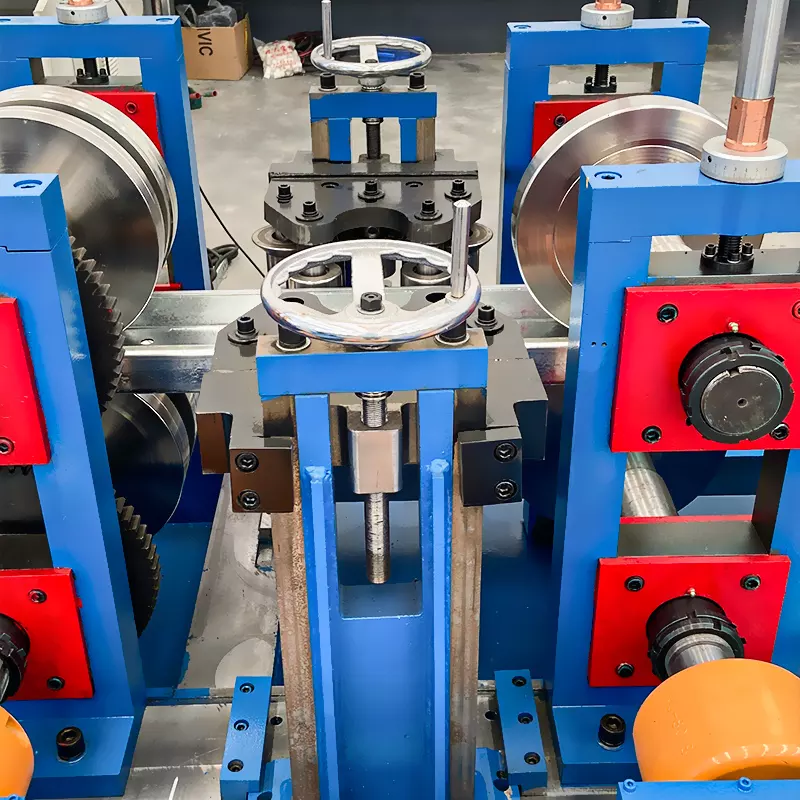

শাটার দরজা রোল ফর্মিং মেশিন হলো শাটার দরজা উৎপাদনে ব্যবহৃত একটি বিশেষায়িত যন্ত্রপাতি, যা নির্মাণ শিল্পে নিরাপত্তা এবং গোপনীয়তার উদ্দেশ্যে সাধারণত ব্যবহৃত হয়। এই মেশিনটি ধাতব চাদরগুলিকে নির্দিষ্ট আকার এবং সাইজে বাঁকানো এবং গঠনের একটি অবিরত প্রক্রিয়া ব্যবহার করে, যা চূড়ান্ত পণ্যের জন্য অভিন্ন এবং সুনির্দিষ্ট উপাদান তৈরি করে। শাটার দরজা রোল ফর্মিং মেশিন ব্যবহারের অনেক উপকারিতা রয়েছে, যার মধ্যে রয়েছে উন্নত দক্ষতা, খরচ সাশ্রয়, কাস্টমাইজেশন বিকল্প এবং উচ্চমানের এবং টেকসই পণ্য। এই পোস্টে, আমরা প্রত্যেকটি উপকারিতা বিস্তারিতভাবে অন্বেষণ করব, যা নির্মাণ শিল্পের ব্যবসায়ের জন্য শাটার দরজা রোল ফর্মিং মেশিনে বিনিয়োগ করা একটি স্মার্ট পছন্দ কেন তা তুলে ধরব।

শাটার দরজা রোল ফর্মিং মেশিন ব্যবহার করে দক্ষতা উন্নয়ন

ব্যবহার করে শাটার দরজা রোল ফর্মিং মেশিন শাটার দরজা উৎপাদনের ঐতিহ্যবাহী পদ্ধতির তুলনায় শাটার দরজা রোল ফর্মিং মেশিন ব্যবহার করে দক্ষতা এবং উৎপাদনশীলতা অনেকাংশে উন্নত করা যায়। প্রথমত, এই মেশিনটি যান্ত্রিক শ্রমের তুলনায় অনেক দ্রুতগতিতে উপাদান উৎপাদন করতে সক্ষম হওয়ায় উল্লেখযোগ্য সময় সাশ্রয় করে। এটি ব্যবসাগুলিকে কঠোর প্রকল্পের সময়সীমা মেনে চলতে এবং সামগ্রিক উৎপাদন বাড়াতে সাহায্য করে।

