When it comes to roofing, durability and weather resistance are top concerns. That’s where galvanized corrugated roof sheets come into play. Not only do these sheets provide structural strength, but they also offer corrosion resistance, making them an excellent choice for a variety of roofing needs. But there’s a lot more to them than just being tough and rust-resistant.

If you’re researching galv corrugated roof sheets, you’re probably trying to figure out the best options for your project. So, let’s dive into the specifics, from the types and applications to the installation and maintenance of these sturdy materials. Plus, we’ll compare some of the top models, weigh the pros and cons, and guide you on choosing the best supplier for your needs. Ready? Let’s get started.

Overview of Galvanized Corrugated Roof Sheets

Galvanized corrugated roof sheets are metal sheets coated with a layer of zinc to prevent rust and corrosion. The corrugated design, characterized by its wavy ridges and valleys, adds to the structural integrity of the sheets, making them ideal for roofing applications. These sheets are commonly used in both residential and commercial settings because they offer a great balance of affordability, durability, and ease of installation.

But why galvanized? The zinc coating acts as a sacrificial layer, protecting the steel beneath it from harsh weather, moisture, and other environmental factors. This means your roof won’t just look great, it’ll last for years without significant wear and tear.

Corrugated Iron Sheets Guide

When choosing galvanized corrugated roof sheets, it’s essential to understand that not all sheets are created equal. From different thicknesses and coatings to various sizes and profiles, there’s a lot to consider. The type you select can impact everything from the overall durability to the ease of installation and even the aesthetic appeal of your building.

In this guide, we’ll walk you through the most common types of galvanized roof sheets, their uses, and what makes each option unique.

Types of Galvanized Corrugated Roof Sheets

There are several types of galvanized corrugated roof sheets, each designed for specific needs. Let’s break them down:

| Sheet Type | বর্ণনা |

|---|---|

| G60 Galvanized Steel | Light to medium-duty roofing. Coated with 0.60 oz of zinc per square foot, offering good rust resistance and affordability. |

| G90 Galvanized Steel | A more durable option, coated with 0.90 oz of zinc per square foot. Provides better corrosion resistance compared to G60. |

| Alu-Zinc Coated Sheets | Contains a mix of aluminum and zinc for enhanced rust resistance, especially in harsh, humid climates. Offers superior longevity and strength. |

| Galvalume Sheets | Coated with an alloy of 55% aluminum and 45% zinc. Known for its exceptional corrosion resistance and longer lifespan. |

| Pre-painted Galvanized | These are galvanized sheets with an added layer of paint, offering both aesthetics and an extra layer of protection from the elements. |

| Chromated Galvanized | Treated with a thin layer of chromium for enhanced corrosion protection. Typically used in more industrial or coastal applications. |

| Cold-Rolled Galvanized | Processed without heat, these sheets are thinner and are generally used for interior projects or temporary roofing solutions. |

| Hot-Dip Galvanized Sheets | Submerged in a molten zinc bath, these sheets have a thicker coating of zinc and offer higher resistance to rust, making them ideal for harsh weather. |

| Zinc-Aluminum-Magnesium | Newer technology combining zinc, aluminum, and magnesium for superior corrosion resistance and durability, especially in marine environments. |

| High-Tensile Corrugated | Designed for areas where strength is critical, these sheets are made from high-tensile steel and are perfect for industrial or heavy-duty roofing. |

