Introducción

Elegir el perfiladora derecha puede ser desafiando-especialmente con tantas opciones disponibles en el mercado. Tanto si compra para montaje de tejados, estanterías, automóviles o paneles solareshaciendo que el elección equivocada puede conducir a costes más elevados, productos de baja calidad e ineficiencias de producción.

Entonces, ¿cómo seleccione la mejor perfiladora para sus necesidades específicas?

En esta guía trataremos:

✅ Factores clave a tener en cuenta al comprar una perfiladora

✅ Los distintos tipos de perfiladoras y sus aplicaciones

✅ Cómo comparar máquinas manuales, semiautomáticas y totalmente automatizadas

✅ Los mejores materiales para el perfilado y su repercusión en la selección de máquinas

✅ Dónde comprar una perfiladora de alta calidad en 2025

Sumerjámonos.

1. Comprender los fundamentos de las perfiladoras

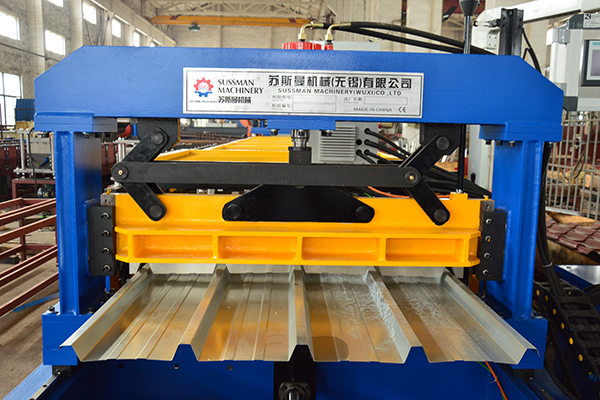

A máquina formadora de rollos es un sistema industrial que dobla gradualmente una chapa o una bobina hasta darle la forma deseada mediante una serie de rodillos. Estas máquinas se utilizan ampliamente en industrias como construcción, automoción, estanterías y energía solar.

Componentes clave de una perfiladora

✅ desbobinador - Sujeta y alimenta la bobina de metal en la máquina.

✅ Estaciones de rodillos - Una serie de rodillos que moldean progresivamente el metal.

✅ Sistema de Corte - Corta automáticamente los perfiles a las longitudes requeridas.

✅ Sistema de control (PLC/AI) - Garantiza la precisión y la automatización.

✅ Sistema de apilado y descarga - Recoge el producto final para facilitar su manipulación.

Consejo profesional: Comprender los componentes básicos de una perfiladora le ayudará a elegir el mejor modelo para sus aplicaciones.

2. Factores clave a tener en cuenta al elegir una perfiladora

A la hora de seleccionar una perfiladora, debe evaluar varios aspectos factores clave para garantizar que cumple sus requisitos de producción.

Consideraciones clave para elegir una perfiladora

| Factor | Por qué es importante |

|---|---|

| Tipo de material y grosor | Determina resistencia de los rodillos y capacidad de conformado. |

| Velocidad de producción | Afecta a volumen de producción y eficiencia. |

| Nivel de automatización | Máquinas totalmente automatizadas reducir los costes de mano de obra y aumentar la precisión. |

| Forma y complejidad del perfil | Algunas máquinas manejan perfiles simplesmientras que otros gestionan diseños complejos. |

| Tiempo de cambio | Si se producen varios perfiles, las herramientas de cambio rápido son esenciales. |

| Tamaño de la máquina y espacio necesario | Garantiza que la máquina se adapta a sus instalaciones. |

| Presupuesto y rentabilidad | Una mayor automatización cuesta más, pero mejora la rentabilidad a largo plazo. |

Consejo profesional: Una perfiladora de alta velocidad totalmente automatizada puede aumentar la productividad hasta 50%.

3. Tipos de perfiladoras y sus aplicaciones

Los distintos sectores requieren diferentes tipos de perfiladoras. He aquí un desglose de los tipos más comunes y sus aplicaciones.

Comparación de las perfiladoras por industria

| Tipo de máquina | Lo mejor para | Características principales |

|---|---|---|

| Máquina Perfiladora de Panel de Techo y Pared | Construcción, Edificios metálicos | Admite varios diseños de panelesProducción a alta velocidad |

| Máquina perfiladora de correas C & Z | Estructuras de acero, almacenes | Rodillos ajustables para Perfiles C y Z |

| Máquina perfiladora de bandeja portacables | Eléctrico e industrial | Produce bandejas de cables perforadas o macizas |

| Máquina Perfiladora de Montaje de Paneles Solares | Energías renovables | Perfiles ligeros y resistentes a la corrosión |

| Máquina Perfiladora de Automóviles | Bastidores de automóviles, Componentes de VE | Procesamiento de acero de alta resistencia, ajustes controlados por IA |

| Máquina perfiladora de estanterías | Almacenes, Logística | Personalizable perfiles de estanterías |

Consejo profesional: Elija una máquina en función de su sector y de los perfiles específicos que necesite producir.

4. Manual vs. Semiautomática vs. Totalmente Automática Máquinas Perfiladoras

El nivel de automatización es una de las decisiones más importantes a la hora de seleccionar una perfiladora.

