শাটার দরজাগুলো অনেক ভবনের গুরুত্বপূর্ণ উপাদান, যা নিরাপত্তা, ইনসুলেশন এবং শব্দ হ্রাস প্রদান করে। এই দরজাগুলোর উৎপাদন সঠিকভাবে কাজ করার জন্য নির্ভুলতা এবং সঠিকতা প্রয়োজন। এখানেই শাটার দরজা রোল ফর্মিং মেশিনগুলোর প্রবেশ।

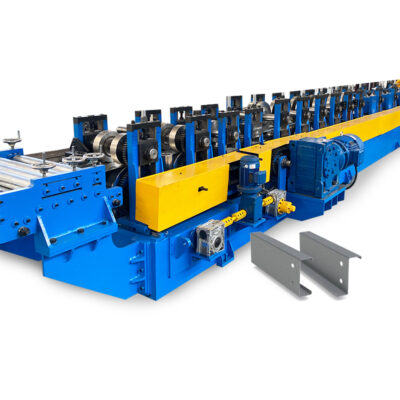

ক শাটার ডোর রোল তৈরির মেশিন এটি উৎপাদন শিল্পে শাটার দরজা উৎপাদনের জন্য ব্যবহৃত এক ধরনের সরঞ্জাম। এটি একাধিক রোলারের সিরিজ ব্যবহার করে ধাতু বা অন্যান্য উপাদানকে পছন্দসই আকারে গঠন করে এবং আকার দেয়। এই প্রক্রিয়াটি স্বয়ংক্রিয়, যা বৃহৎ পরিমাণ শাটার দরজা উৎপাদনের জন্য দ্রুত এবং দক্ষ উপায়।

উৎপাদন শিল্পে শাটার দরজা রোল ফর্মিং মেশিনগুলোর গুরুত্ব অতিরঞ্জিত করা যায় না। এই মেশিনগুলো শাটার দরজা উৎপাদনের পদ্ধতিকে বিপ্লবী করে তুলেছে, প্রক্রিয়াটিকে অভূতপূর্বভাবে খরচ-কার্যকর এবং নির্ভরযোগ্য করে তুলেছে। এই বিস্তারিত নির্দেশিকায় আমরা উৎপাদিত শাটার দরজার ধরন, রোল ফর্মিং প্রক্রিয়া এবং এই সরঞ্জাম ব্যবহারের সুবিধাগুলো অন্বেষণ করব। চলুন শুরু করি!

শাটার দরজা রোল ফর্মিং মেশিন দ্বারা উৎপাদিত শাটার দরজার ধরনসমূহ

শাটার দরজা রোল ফর্মিং মেশিন বিভিন্ন ধরনের শাটার দরজা উৎপাদনের জন্য ব্যবহার করা যায়, প্রত্যেকটির অনন্য বৈশিষ্ট্য এবং সুবিধা রয়েছে। নিম্নে রোল ফর্মিং মেশিন ব্যবহার করে উৎপাদিত কয়েকটি ভিন্ন ধরনের শাটার দরজার উল্লেখ করা হলো:

- ইস্পাত শাটার দরজা: এগুলি রোল ফর্মিং মেশিন ব্যবহার করে উৎপাদিত শাটার দরজার সবচেয়ে সাধারণ ধরন। ইস্পাত শাটার দরজাগুলি শক্তিশালী, টেকসই এবং বাণিজ্যিক ও শিল্প ভবনের জন্য উৎকৃষ্ট নিরাপত্তা নিশ্চিত করে।

- অ্যালুমিনিয়াম শাটার দরজা: অ্যালুমিনিয়াম শাটার দরজাগুলি হালকা ওজনের, যা তাদের আবাসিক প্রয়োগের জন্য আদর্শ করে তোলে। এগুলি ক্ষয়প্রতিরোধী, যা উচ্চ আর্দ্রতা বা লবণাক্ত জলের সংস্পর্শে থাকা এলাকার জন্য চমৎকার পছন্দ।

