শাটার ডোর রোল ফর্মিং মেশিন উৎপাদন শিল্পে ব্যাপকভাবে ব্যবহৃত হয় গ্যারেজ দরজা থেকে বাণিজ্যিক দোকানের সামনের অংশ পর্যন্ত বিভিন্ন পণ্য উৎপাদনের জন্য। এই মেশিনগুলি ধাতব চাদরগুলিকে নির্দিষ্ট প্রোফাইল এবং মাত্রায় আকার দেওয়ার জন্য অবিরত বাঁকানো প্রক্রিয়া ব্যবহার করে, যা অনেক উৎপাদন চাহিদার জন্য একটি বহুমুখী এবং দক্ষ সমাধান করে তোলে। তবে, বাজারে উপলব্ধ বিভিন্ন ধরনের রোল ফর্মিং মেশিনের কারণে, আপনার চাহিদার জন্য কোনটি সবচেয়ে উপযুক্ত তা নির্ধারণ করা চ্যালেঞ্জিং হতে পারে। এই পোস্টে আমরা উপলব্ধ শাটার দরজা রোল ফর্মিং মেশিনের বিভিন্ন ধরন, তাদের ক্ষমতা এবং সুবিধা ও সীমাবদ্ধতা নিয়ে আলোচনা করব, যাতে আপনার উৎপাদন চাহিদা পূরণের জন্য মেশিন নির্বাচন করার সময় সচেতন সিদ্ধান্ত নিতে সাহায্য করা যায়।

শাটার দরজা রোল ফর্মিং মেশিন: সিঙ্গেল-শ্যাফট

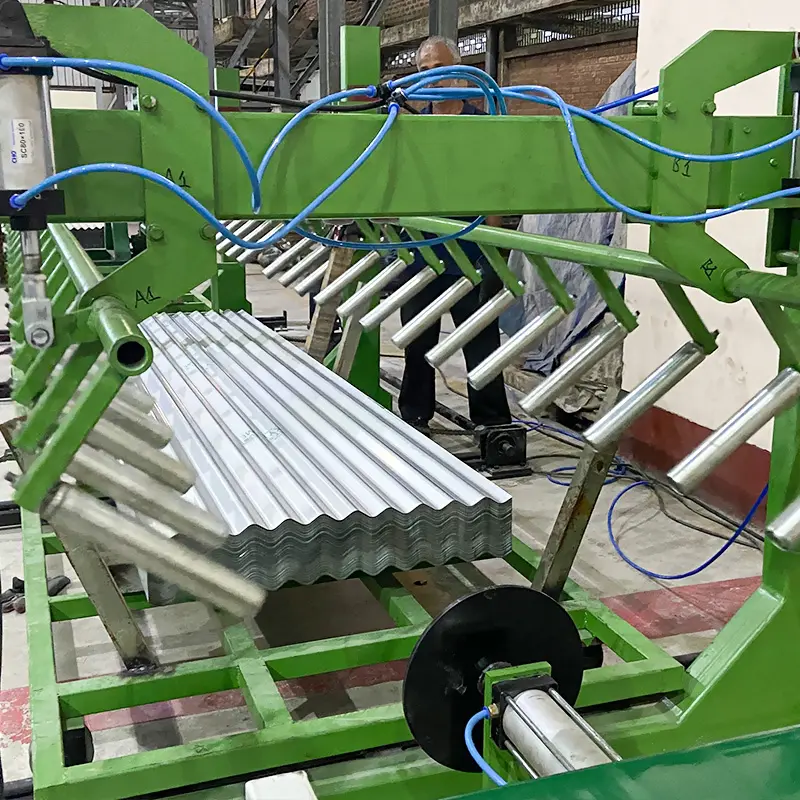

সিঙ্গেল-শ্যাফট রোল ফর্মিং মেশিনগুলি একটি ধরনের রোল ফর্মিং মেশিন যা একটি সেট রোলার ব্যবহার করে ধাতব চাদরগুলিকে নির্দিষ্ট প্রোফাইলে বাঁকিয়ে আকার দেয়। এই মেশিনগুলি ধাতব চাদরটিকে একাধিক রোলারের মধ্য দিয়ে অবিরতভাবে খাওয়ানো করে চালিত হয়, যা ধাপে ধাপে চাদরটিকে কাঙ্ক্ষিত প্রোফাইলে বাঁকিয়ে আকার দেয়।

