Las excavadoras son la columna vertebral de construcción, minería y desarrollo de infraestructurasque requiere componentes duraderos y muy resistentes que puedan soportar condiciones de trabajo extremas. Para satisfacer estas exigencias, los fabricantes confían en Perfiladoras para excavadorasque permiten fabricación de alta velocidad y precisión de componentes estructurales para equipos pesados.

Estas avanzadas máquinas de perfilado están diseñadas para procesar acero de alta resistencia, paneles de chasis reforzados, soportes de brazos hidráulicos y componentes del tren de rodajegarantizando durabilidad superior, eficiencia ligera y producción rentable.

En esta guía, exploraremos las aplicaciones, precios, características principales, tendencias del sector y por qué Wuxi Sunway Machinery lidera el sector de las soluciones de perfilado para excavadoras..

¿Qué son las perfiladoras para excavadoras?

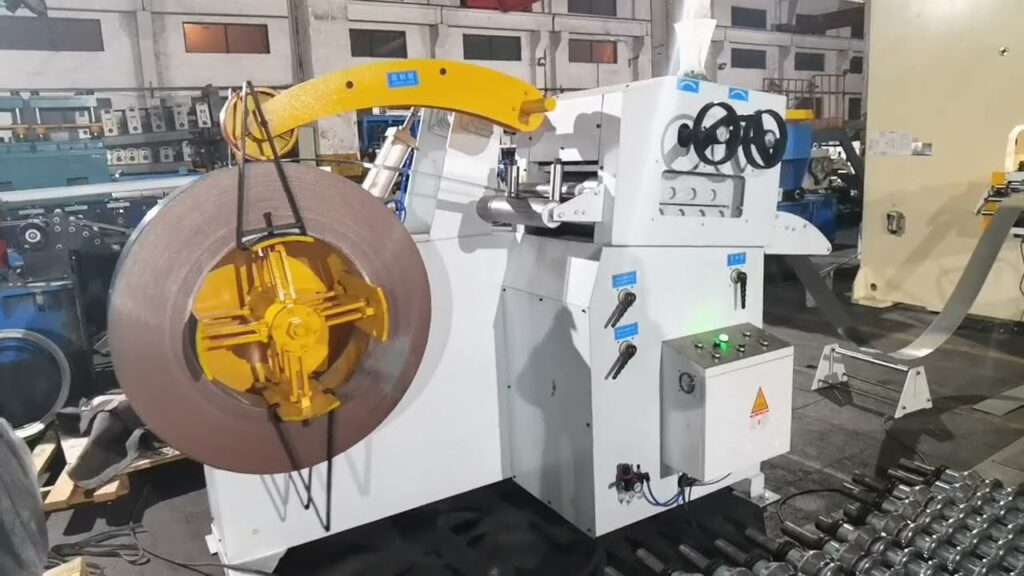

Un Máquina perfiladora para excavadoras es un sistema industrial diseñado para fabricar componentes metálicos resistentes utilizado en excavadoras, bulldozers y otros equipos de movimiento de tierras. Estas máquinas garantizan producción automatizada de alta velocidad con cortes, doblados y procesamiento de refuerzos precisosoptimizar fuerza y rendimiento de la excavadora.

Características principales de las perfiladoras para excavadoras

- Procesado de aceros de alta resistencia y materiales resistentes al desgaste - Garantiza larga durabilidad bajo cargas extremas.

- Perfiles estructurales personalizables para maquinaria pesada - Soportes varias piezas de excavadoras, incluidos soportes de chasis, soportes de brazos hidráulicos y paneles del tren de rodaje.

- Perforación automática y corte de precisión - Facilita montaje rápido e integración modular.

- Revestimientos resistentes a la corrosión y a prueba de golpes - Proporciona mayor vida útil en entornos difíciles.

- Supervisión inteligente e integración de IoT - Permite detección de defectos en tiempo real y mantenimiento predictivo.

- Producción a alta velocidad - Activa fabricación en serie con el mínimo desperdicio de material.

- Mayor capacidad de carga - Reuniones normas mundiales de la industria de la construcción y la minería.

Aplicaciones de las perfiladoras para excavadoras

Los sectores de la construcción y la minería necesitan excavadoras robustas y de alto rendimientoLos fabricantes necesitan sistemas eficaces y automatizados producir componentes de acero a escala. Perfiladoras para excavadoras permiten a los fabricantes producir componentes especializados para diversas aplicaciones:

1. Estructuras de chasis y bastidor de excavadoras

- Caso práctico: Fabricación chasis reforzados para excavadoras y maquinaria pesada.

