAY MACHINERY CO., LTD.

Reflexiones finales

Invertir en un máquina formadora de rollos es esencial para industrias que requieren flexibilidad, eficiencia y producción de alta velocidad. Elegir una fabricante de confianza garantiza fiabilidad y rentabilidad a largo plazo.

WUXI SUNWAY MACHINERY CO., LTD es un fabricante líder mundial de perfiladoras a medida, ofreciendo tecnología avanzada, asistencia experta y precios competitivos.

¿Quieres un máquina formadora de rodillos? Póngase en contacto con nosotros