সিঙ্গেল-শ্যাফট রোল ফর্মিং মেশিনগুলি বহুমুখী এবং বিস্তৃত পরিসরের পণ্য উৎপাদন করতে পারে, যার মধ্যে রয়েছে গ্যারেজ দরজা, শিল্প শাটার এবং বাণিজ্যিক দোকানের সামনের অংশ। এগুলি সমান ক্রস-সেকশনের সাধারণ প্রোফাইল উৎপাদনের জন্যও উপযুক্ত, যেমন সমতল বা কোণাকৃতির আকার।

সিঙ্গেল-শ্যাফট রোল ফর্মিং মেশিনের সুবিধাগুলির মধ্যে একটি হলো তাদের সরলতা এবং ব্যবহারের সহজতা। এই মেশিনগুলি সহজে চালানো যায় এবং ন্যূনতম রক্ষণাবেক্ষণের প্রয়োজন হয়, যা ছোট বা মাঝারি আকারের উৎপাদনের জন্য আকর্ষণীয় বিকল্প করে তোলে।

তবে, সিঙ্গেল-শ্যাফট রোল ফর্মিং মেশিনগুলির কিছু সীমাবদ্ধতাও রয়েছে। এগুলি জটিল আকার বা প্রোফাইল উৎপাদনের জন্য উপযুক্ত নয় যা একাধিক বাঁকা বা ক্রস-সেকশনাল এরিয়ায় পরিবর্তনের প্রয়োজন। অতিরিক্তভাবে, সিঙ্গেল-শ্যাফট রোল ফর্মিং মেশিনগুলি একটি সেট রোলার ব্যবহার করার কারণে চূড়ান্ত পণ্যে কিছু পৃষ্ঠের ত্রুটি বা অনিয়মিততা উৎপাদন করতে পারে।

উপসংহারে, সিঙ্গেল-শ্যাফট রোল ফর্মিং মেশিনগুলি সমান ক্রস-সেকশনের বিস্তৃত পরিসরের পণ্য উৎপাদনের জন্য একটি বহুমুখী এবং সরল বিকল্প। যদিও এদের কিছু সীমাবদ্ধতা রয়েছে, তবুও সাধারণ প্রোফাইলের প্রয়োজনীয় ছোট বা মাঝারি আকারের উৎপাদনের জন্য এগুলি আকর্ষণীয় বিকল্প।

শাটার দরজা রোল ফর্মিং মেশিন: ডাবল-শ্যাফট

-

বৈদ্যুতিক মন্ত্রিসভা ফ্রেম রোল গঠনের মেশিন

বৈদ্যুতিক মন্ত্রিসভা ফ্রেম রোল গঠনের মেশিন -

দিন রেল রোল ফর্মিং মেশিন

দিন রেল রোল ফর্মিং মেশিন -

তারের মই রোল ফর্মিং মেশিন

তারের মই রোল ফর্মিং মেশিন -

পিভি মাউন্টিং বন্ধনী সি শেপ প্রোফাইল রোল ফর্মিং মেশিন

পিভি মাউন্টিং বন্ধনী সি শেপ প্রোফাইল রোল ফর্মিং মেশিন -

তারের ট্রে রোল ফর্মিং মেশিন

তারের ট্রে রোল ফর্মিং মেশিন -

পিভি মাউন্টিং ব্র্যাকেট রোল ফর্মিং মেশিন (HAT / ওমেগা প্রোফাইল)