তাছাড়া, শাটার দরজা রোল ফর্মিং মেশিন ব্যবহার করে শ্রম খরচ অনেকাংশে কমানো যায়। ঐতিহ্যবাহী পদ্ধতিতে, ধাতব চাদরগুলিকে কামানো এবং আকার দেওয়ার জন্য অসংখ্য শ্রমিকের প্রয়োজন হয়, যা সময়সাপেক্ষ এবং শ্রমনির্ভর। তবে রোল ফর্মিং মেশিনে মেশিন পরিচালনা এবং উৎপাদন প্রক্রিয়া তত্ত্বাবধানের জন্য কম শ্রমিকের প্রয়োজন হয়। এটি ব্যবসাগুলির জন্য উল্লেখযোগ্য খরচ সাশ্রয় ঘটায়।

এছাড়াও, শাটার দরজা রোল ফর্মিং মেশিন প্রতিবার অভিন্ন ফলাফল উৎপাদন করে, যার ফলে উৎপাদন প্রক্রিয়ায় কম অপচয় এবং কম ত্রুটি হয়। নির্মাণ শিল্পে অভিন্নতা বিশেষভাবে গুরুত্বপূর্ণ, যেখানে নিরাপত্তা এবং কার্যকারিতার জন্য সুনির্দিষ্টতা অপরিহার্য। রোল ফর্মিং মেশিন দিয়ে ব্যবসাগুলি নিশ্চিত করতে পারে যে প্রত্যেক উপাদান একই উচ্চ মানে উৎপাদিত হয়, যা ব্যয়বহুল ভুল এবং বিলম্ব এড়াতে সাহায্য করে।

সামগ্রিকভাবে, শাটার দরজা রোল ফর্মিং মেশিন ব্যবহার করে দক্ষতা এবং উৎপাদনশীলতা বাড়ানো যায়, সময় এবং শ্রম খরচ সাশ্রয় করা যায় এবং অভিন্ন ও সুনির্দিষ্ট ফলাফল উৎপাদিত হয়। এই উপকারিতাগুলি ব্যবসার লাভজনকতা এবং গ্রাহকদের চাহিদা পূরণের ক্ষমতায় উল্লেখযোগ্য প্রভাব ফেলতে পারে।

খরচ সাশ্রয়ের জন্য শাটার দরজা রোল ফর্মিং মেশিন ব্যবহার

-

বৈদ্যুতিক মন্ত্রিসভা ফ্রেম রোল গঠনের মেশিন

বৈদ্যুতিক মন্ত্রিসভা ফ্রেম রোল গঠনের মেশিন -

দিন রেল রোল ফর্মিং মেশিন

দিন রেল রোল ফর্মিং মেশিন -

তারের মই রোল ফর্মিং মেশিন

তারের মই রোল ফর্মিং মেশিন -

পিভি মাউন্টিং বন্ধনী সি শেপ প্রোফাইল রোল ফর্মিং মেশিন

পিভি মাউন্টিং বন্ধনী সি শেপ প্রোফাইল রোল ফর্মিং মেশিন -

তারের ট্রে রোল ফর্মিং মেশিন

তারের ট্রে রোল ফর্মিং মেশিন -

পিভি মাউন্টিং ব্র্যাকেট রোল ফর্মিং মেশিন (HAT / ওমেগা প্রোফাইল)

