হালকা ইস্পাত রোলফর্ম মেশিন কী?

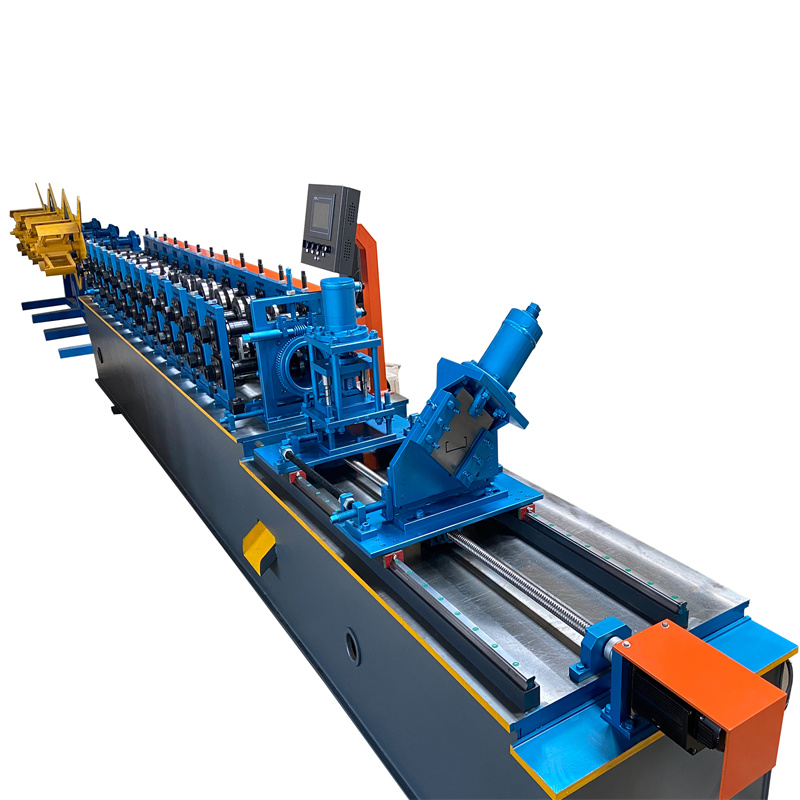

হালকা ইস্পাত রোলফর্ম মেশিন বিশেষায়িত যন্ত্রপাতি যা হালকা গেজ স্টিল পণ্য উৎপাদনে ব্যবহৃত হয়। এই মেশিনগুলি ধাতু শীটগুলিকে নির্দিষ্ট প্রোফাইল এবং আকারে রূপান্তর করার জন্য একটি অবিরত বাঁকানো প্রক্রিয়া ব্যবহার করে। উৎপাদন শিল্পে তাদের বহুমুখিতা, দক্ষতা এবং খরচ-কার্যকারিতার কারণে হালকা ইস্পাত রোলফর্ম মেশিনগুলি অপরিহার্য।

হালকা ইস্পাত রোলফর্ম মেশিনের কার্যক্রমে স্টিল শীটগুলিকে একাধিক রোলারের সিরিজে খাওয়ানো হয়, যা উপাদানটিকে কাঙ্ক্ষিত আকারে বাঁকিয়ে এবং রূপ দেয়। মেশিনগুলি ছাদের শীট, দেয়ালের ফ্রেম, স্টাড এবং ট্র্যাকসহ বিভিন্ন পণ্য উৎপাদন করতে পারে। বিভিন্ন আকার এবং সাইজ উৎপাদনের ক্ষমতার সাথে হালকা ইস্পাত রোলফর্ম মেশিনগুলি উৎপাদনে উচ্চমাত্রার নমনীয়তা প্রদান করে।

অন্যান্য উৎপাদন প্রক্রিয়ার তুলনায় হালকা ইস্পাত রোলফর্ম মেশিনগুলি অসংখ্য সুবিধা প্রদান করে। তারা দ্রুততর, আরও সুনির্দিষ্ট এবং খরচ-কার্যকারী। তারা ন্যূনতম টুলিং প্রয়োজন করে এবং কম শক্তি খরচ করে, যা তাদের পরিবেশবান্ধব বিকল্প করে তোলে। এছাড়া, হালকা ইস্পাত রোলফর্ম মেশিনগুলি অ্যালুমিনিয়াম থেকে স্টেইনলেস স্টিল পর্যন্ত বিস্তৃত উপাদান পরিচালনা করতে পারে, যা বিভিন্ন শিল্পের জন্য উপযুক্ত।

