বৈশিষ্ট্য

হোলো গাইড রেল প্রোডাকশন লাইন বিভিন্ন লিফট হোলো গাইড রেল তৈরির জন্য ডিজাইন করা হয়েছে যার দেয়ালের পুরুত্ব ২.৩মিমি-৩.২মিমি। এই নতুন ধরনের প্রোডাকশন লাইনের উচ্চ নির্ভুলতা এবং উচ্চ প্রক্রিয়াকরণ গতির মতো সুবিধা রয়েছে। এর প্রক্রিয়াকরণ গতি ঐতিহ্যগতের কয়েকগুণ হতে পারে।

অ্যাপ্লিকেশন

সমাপ্ত পণ্যগুলো লিফট ইত্যাদিতে ব্যাপকভাবে ব্যবহৃত হয়।

প্রক্রিয়া প্রবাহ

আনকয়লার — শিয়ার এবং বাট ওয়েল্ডার — অ্যাকিউমুলেটর — লেভেলিং — রোল ফর্মিং — ফ্লায়িং কাটিং — রান আউট টেবিল

মেশিন কনফিগারেশন

| ১. ডাবল হেড আনকয়লার |

২. শিয়ার এবং বাট ওয়েল্ডার

|

| ৩. হরিজন্টাল অ্যাকিউমুলেটর | ৪. লেভেলিং |

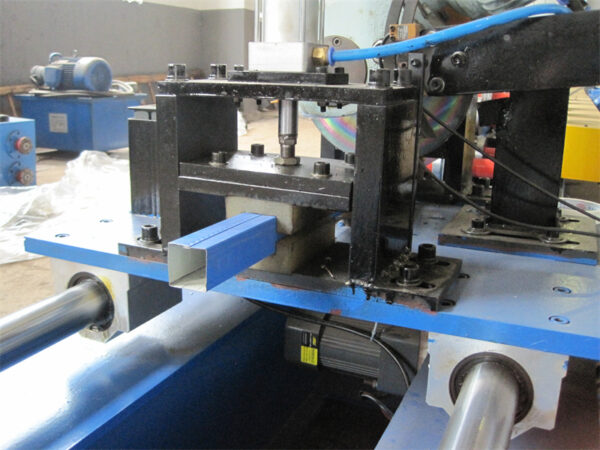

| 5. রোল ফর্মিং মেশিন | ৬. ফ্লায়িং কাটিং ডিভাইস |

| 7. রান আউট টেবিল |

গাইড রেল রোল ফর্মিং মেশিনের কার্যপ্রণালী কী?

গাইড রেল রোল ফর্মিং মেশিনটি গাইড রেল উৎপাদনের জন্য ডিজাইন করা হয়েছে, যা গার্ডরেল বা নিরাপত্তা বাধা নামেও পরিচিত। গাইড রেল রোল ফর্মিং মেশিনের কার্যনীতি নিম্নলিখিত বিভিন্ন ধাপ নিয়ে গঠিত:

- উপাদান সরবরাহ: প্রক্রিয়াটি সাধারণত ইস্পাত বা অ্যালুমিনিয়ামের কয়েল আকারে কাঁচামালের সাথে শুরু হয়, যা ডিকয়লারে লোড করা হয়। উপাদানগুলি রোলারের সেটের মাধ্যমে রোল ফর্মিং মেশিনে সরবরাহ করা হয়।

- রোল ফর্মিং: কাঁচামালটি একাধিক রোলার স্টেশনের মধ্য দিয়ে অতিক্রম করে, যার প্রত্যেকটি উপাদানকে ধীরে ধীরে আকার দেয়। এই রোলারগুলি কৌশলগতভাবে অবস্থিত এবং গাইড রেলের কাঙ্ক্ষিত প্রোফাইল গঠনের জন্য ডিজাইন করা হয়েছে। রোলারগুলি উপাদানের উপর চাপ প্রয়োগ করে এটিকে কাঙ্ক্ষিত আকারে বাঁকিয়ে এবং গঠন করে।