- Por qué es esencial: Proporciona integridad estructural y resistencia a los impactos en entornos difíciles.

2. Paneles de soporte del brazo hidráulico y de la pluma

- Caso práctico: Producción soportes de brazo de alta resistencia para plumas de excavadoras y sistemas hidráulicos.

- Por qué es beneficioso: Garantiza funcionamiento suave y estabilidad con cargas pesadas.

3. Raíles del tren de rodaje y paneles de refuerzo

- Caso práctico: Fabricación paneles de acero resistentes al desgaste para orugas y trenes de rodaje de excavadoras.

- Por qué es importante: Mejora durabilidad y tracción en terrenos difíciles.

4. Protección de la cabina de la excavadora y bastidores de seguridad

- Caso práctico: Desarrollando bastidores de seguridad de acero reforzado y cabinas de mando.

- Por qué es necesario: Protege a los operarios de los escombros, vuelcos y condiciones adversas de la obra.

5. Componentes de contrapeso y equilibrio de carga

- Caso práctico: Producción paneles estructurales de contrapeso para mejorar la estabilidad de la excavadora.

- Por qué es innovador: Mejora equilibrio y distribución de la carga para una excavación de precisión.

6. Componentes inteligentes para excavadoras con sensores integrados

- Caso práctico: Fabricación paneles de excavadora con sensores inteligentes para la supervisión en tiempo real.

- Por qué es fundamental: Activa mantenimiento predictivo y telediagnóstico.

Características principales de la Máquina Perfiladora de Excavadora Wuxi Sunway

Wuxi Sunway Machinery es líder mundial en tecnología de perfilado para excavadoras, ofreciendo soluciones de alto rendimiento diseñadas con precisión para fabricantes de maquinaria pesada y de construcción. Sus máquinas están diseñadas para aumentar la productividad, reducir los costes y mejorar la durabilidad estructural.

1. Perfiles estructurales personalizables para maquinaria pesada

- Qué ofrece: Máquinas equipadas con utillaje ajustable para fabricar bastidores de excavadoras, vigas de soporte y paneles de refuerzo.

- Por qué es fundamental: Admite diversas configuraciones de excavadoras, desde modelos compactos hasta excavadoras mineras de gran tamaño.

2. Capacidad de procesamiento multimaterial

- Qué procesa:

- Acero de alta resistencia - Proporciona máxima resistencia para estructuras de excavadoras.

- Aleaciones de acero resistentes al desgaste - Mejora durabilidad en entornos de trabajo extremos.

- Corrosión-Acero revestido - Garantiza mayor vida útil en condiciones húmedas y abrasivas.

- Por qué es esencial: Acomoda diversos requisitos de fabricación de excavadoras.

3. Producción automatizada de alta velocidad

- Lo que consigue: Procesa hasta 80 metros de metal por minuto con intervención manual mínima.

- Por qué es eficaz: Cumple grandes volúmenes de producción con una calidad constante.

4. Perforación, corte de ranuras y plegado integrados

- Qué permite: Puntos de montaje pretaladrados y plegado de precisión para un montaje rápido.

- Por qué es beneficioso: Reduce el trabajo manual y mejora el diseño de componentes modulares.

5. Recubrimientos resistentes a la corrosión y a prueba de impactos

- Lo que ofrece: Máquinas capaces de aplicación de revestimientos protectores durante la producción.

- Por qué es beneficioso: Garantiza mayor vida útil del producto y cumplimiento de las normas de seguridad en la construcción.

6. Supervisión inteligente y control de calidad habilitado para IoT

- Qué integra: Detección de defectos en tiempo real, mantenimiento predictivo y supervisión remota de máquinas.

- Por qué es innovador: Reduce residuos, minimiza el tiempo de inactividad y mejora la eficacia operativa..