- পিভিসি শাটার দরজা: পিভিসি শাটার দরজাগুলি হালকা ওজনের, রক্ষণাবেক্ষণ সহজ এবং উৎকৃষ্ট ইনসুলেশন গুণাবলী প্রদান করে। এগুলি সাধারণত গ্যারেজ বা প্যাটিওর মতো আবাসিক প্রয়োগে ব্যবহৃত হয়।

- অগ্নিনিরোধক শাটার দরজা: এগুলি বিশেষায়িত দরজা যা অগ্নিকাণ্ড সহ্য করার জন্য এবং জ্বালার বিস্তার রোধ করার জন্য তৈরি। এগুলি গুদাম বা কারখানার মতো বাণিজ্যিক বা শিল্প ভবনে সাধারণত ব্যবহৃত হয়।

- ঝড়ো শাটার দরজা: এই দরজাগুলি ঝড়ো বাতাস বা অন্যান্য মারাত্মক আবহাওয়ার সময় ভবন রক্ষা করার জন্য তৈরি। এগুলি উপকূলীয় এলাকা বা ঝড়প্রবণ অঞ্চলে সাধারণত ব্যবহৃত হয়।

- ছিদ্রযুক্ত শাটার দরজা: এই দরজাগুলিতে ছোট ছিদ্র বা ছোরাকাটি রয়েছে, যা বায়ু চলাচল এবং দৃশ্যমানতা নিশ্চিত করে যখন নিরাপত্তা প্রদান করে। এগুলি খুচরা বিক্রয় প্রয়োগ বা বায়ু প্রবাহ গুরুত্বপূর্ণ এলাকায় সাধারণত ব্যবহৃত হয়।

সামগ্রিকভাবে, শাটার দরজা রোল ফর্মিং মেশিন বিভিন্ন প্রয়োগের প্রয়োজনীয়তা পূরণের জন্য বিস্তৃত শাটার দরজা উৎপাদন করতে পারে। উৎপাদিত শাটার দরজার ধরন উপকরণের উপর এবং প্রকল্পের নির্দিষ্ট চাহিদার উপর নির্ভর করবে।

শাটার দরজা রোল ফর্মিং মেশিনের রোল ফর্মিং প্রক্রিয়া

-

হাল্কা কিল ওয়াল অ্যাঙ্গেল রোল ফর্মিং মেশিন প্রোটেক্টর কর্নার ওয়াল অ্যাঙ্গেল ফর্মিং মেশিন

হাল্কা কিল ওয়াল অ্যাঙ্গেল রোল ফর্মিং মেশিন প্রোটেক্টর কর্নার ওয়াল অ্যাঙ্গেল ফর্মিং মেশিন -

হাল্কা কিল কর্নার বিড মেকিং মেশিন V Keel অ্যাঙ্গেল আয়রন রোল তৈরির মেশিন

হাল্কা কিল কর্নার বিড মেকিং মেশিন V Keel অ্যাঙ্গেল আয়রন রোল তৈরির মেশিন -

সম্পূর্ণ স্বয়ংক্রিয় CZ Purlin মেশিন ইস্পাত ধাতু প্রাক্তন ফ্রেম এবং Purlin মেশিন

সম্পূর্ণ স্বয়ংক্রিয় CZ Purlin মেশিন ইস্পাত ধাতু প্রাক্তন ফ্রেম এবং Purlin মেশিন -

সম্পূর্ণ স্বয়ংক্রিয় হাইড্রোলিক ইজি অপারেশন 80-300 অ্যাডজাস্টেবল সি পুরলিন মেকিং মেশিন রোল ফর্মিং মেশিনারি

সম্পূর্ণ স্বয়ংক্রিয় হাইড্রোলিক ইজি অপারেশন 80-300 অ্যাডজাস্টেবল সি পুরলিন মেকিং মেশিন রোল ফর্মিং মেশিনারি

