Imagine driving down a highway, the wind whipping through your hair as you cruise along the open road. Suddenly, a car swerves out of control. Your heart jumps into your throat, but then you see it – a flash of metal separating you from danger. That, my friend, is the life-saving work of a highway guardrail.

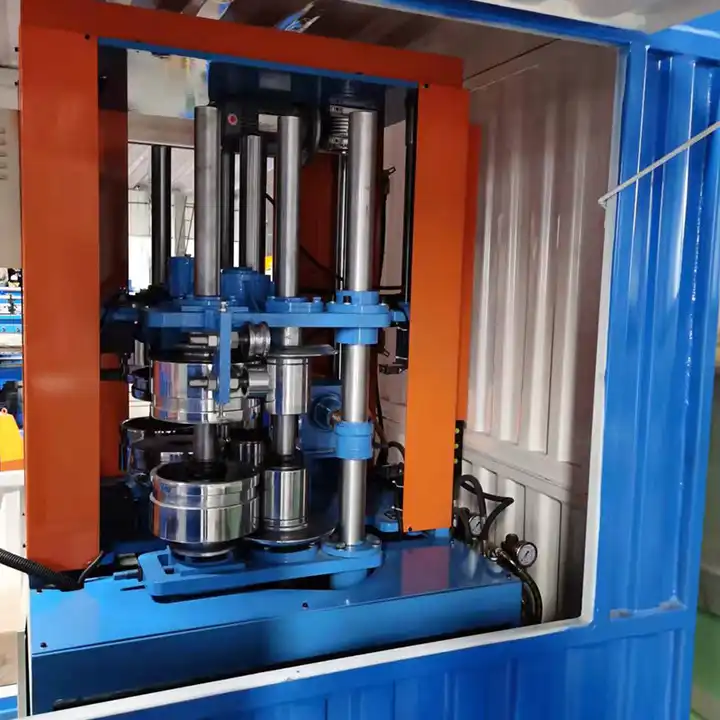

But have you ever stopped to wonder how these ubiquitous guardians of the road are made? The answer lies in a powerful machine called a হাইওয়ে গার্ডরেল রোল ফর্মিং মেশিন. In this comprehensive guide, we’ll delve into the world of these fascinating machines, exploring their function, different types, advantages, and even answer some frequently asked questions. So, buckle up and get ready for a deep dive!

Function of হাইওয়ে গার্ডরেল রোল ফর্মিং মেশিন

Think of a highway guardrail roll forming machine as a metal origami master on steroids. It takes long coils of steel and, through a series of precisely positioned rollers, bends and shapes them into the familiar guardrail profiles we see along highways.

Here’s a breakdown of the process:

- Uncoiling: The machine starts with a large coil of steel sheet fed through a series of rollers that gradually straighten and flatten it.

- Feeding: The flattened steel sheet is then fed into the forming stations.

- Forming: Each forming station has a set of rollers specifically designed to create a particular bend or shape in the metal sheet. The sheet passes through multiple stations, each adding a new fold or curve until the desired guardrail profile is achieved.

- পাঞ্চিং: Depending on the specific guardrail design, the machine may also have punching stations that create holes for fasteners or connection points.

- কাটিং: Finally, a cutting mechanism precisely severs the formed guardrail to the required length.

The entire process is automated and controlled by a Programmable Logic Controller (PLC), ensuring consistent and high-quality production.

Key Functionalities:

- Bending and shaping steel sheets into various guardrail profiles

- Punching holes for fasteners and connections

- Cutting guardrails to specific lengths

- Automated and PLC-controlled operation for consistent production

Types of Highway Guardrail Roll Forming Machines

Just like there’s more than one way to skin a cat, there’s more than one type of highway guardrail roll forming machine. Here’s a breakdown of the two main categories:

- Single Lane Roll Forming Machines: These workhorses are designed to produce guardrails for a single traffic lane. They are typically more compact and affordable compared to their multi-lane counterparts.

- Multi-Lane Roll Forming Machines: As the name suggests, these machines can handle the production of guardrails for multiple lanes simultaneously. They are ideal for high-volume production facilities and offer greater efficiency.

Additional Factors to Consider:

- Guardrail Profile: Different machines are designed to produce specific guardrail shapes like W-beam, thrie-beam, or box beam profiles.