- কাটিং: গাইড রেল প্রোফাইল গঠিত হওয়ার পর, রোল ফর্মিং মেশিনটি কাটিং প্রক্রিয়া ব্যবহার করে অবিরত দৈর্ঘ্যের গাইড রেলকে কাঙ্ক্ষিত দৈর্ঘ্যের ব্যক্তিগত অংশে বিভক্ত করে। এটি বিভিন্ন কাটিং পদ্ধতি ব্যবহার করে সম্পন্ন করা যায়, যেমন ফ্লাইং কাটঅফ বা হাইড্রোলিক শিয়ারিং।

- গঠন এবং ফিনিশিং: নির্দিষ্ট প্রয়োজনীয়তা অনুসারে, গাইড রেলের কার্যকারিতা বা চেহারা উন্নত করার জন্য অতিরিক্ত কাজ সম্পাদন করা যেতে পারে। এই কাজগুলির মধ্যে আনুষাঙ্গিক সংযুক্ত করার জন্য ছিদ্র সৃষ্টি, শক্তি বৃদ্ধির জন্য এমবসিং বা ক্ষয় প্রতিরোধের জন্য গ্যালভানাইজিং বা পেইন্টিংয়ের মতো পৃষ্ঠ চিকিত্সা অন্তর্ভুক্ত থাকতে পারে।

- স্ট্যাকিং বা প্যাকেজিং: সমাপ্ত গাইড রেল অংশগুলি তখন আরও প্রক্রিয়াকরণের জন্য স্ট্যাক করা হয় বা পরিবহন এবং ডেলিভারির জন্য প্যাকেজ করা হয়।

সমগ্র প্রক্রিয়ায়, গাইড রেল রোল ফর্মিং মেশিনটি রোলার, কাটিং প্রক্রিয়া এবং অন্যান্য উপাদানের সুনির্দিষ্ট নিয়ন্ত্রণের উপর নির্ভর করে গাইড রেল প্রোফাইলের সঠিক গঠন নিশ্চিত করে। মেশিনের নিয়ন্ত্রণ ব্যবস্থা কাঙ্ক্ষিত স্পেসিফিকেশন এবং সেটিংসের ভিত্তিতে এই উপাদানগুলির গতিবিধি এবং কার্যকলাপ সমন্বয় করে। এটি উচ্চ নির্ভুলতা এবং দক্ষতার সাথে গাইড রেলের সামঞ্জস্যপূর্ণ উৎপাদন সম্ভব করে।

ডিআইএন রেল রোল ফর্মিং মেশিনের প্রয়োগ

ডিআইএন রেল রোল ফর্মিং মেশিনটি বিদ্যুত এবং ইলেকট্রনিক ইনস্টলেশনের জন্য স্ট্যান্ডার্ডাইজড মেটাল রেল যা ডিআইএন রেল উৎপাদনের জন্য বিশেষভাবে ডিজাইন করা হয়েছে। ডিআইএন রেল রোল ফর্মিং মেশিনের প্রয়োগ বিভিন্ন শিল্পে ডিআইএন রেল উৎপাদনে নিহিত, যার মধ্যে রয়েছে:

- ইলেকট্রিক্যাল প্যানেল উৎপাদন: ডিআইএন রেলগুলি ইলেকট্রিক্যাল প্যানেলে সাধারণত ব্যবহৃত হয় যাতে সার্কিট ব্রেকার, রেলে, টার্মিনাল ব্লক এবং পাওয়ার সাপ্লাইয়ের মতো ইলেকট্রিক্যাল উপাদানের জন্য স্ট্যান্ডার্ডাইজড মাউন্টিং প্ল্যাটফর্ম প্রদান করা যায়। ডিআইএন রেল রোল ফর্মিং মেশিনটি ইলেকট্রিক্যাল প্যানেল উৎপাদকদের নির্দিষ্ট প্রয়োজনীয়তা পূরণের জন্য বিভিন্ন আকার এবং কনফিগারেশনের ডিআইএন রেল উৎপাদনে ব্যবহৃত হয়।