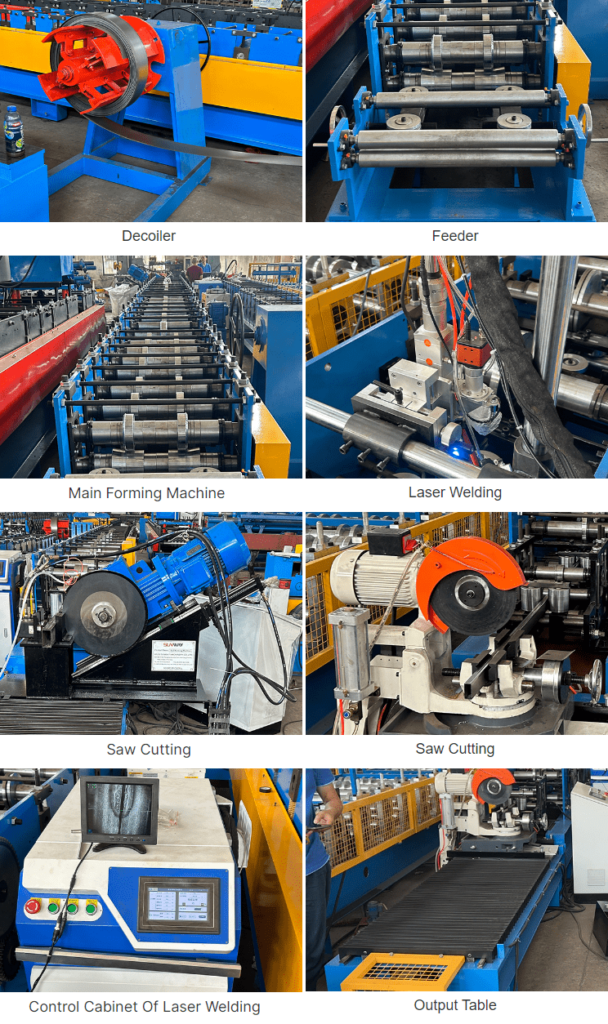

The Working Process of Galvanized Corrugated Roof Sheets

The process of making galvanized corrugated roof sheets begins with cold or hot-rolled steel. This steel is passed through a series of rollers to give it its characteristic corrugated shape. Next, the steel is dipped into a molten zinc bath in a process known as hot-dip galvanization. Alternatively, it can be electro-galvanized, where zinc is applied using an electric current.

The corrugated profile itself serves a functional purpose: the ridges and valleys increase the strength of the sheet, making it more rigid and able to span longer distances. This design also helps channel water away, making it a natural fit for roofing in areas with heavy rainfall.

Once the zinc layer is applied, the sheet undergoes additional treatments, such as painting or chromating, depending on the type of finish desired.

Key Components and Their Functions in Galvanized Corrugated Roof Sheets

To understand how galvanized corrugated roof sheets work, it’s important to familiarize yourself with their core components. Here’s a quick breakdown of the most critical parts:

| Component | Function |

|---|---|

| Steel Base | Provides structural integrity, supporting the weight of the roof and ensuring durability under various conditions. |

| Zinc Coating | Acts as a protective layer, preventing rust and corrosion. It sacrifices itself to protect the steel underneath. |

| Corrugated Profile | Enhances rigidity, allowing the sheet to span greater distances without bending or sagging under pressure. |

| Aluminum Additive | In some sheets, aluminum is added to enhance corrosion resistance, particularly in salty or humid environments. |

| Paint Layer | For pre-painted varieties, the paint provides aesthetic value and additional protection from UV rays and weather. |

| Chromium Treatment | For chromated sheets, this adds an extra layer of corrosion resistance, ideal for highly corrosive environments. |