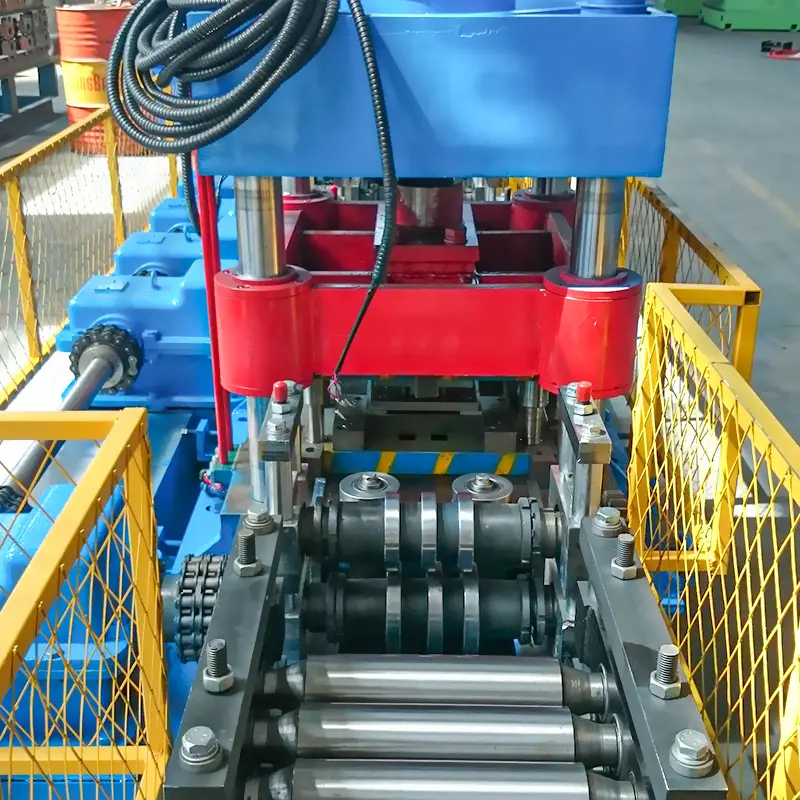

শাটার দরজা রোল ফর্মিং মেশিনের ব্যবহৃত রোল ফর্মিং প্রক্রিয়া একটি অবিচ্ছিন্ন প্রক্রিয়া যা ধাতু বা অন্যান্য উপাদানকে মেশিনের মধ্য দিয়ে সরবরাহ করে, একাধিক রোলার ব্যবহার করে কাঙ্ক্ষিত প্রোফাইলে গঠন করে এবং প্রয়োজনীয় দৈর্ঘ্যে কাটে। এখানে রোল ফর্মিং প্রক্রিয়ার বিস্তারিত বিভাজন দেওয়া হলো:

- উপাদান সরবরাহ: রোল ফর্মিং প্রক্রিয়া শুরু হয় ধাতু বা উপাদানকে ডিকয়লারের মধ্য দিয়ে সরবরাহ করে, যা উপাদানটি স্থির রেখে মেশিনে সরবরাহ করে। উপাদানটি তারপর ফিডারের মধ্য দিয়ে যায়, যা সামঞ্জস্যপূর্ণ গতিতে মেশিনে সরবরাহ নিশ্চিত করে।

- রোল ফর্মিং: উপাদানটি তারপর একাধিক রোলারের মধ্য দিয়ে যায় যা কাঙ্ক্ষিত প্রোফাইলে গঠন করার জন্য তৈরি। রোলারগুলি জোড়ায় সাজানো এবং অবিচ্ছিন্ন চক্রে কাজ করে উপাদানকে ধীরে ধীরে চূড়ান্ত আকারে গঠন করে।