Comparación de máquinas manuales, semiautomáticas y totalmente automatizadas

| Característica | Máquina manual | Máquina semiautomática | Máquina totalmente automatizada |

|---|---|---|---|

| Requisitos laborales | Alta | Medio | Bajo |

| Velocidad de producción | Lento | Moderado | Alta |

| Precisión y coherencia | Baja | Medio | Alta |

| Tiempo de preparación y cambio | Largo | Moderado | Corto |

| Lo mejor para | Producción a pequeña escala | Operaciones a media escala | Fabricación a gran escala |

| Costo | Bajo | Medio | Mayor inversión inicial pero mejor retorno de la inversión |

Consejo profesional: Si necesita una producción de gran volumen con una mano de obra mínima, una perfiladora totalmente automatizada es la mejor opción.

5. Los mejores materiales para el perfilado y cómo afectan a la selección de la máquina

No todas las perfiladoras pueden todo tipo de material. El tipo y el grosor del material influyen significativamente en la la potencia de la máquina, la resistencia de los rodillos y el mecanismo de corte.

Consideraciones sobre los materiales de las perfiladoras

| Tipo de material | Aplicaciones comunes | Requisitos de la máquina |

|---|---|---|

| Acero laminado en frío | Tejados, automoción, estanterías | Perfiladora estándar |

| Acero galvanizado | Bastidores de paneles solares, construcción | Rodillos resistentes a la corrosión |

| Aluminio | Aeroespacial, electrónica, energía solar | Sistema de encofrado ligero |

| Acero inoxidable | Medicina, procesamiento de alimentos, industria | Rodillos de alta presión, corte de precisión |

| Acero avanzado de alta resistencia (AHSS) | Componentes para automóviles y vehículos eléctricos | Rodillos resistentes, conformado controlado por IA |

Consejo profesional: Combinar su perfiladora con el material adecuado garantiza durabilidad y precisión en la producción.

6. Comprensión de las configuraciones y opciones de personalización de las perfiladoras

No todas las perfiladoras son iguales. Algunas se construyen para perfiles estándarmientras que otros son adaptado a las necesidades específicas del sector. Seleccionar el configuración es fundamental para precisión, eficacia y rendimiento óptimo de la producción.

Configuraciones habituales de las perfiladoras

| Tipo de configuración | Lo mejor para | Características principales |

|---|---|---|

| Máquina perfiladora de una cara | Perfiles metálicos simples | Estaciones de rodillos básicas, rentables |

| Máquina Perfiladora de Doble Cara | Producir dos perfiles simultáneamente | Conformado de doble vía, mayor eficacia |

| Máquina perfiladora multiperfil | Industrias que necesitan varios cambios de perfil | Herramientas de cambio rápido, juegos de rodillos flexibles |

| Máquina Perfiladora Tipo Casete | Grandes necesidades de personalización | Casetes de rodillos intercambiables |

| Máquina Perfiladora de Corte Volante | Líneas de producción de alta velocidad | Formación continua, sistema de corte sobre la marcha |

Cuándo elegir una perfiladora personalizada

✅ Formas de perfil únicas - Si su sector requiere perfiles no estándar, a la máquina a medida es esencial.

✅ Producción de gran volumen - Para producción masiva, a línea de perfilado totalmente automatizada se recomienda.

✅ Necesidades de cambio rápido - Si produce varios perfiles, a máquina de casetes o multiperfil es ideal.

✅ Requisitos específicos de material - Algunas industrias requieren metales más gruesos o revestimientos especialesque puede necesitar rodillos reforzados.

Consejo profesional: Si necesita flexibilidad, una perfiladora multiperfil o de tipo casete le permitirá realizar ajustes rápidos para diferentes líneas de productos.

7. Comparación entre perfiladoras nuevas y usadas: ¿Cuál es mejor?

Al comprar una perfiladora, es posible que se pregunte: ¿Debo comprar una máquina nueva o usada? Ambas opciones tienen pros y contras, dependiendo de su presupuesto, necesidades de producción y objetivos a largo plazo.

Perfiladoras Nuevas vs. Usadas: Diferencias clave

| Factor | Nueva perfiladora | Perfiladoras usadas |

|---|---|---|

| Coste inicial | Más alto | Baja |

| Eficiencia operativa | Mejores prestaciones, última tecnología | Puede tener desgaste |

| Opciones de personalización | Totalmente personalizable | Personalización limitada |

| Garantía y asistencia | Garantía del fabricante incluida | Sin soporte del fabricante |

| Fiabilidad a largo plazo | Mayor vida útil, mantenimiento mínimo | Puede requerir reparaciones frecuentes |

| Eficiencia energética | Utiliza modernos sistemas de ahorro de energía | Los modelos más antiguos pueden consumir más energía |

Cuándo elegir una nueva perfiladora

✅ Si necesita una máquina con la última tecnología de automatización e IA

✅ Si necesita una solución de perfilado personalizada

✅ Si desea una máquina con una larga vida útil y un mantenimiento mínimo

Cuándo considerar una perfiladora usada

✅ Si tienes un presupuesto limitado y necesitas una solución temporal

✅ Si la máquina procede de un proveedor fiable con un historial de rendimiento verificado

Consejo profesional: Mientras que las máquinas usadas pueden ahorrar dinero por adelantado, las nuevas perfiladoras ofrecen mayor eficiencia, mayor vida útil y menores costes de mantenimiento a largo plazo.