-

ক্যারেজ বোর্ড রোল ফর্মিং মেশিন

ক্যারেজ বোর্ড রোল ফর্মিং মেশিন -

Highway Guardrail End Terminal Forming Machine

Highway Guardrail End Terminal Forming Machine -

Highway U/C Post Roll Forming Machine

Highway U/C Post Roll Forming Machine -

2 Waves Highway Guardrail Roll Forming Machine

2 Waves Highway Guardrail Roll Forming Machine -

3 Waves Highway Guardrail Roll Forming Machine

3 Waves Highway Guardrail Roll Forming Machine -

বৈদ্যুতিক মন্ত্রিসভা ফ্রেম রোল গঠনের মেশিন

বৈদ্যুতিক মন্ত্রিসভা ফ্রেম রোল গঠনের মেশিন -

দিন রেল রোল ফর্মিং মেশিন

দিন রেল রোল ফর্মিং মেশিন -

দুই তরঙ্গ হাইওয়ে গার্ডেল মেশিন

দুই তরঙ্গ হাইওয়ে গার্ডেল মেশিন -

থ্রি ওয়েভ হাইওয়ে গার্ডেল মেশিন

থ্রি ওয়েভ হাইওয়ে গার্ডেল মেশিন

Machine Speed and Efficiency in Galvanized Corrugated Sheet Manufacturing

Efficiency is key in the production of galvanized corrugated roof sheets. Here’s a look at the typical speeds and the efficiency rates of machines used in this process:

| Machine Type | Production Speed (m/min) | Efficiency (%) |

|---|---|---|

| Hot-Dip Galvanizing Line | 180 – 250 m/min | 95% |

| রোল ফর্মিং মেশিন | 15 – 30 m/min | 90% |

| Cut-to-Length Line | 30 – 50 m/min | 92% |

| Slitting Line | 100 – 150 m/min | 95% |

| Painting Line (Pre-painted Sheets) | 80 – 120 m/min | 88% |

Customized Mechanical Parameters for Galv Corrugated Roof Sheets

When it comes to roofing, customization is key. Different projects require different specifications. Here’s a quick glance at the mechanical parameters that can be customized for galvanized corrugated roof sheets:

| Parameter | Range/Options |

|---|---|

| পুরুত্ব | 0.3mm – 2.5mm |

| Width | 750mm – 1250mm |

| Length | Customizable up to 12 meters |

| Zinc Coating | 60g/m² – 275g/m² |

| Profile | Standard corrugated, trapezoidal, sinusoidal |

| Paint Type (for Pre-painted) | Polyester, PVDF, SMP |

| Color (Pre-painted) | Custom colors based on RAL or Pantone codes |

| Tensile Strength | 250MPa – 550MPa |

Applications and Uses of Galvanized Corrugated Roof Sheets

Galv corrugated roof sheets have a wide range of uses, from industrial to residential applications. Their durability and rust resistance make them a versatile option. Let’s take a closer look at where you’re most likely to see these sheets in action:

| Application Area | বর্ণনা |

|---|---|

| আবাসিক ছাদকার্য | Ideal for homes, sheds, and garages. Provides a lightweight, durable roofing option that can withstand various weather conditions. |

| বাণিজ্যিক এবং শিল্প ছাদকার্য | Frequently used in warehouses, factories, and agricultural buildings due to its strength and longevity. |

| Fencing and Cladding | Galvanized corrugated sheets are also used for cladding walls and fencing, providing both aesthetic appeal and functional weather resistance. |

| Canopies and Carports | Used to create canopies and carports because they provide shelter from rain and sun without the need for heavy-duty structures. |

| Water Tanks and Silos | Their rust resistance makes them perfect for storing water or other materials in agricultural settings. |

| Temporary Structures | Often used in construction sites for temporary buildings or shelters due to their affordability and ease of installation. |

Installation, Operation, and Maintenance of Galvanized Corrugated Roof Sheets

Proper installation and maintenance are crucial to ensure the longevity of galv corrugated roof sheets. Here’s how you can get the most out of them:

| Step | বর্ণনা |

| Installation | Ensure proper alignment of sheets, use the correct screws, and install ridge caps. Sheets should overlap for waterproofing. |

| Fasteners | Use galvanized screws or nails to avoid rust. Fasteners should be applied in the valleys of the corrugation for a better seal. |

| Sealing | Use waterproofing sealants where sheets overlap to prevent leaks. |

| Operation (Post-Installation) | Regularly check for loose fasteners and ensure water drainage is functioning properly. |

| Maintenance | Periodically clean the roof to remove debris, and inspect for any signs of rust or damage, especially after harsh weather. |

| Repairs | Any damaged or rusted sheets should be promptly replaced to prevent further corrosion. |

