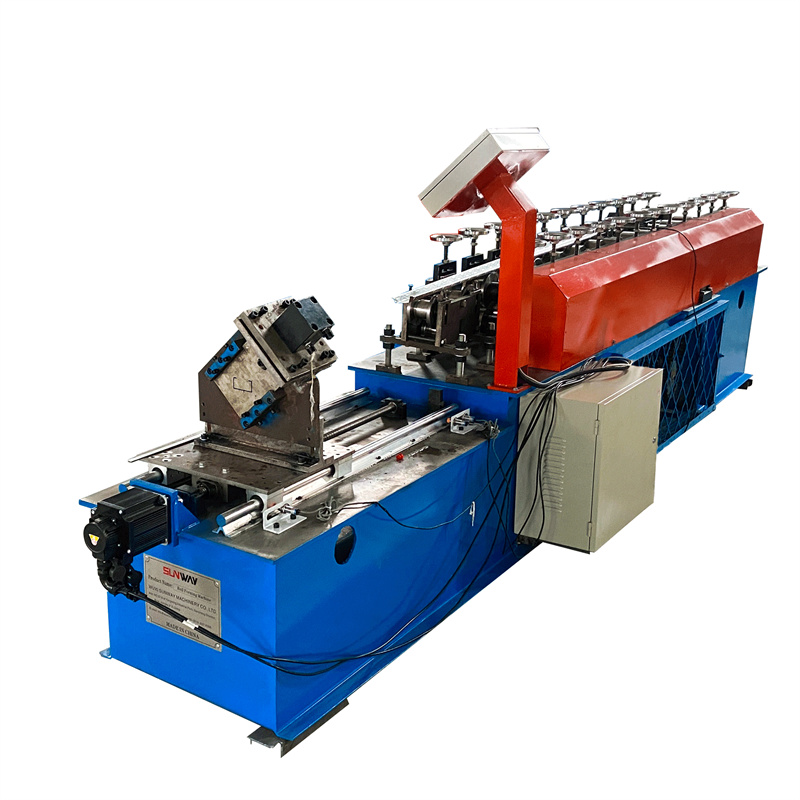

এই নিবন্ধে আলোচনা করা হয়েছে যে মেটাল ফর্ম দ্বারা বিকশিত একটি নতুন ধাতব স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন কীভাবে ইস্পাত কোম্পানিগুলোর শীট মেটাল উৎপাদন পদ্ধতিকে বিপ্লবী করে তুলতে পারে। নিবন্ধটি মেশিনের নকশা নিয়ে আলোচনা করে, যা কমপ্যাক্ট এবং বাজারের অন্যান্য মেশিনের চেয়ে সংকীর্ণ বাঁকা তৈরি করতে সক্ষম।

একটি ধাতু অশ্বপালনের এবং ট্র্যাক রোল গঠন মেশিন কি?

ক মেটাল স্টাড এবং ট্র্যাক রোল তৈরির মেশিন শিট মেটাল ফ্যাব্রিকেশনের জন্য মূল্যবান সরঞ্

এই ধরনের যন্ত্র কাস্টম অংশ তৈরিতে বিশেষভাবে সহায়ক। এটি ব্যবহার করে আপনি জটিল বিবরণ এবং নকশা তৈরি করতে পারেন, যা হাতে কাজ করে অর্জন করা কঠিন বা অসম্ভব। ফলস্বরূপ, মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন অটোমোটিভ শিল্প, এরোস্পেস শিল্প, চিকিৎসা শিল্পসহ বিভিন্ন ব্যবসায়িক প্রতিষ্ঠানে প্রায়শই ব্যবহৃত হয়।

এটি কীভাবে কাজ করে?

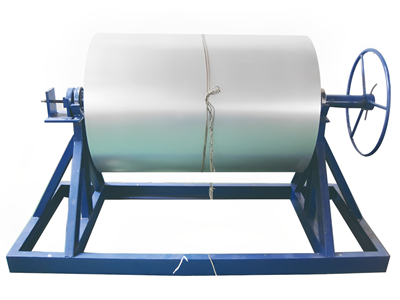

বিক্রয়ের জন্য মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন একটি অত্যাধুনিক, উচ্চগতির যন্ত্র যা বিভিন্ন প্রয়োগের জন্য সহজেই ধাতব স্টাড এবং ট্র্যাক গঠন করতে পারে। এই যন্ত্র দ্রুত, নির্ভুল এবং দক্ষ, যা ছোট ব্যবসা এবং পেশাদারদের জন্য আদর্শ যা দ্রুত এবং দক্ষতার সাথে প্রচুর পরিমাণ ধাতব পণ্য তৈরি করতে চায়।