- শিল্প অটোমেশন: ডিআইএন রেলগুলি শিল্প অটোমেশন সিস্টেমে প্রোগ্রামেবল লজিক কন্ট্রোলার (পিএলসি), মোটর স্টার্টার, কনট্যাক্টর এবং পাওয়ার ডিস্ট্রিবিউশন মডিউলের মতো বিভিন্ন নিয়ন্ত্রণ ডিভাইস মাউন্ট এবং সংগঠিত করার জন্য ব্যাপকভাবে ব্যবহৃত হয়। ডিআইএন রেল রোল ফর্মিং মেশিনটি শিল্প অটোমেশন প্রয়োগে ব্যবহৃত স্ট্যান্ডার্ডাইজড মাউন্টিং মাপের সাথে সামঞ্জস্যপূর্ণ ডিআইএন রেল উৎপাদনে গুরুত্বপূর্ণ ভূমিকা পালন করে।

- ভবন অটোমেশন: ডিআইএন রেলগুলি ভবন অটোমেশন সিস্টেমে এইচভিএসি (হিটিং, ভেন্টিলেশন এবং এয়ার কন্ডিশনিং), আলোকসজ্জা, নিরাপত্তা সিস্টেম এবং অন্যান্য ভবন ব্যবস্থাপনা সিস্টেমের নিয়ন্ত্রণ ডিভাইস মাউন্ট করার জন্য ব্যবহৃত হয়। ডিআইএন রেল রোল ফর্মিং মেশিনটি ভবন অটোমেশন অবকর্ণায় এই নিয়ন্ত্রণ ডিভাইসগুলির সহজ ইনস্টলেশন এবং সংগঠন সম্ভব করে এমন ডিআইএন রেল উৎপাদন করে।

- নবায়নযোগ্য শক্তি ব্যবস্থা: ডিআইএন রেলগুলি নবায়নযোগ্য শক্তি ব্যবস্থায় ব্যবহৃত হয়, যার মধ্যে সৌরশক্তি ইনস্টলেশন এবং বায়ু শক্তি ব্যবস্থা অন্তর্ভুক্ত। এগুলি সৌর ইনভার্টার, চার্জ কন্ট্রোলার, মনিটরিং ডিভাইস এবং যোগাযোগ সরঞ্জামের মতো উপাদান স্থাপনের জন্য ব্যবহৃত হয়। ডিআইএন রেল রোল ফর্মিং মেশিন এই নবায়নযোগ্য শক্তি অ্যাপ্লিকেশনের জন্য উপযুক্ত ডিআইএন রেল উৎপাদনে সহায়তা করে।

- রেলপথ এবং পরিবহন: ডিআইএন রেলগুলি রেলপথ এবং পরিবহন ব্যবস্থায় নিয়ন্ত্রণ যন্ত্রপাতি এবং ট্রেন, ট্রাম ও অন্যান্য যানবাহনের উপর ইলেকট্রিকাল সরঞ্জাম স্থাপনের জন্য ব্যবহৃত হয়। ডিআইএন রেল রোল ফর্মিং মেশিন এই পরিবহন ব্যবস্থার প্রয়োজনীয়তা পূরণকারী ডিআইএন রেল উৎপাদন করে, যা ইলেকট্রিকাল উপাদানের নিরাপদ ও নির্ভরযোগ্য স্থাপন নিশ্চিত করে।

সামগ্রিকভাবে, ডিআইএন রেল রোল ফর্মিং মেশিনের প্রয়োগ ইলেকট্রিকাল ও ইলেকট্রনিক উপাদানের জন্য মানকীকৃত স্থাপন ব্যবস্থার উপর নির্ভরশীল শিল্পক্ষেত্রে ব্যাপক, যা সরঞ্জাম স্থাপন ও সংগঠনের জন্য দক্ষ ও নির্ভরযোগ্য সমাধান প্রদান করে।

স্লাইড রেল রোল ফর্মিং মেশিন এবং ডিআইএন রেল রোল ফর্মিং মেশিনের মধ্যে পার্থক্য কী?