Precios de las perfiladoras para excavadoras

El coste de un Máquina perfiladora para excavadoras depende de características, capacidad de producción y opciones de personalización. A continuación figura una guía general de precios para 2025:

| Tipo de máquina | Capacidades | Gama de precios (USD) |

|---|---|---|

| Máquinas estándar | Producción básica de chasis de excavadoras | 400,000–400,000–400,000–1,000,000 |

| Máquinas avanzadas | Producción a alta velocidad con perforación automática | 1,000,000–1,000,000–1,000,000–3,000,000 |

| Máquinas inteligentes personalizables | Soluciones de Industria 4.0 totalmente automatizadas y conectadas a IoT | 3,000,000–3,000,000–3,000,000–7,000,000 |

Para obtener precios personalizados y opciones de financiación, póngase en contacto con Maquinaria Wuxi Sunway.

Historias reales de éxito: Cómo las perfiladoras de excavadoras están transformando la fabricación de maquinaria pesada

En obras de construcción urbanas a explotaciones mineras de gran profundidad, Perfiladoras para excavadoras ayudar a los fabricantes producción a escala, reducir costes y mejorar la durabilidad. A continuación aplicaciones reales mostrando el impacto de estas máquinas en fabricación de excavadoras.

1. Fabricación de grandes excavadoras en Estados Unidos

Cliente: A principal fabricante estadounidense de maquinaria de construcción.

Desafío: Necesario paneles de acero de alta resistencia para bastidores de excavadoras y refuerzos del tren de rodaje.

Solución: Wuxi Sunway Machinery suministró un perfiladora a medida capaz de procesar acero resistente al desgaste.

Resultado:

✅ Mayor durabilidadgarantizando mayor vida útil en condiciones duras.

✅ Reducción de los costes de producción en 30%aumentando rentabilidad.

✅ Proceso de fabricación más rápidopermitiendo mayores volúmenes de producción.

2. Producción de excavadoras mineras para proyectos sudamericanos

Cliente: A proveedor de equipos mineros para operaciones de extracción a gran escala en Chile y Perú.

Desafío: Requerido refuerzos de chasis y pluma de alta resistencia para excavadoras que trabajan en condiciones mineras extremas.

Solución: Wuxi Sunway proporcionó un perfiladora optimizada para el procesado de acero de alta resistencia.

Resultado:

✅ Mayor resistencia a la tensión mecánicaprevenir avería de equipos en explotaciones mineras.

✅ Mayor vida útil de los componentes de la excavadorareduciendo tiempo de inactividad por mantenimiento.

✅ Mayor capacidad de cargagarantizando mejor rendimiento en explotaciones mineras profundas.

3. Producción de bastidores de excavadoras compactas en Europa

Cliente: A Fabricante europeo especializado en excavadoras compactas y urbanas.

Desafío: Necesario materiales de bastidor ligeros pero resistentes para una excavación urbana eficaz.

Solución: Wuxi Sunway entregó un perfiladora capaz de procesar aleaciones de aluminio.

Resultado:

✅ Reducción del peso total de la máquinaaumentando eficiencia de combustible.

✅ Mayor maniobrabilidadmejorando rendimiento de la excavadora en espacios confinados.

✅ Uso optimizado del materialminimizando residuos y costes de producción.

4. Componentes inteligentes de excavadoras para la construcción en Oriente Medio

Cliente: A empresa de tecnología de la construcción centrada en soluciones inteligentes para excavadoras.

Desafío: Necesario paneles estructurales con sensores integrados para sistemas automatizados de excavación.

Solución: Wuxi Sunway proporcionó un perfiladora de alta tecnología capaz de integrar sensores en el proceso de producción.

Resultado:

✅ Control en tiempo real del rendimiento de la excavadora.

✅ Reducción del riesgo de averías gracias al mantenimiento predictivo.

✅ Despliegue más rápido de excavadoras inteligentes en proyectos de construcción a gran escala.

5. Piezas de excavadora resistentes a la corrosión para la construcción costera en Australia

Cliente: A empresa especializada en infraestructuras costeras y equipos de dragado.

Desafío: Necesario paneles de acero resistentes a la corrosión para excavadoras que trabajan en ambientes salinos.

Solución: Wuxi Sunway proporcionó un perfiladora con aplicación integrada de revestimiento anticorrosión.

Resultado:

✅ Mayor vida útil de los componentesreduciendo costes de sustitución.

✅ Mayor resistencia a la oxidación y a los daños causados por el agua salada.

✅ Mayor fiabilidad de los equipos en proyectos de excavación costera.

