ভূমিকা

Choosing the right roll forming machine can be challenging—especially with so many options available in the market. Whether you’re buying for roofing, shelving, automotive, or solar panel mounting, making the wrong choice can lead to higher costs, low-quality products, and production inefficiencies.

So, how do you select the best roll forming machine for your specific needs?

In this guide, we’ll cover:

✅ Key factors to consider when buying a roll forming machine

✅ The different types of roll forming machines and their applications

✅ How to compare manual, semi-automated, and fully automated machines

✅ The best materials for roll forming and their impact on machine selection

✅ Where to buy a high-quality roll forming machine in 2025

Let’s dive in!

1. Understanding the Basics of Roll Forming Machines

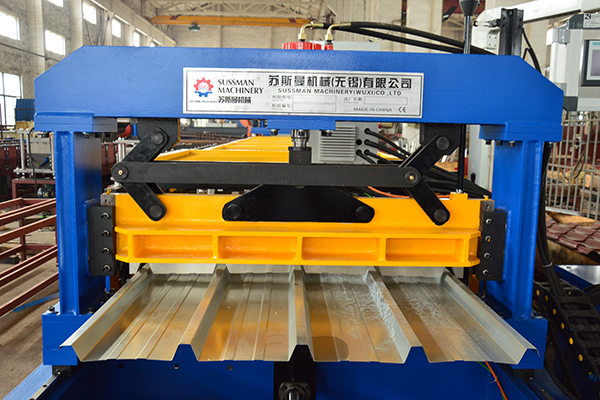

ক রোল গঠনের মেশিন is an industrial system that gradually bends a metal sheet or coil into a desired shape using a series of rollers. These machines are widely used in industries like construction, automotive, racking & shelving, and solar energy.

Key Components of a Roll Forming Machine

✅ ডিকয়লার – Holds and feeds the metal coil into the machine.

✅ Roller Stations – A series of rollers that progressively shape the metal.

✅ কাটিং সিস্টেম – Automatically cuts the profiles to the required lengths.

✅ Control System (PLC/AI) – Ensures precision and automation.

✅ Stacking & Unloading System – Collects the final product for easy handling.

Pro Tip: Understanding the core components of a roll forming machine helps you choose the best model for your applications!

2. Key Factors to Consider When Choosing a Roll Forming Machine

When selecting a roll forming machine, you need to evaluate several key factors to ensure it meets your production requirements.

Key Considerations for Choosing a Roll Forming Machine

| কারণ | Why It Matters |

|---|---|

| Material Type & Thickness | Determines roller strength and forming capabilities. |

| উৎপাদন গতি | Affects output volume and efficiency. |

| অটোমেশনের স্তর | Fully automated machines reduce labor costs and increase precision. |

| Profile Shape & Complexity | Some machines handle simple profiles, while others manage complex designs. |

| Changeover Time | If producing multiple profiles, quick-change tooling is essential. |

| Machine Size & Space Requirements | Ensures the machine fits in your facility. |

| Budget & ROI | Higher automation costs more but improves long-term profitability. |

Pro Tip: A high-speed, fully automated roll forming machine can increase productivity by up to 50%!

3. Types of Roll Forming Machines & Their Applications

Different industries require different types of roll forming machines. Here’s a breakdown of the most common types and their applications.

Comparison of Roll Forming Machines by Industry

| Machine Type | Best For | Key Features |

|---|---|---|

| Roofing & Wall Panel Roll Forming Machine | Construction, Metal Buildings | Supports various panel designs, high-speed production |

| C & Z Purlin Roll Forming Machine | Steel Structures, Warehouses | Adjustable rollers for C and Z profiles |

| তারের ট্রে রোল ফর্মিং মেশিন | Electrical & Industrial | Produces perforated or solid cable trays |

| Solar Panel Mounting Roll Forming Machine | Renewable Energy | Lightweight, corrosion-resistant profiles |

| Automotive Roll Forming Machine | Car Frames, EV Components | High-strength steel processing, AI-controlled adjustments |

| Racking & Shelving Roll Forming Machine | Warehouses, Logistics | কাস্টমাইজযোগ্য storage rack profiles |

Pro Tip: Choose a machine based on your industry and the specific profiles you need to produce!

