Steel roofing sheets are a versatile, durable, and increasingly popular choice for roofing solutions. Whether you’re looking to replace your existing roof or installing a new one, steel roofing sheets offer a plethora of benefits. This comprehensive guide dives into everything you need to know about steel roofing sheets, from types and models to installation and maintenance.

Overview of Steel Roofing Sheets

Steel roofing sheets are crafted from robust metal alloys, designed to withstand harsh weather conditions while providing a sleek and modern look. They’re often coated with a protective layer to prevent rust and corrosion, ensuring longevity. Let’s explore the specifics of these roofing solutions.

Key Details of Steel Roofing Sheets

Steel roofing sheets come in various forms and styles, making them suitable for a wide range of applications, including residential, commercial, and industrial buildings. They are known for their strength, durability, and energy efficiency.

- Durability: Steel roofs can last up to 50 years or more with proper maintenance.

- Energy Efficiency: Reflective coatings help reduce energy costs by reflecting sunlight and reducing heat absorption.

- Variety: Available in multiple styles, colors, and finishes to match any architectural design.

- Environmentally Friendly: Often made from recycled materials and are 100% recyclable at the end of their life cycle.

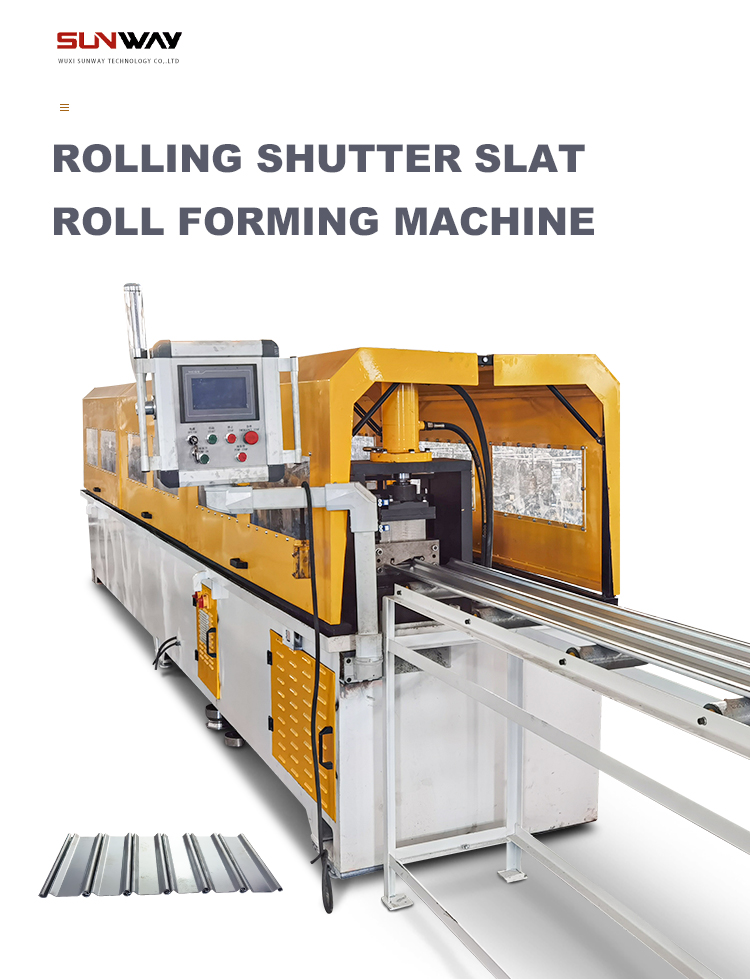

Roll Forming Machine Guide for Steel Roofing Sheets

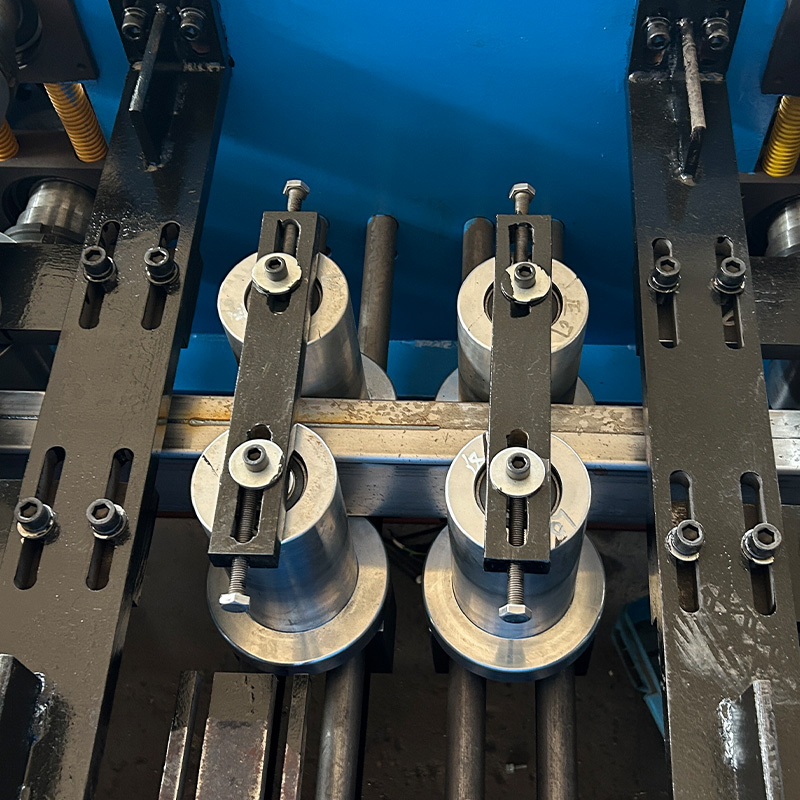

Roll forming is a continuous bending operation in which a long strip of sheet metal (typically coiled steel) is passed through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section profile is obtained. Here’s a detailed look at the roll forming machine guide:

Working Process of Roll Forming Machines

- ডিকয়লিং: The metal coil is fed into the machine.

- Feeding: The material is continuously fed into the roll forming machine.

- রোল ফর্মিং: The material passes through various rolls which bend it into the desired shape.

- কাটিং: The shaped metal is cut to the required length.

- Collecting: The finished product is collected and prepared for shipping.

Types of Steel Roofing Sheets

Steel roofing sheets come in various types, each with specific features and benefits. Here are some of the most popular types:

| Type | বর্ণনা |

|---|---|

| Corrugated Steel Sheets | Known for their wavy design, these sheets are extremely durable and provide excellent water runoff. |

| Galvanized Steel Sheets | Coated with a layer of zinc, these sheets offer superior rust resistance. |

| Galvalume Steel Sheets | Coated with a mixture of aluminum and zinc, providing enhanced corrosion resistance and heat reflectivity. |

| Color Coated Steel Sheets | Painted steel sheets that offer aesthetic appeal along with corrosion resistance. |