সামগ্রিকভাবে, হালকা ইস্পাত রোলফর্ম মেশিনগুলি উৎপাদন শিল্পে অত্যাবশ্যকীয়। তারা হালকা গেজ স্টিল পণ্য উৎপাদনের জন্য দক্ষ, সুনির্দিষ্ট এবং খরচ-কার্যকারী সমাধান প্রদান করে, যা অনেক উৎপাদকের জন্য জনপ্রিয় পছন্দ করে তোলে। এই মেশিনগুলির বহুমুখিতা, দক্ষতা, কম শক্তি খরচ এবং খরচ-কার্যকারিতা শিল্পের জন্য মূল্যবান সম্পদ করে তোলে।

হালকা ইস্পাত রোলফর্ম মেশিন —— দক্ষতার জন্য ডিজাইন

হালকা ইস্পাত রোলফর্ম মেশিনগুলি দক্ষ উৎপাদন প্রক্রিয়ার জন্য ডিজাইন করা যেতে পারে। দক্ষতা সর্বোচ্চ করতে এবং বর্জ্য কমাতে লিন উৎপাদন, সিক্স সিগমা এবং টোটাল কোয়ালিটি ম্যানেজমেন্টের মতো ডিজাইন নীতিগুলি বাস্তবায়ন করা অপরিহার্য।

লিন উৎপাদন একটি ডিজাইন নীতি যা উৎপাদন প্রক্রিয়ায় অপচয়মূলক অনুশীলনগুলি নির্মূল করার উপর দৃষ্টি নিবদ্ধ করে। ইনভেন্টরি স্তর কমিয়ে, লিড টাইম হ্রাস করে এবং ওয়ার্কফ্লো অপ্টিমাইজ করে হালকা ইস্পাত রোলফর্ম মেশিনগুলি সেটআপ সময় কমাতে এবং চক্র সময় উন্নত করতে ব্যবহার করা যায়।

সিক্স সিগমা হালকা ইস্পাত রোলফর্ম মেশিনগুলিতে প্রয়োগ করা যায় এমন আরেকটি ডিজাইন নীতি। এই পদ্ধতি ত্রুটি এবং পরিবর্তনশীলতা হ্রাস করে উৎপাদন প্রক্রিয়ার গুণমান উন্নয়নের উপর দৃষ্টি নিবদ্ধ করে। পরিসংখ্যানগত প্রক্রিয়া নিয়ন্ত্রণ কৌশল প্রয়োগ, ত্রুটির মূল কারণ চিহ্নিতকরণ এবং প্রক্রিয়া পরামিতি অপ্টিমাইজ করে হালকা ইস্পাত রোলফর্ম মেশিনগুলি উচ্চমানের পণ্য উৎপাদন, বর্জ্য হ্রাস এবং গ্রাহক সন্তুষ্টি বৃদ্ধি করতে পারে।

টোটাল কোয়ালিটি ম্যানেজমেন্ট উৎপাদন প্রক্রিয়ার অবিরত উন্নয়নের সাথে যুক্ত একটি ডিজাইন নীতি যা গ্রাহকের চাহিদা এবং প্রতিক্রিয়ার উপর দৃষ্টি নিবদ্ধ করে। গুণমান নিয়ন্ত্রণ ব্যবস্থা যেমন পরিদর্শন এবং পরীক্ষা প্রয়োগ এবং গ্রাহকের প্রতিক্রিয়া ব্যবহার করে উৎপাদন প্রক্রিয়া উন্নয়ন করে হালকা ইস্পাত রোলফর্ম মেশিনগুলি উচ্চমানের পণ্য উৎপাদন, বর্জ্য হ্রাস এবং গ্রাহক সন্তুষ্টি বৃদ্ধি করতে পারে।