- Material Thickness: The machine’s capacity will depend on the thickness of the steel sheet it can handle.

- Production Speed: Machines vary in their output speed, with some capable of producing guardrails at a faster rate than others.

Choosing the Right Machine:

The type of highway guardrail roll forming machine you choose will depend on your specific needs. Consider factors like the volume of guardrails you need to produce, the desired profile type, and your budget.

-

রোলিং শাটার স্ল্যাট রোল ফর্মিং মেশিন

রোলিং শাটার স্ল্যাট রোল ফর্মিং মেশিন -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

বৈদ্যুতিক মন্ত্রিসভা ফ্রেম রোল গঠনের মেশিন

বৈদ্যুতিক মন্ত্রিসভা ফ্রেম রোল গঠনের মেশিন -

দিন রেল রোল ফর্মিং মেশিন

দিন রেল রোল ফর্মিং মেশিন -

দুই তরঙ্গ হাইওয়ে গার্ডেল মেশিন

দুই তরঙ্গ হাইওয়ে গার্ডেল মেশিন -

থ্রি ওয়েভ হাইওয়ে গার্ডেল মেশিন

থ্রি ওয়েভ হাইওয়ে গার্ডেল মেশিন

Advantages of Highway Guardrail Roll Forming Machines

So, why exactly are highway guardrail roll forming machines such a game-changer in the world of road safety? Let’s explore some of their key advantages:

- Efficiency: Compared to traditional methods of guardrail production, roll forming machines offer a significant boost in efficiency. They can produce large quantities of guardrails in a shorter time frame.

- Consistency: The automated nature of roll forming machines ensures consistent quality and dimensional accuracy in the final product. This translates to guardrails that perform reliably in the event of a collision.

- Cost-Effectiveness: While the initial investment in a roll forming machine can be substantial, the long-term cost savings are undeniable. Mass production reduces the overall cost per guardrail compared to manual fabrication methods.

- বহুমুখিতা: Modern roll forming machines can be adapted to produce a wide variety of guardrail profiles, catering to different needs and specifications.

- Reduced Waste: The precise nature of roll forming minimizes material waste compared to traditional cutting methods.

The Bottom Line:

Highway guardrail roll forming machines are a cornerstone of modern road safety infrastructure. They offer a combination of efficiency, consistency, and cost-effectiveness that is simply unmatched by other methods.

Applications of Highway Guardrail Roll Forming Machines

Beyond the obvious application of producing guardrails for highways, these versatile machines have a broader reach than you might think. Here are some additional applications:

- Roadside Barriers: Guardrail roll forming machines can be used to create a variety of roadside barriers, including median barriers that separate opposing lanes of traffic and bridge railings that provide pedestrian and vehicle safety.

- Construction Sites: Temporary guardrails are essential for safety at construction zones. Roll forming machines can produce these temporary guardrails quickly and efficiently.

- Traffic Management: Roll formed guardrails can be used to create channelization barriers to guide traffic flow during road construction or special events.

- Solar Panel Mounting Systems: Some manufacturers have adapted their roll forming technology to create support structures for solar panels. The ability to form specific shapes and profiles makes them suitable for various solar panel mounting applications.

- Metal Cladding and Trims: While not their primary function, some roll forming machines can also be used to produce metal cladding panels and trims for buildings and other structures.

Thinking Outside the Box:

The ingenuity of engineers continues to find new applications for highway guardrail roll forming machines. As technology evolves, we can expect to see even more innovative uses for this versatile equipment.

Key Considerations When Buying a Highway Guardrail Roll Forming Machine

So, you’ve decided to invest in a highway guardrail roll forming machine. Excellent choice! But before you take the plunge, here are some key considerations to keep in mind:

- Production Needs: First and foremost, carefully assess your production needs. How many guardrails do you need to produce per day, week, or month? This will help determine the capacity and speed required of the machine.

- Guardrail Profile: As mentioned earlier, different machines are designed to produce specific guardrail profiles. Ensure the machine you choose can handle the exact profile type you need.

- Material Compatibility: The machine’s capacity should be compatible with the thickness and type of steel sheet you plan to use.

- Machine Features: Consider the additional features offered by different machines. Does it have an automatic stacking system for finished guardrails? Does it offer quick-change tooling for easy profile switching?