Tendencias futuras en la fabricación de excavadoras para 2025

En la fabricación de maquinaria pesada evolucionala demanda de excavadoras más fuertes, ligeras y eficientes está aumentando. Los fabricantes están adoptando nuevos materiales, automatización y tecnologías basadas en IA para mejorar el rendimiento de las excavadoras. A continuación se indican las tendencias clave que configuran el futuro de Perfiladoras para excavadoras.

1. Fabricación basada en IA para ingeniería de precisión

- Tendencia: Los sistemas basados en IA permiten ajustes en tiempo real en el procesamiento de materiales para optimizar los componentes de las excavadoras.

- Impacto en las máquinas: Los sistemas de perfilado integrarán Control de calidad basado en IA para una mayor eficacia y durabilidad estructural.

2. Materiales ultraligeros y de alta resistencia

- Tendencia: Mayor uso de aleaciones avanzadas de acero, materiales compuestos y aluminio reforzado.

- Impacto en las máquinas: Las máquinas se optimizarán para transformación multimaterial para mejorar la relación resistencia-peso.

3. Bastidores de excavadora modulares para personalización

- Tendencia: Crecimiento en diseños de excavadoras modulares para facilitar la personalización y el montaje rápido.

- Impacto en las máquinas: Los sistemas de perfilado darán prioridad componentes de bastidor intercambiables y características de montaje rápido.

4. Revestimientos resistentes a la corrosión y al desgaste

- Tendencia: Más estricto normas de durabilidad para excavadoras utilizadas en entornos extremos.

- Impacto en las máquinas: Las máquinas integrarán sistemas de aplicación de revestimientos para una mayor longevidad de los componentes.

5. Excavadoras inteligentes con IoT y capacidades autónomas

- Tendencia: Inversión en equipos de construcción autónomos y sistemas de excavación basados en IA.

- Impacto en las máquinas: Aumento de la demanda de paneles perfilados con sensores inteligentes integrados.

Innovaciones en perfiladoras de excavadoras para 2025

La próxima generación de Perfiladoras para excavadoras está llamada a revolucionar construcción y fabricación de maquinaria pesada. A continuación figuran algunas de las últimas innovaciones:

1. Fabricación de precisión guiada por IA

- Qué permite: Sistemas basados en IA ajuste automático de los parámetros de conformado para una integridad estructural óptima.

- Por qué es revolucionario: Reduce residuos, mejora la eficacia y garantiza una calidad constante de los productos..

2. Recubrimientos resistentes al desgaste y a la corrosión

- Lo que añade: Máquinas capaces de aplicación de revestimientos protectores para mejorar la longevidad de los componentes.

- Por qué es valioso: Amplía vida útil de la excavadora y reduce los costes de mantenimiento.

3. Unidades portátiles de perfilado in situ

- Qué ofrece: Máquinas móviles de perfilado para fabricación de maquinaria pesada localizada y a la carta.

- Por qué cambia el juego: Reduce costes logísticos y permite una producción rápida de componentes en las obras..

4. Supervisión inteligente y mantenimiento predictivo

- Qué integra: Sistemas basados en IoT para detección de defectos en tiempo real y programación predictiva del mantenimiento.

- Por qué es esencial: Minimiza los tiempos de inactividad y garantiza la eficacia continua de la producción.

Por qué Wuxi Sunway Machinery lidera la industria de fabricación de excavadoras

1. Décadas de experiencia

Con años de experienciaWuxi Sunway tiene una trayectoria de excelencia demostrada en soluciones de perfilado para excavadoras.

2. Tecnología punta

Incorpora funciones avanzadas como IA, automatización basada en IoT y laminado de alta velocidad.

3. Excelencia en la personalización

Ofertas soluciones a medida para fabricantes de excavadoras y proveedores de maquinaria pesada.

4. Liderazgo mundial del sector

De confianza constructoras, empresas mineras y promotores de infraestructuras de todo el mundo.

5. Apoyo integral

Proporciona asesoramiento, instalación, formación y servicios posventa para un funcionamiento sin problemas.

Visite su sitio web oficial para explorar sus ofertas o solicitar una solución personalizada de perfilado para excavadoras a la medida de sus necesidades.

Reflexiones finales: El futuro de la fabricación de excavadoras con la tecnología de perfilado

¿Quiere optimizar su proceso de producción de componentes para excavadoras? Asociarse con Maquinaria Wuxi Sunway y lleve su fabricación de maquinaria pesada al siguiente nivel.