4. Manual vs. Semi-Automated vs. Fully Automated Roll Forming Machines

The level of automation is one of the most important decisions when selecting a roll forming machine.

Comparison of Manual, Semi-Automated, and Fully Automated Machines

| Feature | Manual Machine | Semi-Automated Machine | Fully Automated Machine |

|---|---|---|---|

| Labor Requirement | High | Medium | Low |

| উৎপাদন গতি | Slow | Moderate | High |

| Precision & Consistency | Lower | Medium | High |

| Setup & Changeover Time | Long | Moderate | Short |

| Best For | Small-scale production | Medium-scale operations | Large-scale manufacturing |

| খরচ | Low | Medium | Higher initial investment but better ROI |

Pro Tip: If you need high-volume production with minimal labor, a fully automated roll forming machine is the best choice!

5. Best Materials for Roll Forming & How They Affect Machine Selection

Not all roll forming machines can handle every type of material. The type and thickness of the material significantly impact the machine’s power, roller strength, and cutting mechanism.

Material Considerations for Roll Forming Machines

| Material Type | Common Applications | Machine Requirements |

|---|---|---|

| Cold Rolled Steel | Roofing, automotive, shelving | Standard roll forming machine |

| Galvanized Steel | Solar panel frames, construction | Corrosion-resistant rollers |

| Aluminum | Aerospace, electronics, solar energy | Lightweight forming system |

| Stainless Steel | Medical, food processing, industrial | High-pressure rollers, precision cutting |

| Advanced High-Strength Steel (AHSS) | Automotive, EV components | Heavy-duty rollers, AI-controlled forming |

Pro Tip: Matching your roll forming machine to the right material ensures durability and precision in production!

6. Understanding Roll Forming Machine Configurations & Customization Options

Not all roll forming machines are the same. Some are built for standard profiles, while others are customized for unique industry needs. Selecting the right configuration is critical to achieving precision, efficiency, and optimal production output.

Common Roll Forming Machine Configurations

| Configuration Type | Best For | Key Features |

|---|---|---|

| Single-Sided Roll Forming Machine | Simple metal profiles | Basic roller stations, cost-effective |

| Double-Sided Roll Forming Machine | Producing two profiles simultaneously | Dual-track forming, increased efficiency |

| Multi-Profile Roll Forming Machine | Industries needing multiple profile changes | Quick-change tooling, flexible roller sets |

| Cassette-Type Roll Forming Machine | High customization needs | Interchangeable roller cassettes |

| Flying Cut-Off Roll Forming Machine | High-speed production lines | Continuous forming, on-the-fly cutting system |

When to Choose a Custom Roll Forming Machine

✅ Unique Profile Shapes – If your industry requires non-standard profiles, a custom machine is essential.

✅ High Volume Production – For mass production, a fully automated roll forming line is recommended.

✅ Fast Changeover Needs – If you produce multiple profiles, a cassette-type or multi-profile machine is ideal.

✅ Specific Material Requirements – Some industries require thicker metals or special coatings, which may need reinforced rollers.

Pro Tip: If you need flexibility, a multi-profile or cassette-type roll forming machine will allow quick adjustments for different product lines!

7. Comparing New vs. Used Roll Forming Machines: Which is Better?

When buying a roll forming machine, you may wonder: Should I buy a new or used machine? Both options have pros and cons, depending on your budget, production needs, and long-term goals.

New vs. Used Roll Forming Machines: Key Differences

| কারণ | New Roll Forming Machine | Used Roll Forming Machine |

|---|---|---|

| Initial Cost | Higher | Lower |

| Operational Efficiency | Best performance, latest technology | May have wear & tear |

| কাস্টমাইজেশন অপশন | Fully customizable | Limited customization |

| Warranty & Support | Manufacturer warranty included | No manufacturer support |

| Long-Term Reliability | Longer lifespan, minimal maintenance | May require frequent repairs |

| শক্তি দক্ষতা | Uses modern energy-saving systems | Older models may consume more energy |

When to Choose a New Roll Forming Machine

✅ If you need a machine with the latest automation and AI technology

✅ If you require a custom roll forming solution

✅ If you want a machine with a long lifespan and minimal maintenance

When to Consider a Used Roll Forming Machine

✅ If you have a limited budget and need a temporary solution

✅ If the machine is from a reliable supplier with a verified history of performance

Pro Tip: While used machines can save money upfront, new roll forming machines offer better efficiency, longer lifespan, and lower maintenance costs in the long run!