পিভি মাউন্টিং ব্র্যাকেট রোল ফর্মিং মেশিন (HAT / ওমেগা প্রোফাইল) -

পিভি মাউন্টিং বন্ধনী জেড শেপ প্রোফাইল রোল ফর্মিং মেশিন

পিভি মাউন্টিং বন্ধনী জেড শেপ প্রোফাইল রোল ফর্মিং মেশিন -

সোলার মাউন্টিং স্ট্রট চ্যানেল রোল তৈরির মেশিন

সোলার মাউন্টিং স্ট্রট চ্যানেল রোল তৈরির মেশিন -

স্ট্রুট চ্যানেল রোল ফর্মিং মেশিন

স্ট্রুট চ্যানেল রোল ফর্মিং মেশিন

শাটার দরজা উৎপাদনে রোল ফর্মিং মেশিন ব্যবহার করে সময়ের সাথে উল্লেখযোগ্য খরচ সাশ্রয় সম্ভব। এর প্রধান কারণ হলো যান্ত্রিক শ্রমের কম প্রয়োজন। আগে উল্লেখিত মতো, যান্ত্রিক উৎপাদন পদ্ধতিতে ধাতব চাদরগুলিকে কামানো এবং আকার দেওয়ার জন্য উল্লেখযোগ্য সংখ্যক শ্রমিকের প্রয়োজন, যা ব্যয়বহুল। তবে রোল ফর্মিং মেশিন উৎপাদন প্রক্রিয়া স্বয়ংক্রিয় করে, যা মেশিন পরিচালনা এবং প্রক্রিয়া তত্ত্বাবধানের জন্য কম শ্রমিকের প্রয়োজন করে। এটি কম শ্রম খরচ এবং বাড়তি দক্ষতা ঘটায়।

রোল ফর্মিং মেশিন ব্যবহার করে খরচ সাশ্রয়ের আরেকটি উপায় হলো উপাদানের অপচয় কমানো। যান্ত্রিক উৎপাদন পদ্ধতিতে শ্রমিকদের ত্রুটির কারণে উচ্চ পর্যায়ের উপাদান অপচয় হয়, যা ব্যয়বহুল অপচয় এবং উৎপাদন খরচ বাড়ায়। বিপরীতে, রোল ফর্মিং মেশিন প্রতিবার সুনির্দিষ্ট, অভিন্ন উপাদান উৎপাদন করে, যার ফলে কম উপাদান অপচয় এবং খরচ কম হয়।

তাছাড়া, রোল ফর্মিং মেশিন ব্যবহার করে ব্যবসাগুলি বহির্গত উৎপাদনের উপর নির্ভর না করে অভ্যন্তরীণভাবে উচ্চমানের পণ্য উৎপাদন করতে পারে। এটি উৎপাদন প্রক্রিয়ার উপর বেশি নিয়ন্ত্রণ প্রদান করে, যাতে পণ্যগুলি তাদের নির্দিষ্ট স্পেসিফিকেশন এবং মান পূরণ করে। অভ্যন্তরীণ উৎপাদন দ্রুত টার্নআরাউন্ড সময় প্রদান করে, যা ইনভেন্টরি এবং গুদামের খরচ কমায়।

সামগ্রিকভাবে, রোল ফর্মিং মেশিন ব্যবহার করে সময়ের সাথে উল্লে

শাটার ডোর রোল ফর্মিং মেশিন ব্যবহারের কাস্টমাইজেশন

শাটার দরজার আকার, আকৃতি এবং নকশা কাস্টমাইজ করার ক্ষমতা রোল ফর্মিং মেশিন ব্যবহারের একটি প্রধান সুবিধা। এই বৈশিষ্ট্য ব্যবসায়ীদের নির্দিষ্ট প্রকল্পের প্রয়োজনীয়তা পূরণ করে এবং তাদের গ্রাহকদের অনন্য চাহিদা সন্তুষ্ট করে এমন শাটার দরজা উৎপাদন করতে সক্ষম করে।

উদাহরণস্বরূপ, ব্যবসায়ী সংস্থাগুলি রোল ফর্মিং মেশিন ব্যবহার করে বিভিন্ন আকারের শাটার দরজা তৈরি করতে পারে, যা নির্দিষ্ট দরজা বা জানালার জন্য উপযুক্ত। এর ফলে শাটার দরজাগুলিকে প্রয়োজনীয় সঠিক মাত্রায় কাস্টমাইজ করা সম্ভব হয়, যা অতিরিক্ত পরিবর্তন বা সংশোধনের প্রয়োজনীয়তা কমিয়ে দেয়।

অতিরিক্তভাবে, রোল ফর্মিং মেশিন ব্যবহার করলে ব্যবসায়ী সংস্থাগুলি উৎপাদন করতে পারে পাল্লা - যুক্ত দরজাবিভিন্ন আকার এবং নকশায়। এটি বিশেষ করে কাস্টমাইজড বা অনন্য পণ্য তৈরিতে বিশেষায়িত ব্যবসায়ীদের জন্য উপকারী। রোল ফর্মিং মেশিন ব্যবহার করে ব্যবসায়ীরা বক্ররেখা, খিলান এবং আরও অনেক কিছুর মতো বিস্তৃত আকার এবং নকশায় শাটার দরজা তৈরি করতে পারে। এতে তারা গ্রাহকদের কাছে আরও বেশি বিকল্প প্রদান করতে পারে এবং প্রতিযোগীদের থেকে আলাদা পণ্য তৈরি করতে সক্ষম হয়।

