As global infrastructure projects and mining operations reach unprecedented depths, the need for durable and precise underground support systems has grown exponentially. At the heart of modern tunneling and mining projects are Underground Support Roll Forming Machines, which enable the efficient production of high-strength supports that reinforce tunnels, shafts, and underground structures.

In this article, we’ll explore the world of Underground Support Roll Forming Machines, their applications in mining and construction, the cutting-edge technologies driving their evolution, and why Wuxi Sunway Machinery is the industry leader in manufacturing these machines. Let’s dig deep into how these machines are transforming underground engineering.

What is an Underground Support Roll Forming Machine?

একটি Underground Support Roll Forming Machine is a specialized piece of industrial equipment designed to produce metal supports, beams, and profiles used in tunneling and mining operations. These supports are critical for stabilizing underground structures, ensuring they can withstand immense pressure, seismic activity, and environmental conditions.

The roll-forming process involves passing metal coils through a series of rollers that gradually shape the material into the desired profile. The resulting supports are lightweight yet incredibly strong, making them ideal for underground applications where both durability and ease of installation are paramount.

From mine roof supports to tunnel lining systems, Underground Support Roll Forming Machines are indispensable tools for ensuring safety and efficiency in challenging environments.

Applications of Underground Support Roll Forming Machines

Underground supports are essential for maintaining the stability and safety of tunnels, mines, and other subterranean structures. Here’s an overview of their primary applications:

1. Tunnel Linings

- Use Case: Lining systems reinforce the walls of tunnels for transportation, utilities, and water management.

- Why It Matters: Roll-formed profiles ensure a secure and uniform fit, reducing the risk of collapse.

2. Mine Roof Supports

- Use Case: Roof supports stabilize ceilings in mines, preventing rockfalls and collapses.

- Why It Matters: High-strength roll-formed supports provide long-term stability even in high-pressure environments.

3. Steel Arches

- Use Case: Steel arches are used as primary supports in tunnels and shafts.

- Why It Matters: Precision-engineered arches distribute weight evenly, ensuring structural integrity.

4. Cable Trays and Utility Systems

- Use Case: Roll-formed profiles support underground cable trays, pipelines, and ventilation systems.

- Why It Matters: Durable and lightweight supports simplify installation and maintenance.

5. Temporary Shoring Systems

- Use Case: Temporary supports stabilize excavation sites during construction or mining.

- Why It Matters: Roll-formed components are easy to assemble and disassemble, saving time and resources.

6. Ground Support for Seismic Zones

- Use Case: Supports are designed to withstand seismic forces in earthquake-prone areas.

- Why It Matters: Roll-formed profiles with advanced alloys enhance resilience against dynamic loads.

Key Features of Wuxi Sunway Underground Support Roll Forming Machines

For underground support systems, precision and durability are non-negotiable. Wuxi Sunway Machinery offers state-of-the-art roll-forming machines tailored to the specific needs of tunneling and mining operations. Here’s what makes their machines stand out:

1. High-Strength Material Processing

- Supported Materials:

- High-strength steel

- Galvanized steel

- Stainless steel

- Aluminum alloys

- Why It Matters: Ensures the production of supports that can withstand extreme pressure and environmental conditions.

2. Multi-Profile Compatibility

- What It Offers: Produces a variety of profiles, including Z- and U-channels, C-beams, steel arches, and custom designs.

- Why It’s Revolutionary: Supports diverse underground engineering applications with a single machine.

3. Integrated Punching and Cutting

- Features: Servo-driven punching and cutting systems ensure precision in length and hole placement.

- Why It’s Important: Reduces the need for secondary operations, improving efficiency.

4. High-Production Speed

- Performance: Capable of producing up to 15 meters of profiles per minute, depending on the complexity of the design.

- Why It Matters: Meets the high-volume demands of large-scale projects.

5. Durability and Corrosion Resistance

- What It Does: Machines process materials with anti-corrosion coatings or treatments.

- Why It Matters: Ensures long-term performance in harsh underground environments.

6. PLC-Controlled Automation

- Features:

- Fully programmable logic controllers (PLC) with a user-friendly interface.

- Stores multiple design parameters for quick setup.

- Real-time monitoring and diagnostics.

- Why It’s Revolutionary: Simplifies operation and ensures consistent quality across production runs.

7. Compact and Modular Design

- What It Offers: Space-efficient designs that integrate seamlessly into existing production lines.