8. The Role of Automation & AI in Modern Roll Forming Machines

Automation and Artificial Intelligence (AI) are revolutionizing the roll forming industry, making machines smarter, faster, and more efficient.

How AI & Automation Improve Roll Forming Machines

✅ AI-Driven Real-Time Adjustments – Machines automatically adjust roller pressure and alignment for precision forming.

✅ Automated Defect Detection – AI detects surface defects and misalignment before they become major issues.

✅ Smart Coil Handling & Unloading – Robotic systems reduce human intervention, increasing efficiency.

✅ Predictive Maintenance – AI predicts wear & tear, preventing costly breakdowns.

Comparison: Manual vs. Automated Roll Forming Machines

| Feature | Manual Machine | Automated Machine |

|---|---|---|

| Labor Dependence | High | Low |

| উৎপাদন গতি | Slower | Up to 50% faster |

| Material Waste | Higher | Lower, optimized with AI |

| Setup & Changeover | Longer | Quick-change tooling available |

| শক্তি দক্ষতা | Standard | Uses smart power-saving technology |

Pro Tip: By 2030, nearly all roll forming machines will feature AI-powered automation for improved efficiency!

9. How to Set Up a Roll Forming Line for Maximum Efficiency

Setting up a roll forming line correctly is essential for smooth operations, minimal downtime, and high-quality production.

Step-by-Step Guide to Setting Up a Roll Forming Line

✅ Step 1: Select the Right Location – Ensure adequate space for coil feeding, forming, and unloading.

✅ Step 2: Install a Reliable Decoiler System – Choose a motorized or hydraulic decoiler for smooth coil feeding.

✅ Step 3: Optimize Roller Alignment & Calibration – Proper roller setup prevents defects in the final product.

✅ Step 4: Integrate a PLC Control System – Use AI-powered controls for real-time adjustments and monitoring.

✅ Step 5: Implement a Quality Control System – Install cameras and sensors to detect defects during forming.

✅ Step 6: Automate Stacking & Packaging – Reduces manual handling and improves efficiency.

Pro Tip: A well-optimized roll forming line can increase production efficiency by up to 40%!

10. Where to Buy the Best Roll Forming Machines in 2025?

জন্য state-of-the-art roll forming machines, visit WUXI SUNWAY MACHINERY CO., LTD.

Why Choose WUXI SUNWAY MACHINERY?

✅ 15+ Years of Experience – A global leader in roll forming machine manufacturing.

✅ Fully Automated, AI-Powered Machines – Designed for high-speed, precision forming.

✅ Custom Roll Forming Solutions – Machines tailored for roofing, automotive, shelving, and solar applications.

✅ Competitive Pricing & Global Shipping – High-quality equipment delivered worldwide.

✅ Reliable After-Sales Support – Spare parts, training, and technical assistance.

Looking for the best roll forming machine? Contact us today!

FAQ: How to Choose a Roll Forming Machine

1. What is the most important factor when choosing a roll forming machine?

- Material type, production volume, automation level, and budget.

2. Should I buy a new or used roll forming machine?

- A new machine provides better efficiency, longer lifespan, and AI-powered automation, while a used machine is a cheaper short-term option.

3. What industries benefit the most from roll forming machines?

- Construction, automotive, solar energy, racking & shelving, and aerospace.

4. How does AI improve roll forming machines?

- AI reduces defects, optimizes material usage, and predicts maintenance needs to maximize efficiency.

5. Where can I find the best roll forming machines in 2025?

- উক্সি সানওয়ে মেশিনারি provides cutting-edge, AI-powered roll forming solutions.

Final Thoughts

অধিকার নির্বাচন রোল গঠনের মেশিন is a major investment, but selecting the correct model ensures high efficiency, precision, and long-term profitability.

✅ Need an AI-powered, high-speed roll forming machine?

✅ Looking for customized roll forming solutions?