- কাটিং সিস্টেম: উপাদানটি কাঙ্ক্ষিত প্রোফাইলে গঠিত হলে, এটি কাট-অফ সিস্টেমের মধ্য দিয়ে যায়, যা এটিকে প্রয়োজনীয় দৈর্ঘ্যে কাটে। কাট-অফ সিস্টেম হতে পারে ফ্লাইং কাট-অফ সিস্টেম, যা উপাদান এখনও মেশিনের মধ্য দিয়ে চলমান অবস্থায় কাটে, অথবা স্থির কাট-অফ সিস্টেম, যা উপাদান মেশিন থেকে বের হলে কাটে।

- নিয়ন্ত্রণ সিস্টেম: রোল ফর্মিং প্রক্রিয়া কম্পিউটারাইজড নিয়ন্ত্রণ সিস্টেম দ্বারা নিয়ন্ত্রিত হয় যা বিভিন্ন প্যারামিটার পর্যবেক্ষণ করে এবং সামঞ্জস্য করে, যেমন উপাদান সরবরাহের গতি, রোলারের চাপ এবং কাট-অফ সিস্টেমের অবস্থান।

- সমাপ্ত পণ্য: উপাদানটি প্রয়োজনীয় দৈর্ঘ্যে কাটা হলে, এটি সমাপ্ত পণ্য হিসেবে মেশিন থেকে বের করে দেওয়া হয়। সমাপ্ত পণ্যটি তারপর আরও প্রক্রিয়াকরণ বা চূড়ান্ত শাটার দরজা পণ্যে সমাবেশ করা যায়।

সারাংশে, শাটার দরজা রোল ফর্মিং মেশিনের ব্যবহৃত রোল ফর্মিং প্রক্রিয়া একটি অবিরত প্রক্রিয়া যা ধাতু বা অন্যান্য উপাদানকে মেশিনের মধ্য দিয়ে সরবরাহ করে, একাধিক রোলারের সাহায্যে কাঙ্ক্ষিত প্রোফাইলে আকার দেয় এবং কাটিং সিস্টেমের মাধ্যমে প্রয়োজনীয় দৈর্ঘ্যে কেটে ফেলে। এই প্রক্রিয়াটি কম্পিউটার নিয়ন্ত্রিত, যা এটিকে অত্যন্ত নির্ভুল এবং দক্ষ করে তোলে।

শাটার দরজা রোল ফর্মিং মেশিনের সুবিধাসমূহ

শাটার ডোর উৎপাদনে শাটার ডোর রোল ফর্মিং মেশিনগুলি অসংখ্য সুবিধা প্রদান করে, যা এগুলিকে আদর্শ পছন্দ করে তোলে। শাটার ডোর রোল ফর্মিং মেশিন ব্যবহারের কয়েকটি মূল সুবিধা নিম্নরূপ:

- ব্যয়-কার্যকর: রোল ফর্মিং শাটার দরজার বড় পরিমাণ উৎপাদনের জন্য একটি ব্যয়-কার্যকর প্রক্রিয়া। এই প্রক্রিয়াটি অত্যন্ত দক্ষ, যা সংক্ষিপ্ত সময়ে উচ্চ পরিমাণ উৎপাদনের অনুমতি দেয় এবং শ্রম খরচ উল্লেখযোগ্যভাবে হ্রাস করে।

- নির্ভুলতা: শাটার দরজা রোল ফর্মিং মেশিনগুলি অত্যন্ত নির্ভুলতার জন্য নকশা করা হয়েছে, যা নিশ্চিত করে যে চূড়ান্ত পণ্য সামঞ্জস্যপূর্ণভাবে নির্ভুল এবং প্রয়োজনীয় স্পেসিফিকেশন পূরণ করে। এটি বিশেষভাবে গুরুত্বপূর্ণ সেই অ্যাপ্লিকেশনগুলির জন্য যেগুলিতে কঠোর টলারেন্স বা জটিল জ্যামিতি প্রয়োজন।