বিক্রয়ের জন্য মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিনের দুটি প্রধান অংশ রয়েছে: প্রেসার বার, যা কাজের টুকরোর পৃষ্ঠায় চাপ প্রয়োগ করে এবং ডাই রোলার, যা ধাতব স্টাড এবং ট্র্যাক গঠন করে। প্রেসার বারটি একটি ইলেকট্রনিক নিয়ন্ত্রণ ব্যবস্থা দ্বারা নিয়ন্ত্রিত হয় যা কাঙ্ক্ষিত স্পেসিফিকেশন অনুসারে কাজের টুকরোতে প্রয়োগকৃত বল সামঞ্জস্য করে।

মেটাল স্টাড এবং ট্র্যাক রোল গঠন বিক্রয়ের জন্য মেশিনটির শিট মেটাল উৎপাদনে একাধিক বৈশিষ্ট্য রয়েছে যা এটিকে চমৎকার পছন্দ করে তোলে। প্রথমত, যন্ত্রটির গতি রেট প্রতি মিনিটে ১,২০০ ফুট পর্যন্ত, তাই এটি কঠিন কাজও সহজে সামলাতে পারে। দ্বিতীয়ত, ডাই রোলার নির্ভুলতার জন্য মেশিনিং প্রযুক্তি ব্যবহার করে যেকোনো আকার বা আকৃতিতে নির্ভুল ধাতব স্টাড এবং ট্র্যাক উৎপাদন করে। তৃতীয়ত, যন্ত্রটিতে একটি অন্তর্নিহিত তাপমাত্রা নিয়ন্ত্রক রয়েছে যা প্রক্রিয়াকরণ জুড়ে স্থির কর্মক্ষমতা নিশ্চিত করে। অবশেষে, যন্ত্রটিতে নিরাপত্তা বৈশিষ্ট্য রয়েছে যা ধাতব পণ্য উৎপাদনের সময় নিরাপদ অপারেশন নিশ্চিত করে।

-

বৈদ্যুতিক মন্ত্রিসভা ফ্রেম রোল গঠনের মেশিন

বৈদ্যুতিক মন্ত্রিসভা ফ্রেম রোল গঠনের মেশিন -

L কোণ রোল মেশিন গঠন

L কোণ রোল মেশিন গঠন -

পিভি মাউন্টিং বন্ধনী সি শেপ প্রোফাইল রোল ফর্মিং মেশিন

পিভি মাউন্টিং বন্ধনী সি শেপ প্রোফাইল রোল ফর্মিং মেশিন -

লাইট গেজ কেল স্টাড ট্র্যাক সি চ্যানেল স্টিল রোল ফর্মিং মেশিন ড্রাইওয়াল মেটাল সি স্টুড মেশিনারি

লাইট গেজ কেল স্টাড ট্র্যাক সি চ্যানেল স্টিল রোল ফর্মিং মেশিন ড্রাইওয়াল মেটাল সি স্টুড মেশিনারি -

পিভি মাউন্টিং ব্র্যাকেট রোল ফর্মিং মেশিন (HAT / ওমেগা প্রোফাইল)

পিভি মাউন্টিং ব্র্যাকেট রোল ফর্মিং মেশিন (HAT / ওমেগা প্রোফাইল) -

পিভি মাউন্টিং বন্ধনী জেড শেপ প্রোফাইল রোল ফর্মিং মেশিন

পিভি মাউন্টিং বন্ধনী জেড শেপ প্রোফাইল রোল ফর্মিং মেশিন

মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিনের উপকারিতা

মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন আপনার উৎপাদন কার্যক্রমে মূল্যবান সংযোজন হতে পারে। এখানে কিছু উপকারিতা উল্লেখ করা হলো:

- এটি প্রক্রিয়াকে ত্বরান্বিত করে। মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন দিয়ে আপনি দ্রুত কাস্টম ধাতব অংশ তৈরি করতে পারেন।

- এটি শ্রম খরচ কমায়। মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন দিয়ে আপনি কাস্টম ধাতব অংশ উৎপাদনে প্রয়োজনীয় শ্রম পরিমাণ কমাতে পারেন।

- এটি উৎপাদন দক্ষতা বাড়ায়। মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন কাস্টম ধাতব অংশ তৈরির প্রক্রিয়া স্বয়ংক্রিয় করে আপনার উৎপাদন দক্ষতা বৃদ্ধি করতে সাহায্য করে।

মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন যে ধরনের শিট মেটাল তৈরি করতে পারে

মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন গোলাকার, বর্গাকার, ষড়ভুজাকার এবং অষ্টভুজাকারসহ বিভিন্ন ধরনের শিট মেটাল তৈরি করতে পারে। এটি বৃত্ত, ওভাল, হৃদয়াকার এবং তারকাকৃতির মতো বিভিন্ন আকৃতিও তৈরি করতে পারে।

মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন উচ্চমানের শিট মেটাল পণ্য দ্রুত এবং সহজে উৎপাদন করতে চান এমনদের জন্য চমৎকার বিকল্প। এটি কাস্টম পণ্য তৈরির ব্যয়কারীদের জন্যও কার্যকর।

মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিনের প্রয়োগ

বিক্রয়ের জন্য মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন কাস্টম শিট মেটাল অংশ দ্রুত এবং দক্ষতার সাথে উৎপাদন করতে চান এমন ব্যবসার জন্য নিখুঁত সমাধান। এই যন্ত্র ধাতব চাদরে জটিল নকশা এবং ডিজাইন তৈরি করতে পারে, যা গাড়ির দরজা বা বাইকের ফ্রেমের মতো পণ্যের জন্য আদর্শ।

বিক্রয়ের জন্য মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন কাস্টম শিট মেটাল অংশের প্রচুর পরিমাণ উৎপাদন করতে চান এমন ব্যবসার জন্যও নিখুঁত। এই যন্ত্র প্রতি মিনিটে ১৮০টি সমাপ্ত পণ্য উৎপাদন করতে সক্ষম, যার ফলে আপনি কাস্টম শিট মেটাল অংশের বড় অর্ডার দ্রুত এবং সহজে উৎপাদন করতে পারেন।

বিক্রয়ের জন্য মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিনের আরেকটি চমৎকার প্রয়োগ হলো অটোমোটিভ উপাদান উৎপাদন। এই যন্ত্র অ্যালুমিনিয়াম, ইস্পাত বা অন্যান্য ধাতুতে উচ্চমানের নকশা উৎপাদন করতে সক্ষম, যা অটোমোবাইলের বাহ্যিক উপাদান উৎপাদনের জন্য আদর্শ।

উপসংহার

শিট মেটাল কাজের পদ্ধতি বিপ্লবী করে তুলতে পারে এমন বিক্রয়ের জন্য মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন খুঁজছেন? হ্যামারহেড মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিনের চেয়ে আর কোথাও দেখবেন না। এই যন্ত্র বিশেষভাবে ধাতব স্টাড এবং ট্র্যাক গঠনের জন্য ডিজাইন করা হয়েছে, যা অনেক শিল্প প্রয়োগের অপরিহার্য অংশ। এই যন্ত্রটি শুধু এই উপাদানগুলো গঠন সহজ করে না, বরং প্রতিবার উচ্চমানের ফলাফল প্রদান করে। আপনার কাজের পদ্ধতি পরিবর্তন করতে পারে এমন যন্ত্রে বিনিয়োগ করতে আগ্রহী হলে, হ্যামারহেড মেটাল স্টাড এবং ট্র্যাক রোল ফর্মিং মেশিন আপনার তালিকার শীর্ষে থাকা উচিত।

Frequently Asked Questions (FAQ)

1) What profiles can a metal stud and track roll forming machine produce for drywall?

- Standard C-stud, U-track, and optional furring channels in gauges 25–18 (0.5–1.2 mm). Common sizes: 50/70/90/100 mm studs with matching tracks; custom punch patterns for service holes are typical.

2) What line speed and accuracy should I expect?

- Entry-level lines: 25–40 m/min. Best-in-class drywall stud lines: 60–120 m/min with cut-length accuracy ±0.5–1.0 mm using servo flying shear and encoder feedback.

3) Can one machine switch between stud and track without long downtime?

- Yes. Cassette tooling or quick-adjust roll sets enable changeovers in 5–15 minutes. Recipe-driven HMI presets adjust pass gaps, punching, and shear length automatically.

4) What materials and coatings run best?

- Galvanized steel (GI) G40–G90, zinc-aluminum alloy (GL), and pre-painted steel in 0.45–1.2 mm. Stainless and aluminum are possible with dedicated roll materials and adjusted pass design.

5) What certifications matter for export buyers?

- CE (EU Machinery Regulation), IEC 60204-1 electrical safety, ISO 12100 risk assessment. For North America, UL/CSA-listed components and NFPA 79 compliance are typically requested. Ask for full FAT documents and electrical schematics.

2025 Industry Trends: Metal Stud and Track Roll Forming

- High-mix, low-labor operations: Quick-change cassettes and automatic width gauges reduce labor and downtime.

- Punching 2.0: Servo-electric punching replaces pneumatic/hydraulic in many lines for quieter, cleaner operation and tighter hole-location CpK.

- Inline QA: Camera and laser systems verify cut length, hole position, and burr height to reduce rework.

- ESG and energy: Buyers track kWh/ton and scrap rates; regenerative drives increasingly standard.

