Visión general de las perfiladoras de bandejas portacables

A máquina perfiladora de bandeja portacables es un equipo especializado diseñado para fabricar bandejas de cables metálicas, que se utilizan para soportar y organizar cables eléctricos en edificios, plantas industriales y centros de datos. Estas máquinas producen bandejas de cables perforadas, tipo escalera y de fondo sólido con alta eficiencia y precisión.

Características principales de las perfiladoras de bandejas portacables

✅ Funcionamiento totalmente automático - Controlado por PLC para precisión y alta eficiencia.

✅ Perfiles personalizables - Produce bandejas de cables perforadas, tipo escalera y de fondo sólido.

✅ Producción a alta velocidad - Capaz de producir 10-30 metros por minuto.

✅ Construcción duradera - Usos rodillos de acero endurecido y sistemas de corte hidráulico.

✅ Sistema de punzonado integrado - Activa perforación de orificios para una gestión fácil de los cables.

En esta guía trataremos:

✅ Tipos de máquinas formadoras de rodillos para bandejas de cables

✅ Cómo funciona el proceso de perfilado

✅ Mejores materiales para bandejas de cables

✅ Análisis de costes y guía de precios

✅ Los mejores fabricantes y por qué Sunway Machine es una elección de confianza

Sumerjámonos.

Tipos de perfiladoras de bandejas portacables

Diferentes perfiladoras de bandejas portacables atienden a diversos necesidades de producción y niveles de automatización.

1. Máquina formadora de rodillos para bandejas de cables perforadas

- Produce bandejas perforadas con orificios preperforados para ventilación.

- Ideal para entornos de alta temperatura donde es necesario el flujo de aire.

2. Máquina formadora de rodillos para bandejas de cables tipo escalera

- Crea bandejas tipo escalera con soportes tipo travesaño para cables pesados.

- Lo mejor para aplicaciones industriales y en plantas de energía.

3. Máquina formadora de rodillos para bandejas de cables de fondo sólido

- Fabrica bandejas de fondo sólido para protección completa de los cables.

- Adecuado para centros de datos y entornos peligrosos.

4. Máquina formadora de rodillos para bandejas de cables totalmente automática

- Características Automatización CNC para cambios rápidos de perfil.

- Ideal para producción a gran escala y de alta eficiencia.

Máquina Sunway proporciona máquinas formadoras de rodillos para bandejas de cables personalizadas con funciones avanzadas de automatización.

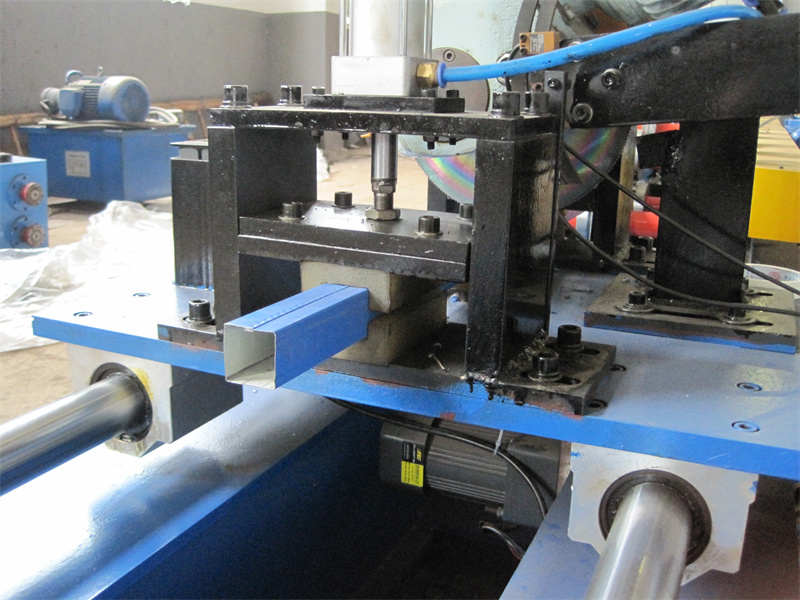

Cómo funciona el formado de rodillos para bandejas de cables

los proceso de perfilado para bandejas de cables implica conformar gradualmente una chapa plana en un estructura de soporte de cables de alta resistencia.

Proceso de formado de rodillos para bandejas de cables paso a paso

| Paso | Descripción |

|---|---|

| 1. Desaceitado | La bobina metálica se coloca en el desbobinador, alimentando la máquina con material. |

| 2. Nivelación y alimentación | La hoja es enderezado y guiado en las estaciones de formación. |

| 3. Punzonado y corte | El sistema hidráulico realiza perforación para la gestión de cables. |

| 4. Perfilado | La hoja pasa por múltiples estaciones de rodillos, formando la forma de la bandeja de cables. |

| 5. Corte final y apilado | La bandeja de cables formada se cortar a la longitud deseada y apilados para su envío. |

Consejo profesional: A máquina formadora de rodillos para bandejas de cables totalmente automática garantiza alta precisión, mínimo desperdicio y mayor velocidad de producción.

Mejores materiales para bandejas de cables

Elegir el material adecuado garantiza resistencia, resistencia a la corrosión y durabilidad.