- Why It Matters: Optimizes factory floor space while enabling future upgrades.

8. Eco-Friendly Features

- What It Includes: Energy-efficient motors and waste-reducing technologies.

- Why It’s Important: Supports sustainable manufacturing practices, reducing energy consumption and material waste.

Production Workflow of an Underground Support Roll Forming Machine

The production process for underground supports is designed to maximize efficiency and precision. Here’s a step-by-step overview:

1. Decoiling

- Raw metal coils are loaded onto the decoiler, which feeds the material into the machine.

2. Leveling

- A leveling system ensures the material is flat and free from warping before entering the roll-forming section.

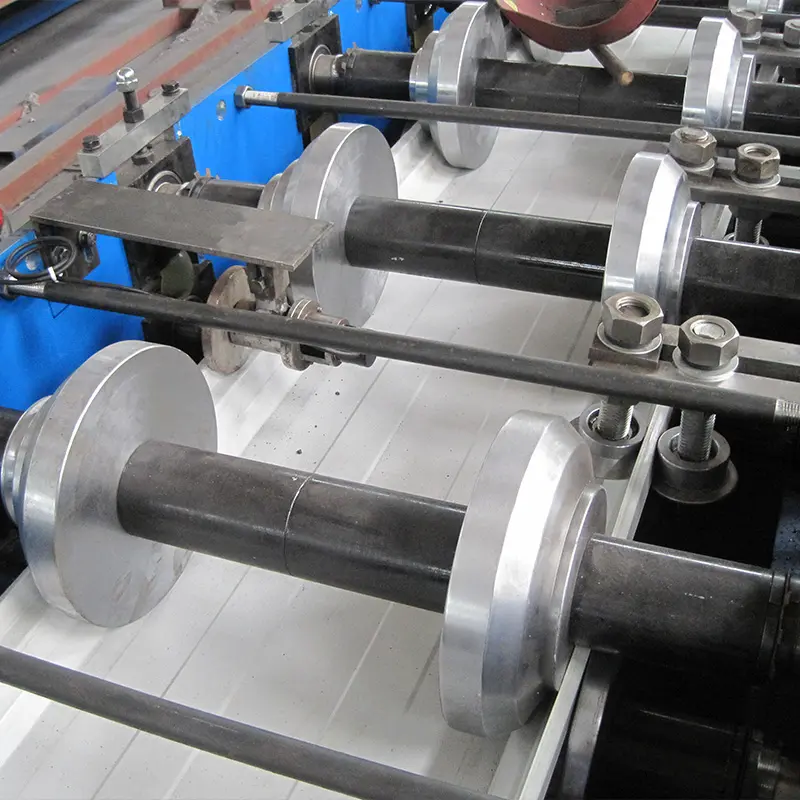

3. Roll Forming

- The material passes through a series of rollers that gradually shape it into the desired profile.

4. Punching and Cutting

- Servo-driven systems create precise holes and trim the profiles to specified lengths.

5. Surface Treatment

- Optional surface treatments, such as galvanization or anti-corrosion coatings, can be applied.

6. Stacking

- Finished supports are automatically stacked for easy packaging and transportation.

Pricing of Underground Support Roll Forming Machines

The cost of an Underground Support Roll Forming Machine depends on its features, production capacity, and customization options. Below is a general pricing guide for 2025:

| Machine Type | Capabilities | Price Range (USD) |

|---|---|---|

| Standard Machines | Basic underground support production | $120,000–$200,000 |

| High-Precision Machines | Advanced tolerances and features | $200,000–$300,000 |

| Fully Customizable Machines | Multi-profile and material capability | $300,000–$450,000 |

For tailored pricing and financing options, contact Wuxi Sunway Machinery.

Advantages of Using Underground Support Roll Forming Machines

Investing in an Underground Support Roll Forming Machine offers numerous benefits for mining and construction companies:

1. Enhanced Efficiency

- High-speed production reduces lead times and increases output.

2. Precision and Consistency

- Ensures uniform quality across all components, minimizing installation issues.

3. Material Versatility

- Supports a wide range of high-strength and corrosion-resistant materials.

4. Cost Savings

- Reduces material waste and labor costs, improving overall profitability.

5. Scalability

- High production capacity allows manufacturers to meet growing demands for large-scale projects.