স্লাইড রেল রোল ফর্মিং মেশিন এবং ডিআইএন রেল রোল ফর্মিং মেশিনের মধ্যে পার্থক্য নিম্নরূপ ব্যাখ্যা করা যায়:

- উদ্দেশ্য: স্লাইড রেল রোল ফর্মিং মেশিন প্রধানত স্লাইড রেল উৎপাদনের জন্য ব্যবহৃত হয়, যা বস্তুসমূহের নির্দেশনা, সমর্থন এবং গতিসম্পাদন সহজতর করার জন্য ব্যবহৃত হয়। এগুলি যন্ত্রপাতি, শিল্প অটোমেশন ব্যবস্থা, কনভেয়র সরঞ্জাম এবং অন্যান্য ক্ষেত্রে সাধারণত প্রয়োগ হয়। অন্যদিকে, ডিআইএন রেল রোল ফর্মিং মেশিন ইলেকট্রিকাল ও ইলেকট্রনিক সরঞ্জাম স্থাপন ও স্থিরীকরণের জন্য ডিআইএন রেল উৎপাদনে ব্যবহৃত হয়।

- আকার এবং মাপ: স্লাইড রেলগুলির সাধারণত ইউ-আকৃতির বা সি-আকৃতির ক্রস-সেকশন থাকে এবং একক-স্লট বা বহু-স্লট কাঠামো হতে পারে। এদের মাপ এবং আকার নির্দিষ্ট প্রয়োগের প্রয়োজন অনুসারে কাস্টমাইজ করা যায়। ডিআইএন রেলগুলি কিন্তু ডিআইএন মানদণ্ড অনুসরণ করে এবং সাধারণত মানকীকৃত ক্রস-সেকশন ও মাপ রাখে যাতে ইলেকট্রিকাল ও ইলেকট্রনিক ডিভাইসের সুবিধাজনক স্থাপন ও মাউন্টিং সম্ভব হয়।

- স্থাপন পদ্ধতি: স্লাইড রেলগুলি সাধারণত বোল্ট, স্ক্রু বা অন্যান্য ফাস্টেনার ব্যবহার করে স্থাপিত হয় যাতে সামঞ্জস্যযোগ্য বা চলমান সমর্থন ও নির্দেশনা প্রদান করা যায়। ডিআইএন রেলগুলি কিন্তু সাধারণত মাউন্টিং স্ক্রু বা অন্যান্য ফাস্টেনার ব্যবহার করে ইলেকট্রিকাল বা ইলেকট্রনিক ডিভাইসের ভিত্তিতে সরাসরি স্থাপিত হয়।

- উৎপাদন প্রক্রিয়া: স্লাইড রেল রোল ফর্মিং মেশিন এবং ডিআইএন রেল রোল ফর্মিং মেশিনের উৎপাদন প্রক্রিয়ায় সামান্য পার্থক্য রয়েছে। স্লাইড রেল রোল ফর্মিং মেশিন স্লাইড রেলের আকার ও মাপ অনুসারে একাধিক রোলার এবং কাটিং ডিভাইস ব্যবহার করে অবিরত কয়েল উপাদানকে কাঙ্ক্ষিত স্লাইড রেল প্রোফাইলে রূপান্তরিত করে। ডিআইএন রেল রোল ফর্মিং মেশিন ডিআইএন মানদণ্ড অনুসরণ করে নির্দিষ্ট রোলার এবং কাটিং ডিভাইস ব্যবহার করে কয়েল উপাদানকে ডিআইএন রেলের মানদণ্ড পূরণকারী করে।

সারাংশে, স্লাইড রেল রোল ফর্মিং মেশিন এবং DIN রেল রোল ফর্মিং মেশিন বিভিন্ন প্রয়োগ এবং মাউন্টিং প্রয়োজনীয়তা পূরণ করে। স্লাইড রেলগুলি বস্তুর গতি নির্দেশনা এবং সমর্থনের জন্য ব্যবহৃত হয়, যেখানে DIN রেলগুলি ইলেকট্রিক্যাল এবং ইলেকট্রনিক সরঞ্জামের স্থাপন এবং স্থিরীকরণের জন্য ব্যবহৃত হয়। এগুলি আকৃতি, আকার এবং উৎপাদন প্রক্রিয়ার দিক থেকে ভিন্ন, যা নির্দিষ্ট প্রয়োগের চাহিদা এবং মানদণ্ড পূরণ করে।

রিভিউ

কোন রিভিউ এখনো আছে।