Comparación de materiales para bandejas de cables

| Material | Propiedades | Lo mejor para |

|---|---|---|

| Acero galvanizado (GI) | Resistente a la corrosión, rentable | Instalaciones eléctricas estándar |

| Acero inoxidable (Acero inoxidable) | Alta resistencia, resistente al óxido | Aplicaciones industriales y exteriores |

| Aleación de aluminio | Ligero, resistente a la corrosión | Centros de datos e infraestructura de TI |

| Acero recubierto de polvo | Acabado estético, duradero | Edificios comerciales |

Máquina Sunway fabrica perfiladoras compatibles con todos los materiales principales para bandejas portacables.

Guía de precios de máquinas formadoras de bandejas portacables por rodillos

El coste de un máquina perfiladora de bandeja portacables depende de factores como nivel de automatización, velocidad de producción y gama de perfiles.

Rangos de precios estimados para máquinas formadoras de bandejas portacables por rodillos

| Tipo de máquina | Gama de precios (USD) | Características |

|---|---|---|

| Máquina manual | 20.000–20.000 – 20.000–50.000 | Ajustes manuales, producción a baja velocidad |

| Máquina semiautomática | 50,000-50,000 - 50,000-100,000 | Controlado por PLC, requiere ajustes manuales del perfil |

| Máquina totalmente automática | 100.000–100.000 – 100.000–250.000 | Cambio rápido de perfiles controlado por CNC |

| Máquina de alta velocidad | 250,000-250,000 - 250,000-500,000 | Automatización avanzada, producción a alta velocidad |

¿Busca un presupuesto personalizado? Póngase en contacto con Sunway Machine hoy mismo.

Principales fabricantes de máquinas formadoras de bandejas portacables por rodillos

Elegir un fabricante de confianza garantiza máquinas de alta calidad, asistencia a largo plazo y servicio mundial.

Comparación de los principales fabricantes de máquinas formadoras de bandejas portacables por rodillos

| Fabricante | País | Especialización | Características principales |

|---|---|---|---|

| WUXI SUNWAY MACHINERY CO., LTD | China | Perfiladoras de bandejas de cables | Diseños personalizados, automatización de alta velocidad, máquinas habilitadas para IoT |

| Dreistern GmbH | Alemania | Conformado de precisión de metales | Máquinas controladas por CNC, fuerte I+D |

| Maquinaria Samco | Canadá | Perfilado para la construcción | Ingeniería personalizada, automatización |

| Grupo Bradbury | EE.UU. | Sistemas de perfilado de alta resistencia | Máquinas robustas, centradas en la automatización |

Veredicto: Si busca un máquina formadora de bandejas portacables por rodillos rentable y de alta velocidad, Máquina Sunway es un la mejor opción para compradores de todo el mundo.

Problemas comunes y soluciones en máquinas formadoras de bandejas portacables por rodillos

Incluso las más avanzadas máquinas formadoras de bandejas portacables por rodillos pueden presentar desafíos operativos, como desalineación de rodillos, deformación del material y perforación imprecisa. Abordar estas cuestiones de forma proactiva garantiza producción fluida y bandejas portacables de alta calidad.

Guía de resolución de problemas

| Edición | Posible causa | Solución |

|---|---|---|

| Bandejas portacables distorsionadas o irregulares | Desalineación de los rodillos, ajuste incorrecto de la presión | Ajuste la alineación de los rodillos y garantice una distribución uniforme de la presión |

| Deslizamiento del material durante el conformado | Rodillos del alimentador sueltos, ajuste incorrecto de la tensión | Apriete los rodillos del alimentador y ajuste la tensión del material |

| Perforación imprecisa | Sistema hidráulico defectuoso, troqueles de punzonado desalineados | Inspeccionar la presión hidráulica y realinear las matrices de punzonado. |

| Vibración excesiva de la máquina | Pernos sueltos, cimentación inestable de la máquina | Asegure los componentes de la máquina y garantice una instalación estable |

| Inexactitud de corte | Cuchillas de corte desgastadas, cortadores desalineados | Sustituya las cuchillas desafiladas y alinee correctamente las cuchillas |

Consejo profesional: Regular realineación de rodillos y ajustes servoaccionados puede mejorar precisión de las bandejas portacables en un 30 %.

Tendencias futuras en máquinas formadoras de bandejas portacables por rodillos

los industria manufacturera está evolucionando, y perfiladoras de bandejas portacables están integrando IA, IoT y automatización para mejorar eficiencia, precisión y sostenibilidad.

Innovaciones clave

1. Control de calidad basado en IA

- Inteligencia artificial los sensores detectan los defectos en tiempo realreduciendo el desperdicio de material.

- Mejora precisión del producto y minimiza los índices de rechazo.

2. Integración de IoT y fábricas inteligentes

- Las máquinas disponen ahora de supervisión en la nubepermitiendo diagnóstico en tiempo real y mantenimiento predictivo.

- Mejora seguimiento de la producción y eficacia operativa.

3. Tecnología de perfilado servoaccionada

- Mejora control de velocidad, precisión y eficiencia energética.