FAQs About Underground Support Roll Forming Machines

| Question | Answer |

|---|---|

| What is the production speed? | Machines can produce up to 15 meters of profiles per minute, depending on the design. |

| Can the machine handle high-strength steel? | Yes, it is specifically designed for processing durable materials like high-strength steel. |

| What is the typical lead time for delivery? | Delivery takes 3–6 months, depending on customization requirements. |

| Does Sunway provide installation support? | Absolutely! Sunway offers on-site installation and commissioning services. |

| What is the machine’s lifespan? | With proper maintenance, the machine can last 10–15 years or more. |

| Is operator training included? | Yes, comprehensive training is provided with every machine purchase. |

Global Trends Driving the Adoption of Underground Support Roll Forming Machines

The mining and tunneling sectors are evolving rapidly, fueled by advancements in technology, growing infrastructure projects, and increasing safety standards. Here are the global trends shaping the demand for Underground Support Roll Forming Machines in 2025:

1. Expansion of Infrastructure Projects

- The Numbers: Global spending on infrastructure is projected to reach $79 trillion by 2040, with significant investments in underground transportation systems, utilities, and storage facilities.

- Impact on Manufacturing: The demand for durable and efficient underground supports has never been higher.

- Why It Matters: Roll-forming machines enable manufacturers to produce high-quality supports in large volumes, meeting the needs of infrastructure megaprojects.

2. Growth in Mining Operations

- The Context: The global mining market is expanding to meet the growing demand for raw materials used in renewable energy, electric vehicles, and electronics.

- Impact on Underground Supports: Deeper mining operations require stronger and more reliable support systems to ensure worker safety and operational efficiency.

- Why It’s Important: Roll-forming machines can produce high-strength supports capable of withstanding the extreme pressures found in deep mines.

3. Increased Focus on Safety Standards

- The Trend: Governments and organizations are implementing stricter safety regulations for underground construction and mining operations.

- Impact on Support Designs: Supports must meet higher standards for load-bearing capacity, durability, and seismic resistance.

- Machine Relevance: Roll-forming machines produce precise, defect-free components that comply with global safety standards.

4. Adoption of Green Manufacturing Practices

- The Push: Companies are prioritizing eco-friendly production methods to reduce their environmental footprint.

- Impact on Roll-Forming Technology: Machines with energy-efficient motors and waste-reducing designs are becoming the industry standard.

- Why It Matters: Green manufacturing isn’t just a trend—it’s a requirement in today’s environmentally conscious world.

5. Rise of Smart Mining and Automation

- What’s Happening: The mining industry is increasingly adopting automation and IoT technologies to improve efficiency and reduce costs.

- Impact on Component Production: Smart mines require custom supports compatible with automated systems.

- Why It’s Exciting: Roll-forming machines with IoT integration can streamline the production process and ensure compatibility with advanced mining technologies.

Technological Advancements in Underground Support Roll Forming Machines

The evolution of Underground Support Roll Forming Machines is driven by game-changing technologies that enhance speed, precision, and sustainability. Let’s explore the latest innovations shaping their future:

1. Artificial Intelligence (AI) Integration

- What It Does: AI algorithms analyze production data to optimize machine performance and detect defects in real-time.

- Benefits:

- Reduces downtime by predicting maintenance needs.

- Enhances quality control by identifying defects early.

- Improves overall production efficiency.

2. Advanced Corrosion-Resistant Coating Systems

- The Innovation: Integrated systems apply anti-corrosion coatings during production, eliminating the need for separate surface treatment processes.

- Why It’s Transformative:

- Extends the lifespan of underground supports.

- Reduces production time and costs.

- Enhances performance in harsh environments.

3. Multi-Profile Flexibility

- What It Offers: Machines can switch between multiple profiles, such as Z-channels, U-beams, and custom designs, without manual adjustments.

- Why It’s Revolutionary: Supports diverse applications in mining, tunneling, and underground construction.

4. Digital Twin Technology

- What It Is: A virtual replica of the machine that simulates production processes and tests new designs.

- Why It’s Beneficial:

- Speeds up prototyping by eliminating trial-and-error processes.

- Identifies potential bottlenecks before production begins.

- Reduces time-to-market for new projects.

5. IoT-Enabled Monitoring

- How It Works: IoT sensors collect real-time data on machine performance, material usage, and output quality.

- Advantages:

- Provides actionable insights to optimize production.