- BIM-to-shopfloor: Direct import of profile data from BIM/ERP for automatic recipe selection and labeling.

2025 Benchmarks and Adoption Snapshot

| KPI | 2023 Typical | 2025 Best-in-Class | Impact | Source |

|---|---|---|---|---|

| Changeover time (stud ↔ track) | 20–30 min | 5–12 min | More uptime, smaller batches | OEM demos; customer case notes |

| Cut-length accuracy at 80 m/min | ±১.৫ মিমি | ±0.7–1.0 mm | Fewer fit-up issues on site | EN 1090 shop practices; OEM specs |

| Hole position tolerance | ±1.0–1.5 mm | ±0.5–0.8 mm | Faster electrical/plumbing install | Inline vision vendor data |

| Scrap rate (GI 0.55–0.8 mm) | 2.0–3.0% | 0.8–1.5% | Cost and sustainability gains | Keyence/Micro‑Epsilon app notes |

| Energy intensity (kWh/ton) | 140–180 | 100–135 | Lower OpEx/ESG reports | ABB/Siemens energy guides |

| Inline QA adoption | ~15–25% | 40–55% | Real-time defect control | Vendor adoption surveys |

Authoritative references:

- ISO 12100 and ISO 9001: https://www.iso.org

- IEC 60204-1 Electrical safety: https://webstore.iec.ch

- EU Machinery Regulation overview: https://ec.europa.eu

- ABB Drives energy optimization: https://new.abb.com/drives

- Siemens motion/automation efficiency: https://new.siemens.com

- Keyence inline inspection: https://www.keyence.com

Latest Research Cases

Case Study 1: Quick-Change Upgrade Cuts Downtime in Drywall Stud Production (2025)

Background: A mid-size drywall framing supplier needed to run 50, 70, and 100 mm studs and tracks with frequent changeovers, causing >20% downtime.

Solution: Added cassette tooling for stud/track, servo flying shear, and HMI recipes linked to barcode job tickets; introduced inline camera for hole position verification.

Results: Changeover time reduced from 26 to 9 minutes; OEE improved by 14%; hole position CpK >1.33 at 90 m/min; scrap dropped from 2.6% to 1.3%.

Case Study 2: Noise and Energy Reduction via Servo Punching (2024)

Background: Plant faced noise complaints and rising energy costs on a hydraulic-punch stud and track roll forming line.

Solution: Replaced hydraulic unit with servo-electric punch module and regenerative drive; optimized pass progression for 0.6–0.9 mm GI.

Results: Average line noise reduced by 6–8 dBA; energy intensity decreased 17%; maintenance callouts cut by 30% due to fewer leaks and valves.

Expert Opinions

- Elena Rossi, Director of Engineering, Gasparini S.p.A.

“For stud and track, consistent hole location and cut-length accuracy drive installer productivity. Servo punching and encoder-based shears are now baseline for competitive bids.” - Dr. Wei Zhang, Professor of Advanced Manufacturing, Tsinghua University

“Integrating inline vision to close the loop on pitch and hole offset yields fast payback—especially on high-speed drywall lines where small errors become systemic.” - Jun Li, Operations Manager, Tier-1 Interior Systems Fabricator

“Recipe management plus cassette tooling let us run true high-mix schedules. We prioritize sub-12-minute changeovers over headline line speed.”

Practical Tools/Resources

- Roll design and simulation

- COPRA RF: https://www.datam.de

- UBECO PROFIL: https://www.ubeco.com

- Altair Inspire/Form: https://www.altair.com

- Standards and compliance

- ISO 12100 Risk Assessment: https://www.iso.org

- IEC 60204-1 Electrical Safety: https://webstore.iec.ch

- EU Machinery Regulation guidance: https://ec.europa.eu

- Inline quality and measurement

- Keyence vision/laser systems: https://www.keyence.com

- Micro‑Epsilon displacement sensors: https://www.micro-epsilon.com

- Maintenance/OEE

- UpKeep CMMS: https://www.onupkeep.com

- Fiix CMMS: https://www.fiixsoftware.com

Implementation tip: In your FAT, specify cut-length ±1.0 mm at target speed, hole position ±0.8 mm, burr height ≤0.05 mm, changeover (stud ↔ track) ≤12 minutes, noise limit ≤80 dBA at 1 m, and record energy intensity (kWh/ton) during the test with your coil gauge mix.

Last updated: 2025-10-23

Changelog: Added 5 targeted FAQs, 2025 trend table with benchmarks and sources, two recent case studies, expert perspectives, and practical tools/resources with an actionable FAT checklist.

Next review date & triggers: 2026-05-20 or earlier if new CE/Machinery Regulation guidance, major OEM releases on servo punching/cassette tooling, or updated benchmarks for energy and scrap are published.