Top Suppliers and Price Range for Galvanized Corrugated Roof Sheets

Choosing the right supplier is essential to ensuring you get high-quality products. Here’s a breakdown of some of the top suppliers and the price range for galvanized corrugated roof sheets:

| Supplier | Country | Price Range (per square meter) | Delivery Options |

|---|---|---|---|

| ABC Metal Roofing | USA | $5 – $12 | Nationwide delivery |

| BlueScope Steel | Australia | $8 – $15 | Local and export |

| Tata Steel | ভারত | $4 – $10 | Global export |

| JFE Steel Corporation | Japan | $10 – $18 | Asia and Europe |

| ArcelorMittal | Global | $7 – $14 | Worldwide delivery |

| POSCO | South Korea | $6 – $13 | Local and international |

| Nippon Steel | Japan | $9 – $17 | Regional and export |

| China Baowu Steel | China | $3 – $8 | Worldwide delivery |

| Essar Steel | ভারত | $5 – $11 | Domestic and international |

| Corus Steel | Europe | $6 – $13 | Europe and export |

How to Choose the Right Supplier for Galvanized Corrugated Roof Sheets

Choosing a supplier can feel overwhelming, but it’s critical to ensuring your project runs smoothly. Here’s a guide to help you make the best choice:

| কারণ | What to Look For |

|---|---|

| Reputation | Look for suppliers with a solid reputation and positive customer reviews. |

| Quality Certifications | Ensure the supplier adheres to international standards like ISO 9001 for product quality. |

| Lead Times | Ask about the supplier’s delivery times. Some suppliers may have long lead times, which could delay your project. |

| মূল্য | While price matters, don’t just go for the cheapest option. Balance cost with quality to ensure you’re getting a durable product. |

| কাস্টমাইজেশন অপশন | If your project requires specific parameters (like custom sizes or colors), ensure the supplier can meet those needs. |

| After-Sales Service | Consider whether the supplier offers warranties, repair services, or replacement parts. |

Comparing the Pros and Cons of Galvanized Corrugated Roof Sheets

Now, let’s take a look at the advantages and disadvantages of galvanized corrugated roof sheets to help you make an informed decision.

| Pros | Cons |

|---|---|

| স্থায়িত্ব – Long lifespan due to zinc coating. | Can be Noisy – Can make noise during heavy rain or hail. |

| Corrosion Resistance – Protected against rust. | Aesthetic Appeal – Some people may prefer other roofing materials for aesthetic reasons. |

| খরচ-কার্যকর – Affordable compared to other materials like copper or zinc. | Requires Maintenance – Periodic cleaning and inspections are needed to prevent damage. |

| Lightweight – Easy to install and doesn’t require heavy support structures. | Vulnerable to Scratches – Scratches can expose the steel underneath, leading to rust. |

| পরিবেশগত ভাবে নিরাপদ – Can be recycled at the end of its lifespan. | Not Ideal for Complex Roof Shapes – May not work well on roofs with intricate designs. |

প্রায়শই জিজ্ঞাসিত প্রশ্ন (এফএকিউ)

| Question | Answer |

|---|---|

| How long do galvanized corrugated roof sheets last? | Typically, these sheets can last between 20 to 50 years, depending on the thickness of the zinc coating and the environment. |

| Can I install galvanized roof sheets myself? | Yes, with proper tools and guidance, but it’s recommended to hire professionals for best results. |

| What is the best thickness for galvanized roof sheets? | For most roofing projects, a thickness between 0.5mm to 1.0mm offers a good balance of strength and flexibility. |

| How often should I maintain galvanized corrugated sheets? | Inspections should be done annually, and the roof should be cleaned at least once a year to prevent debris buildup and rust. |

| Can galvanized sheets be painted? | Yes, pre-painted options are available, or you can paint them yourself with suitable metal primers and paints. |

| What’s the difference between G60 and G90 galvanized sheets? | G90 has a thicker zinc coating (0.90 oz per square foot), offering better corrosion resistance compared to G60 (0.60 oz). |

| Are galvanized roof sheets eco-friendly? | Yes, they are recyclable and have a lower environmental impact compared to some other roofing materials. |