পিভি মাউন্টিং ব্র্যাকেট রোল ফর্মিং মেশিন (HAT / ওমেগা প্রোফাইল) -

পিভি মাউন্টিং বন্ধনী জেড শেপ প্রোফাইল রোল ফর্মিং মেশিন

পিভি মাউন্টিং বন্ধনী জেড শেপ প্রোফাইল রোল ফর্মিং মেশিন -

সোলার মাউন্টিং স্ট্রট চ্যানেল রোল তৈরির মেশিন

সোলার মাউন্টিং স্ট্রট চ্যানেল রোল তৈরির মেশিন -

স্ট্রুট চ্যানেল রোল ফর্মিং মেশিন

স্ট্রুট চ্যানেল রোল ফর্মিং মেশিন

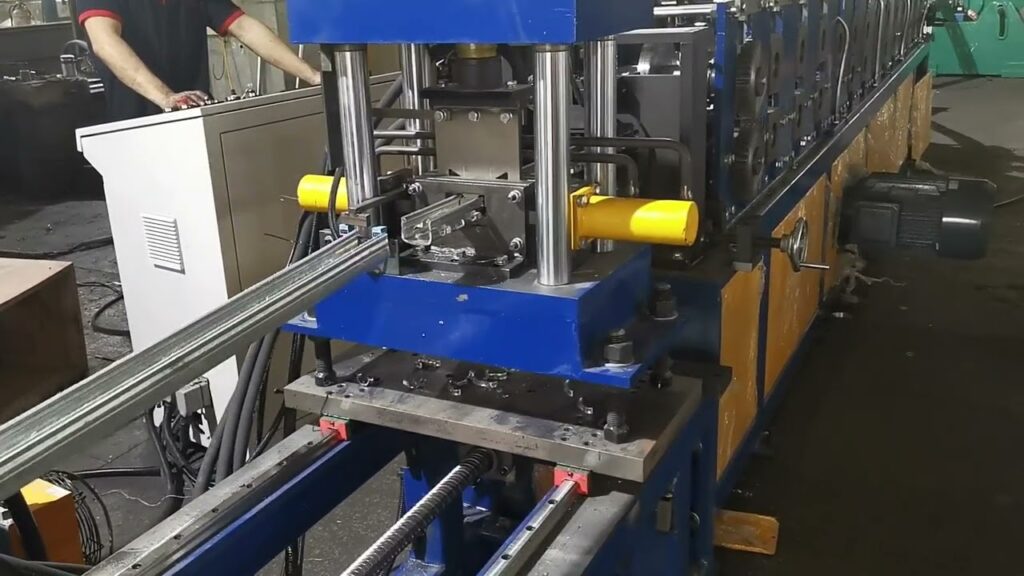

ডাবল-শ্যাফট রোল ফর্মিং মেশিনগুলি দুটি সেট রোলার ব্যবহার করে ধাতব চাদরগুলিকে নির্দিষ্ট প্রোফাইলে বাঁকিয়ে আকার দেয় এমন এক ধরনের রোল ফর্মিং মেশিন। এই মেশিনগুলি ধাতব চাদরটিকে দুটি সেট রোলারের মধ্য দিয়ে অবিরতভাবে খাওয়ানো করে চালিত হয় যা একসঙ্গে কাজ করে ধাপে ধাপে চাদরটিকে কাঙ্ক্ষিত প্রোফাইলে বাঁকিয়ে আকার দেয়।

ডাবল-শ্যাফট রোল ফর্মিং মেশিনগুলি সিঙ্গেল-শ্যাফট মেশিনের তুলনায় বেশ কয়েকটি সুবিধা প্রদান করে, যার মধ্যে রয়েছে উচ্চতর গতি, বেশি নির্ভুলতা এবং উন্নত পণ্যের গুণমান। দুটি সেট রোলারের ব্যবহার জটিল প্রোফাইল এবং আকারগুলি বেশি নির্ভুলতা এবং অভিন্নতার সঙ্গে উৎপাদন করতে সক্ষম করে। অতিরিক্তভাবে, ডাবল-শ্যাফট রোল ফর্মিং মেশিনগুলি উচ্চতর গতিতে পণ্য উৎপাদন করতে পারে, যা উৎপাদন আউটপুট এবং দক্ষতা বাড়ায়।

ডাবল-শ্যাফট রোল ফর্মিং মেশিন ব্যবহার করে উৎপাদিত পণ্যের মধ্যে রয়েছে গ্যারেজ দরজা, ধাতব ছাদ এবং বিভিন্ন ভবনের উপাদান। এই মেশিনগুলি ইস্পাত, অ্যালুমিনিয়াম এবং তামা সহ বিস্তৃত পরিসরের উপাদান পরিচালনা করতে পারে।