সামগ্রিকভাবে, রোল ফর্মিং মেশিন ব্যবহার করে শাটার দরজার আকার, মাত্রা এবং নকশা কাস্টমাইজ করার ক্ষমতা নির্দিষ্ট প্রকল্পের প্রয়োজনীয়তা পূরণ এবং গ্রাহকের চাহিদা সন্তুষ্ট করার জন্য অত্যন্ত উপকারী। কাস্টমাইজড পণ্য প্রদান করে ব্যবসায়ীরা প্রতিযোগীদের থেকে নিজেদের আলাদা করে তুলতে পারে এবং গ্রাহকদের সাথে শক্তিশালী সম্পর্ক গড়ে তুলতে পারে।

রোল ফর্মিং মেশিন ব্যবহারের স্থায়িত্ব এবং গুণমান

শাটার দরজা উৎপাদনে রোল ফর্মিং মেশিন ব্যবহারের আরেকটি মূল সুবিধা হলো এর প্রদানকৃত উচ্চমানের স্থায়িত্ব এবং গুণমান। এটি মেশিনের নির্ভুলতা এবং সঠিকতার কারণে সম্ভব, যা সামঞ্জস্যপূর্ণ উচ্চমানের এবং দীর্ঘস্থায়ী পণ্য উৎপাদন নিশ্চিত করে।

রোল ফর্মিং মেশিন ধাতু পাতগুলিকে নির্ভুল এবং অভিন্ন উপাদানে বাঁকানো এবং আকার দেওয়ার জন্য একটি অবিরত প্রক্রিয়া ব্যবহার করে। এটি নিশ্চিত করে যে প্রতিটি উপাদান সঠিক স্পেসিফিকেশন অনুসারে উৎপাদিত হয়, অভিন্ন পুরুত্ব এবং শক্তির সাথে। মেশিনের নির্ভুলতা এবং সঠিকতা নিশ্চিত করে যে প্রতিটি উপাদান নিখুঁতভাবে খাপ খায়, ফলে ত্রুটি বা কমতি মুক্ত একটি সমাপ্ত পণ্য তৈরি হয়।

অতিরিক্তভাবে, রোল ফর্মিং মেশিনের ব্যবহার শাটার দরজার সামগ্রিক স্থায়িত্ব উন্নত করতে পারে। মেশিনের অবিরত প্রক্রিয়া শক্তিশালী এবং ঘর্ষণ প্রতিরোধী উপাদান তৈরি করতে পারে, যা পণ্যের দীর্ঘায়ু নিশ্চিত করে। এর ফলে ব্যবসায়ীরা আরও নির্ভরযোগ্য শাটার দরজা উৎপাদন করতে পারে যা সময়ের সাথে কম রক্ষণাবেক্ষণের প্রয়োজন হয়।

সামগ্রিকভাবে, রোল ফর্মিং মেশিনের নির্ভুলতা এবং সঠিকতা সামঞ্জস্যপূর্ণ উচ্চমানের এবং দীর্ঘস্থায়ী শাটার দরজা উৎপাদন করতে পারে। এটি ব্যবসায়ীদের নির্ভরযোগ্য এবং স্থায়ী পণ্য উৎপাদনে শক্তিশালী খ্যাতি গড়ে তুলতে সাহায্য করে, যা গ্রাহকের আনুগত্য এবং সন্তুষ্টি বাড়ায়।

উপসংহারে, নির্মাণ শিল্পের ব্যবসায়ীদের জন্য শাটার দরজা রোল ফর্মিং মেশিনের ব্যবহার অসংখ্য সুবিধা প্রদান করে। এটি দক্ষতা এবং উৎপাদনশীলতা উন্নত করে, শ্রম খরচ কমায়, উপাদানের অপচয় হ্রাস করে, কাস্টমাইজেশনের সুযোগ প্রদান করে এবং উচ্চমানের স্থায়ী পণ্য উৎপাদন করে। এই সুবিধাগুলি ব্যবসায়ের লাভজনকতা এবং গ্রাহকের চাহিদা পূরণের ক্ষমতায় উল্লেখযোগ্য প্রভাব ফেলতে পারে। শাটার দরজা রোল ফর্মিং মেশিনে বিনিয়োগ করে ব্যবসায়ীরা প্রতিযোগীদের থেকে আলাদা হতে পারে, গ্রাহক সম্পর্ক শক্তিশালী করতে পারে এবং দীর্ঘমেয়াদে লাভবৃদ্ধি করতে পারে।