- Reputation of the Manufacturer: Do your research and choose a reputable manufacturer with a history of producing high-quality and reliable roll forming machines.

- After-Sales Support: A strong after-sales support network is crucial for ensuring you get the assistance you need when it comes to maintenance, troubleshooting, and spare parts.

Remember: Purchasing a highway guardrail roll forming machine is a significant investment. Taking the time to carefully consider your needs and compare different machines will ensure you make the best choice for your specific application.

Cost of Highway Guardrail Roll Forming Machines

The cost of a highway guardrail roll forming machine can vary depending on several factors, including:

- Machine Type: Single lane machines are generally less expensive than multi-lane machines.

- Features: Machines with additional features like automatic stacking or quick-change tooling will command a higher price tag.

- Brand and Reputation: Reputable brands with a proven track record may charge more than lesser-known manufacturers.

- Machine Capacity: Machines with a higher production capacity will typically be more expensive.

Here’s a ballpark range to give you an idea:

- Basic Single Lane Machine: $20,000 – $40,000 USD

- Multi-Lane Machine: $50,000 – $150,000 USD +

Additional Costs to Consider:

- Installation: Factor in the cost of installation and setup for the machine.

- Tooling: Depending on the specific guardrail profiles you need to produce, you may require additional tooling for the machine.

- Maintenance: Regular maintenance is essential to ensure the smooth operation of your machine. Budget for ongoing maintenance costs.

Finding the Right Price:

Getting competitive quotes from multiple manufacturers is key to finding the best price for your highway guardrail roll forming machine. Don’t be afraid to negotiate and consider the total cost of ownership, including not just the initial purchase price but also installation, tooling, and maintenance costs.

Here’s a table summarizing the Cost of Highway Guardrail Roll Forming Machines:

| Feature | বর্ণনা |

|---|---|

| Machine Type | Single Lane vs. Multi-Lane |

| বৈশিষ্ট্য | Automatic Stacking, Quick-Change Tooling |

| Brand & Reputation | Established vs. Lesser-Known Manufacturer |

| Machine Capacity | Production Output per Unit Time |

| Price Range (USD) | |

| Basic Single Lane Machine | $20,000 – $40,000 |

| Multi-Lane Machine | $50,000 – $150,000+ |

| Additional Costs | |

| Tooling | Specific Guardrail Profile Requirements |

| Maintenance | Ongoing Expenses |

Beyond the Bottom Line:

While price is certainly a factor, it shouldn’t be the sole deciding element. Remember, purchasing a হাইওয়ে গার্ডরেল রোল ফর্মিং মেশিন is an investment in your business’s future. Consider factors like the machine’s reliability, durability, and after-sales support when making your final decision. A higher upfront cost might be justified by a machine that delivers superior performance and lower long-term maintenance needs.

FAQ

Here are some frequently asked questions (FAQ) about highway guardrail roll forming machines:

Q: What is the warranty on a highway guardrail roll forming machine?

উত্তর: The warranty period will vary depending on the manufacturer and the specific machine model. Typical warranties range from 1 to 3 years, but some manufacturers may offer extended warranties for an additional cost.

Q: What kind of training is provided with a highway guardrail roll forming machine?

উত্তর: Reputable manufacturers will typically provide some level of training on how to operate and maintain the machine. This training may be conducted on-site at your facility or at the manufacturer’s location.

Q: How much maintenance is required for a highway guardrail roll forming machine?

উত্তর: Regular preventative maintenance is essential to ensure the smooth operation and longevity of your machine. The specific maintenance schedule will vary depending on the machine model and usage, but it typically involves tasks like lubricating moving parts, inspecting for wear and tear, and changing filters.

Q: Can a highway guardrail roll forming machine be used to produce custom guardrail profiles?

উত্তর: Some machines offer the flexibility to produce custom guardrail profiles with the appropriate tooling. However, this may require working directly with the manufacturer to design and create the necessary tooling.

Q: Where can I find financing for a highway guardrail roll forming machine?

উত্তর: Several financing options may be available for purchasing a highway guardrail roll forming machine. Equipment leasing companies and some manufacturers may offer financing programs. It’s also advisable to explore traditional bank loans or lines of credit.