ডাবল-শ্যাফট রোল ফর্মিং মেশিনের সুবিধাগুলির মধ্যে একটি হলো সিঙ্গেল-শ্যাফট মেশিনের তুলনায় জটিল প্রোফাইল এবং আকার উৎপাদনের ক্ষমতা। এগুলি উচ্চতর নির্ভুলতা এবং অভিন্নতার সঙ্গে পণ্য উৎপাদন করতে পারে, যা ত্রুটি কমায় এবং পণ্যের গুণমান বাড়ায়। অতিরিক্তভাবে, তাদের উচ্চতর উৎপাদন গতি দক্ষতা বাড়াতে এবং উৎপাদন খরচ কমাতে পারে।

উপসংহারে, ডাবল-শ্যাফট রোল ফর্মিং মেশিনগুলি গতি, নির্ভুলতা এবং পণ্যের গুণমানের দিক থেকে সিঙ্গেল-শ্যাফট মেশিনের তুলনায় বেশ কয়েকটি সুবিধা প্রদান করে। এগুলি গ্যারেজ দরজা থেকে ধাতব ছাদ পর্যন্ত বিস্তৃত পরিসরের পণ্য উৎপাদনের জন্য উপযুক্ত এবং বিভিন্ন উপাদান পরিচালনা করতে পারে।

শাটার দরজা রোল ফর্মিং মেশিন: মাল্টি-রোল

মাল্টি-রোল ফর্মিং মেশিনগুলি তিন বা তার বেশি সেট রোলার ব্যবহার করে ধাতব চাদরগুলিকে জটিল আকার এবং প্রোফাইলে উচ্চ নির্ভুলতা এবং পুনরাবৃত্তিযোগ্যতার সঙ্গে বাঁকিয়ে আকার দেয় এমন এক ধরনের রোল ফর্মিং মেশিন। এই মেশিনগুলি বিভিন্ন পুরুত্ব এবং প্রস্থের উপাদান পরিচালনা করতে পারে এবং চ্যালেঞ্জিং জ্যামিতি এবং টলারেন্সের অংশ উৎপাদনের জন্য উপযুক্ত।

মাল্টি-রোল ফর্মিং মেশিনগুলি ধাতব চাদরটিকে একাধিক সেট রোলারের মধ্য দিয়ে খাওয়ানো করে চালিত হয় যা ধাপে ধাপে চাদরটিকে কাঙ্ক্ষিত প্রোফাইলে আকার দেয়। প্রতিটি সেট রোলার অন্যান্যের সঙ্গে একসঙ্গে কাজ করে চাদরটিকে বিভিন্ন দিকে বাঁকায়, জটিল আকার এবং জ্যামিতি তৈরি করে।

মাল্টি-রোল ফর্মিং মেশিনের সুবিধাগুলির মধ্যে রয়েছে জটিল আকার এবং প্রোফাইল উচ্চ নির্ভুলতা এবং পুনরাবৃত্তিযোগ্যতার সঙ্গে উৎপাদনের ক্ষমতা। এই মেশিনগুলি টাইট টলারেন্সের অংশ তৈরি করতে পারে, অতিরিক্ত মেশিনিং বা প্রক্রিয়াকরণের প্রয়োজনীয়তা কমায়। অতিরিক্তভাবে, মাল্টি-রোল ফর্মিং মেশিনগুলি ইস্পাত, অ্যালুমিনিয়াম এবং তামা সহ বিস্তৃত পরিসরের উপাদান পরিচালনা করতে পারে।

মাল্টি-রোল ফর্মিং মেশিন ব্যবহার করে উৎপাদিত পণ্যের মধ্যে রয়েছে অটোমোটিভ অংশ, এয়ারোস্পেস উপাদান এবং উচ্চ-নির্ভুলতার যন্ত্রাংশ। এই মেশিনগুলি জটিল জ্যামিতির জানালার ফ্রেম এবং ধাতব ক্ল্যাডিংয়ের মতো ভবনের উপাদানও উৎপাদন করতে পারে।