- Enables remote diagnostics and troubleshooting.

- Reduces the risk of unexpected downtime.

6. Servo-Driven Precision

- The Technology: High-speed servo motors control the roll-forming process with exceptional accuracy.

- Why It’s Important:

- Ensures consistent dimensions and smooth finishes.

- Reduces material waste, improving cost efficiency.

- Enhances the structural quality of underground supports.

Environmental Benefits of Underground Support Roll Forming Machines

Sustainability is a growing concern for the mining and construction industries. Here’s how Underground Support Roll Forming Machines contribute to eco-friendly production:

1. Reduced Material Waste

- How It Works: Roll-forming technology optimizes material usage, reducing scrap and waste.

- Impact: Lowers production costs while conserving raw materials.

2. Energy Efficiency

- The Innovation: Modern machines are equipped with energy-efficient motors and systems that consume less electricity.

- Why It Matters: Supports manufacturers in achieving their carbon reduction goals.

3. Localized Production

- What It Does: Enables manufacturers to produce supports locally, reducing the environmental impact of transportation.

- Outcome: Contributes to regional sustainability goals while improving supply chain efficiency.

4. Recyclable Components

- The Advantage: Supports produced from high-strength steel and aluminum are fully recyclable.

- Why It’s Important: Encourages a circular economy and minimizes landfill waste.

Comparison: Underground Support Roll Forming Machines vs. Traditional Methods

Let’s compare Underground Support Roll Forming Machines with conventional manufacturing methods like manual welding or stamping:

| Feature | রোল ফর্মিং মেশিন | Traditional Methods |

|---|---|---|

| Precision | High; ensures consistent dimensions | Moderate; prone to human error |

| উৎপাদন গতি | High; up to 15 meters per minute | Slow; labor-intensive processes |

| অটোমেশন | Fully automated with IoT integration | Mostly manual or semi-automated |

| Material Waste | Minimal; optimized processes reduce scrap | Higher; less efficient material usage |

| কাস্টমাইজেশন | Easily customizable for various profiles | Limited flexibility; requires separate tooling |

| খরচের দক্ষতা | Higher initial cost, lower operational costs | Lower initial cost, higher long-term costs |

| Scalability | Ideal for mass production | Limited scalability for high-volume demand |

Additional FAQs About Underground Support Roll Forming Machines

| Question | Answer |

|---|---|

| Can the machine handle ultra-thin materials? | Yes, it can process materials as thin as 0.5mm, depending on the profile design. |

| What is the maximum material thickness? | The machine can process materials up to 3.5mm thick, depending on the design. |

| Is remote monitoring available? | Yes, IoT-enabled machines allow for remote diagnostics and performance tracking. |

| What industries benefit from this machine? | Besides mining, industries like construction, utilities, and transportation can also use these machines. |

| What is the typical lead time for delivery? | Delivery takes 3–6 months, depending on customization requirements. |

| Does Sunway offer technical support? | Absolutely! Wuxi Sunway provides on-site training, troubleshooting, and after-sales support. |

Why Choose Wuxi Sunway Machinery for Underground Support Roll Forming Machines?

Here’s why Wuxi Sunway Machinery is the trusted partner for underground support manufacturing worldwide:

- Proven Expertise: Decades of experience in designing and manufacturing roll-forming solutions.

- Global Presence: Trusted by leading companies in mining, construction, and infrastructure sectors across Asia, Europe, and the Americas.

- Customization Excellence: Machines tailored to meet specific underground engineering requirements.

- Sustainability Commitment: Eco-friendly designs that minimize waste and conserve energy.

- Innovation Leadership: Cutting-edge features like AI, IoT integration, and digital twin technology set Sunway apart.

- Comprehensive Support: From installation to troubleshooting, Sunway ensures seamless operations.

Conclusion: Building Stronger Foundations with Roll Forming Technology

দ্য Underground Support Roll Forming Machine is a game-changer for mining and tunneling operations, enabling the efficient production of high-quality, durable supports. Whether you’re stabilizing a mining shaft, reinforcing a tunnel, or supporting a utility system, these machines offer the precision, speed, and reliability needed to succeed in challenging environments.

Ready to elevate your underground engineering projects? Contact Wuxi Sunway Machinery today to explore their innovative roll-forming solutions. Together, let’s shape the future of underground safety and efficiency—one support at a time!