8. El papel de la automatización y la IA en las modernas perfiladoras

Automatización e Inteligencia Artificial (AI) son revolucionando la industria del perfiladomáquinas de fabricación más inteligente, más rápido y más eficaz.

Cómo la IA y la automatización mejoran las perfiladoras

✅ Ajustes en tiempo real basados en IA - Máquinas automáticas ajuste la presión y la alineación de los rodillos para un conformado de precisión.

✅ Detección automática de defectos - La IA detecta defectos superficiales y desalineación antes de que se conviertan en problemas graves.

✅ Manipulación y descarga inteligente de bobinas - Sistemas robóticos reducir la intervención humanaaumentando la eficacia.

✅ Mantenimiento predictivo - La IA predice desgasteevitando costosas averías.

Comparación: Perfiladoras manuales frente a automatizadas

| Característica | Máquina manual | Máquina automática |

|---|---|---|

| Dependencia laboral | Alta | Bajo |

| Velocidad de producción | Más lento | Hasta 50% más rápido |

| Residuos materiales | Más alto | Más bajo, optimizado con IA |

| Puesta en marcha y cambio | Más largo | Herramientas de cambio rápido disponibles |

| Eficiencia energética | Estándar | Utiliza tecnología inteligente de ahorro de energía |

Consejo profesional: Para 2030, casi todas las máquinas de perfilado contarán con automatización basada en IA para mejorar la eficiencia.

9. Cómo configurar una línea de perfilado para obtener la máxima eficiencia

Instalación de una línea de perfilado correctamente es esencial para buen funcionamiento, tiempos de inactividad mínimos y producción de alta calidad.

Guía paso a paso para montar una línea de perfilado

✅ Paso 1: Seleccionar la ubicación adecuada - Garantizar espacio adecuado para la alimentación, formación y descarga de bobinas.

✅ Paso 2: Instalar un sistema de desacoplamiento fiable - Elija una desenrollador motorizado o hidráulico para alimentación suave de bobinas.

✅ Paso 3: Optimizar la alineación y el calibrado de los rodillos - Correcto la configuración de los rodillos evita defectos en el producto final.

✅ Paso 4: Integrar un sistema de control PLC - Utilización Controles basados en IA para ajustes y control en tiempo real.

✅ Paso 5: Implantar un sistema de control de calidad - Instalar cámaras y sensores a detectar defectos durante el conformado.

✅ Paso 6: Automatizar el apilado y el embalaje - Reduce manipulación manual y mejora la eficacia.

Consejo profesional: ¡Una línea de perfilado bien optimizada puede aumentar la eficiencia de la producción hasta 40%!

10. ¿Dónde comprar las mejores perfiladoras en 2025?

Para máquinas perfiladoras de última generaciónVisite WUXI SUNWAY MACHINERY CO., LTD.

¿Por qué elegir WUXI SUNWAY MACHINERY?

✅ Más de 15 años de experiencia - Líder mundial en la fabricación de maquinaria de perfilado.

✅ Máquinas totalmente automatizadas y dotadas de inteligencia artificial - Diseñado para conformado de alta velocidad y precisión.

✅ Soluciones personalizadas de perfilado - Máquinas a medida para aplicaciones para tejados, automoción, estanterías y energía solar.

✅ Precios competitivos y envíos internacionales - Equipos de alta calidad en todo el mundo.

✅ Asistencia posventa fiable - Piezas de repuesto, formación y asistencia técnica.

¿Busca la mejor perfiladora? Póngase en contacto con nosotros

PREGUNTAS FRECUENTES: Cómo elegir una perfiladora

1. ¿Cuál es el factor más importante a la hora de elegir una perfiladora?

- Tipo de material, volumen de producción, nivel de automatización y presupuesto.

2. ¿Debo comprar una perfiladora nueva o usada?

- Una nueva máquina ofrece mayor eficiencia, vida útil más larga y automatización basada en IA, mientras que una máquina usada es un opción más barata a corto plazo.

3. ¿Qué industrias se benefician más de las perfiladoras?

- Construcción, automoción, energía solar, estanterías y aeroespacial.

4. ¿Cómo mejora la IA las máquinas de perfilado?

- AI reduce los defectos, optimiza el uso del material y predice las necesidades de mantenimiento a maximizar la eficiencia.

5. ¿Dónde puedo encontrar las mejores perfiladoras en 2025?

- MAQUINARIA WUXI SUNWAY proporciona soluciones avanzadas de perfilado basadas en inteligencia artificial.

Reflexiones finales

Elegir bien máquina formadora de rollos es un inversión importantepero seleccionando el modelo correcto garantiza alta eficacia, precisión y rentabilidad a largo plazo.

✅ Necesita un Perfiladora de alta velocidad con inteligencia artificial?

✅ Buscando soluciones personalizadas de perfilado?