উপসংহারে, মাল্টি-রোল ফর্মিং মেশিনগুলি অন্যান্য ধরনের রোল ফর্মিং মেশিনের তুলনায় বেশ কয়েকটি সুবিধা প্রদান করে, যার মধ্যে রয়েছে জটিল আকার এবং প্রোফাইল উচ্চ নির্ভুলতা এবং পুনরাবৃত্তিযোগ্যতার সাথে উৎপাদনের ক্ষমতা। এগুলি চ্যালেঞ্জিং জ্যামিতি এবং টলারেন্স সহ বিভিন্ন ধরনের অংশ এবং উপাদান উৎপাদনের জন্য উপযুক্ত।

শাটার ডোর রোল ফর্মিং মেশিন: উচ্চ-গতির

উচ্চ-গতির রোল ফর্মিং মেশিনগুলি রোল ফর্মিং মেশিনের একটি ধরন যা অসাধারণ নির্ভুলতা এবং গুণমানের সাথে উচ্চ গতিতে বড় পরিমাণে পণ্য উৎপাদন করতে পারে। এই মেশিনগুলি ধাতব চাদরগুলিকে একাধিক রোলারের মাধ্যমে ক্রমাগত খাওয়ানোর মাধ্যমে কাজ করে, যা চাদরটিকে কাঙ্ক্ষিত প্রোফাইলে ধাপে ধাপে বাঁকিয়ে গঠন করে।

উচ্চ-গতির রোল ফর্মিং মেশিনের প্রধান সুবিধা হলো এদের দ্রুত এবং দক্ষতার সাথে বড় পরিমাণে পণ্য উৎপাদনের ক্ষমতা। এই মেশিনগুলি প্রতি মিনিটে ৬০০ ফুট পর্যন্ত পণ্য উৎপাদন করতে পারে, যা উৎপাদন সময় এবং খরচ উল্লেখযোগ্যভাবে কমিয়ে দেয়। এছাড়াও, উচ্চ গতিতেও উচ্চ-গতির রোল ফর্মিং মেশিনগুলি অসাধারণ নির্ভুলতা এবং গুণমান বজায় রাখতে পারে, যার ফলে কম ত্রুটি এবং উচ্চতর পণ্যের গুণমান লাভ হয়।

উচ্চ-গতির রোল ফর্মিং মেশিন ব্যবহার করে উৎপাদিত পণ্যের মধ্যে রয়েছে অটোমোটিভ অংশ, ধাতব ছাদ এবং সাইডিং এবং শিল্প উপাদান। এই মেশিনগুলি ইস্পাত, অ্যালুমিনিয়াম এবং তামার মতো বিভিন্ন ধরনের উপাদান পরিচালনা করতে পারে।

উচ্চ-গতির রোল ফর্মিং মেশিনগুলি সুনির্দিষ্ট সহনশীলতা বজায় রাখতে এবং সামঞ্জস্যপূর্ণ পণ্যের গুণমান নিশ্চিত করতে উন্নত সেন্সর এবং নিয়ন্ত্রণ ব্যবস্থা ব্যবহার করে। এছাড়াও, এগুলিতে বিভিন্ন প্রোফাইল উৎপাদনের জন্য সহজেই পরিবর্তনযোগ্য উন্নত টুলিং সিস্টেম রয়েছে, যা উৎপাদকদের পরিবর্তনশীল উৎপাদন চাহিদার সাথে দ্রুত খাপ খাইয়ে নিতে সাহায্য করে।

উপসংহারে, উচ্চ-গতির রোল ফর্মিং মেশিনগুলি উচ্চ গতিতে বড় পরিমাণে পণ্য উৎপাদনের জন্য অত্যন্ত দক্ষ এবং নির্ভুল বিকল্প। এগুলি অসাধারণ নির্ভুলতা এবং গুণমান প্রদান করে, যা অটোমোটিভ অংশ, ধাতব ছাদ এবং সাইডিং এবং শিল্প উপাদান সহ বিস্তৃত পরিসরের পণ্যের জন্য উপযুক্ত করে তোলে। এদের উন্নত নিয়ন্ত্রণ এবং টুলিং সিস্টেম উৎপাদকদের পরিবর্তনশীল উৎপাদন চাহিদার সাথে দ্রুত খাপ খাইয়ে নিতে সাহায্য করে।