- Reduce desgaste de los componentes mecánicos, aumentando su vida útil.

4. Ajustes de perfil totalmente automatizados

- Elimina ajustes manuales al cambiar entre diferentes perfiles de bandejas portacables.

- Controlado por CNC cambios automáticos de perfil reducir el tiempo de inactividad y mejorar la eficiencia.

¡Actualizar a máquinas formadoras de bandejas portacables por rodillos con IA puede aumentar la eficiencia de producción hasta en un 50 %!

Laminado en frío frente a plegado por prensa para la producción de bandejas portacables

Los fabricantes deben evaluar velocidad de producción, desperdicio de material y rentabilidad a la hora de elegir entre perfilado y plegado para la producción de bandejas portacables.

Comparación entre laminado en frío y plegado por prensa para bandejas portacables

| Característica | Perfilado | Frenado a presión |

|---|---|---|

| Velocidad de producción | Más rápido para perfiles largos y continuos | Más lento para curvas personalizadas |

| Residuos materiales | Residuos mínimos | Mayor rechazo de material |

| Costes de utillaje | Mayor inversión inicial, menor coste a largo plazo | Menor coste inicial, mayor coste operativo |

| Lo mejor para | Producción industrial de gran volumen | Componentes metálicos personalizados de bajo volumen |

Veredicto: Si necesita producción continua a alta velocidad con un mínimo de residuos, el laminado en frío para bandejas portacables es la mejor opción.

Automatización en máquinas formadoras de bandejas portacables por rodillos

La automatización es revolucionando el proceso de fabricación, haciendo que las máquinas de perfilado más inteligente, más rápido y más eficaz.

Principales ventajas

| Característica | Beneficio |

|---|---|

| Sistemas de control PLC y CNC | Garantiza mediciones precisas y minimiza los errores humanos |

| Detección de defectos basada en IA | Identifica los problemas en tiempo real, reduciendo el desperdicio de material |

| IoT y supervisión remota | Permite a los operarios controlar el rendimiento de la máquina desde cualquier lugar |

| Cambio automático de perfiles | Reduce el tiempo de inactividad al cambiar de perfil |

| Servomotores de bajo consumo | Reduce los costes operativos y mejora la sostenibilidad |

Máquinas formadoras de bandejas portacables por rodillos totalmente automatizadas de Máquina Sunway mejorar la eficiencia de la producción hasta 40%!

Consejos esenciales de mantenimiento para máquinas formadoras de bandejas portacables por rodillos

Adecuado mantenimiento garantiza mayor vida útil de la máquina y calidad de producción constante.

Lista de verificación de mantenimiento

| Tarea | Frecuencia | Propósito |

|---|---|---|

| Lubricar rodillos y cojinetes | Semanal | Evita el desgaste |

| Comprobar la alineación de los rodillos | Mensualmente | Garantiza la producción de perfiles precisos |

| Inspeccionar el mecanismo de corte | Trimestral | Evita cortes defectuosos y desalineaciones |

| Componentes limpios de la máquina | Diario | Elimina el polvo y los residuos que pueden afectar al rendimiento |

| Actualización de software y calibración | Semestralmente | Mantiene optimizadas las funciones de automatización |

Consejo profesional: El mantenimiento programado puede prolongar la vida útil de la máquina en 50% y reducir los fallos en 70%.

Preguntas más frecuentes

1. ¿A qué velocidad puede producir bandejas una máquina formadora de bandejas portacables por rodillos?

Los modelos de alta velocidad pueden producir hasta 30 metros por minutoen función del perfil.

2. ¿Qué perfiles de bandejas portacables se pueden producir?

La mayoría de las máquinas pueden producir bandejas de cables perforadas, tipo escalera y de fondo sólido.

3. ¿Cuánto cuesta una máquina formadora de bandejas portacables por rodillos?

El precio oscila entre 20.000paramodelosbásicos∗∗a∗∗20.000 para modelos básicos** a **20.000paramodelosbásicos∗∗a∗∗500.000 para sistemas totalmente automatizados.

4. ¿Qué materiales se pueden usar en máquinas formadoras de bandejas portacables por rodillos?

Los materiales más comunes son acero galvanizado, acero inoxidable, aluminio y acero con recubrimiento en polvo.

5. ¿Dónde puedo comprar una máquina formadora de bandejas portacables por rodillos de alta calidad?

Para máquinas formadoras de bandejas portacables por rodillos personalizadas y de alta velocidadVisite WUXI SUNWAY MACHINERY CO., LTD.

Reflexiones finales

Invertir en un máquina perfiladora de bandeja portacables es esencial para producción eficiente y de alta calidad de bandejas portacables. Tanto si necesita un sistema estándar o totalmente automatizadoelegir un fabricante de confianza garantiza fiabilidad y rentabilidad a largo plazo.

WUXI SUNWAY MACHINERY CO., LTD es un fabricante líder mundial de máquinas formadoras de bandejas portacables por rodillos personalizadas, ofreciendo tecnología avanzada, asistencia experta y precios competitivos.

¿Quieres un máquina formadora de bandejas portacables por rodillos personalizada? Póngase en contacto con nosotros