| Stone-Coated Steel Sheets | Steel sheets coated with stone granules, offering a traditional look with modern durability. |

| Standing Seam Steel Sheets | Features raised seams that interlock, providing a sleek and modern appearance. |

| Ribbed Steel Sheets | Characterized by raised ribs, providing additional strength and rigidity. |

| Polyester Painted Sheets | Steel sheets coated with polyester paint, offering a durable and attractive finish. |

| Aluminum-Zinc Alloy Coated Sheets | Offers superior protection against corrosion and is lighter in weight compared to galvanized steel. |

| Cold-Rolled Steel Sheets | Processed at room temperature, these sheets offer a smooth finish and higher strength. |

Key Components of Steel Roofing Sheets and Their Functions

Understanding the components and their functions can help in selecting the right steel roofing sheets for your needs. Here’s a breakdown:

| Component | Function |

|---|---|

| Base Steel | Provides the primary structural integrity and strength of the roofing sheet. |

| Protective Coating | Enhances rust and corrosion resistance, prolonging the lifespan of the sheet. |

| Primer Coating | Acts as an adhesive layer for the topcoat, ensuring better paint adhesion and durability. |

| Topcoat | Provides aesthetic appeal and additional protective properties against UV rays and weather. |

| Back Coat | Protects the underside of the sheet and adds an additional layer of corrosion resistance. |

-

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

দ্রাক্ষাক্ষেত্র পোস্ট রোল ফর্মিং মেশিন

দ্রাক্ষাক্ষেত্র পোস্ট রোল ফর্মিং মেশিন -

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য সিগমা Purlin রোল ফর্মিং মেশিন

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য সিগমা Purlin রোল ফর্মিং মেশিন -

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য CZ Purlin রোল ফর্মিং মেশিন

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য CZ Purlin রোল ফর্মিং মেশিন -

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য Z Purlin রোল তৈরির মেশিন

স্বয়ংক্রিয় আকার পরিবর্তনযোগ্য Z Purlin রোল তৈরির মেশিন -

অটো সাইজ চেঞ্জেবল সি ইউ পারলিন রোল ফর্মিং মেশিন

অটো সাইজ চেঞ্জেবল সি ইউ পারলিন রোল ফর্মিং মেশিন

Machine Speed and Efficiency in Steel Roofing Sheet Production

When selecting machinery for producing steel roofing sheets, speed and efficiency are crucial. Here’s a look at the performance metrics of roll forming machines:

| Parameter | Value |

|---|---|

| Max Production Speed | Up to 30 meters per minute |

| Efficiency Rate | Approximately 95% |

| ফর্মিং স্টেশন | 10-30 stations depending on the complexity |

| Power Requirement | 15-50 kW depending on the machine size and capacity |

Customized Mechanical Parameters for Steel Roofing Sheets

Customization is key to meeting specific project requirements. Here are some typical mechanical parameters that can be customized:

| Parameter | বর্ণনা |

|---|---|

| পুরুত্ব | Ranges from 0.2 mm to 1.2 mm |

| Width | Varies from 600 mm to 1250 mm |

| Length | Customizable according to project needs |

| Coating Thickness | Zinc coating from 60 g/m² to 275 g/m² |

| Color Options | Wide range of RAL colors available |

| Profile Design | Customizable profiles to match architectural needs |

Applications and Uses of Steel Roofing Sheets

Steel roofing sheets are incredibly versatile. Here’s a breakdown of their common applications:

| Application Area | বর্ণনা |

|---|---|

| আবাসিক ছাদকার্য | Ideal for homes due to durability and aesthetic appeal. |

| বাণিজ্যিক ভবনসমূহ | Used in shopping malls, office buildings for modern appearance. |

| Industrial Roofing | Suitable for factories and warehouses due to their robustness. |

| কৃষি ভবন | Commonly used in barns, silos for weather resistance. |

| Public Infrastructure | Utilized in schools, hospitals for long-lasting protection. |

| Recreational Buildings | Perfect for sports complexes and recreational facilities. |

| Temporary Structures | Used in event tents, temporary shelters due to ease of installation. |

Installation, Operation, and Maintenance of Steel Roofing Sheets

Proper installation, operation, and maintenance are crucial to ensure the longevity and performance of steel roofing sheets. Here’s a guide:

Installation Steps

- Preparation: Ensure the roof structure is clean and debris-free.

- সারিবদ্ধকরণ: Align the first sheet with the edge of the roof.

- Fastening: Use appropriate screws and fasteners to secure the sheet.

- Overlapping: Overlap the next sheet over the previous one.

- Sealing: Apply sealant to joints to prevent water ingress.

- Finishing: Check for any gaps or loose fasteners and fix them.

Operation Tips

- Regular Inspections: Periodically inspect the roof for damage or wear.

- পরিষ্কারকরণ: Clean the roof surface to remove debris and prevent moss growth.

- Repairs: Address any minor damages promptly to avoid larger issues.

Maintenance Guide

| Maintenance Task | Frequency |

|---|---|

| পরিদর্শন | Every 6 months |

| পরিষ্কার করা | Annually |

| Sealant Reapplication | Every 2-3 years |

| Fastener Check | Annually |

| Repainting | Every 5-10 years depending on the environment |

Suppliers and Price Range of Steel Roofing Sheets

Selecting a reliable supplier is critical. Here are some popular suppliers and their price ranges:

| Supplier | Price Range per Square Meter (USD) |

|---|---|

| ABC Metalworks | $5 – $8 |

| SteelCo | $6 – $9 |

| MetalRoofing Ltd | $7 – $10 |

| RoofTech Inc | $6.5 – $9.5 |

| Galvanized Masters | $5.5 – $8.5 |

How to Choose the Right Supplier for Steel Roofing Sheets

Choosing the right supplier involves several factors. Here are some tips:

- Reputation: Look for suppliers with a strong reputation and positive reviews.

- Quality: Ensure the materials meet industry standards and certifications.

- Pricing: Compare prices but be wary of deals that seem too good to be true.

- Support: Opt for suppliers who offer excellent customer support and after-sales service.

- Delivery: Check if the supplier can deliver within your required timeframe.

Advantages and Limitations of Steel Roofing Sheets

Advantages

- Durability: Lasts longer than traditional roofing materials.

- Energy Efficiency: Reflective coatings help in reducing energy costs.

- Aesthetic Appeal: Available in various colors and styles.

- Eco-Friendly: Often made from recycled materials.

- কম রক্ষণাবেক্ষণ: Requires minimal upkeep compared to other roofing materials.

Limitations

- Cost: Higher initial cost compared to some traditional roofing materials.

- Noise: Can be noisier during rain or hailstorms if not properly insulated.

- Dent Resistance: May dent under severe impact from hail or debris.

FAQ

| Question | Answer |

|---|---|

| What are steel roofing sheets made of? | Typically made from steel alloys and coated with zinc or aluminum for added protection. |

| How long do steel roofing sheets last? | They can last up to 50 years or more with proper maintenance. |

| Are steel roofs noisy? | They can be, but proper insulation can significantly reduce noise. |

| Can steel roofing sheets be installed over existing roofs? | Yes, they can often be installed over existing shingles. |

| Are steel roofing sheets energy efficient? | Yes, especially those with reflective coatings. |

| Do steel roofing sheets rust? | They are designed to resist rust and corrosion, especially those with protective coatings. |

| How much do steel roofing sheets cost? | Prices vary, typically ranging from $5 to $10 per square meter depending on the type and supplier. |

| Are steel roofs environmentally friendly? | Yes, they are often made from recycled materials and are 100% recyclable. |

| What is the best type of steel roofing sheet? | It depends on your specific needs and preferences, such as aesthetics, durability, and budget. |

উপসংহার

Steel roofing sheets are a highly durable, efficient, and versatile option for roofing needs. By understanding the types, key components, installation process, and maintenance requirements, you can make an informed decision that suits your specific project requirements. Whether you’re looking for longevity, aesthetic appeal, or energy efficiency, steel roofing sheets offer a compelling solution.