সামগ্রিকভাবে, উৎপাদন চাহিদা পূরণের জন্য সঠিক ধরনের শাটার ডোর রোল ফর্মিং মেশিন নির্বাচন করা অত্যন্ত গুরুত্বপূর্ণ। সিঙ্গেল-শ্যাফট মেশিনগুলি সহজ এবং বহুমুখী হলেও, ডাবল-শ্যাফট মেশিনগুলি উচ্চতর গতি, নির্ভুলতা এবং পণ্যের গুণমান প্রদান করে। মাল্টি-রোল ফর্মিং মেশিনগুলি জটিল আকার উৎপাদন করতে পারে, যখন উচ্চ-গতির মেশিনগুলি বড় পরিমাণে পণ্য দক্ষতার সাথে উৎপাদন করতে পারে। প্রত্যেক ধরনের মেশিনের ক্ষমতা এবং সুবিধা বোঝা উৎপাদকদের সচেতন সিদ্ধান্ত নিতে এবং সর্বোত্তম উৎপাদন ফলাফল অর্জন করতে সাহায্য করতে পারে।

Additional Frequently Asked Questions (FAQ)

1) What coil specs are typical for shutter door roll forming machines?

Most shutter lines process galvanized steel or pre-painted steel at 0.5–1.2 mm thickness, 100–500 mm strip width, 230–550 MPa yield strength, coil ID 508/610 mm, and max coil weight 3–7 tons. Always match specs to your decoiler, feeder, and tooling.

2) Which machine type is best for insulated or perforated shutter slats?

Double-shaft or multi-roll machines with pre-punch/perforation cassettes and foam-injection options handle insulated or ventilated slats better due to tighter pass control and add-on modules.

3) How fast do “high-speed” shutter door roll forming machines actually run?

High-speed shutter lines typically run 40–120 m/min (130–395 ft/min) depending on profile complexity, inline punching, and cut-off type. Real-world speeds drop if adding embossing, locking hooks, or flying notch cuts.

4) What affects profile quality and noise performance of shutter doors?

Pass design, lateral guides, anti-twist straighteners, and consistent material thickness reduce oil-canning and chatter. For quieter doors, specify hemmed edges, felt/brush inserts, and precise end-lock punching.

5) How should I compare total cost of ownership (TCO) across machine types?

Evaluate uptime, changeover time, scrap rate, energy use (kWh/ton), tooling life, and service availability. High-speed and multi-roll systems cost more upfront but can deliver lower cost per meter at volume.

2025 Industry Trends: Shutter Door Roll Forming Machines

- Rapid tool-less changeover: Servo-adjusted roll gaps and rafted stands reduce changeover from 45–60 minutes to 8–12 minutes for common shutter slat widths.

- Inline QC becomes standard: Laser profilometry checks crown, hook depth, and hem closure; SPC dashboards flag drift before defects ship.

- Energy-optimized drives: Wider adoption of high-efficiency motors and VFDs cuts energy per ton by 10–20%.

- Safety upgrades: PL e safety circuits, interlocked guards, and light curtains are now expected on CE/UL-compliant lines.

- Materials shift: More 350–550 MPa steels to achieve slimmer, stronger slats; pre-painted systems with harder topcoats for scratch resistance in high-traffic storefronts.

- Digital integration: OPC UA connectivity to MES/ERP for recipe control, coil traceability, and downtime analytics.