- গতি: রোল ফর্মিং একটি উচ্চ-গতির প্রক্রিয়া, যা সংক্ষিপ্ত সময়ে শাটার দরজার বড় পরিমাণ উৎপাদনের অনুমতি দেয়। এটি বিশেষভাবে উচ্চ পরিমাণ পণ্য আউটপুট প্রয়োজনীয় বৃহৎ-স্কেল উৎপাদন অপারেশনের জন্য উপযোগী।

- নমনীয়তা: শাটার দরজা রোল ফর্মিং মেশিনগুলি বিভিন্ন শাটার দরজা প্রোফাইল এবং সাইজ উৎপাদন করতে পারে, যা উৎপাদকদের বিভিন্ন গ্রাহকের প্রয়োজনীয়তা পূরণের জন্য নমনীয়তা প্রদান করে।

- গুণমান: রোল ফর্মিং সামঞ্জস্যপূর্ণ মাত্রা এবং ফিনিশিং সহ উচ্চ-গুণমানের পণ্য উৎপাদন করে, যা উচ্চ স্তরের পণ্য গুণমান প্রয়োজনীয় অ্যাপ্লিকেশনের জন্য একটি আদর্শ পছন্দ।

- উপাদান সাশ্রয়: রোল ফর্মিং উৎপাদন প্রক্রিয়ার সময় উৎপন্ন বর্জ্য উপাদানের পরিমাণ ন্যূনতম করতে পারে, যা উৎপাদকদের জন্য খরচ সাশ্রয় ঘটায়।

- কম রক্ষণাবেক্ষণ: শাটার দরজা রোল ফর্মিং মেশিনগুলি কম রক্ষণাবেক্ষণের জন্য নকশা করা হয়েছে, যা ঘন ঘন মেরামত বা অংশ প্রতিস্থাপনের প্রয়োজনীয়তা হ্রাস করে।

সারাংশে, শাটার দরজা রোল ফর্মিং মেশিনগুলি উৎপাদনের জন্য অসংখ্য সুবিধা প্রদান করে, যার মধ্যে রয়েছে ব্যয়-কার্যকরতা, নির্ভুলতা, গতি, নমনীয়তা, গুণমান, উপাদান সাশ্রয় এবং কম রক্ষণাবেক্ষণ। এই সুবিধাগুলি শাটার দরজা রোল ফর্মিং মেশিনগুলিকে উচ্চ-গুণমানের শাটার দরজা দক্ষ এবং ব্যয়-কার্যকরভাবে উৎপাদনের জন্য আদর্শ পছন্দ করে তোলে।

উপসংহারে, শাটার দরজা রোল ফর্মিং মেশিনগুলি শাটার দরজা উৎপাদনের পদ্ধতিকে বিপ্লবী করে তুলেছে। এগুলি বিভিন্ন শাটার দরজা প্রোফাইল এবং সাইজ উৎপাদনের জন্য একটি ব্যয়-কার্যকর, নির্ভুল এবং দ্রুত পদ্ধতি প্রদান করে, সামঞ্জস্যপূর্ণ গুণমান এবং ন্যূনতম বর্জ্য সহ। বিভিন্ন উপাদান, শাটার দরজার প্রকারভেদ, রোল ফর্মিং প্রক্রিয়া এবং এই মেশিনগুলির সুবিধা বোঝার মাধ্যমে উৎপাদকরা সচেতন সিদ্ধান্ত নিতে পারেন এবং তাদের উৎপাদন দক্ষতা সর্বোচ্চ করতে পারেন। শাটার দরজা রোল ফর্মিং মেশিনগুলি উৎপাদন শিল্পের জন্য একটি অপরিহার্য হাতিয়ার, যা উচ্চ-গুণমানের শাটার দরজা উৎপাদনের জন্য প্রয়োজনীয় নির্ভুলতা এবং নির্ভরযোগ্যতা প্রদান করে।