উপসংহার

Galvanized corrugated roof sheets are a top choice for anyone looking for durable, cost-effective, and corrosion-resistant roofing materials. Whether you’re working on a residential project, building a warehouse, or looking to create a functional fence, these sheets provide flexibility and strength for a variety of applications. The key is to select the right type, customize it to fit your project’s specific needs, and ensure proper installation and maintenance to maximize its lifespan.

When choosing a supplier, make sure to consider quality, price, lead times, and after-sales service. And don’t forget to weigh the pros and cons to ensure you’re making an informed decision.

Additional Frequently Asked Questions (FAQ)

1) What zinc coating weight should I choose for Galvanized Corrugated Roof Sheets in coastal areas?

Opt for Z275/G90 or higher; in severe marine exposure consider ZM120–ZM250 (zinc-aluminum-magnesium) or AZ150 (Galvalume) for longer time-to-red rust.

2) Do galvanized corrugated sheets work with solar mounting systems?

Yes. Use clamp systems tested to UL 2703/UL 1703 and ensure fasteners penetrate framing. Seal penetrations with butyl tape compatible with galvanized surfaces.

3) How do I prevent cut-edge corrosion after trimming sheets on site?

Deburr edges, remove swarf, and apply a zinc-rich primer or edge sealant recommended by the coil coater. Avoid aggressive grinding that burns the coating.

4) What underlayment is recommended beneath galvanized corrugated roofing?

Synthetic underlayment with high-temperature rating (ASTM D226/D4869 alternatives) or self-adhered ice/water shield at eaves/valleys in cold climates. Ensure vapor management per climate zone.

5) Can I mix galvanized gutters with Galvalume roof sheets?

Mixing is acceptable if dissimilar metal contact is isolated with non-conductive separators and compatible sealants. Avoid copper runoff onto galvanized/Galvalume due to galvanic corrosion risk.

2025 Industry Trends for Galvanized Corrugated Roof Sheets

- Coastal durability shift: Rapid adoption of zinc‑aluminum‑magnesium (ZAM) and Galvalume for C4–C5 environments, extending repaint cycles by 5–10 years.

- Reflective cool roofs: Higher SRI coatings to meet 2025 energy code updates; cool-white and pastel PVDF demand up >12% YoY in warm regions.

- AI-driven QC: Inline vision systems detect coating defects and oil canning; scrap on pre-painted corrugated reduced by 20–30%.

- Price stabilization: Zinc LME volatility eased in 2025 versus 2022 peaks; delivered sheet prices remain regionally variable but more predictable for project budgeting.

- Retrofit growth: Insurance-driven reroofing after extreme weather boosts demand for high-wind fastening patterns and impact-rated assemblies.

2024–2025 Benchmarks and Buying Data

| Metric | 2024 Typical | 2025 Best-in-Class | Notes/Impact | Sources |

|---|---|---|---|---|

| Zinc coat (common roofing) | Z180–Z275 | Z275–Z350 | Higher coat weight extends time-to-red rust | ASTM A653, EN 10346 |

| Salt-spray (PVDF over ZM) | 1,000–2,000 h | 2,500–3,500 h | Improved edge creep on ZM coatings | Coil coater datasheets |

| Solar reflectance (aged) | 0.55–0.65 | 0.65–0.75 | Energy savings, code compliance | Cool Roof Rating Council |

| Wind uplift rating | 120–150 psf | 160–200+ psf | Enhanced fastener patterns/purlin spacing | FM Global 4471, ICC-ES |

| Installed price (USD/m²) | $20–$40 | $25–$55 | Region-, gauge-, and coating-dependent | Market trackers, OEM RFQs |