2024–2025 Benchmarks and Adoption Metrics

| Metric (shutter door profiles) | 2024 Baseline | 2025 Estimate | Buyer Impact | Source/Notes |

|---|---|---|---|---|

| Typical line speed (with flying cut) | 30–80 m/min | 40–120 m/min | +20–40% throughput | Vendor datasheets; MetalForming Magazine |

| Auto changeover adoption | ~35% | 55–65% | Faster changeovers; lower scrap | Industry surveys (SME, MFM) |

| Inline laser QC on slat geometry | ~15% | 30–40% | Fewer defects; SPC | SME Smart Manufacturing |

| Energy use per ton formed | 95–120 kWh/t | 80–105 kWh/t | Lower OPEX | OEM claims; VFD adoption |

| High-strength coils (≥350 MPa) usage | 40–50% | 55–65% | Weight down; durability up | Coil mills, AISI trends |

| Remote diagnostics-enabled PLCs | ~50% | 70–80% | Faster service | Siemens/Rockwell solution notes |

Authoritative references:

- AISI Cold-Formed Steel resources: https://www.buildusingsteel.org

- OSHA Machine Guarding: https://www.osha.gov

- European Machinery Safety (CE): https://single-market-economy.ec.europa.eu/sectors/mechanical-engineering/machine-safety_en

- SME Smart Manufacturing articles: https://www.sme.org

- MetalForming Magazine trends: https://www.metalformingmagazine.com

Latest Research Cases

Case Study 1: Tool-less Changeover Cuts Scrap for Retail Shutter Line (2025)

Background: A door manufacturer running 6 slat variants on a double-shaft line faced 38–50 minutes changeover and 3.2% scrap.

Solution: Upgraded to servo-adjusted roll gaps, rafted tooling carts, and inline laser check for hook depth and hem closure; integrated OPC UA to MES.

Results: Changeover reduced to 10–12 minutes; scrap fell to 1.1%; overall throughput increased 27% at 85 m/min.

Case Study 2: High-Strength Coil Adoption for Vandal-Resistant Storefronts (2024)

Background: Urban storefront client required stronger slats without weight penalties.

Solution: Re-designed pass progression for 500 MPa GI pre-painted steel; added anti-twist straightener and tighter flying cut tolerances.

Results: Slat mass reduced 9% with +18% bending resistance; line speed maintained at 70 m/min; defect rate (edge waviness) decreased by 42%.

Expert Opinions

- John Keane, VP Engineering, The Bradbury Group

Key viewpoint: “Servo-driven rafted systems are becoming the default for shutter slats—faster size changes and better hook consistency directly translate to quieter, smoother roll-ups.”

Source: https://bradburygroup.com - Dr. Helen Chen, Senior Materials Engineer, BlueScope Steel

Key viewpoint: “When forming pre-painted high-MPa coils, controlling edge strain and pass alignment is critical to prevent microcracking of coatings, which drives long-term corrosion performance.”

Source: https://bluescope.com - Mark Crawford, Editor, MetalForming Magazine

Key viewpoint: “Inline laser metrology and SPC are shifting quality from post-process inspection to real-time control, reducing warranty claims on shutter assemblies.”

Source: https://www.metalformingmagazine.com

Practical Tools/Resources

- Standards and design

- AISI design guides for cold-formed steel: https://www.buildusingsteel.org

- MBMA Metal Building Systems Manual: https://www.mbma.com

- Machine selection and OEMs

- The Bradbury Group shutter solutions: https://bradburygroup.com

- Samco Machinery shutter lines: https://www.samco-machinery.com

- DALLAN roll forming for shutters: https://www.dallan.com

- Controls and integration

- Siemens PLC/HMI libraries and OPC UA: https://support.industry.siemens.com

- Rockwell Automation Knowledgebase: https://rockwellautomation.custhelp.com

- Quality and safety

- NIST SPC resources: https://www.nist.gov

- OSHA eTool for machine guarding: https://www.osha.gov/etools/machine-guarding

- Costing and benchmarking

- RSMeans data (manufacturing lines): https://www.rsmeans.com

- Industry news and education

- SME Smart Manufacturing: https://www.sme.org

- Fabricators & Manufacturers Association (FMA): https://www.fmanet.org

Last updated: 2025-10-22

Changelog: Added 5 focused FAQs; introduced 2025 trend insights with benchmark table and sources; included two recent case studies; compiled expert viewpoints with citations; curated practical tools/resources relevant to shutter door roll forming machines

Next review date & triggers: 2026-04-22 or earlier if AISI/MBMA standards update, major PLC firmware releases, or coil supply shifts (≥350 MPa steels and pre-painted systems)