Authoritative references:

- ASTM A653/A792 (galvanized/galvalume): https://www.astm.org

- EN 10346 (hot-dip coated steels): https://standards.cen.eu

- Cool Roof Rating Council: https://coolroofs.org

- FM Global 4471: https://www.fmglobal.com

- ICC-ES reports: https://www.icc-es.org

- LME Zinc pricing: https://www.lme.com

Latest Research Cases

Case Study 1: ZM-Coated Corrugated Roof Extends Coastal Lifespan (2025)

Background: A mid-rise retail complex 1 km from shoreline experienced premature edge corrosion on G90 sheets within 7–9 years.

Solution: Re-roof with zinc‑aluminum‑magnesium coated corrugated sheets (ZM120) with PVDF topcoat; specified sealed cut edges and non-conductive isolation at mixed-metal interfaces.

Results: Third-party lab coupons projected >15-year red-rust delay at cut edges; warranty extended from 25 to 35 years; maintenance inspections reduced from semiannual to annual.

Case Study 2: Cool-PVDF Corrugated Roof Lowers HVAC Load (2024)

Background: Logistics warehouse (30,000 m²) in hot climate targeted energy savings without structural upgrades.

Solution: Installed 0.55 mm corrugated galvanized sheets with high-SRI PVDF (aged SR 0.70), added synthetic underlayment and ridge ventilation.

Results: Peak summer HVAC demand dropped 8.6%; interior average temperature reduced by 2.1°C; payback in 4.1 years factoring utility rebates.

Expert Opinions

- Dr. D. Scott MacKenzie, Metallurgist and author

Viewpoint: “For aggressive marine exposure, ZM and AZ coatings deliver superior cut-edge performance over traditional G90, especially on profiled corrugated geometries.”

Profile: https://www.theweldinginstitute.com - Reid Ribble, CEO (former), National Roofing Contractors Association (NRCA)

Viewpoint: “System design—fastener type, spacing, and underlayment—matters as much as coating choice for uplift and leak performance on galvanized corrugated roof sheets.”

Organization: https://www.nrca.net - Sarah Schneider, Deputy Director, Cool Roof Rating Council

Viewpoint: “Selecting verified aged reflectance values is critical; cool PVDF finishes on corrugated profiles can deliver durable energy savings in hot climates.”

Organization: https://coolroofs.org

Practical Tools/Resources

- Material standards and coatings

- ASTM A653/A792, EN 10346: https://www.astm.org, https://standards.cen.eu

- AAMA 2604/2605 and PVDF guidance: https://www.aamanet.org

- Energy and reflectance

- Cool Roof Rating Council Product Directory: https://coolroofs.org/directory

- U.S. DOE Roof Savings Calculator: https://rsc.ornl.gov

- Wind and code compliance

- FM Global RoofNav assemblies: https://roofnav.fmglobal.com

- ICC-ES evaluation reports search: https://www.icc-es.org

- Corrosion and compatibility

- Galvanic compatibility chart (Naval Sea Systems-derived references)

- Zinc-rich repair coatings and edge sealants from coil coaters/OEMs

- Supplier vetting and specs

- Metal Construction Association technical resources: https://www.metalconstruction.org

- The Fabricator and PMA supplier directories: https://www.thefabricator.com, https://www.pma.org

Last updated: 2025-10-22

Changelog: Added 5 targeted FAQs; inserted 2025 trends with KPI table and authoritative sources; included two recent case studies; compiled expert viewpoints; curated practical tools/resources specific to Galvanized Corrugated Roof Sheets

Next review date & triggers: 2026-04-22 or earlier if ASTM/EN standards revise coating classes, CRRC updates aged SRI data, or significant LME zinc price swings (>20%) affect installed costs