সারাংশে, হালকা ইস্পাত রোলফর্ম মেশিনগুলিতে দক্ষতার জন্য ডিজাইন করা মেশিনের কর্মক্ষমতা সর্বোচ্চ করার জন্য অত্যন্ত গুরুত্বপূর্ণ। লিন ম্যানুফ্যাকচারিং-এর মতো ডিজাইন নীতি প্রয়োগ করে, সিক্স সিগমা, এবং টোটাল কোয়ালিটি ম্যানেজমেন্ট, উৎপাদকরা উৎপাদন প্রক্রিয়া অপ্টিমাইজ, বর্জ্য হ্রাস, পণ্যের গুণমান উন্নয়ন এবং গ্রাহক সন্তুষ্টি বৃদ্ধি করতে পারেন।

হালকা ইস্পাত রোলফর্ম মেশিনগুলির সুবিধাসমূহ

হালকা ইস্পাত রোলফর্ম মেশিনগুলি অন্যান্য উৎপাদন প্রক্রিয়ার তুলনায় বেশ কয়েকটি সুবিধা প্রদান করে। এই সুবিধাগুলির মধ্যে রয়েছে বিভিন্ন ধরনের উপকরণ হ্যান্ডেল করার ক্ষমতা, জটিল আকার উৎপাদন এবং উচ্চ নির্ভুলতা অর্জন। এই সুবিধাগুলি দক্ষতা বৃদ্ধি, বর্জ্য হ্রাস এবং গুণমান উন্নয়নে রূপান্তরিত হয়।

হালকা ইস্পাত রোলফর্ম মেশিনগুলির প্রাথমিক সুবিধাগুলির মধ্যে একটি হল বিভিন্ন ধরনের উপকরণ হ্যান্ডেল করার ক্ষমতা। এই মেশিনগুলি বিভিন্ন মিশ্রধাতু, পুরুত্ব এবং আবরণযুক্ত ইস্পাতের চাদর গঠন এবং আকার দিতে পারে, যা বিভিন্ন শিল্পে ব্যবহারের উপযোগী করে তোলে।

হালকা ইস্পাত রোলফর্ম মেশিনগুলির আরেকটি সুবিধা হল জটিল আকার উৎপাদনের ক্ষমতা। এই মেশিনগুলি বাঁকানো এবং সরু অংশসহ জটিল আকার তৈরি করতে পারে, যা অন্যান্য উৎপাদন প্রক্রিয়ায় কঠিন বা অসম্ভব। এই ক্ষমতা উৎপাদকদের নির্দিষ্ট অ্যাপ্লিকেশনের জন্য কাস্টমাইজড পণ্য উৎপাদন করতে সাহায্য করে।

হালকা ইস্পাত রোলফর্ম মেশিনগুলি উচ্চ নির্ভুলতাও প্রদান করে। এই মেশিনগুলি কঠোর টলারেন্সসহ সামঞ্জস্যপূর্ণ এবং নির্ভুল আকার উৎপাদন করতে পারে। এই নির্ভুলতা ত্রুটি এবং স্ক্র্যাপ উপকরণ কমিয়ে বর্জ্য হ্রাস করে। এছাড়া, এটি চূড়ান্ত পণ্য প্রয়োজনীয় স্পেসিফিকেশন পূরণ বা অতিক্রম করে গুণমান উন্নয়ন করে।

হালকা ইস্পাত রোলফর্ম মেশিনগুলির সুবিধাগুলি দক্ষতা বৃদ্ধি, বর্জ্য হ্রাস এবং গুণমান উন্নয়নে রূপান্তরিত হয়। বিভিন্ন উপকরণ হ্যান্ডেল এবং জটিল আকার উৎপাদনের ক্ষমতা একাধিক মেশিন এবং টুলিং পরিবর্তনের প্রয়োজনীয়তা হ্রাস করে দক্ষতা বৃদ্ধি করে। উচ্চ নির্ভুলতা ত্রুটি এবং স্ক্র্যাপ কমিয়ে বর্জ্য হ্রাস করে, যা দক্ষতা উন্নয়ন এবং খরচ হ্রাস করে। উন্নত গুণমান গ্রাহক সন্তুষ্টি বৃদ্ধি এবং ওয়ারেন্টি দাবি হ্রাস করে।

সামগ্রিকভাবে, হালকা ইস্পাত রোলফর্ম মেশিনগুলির নির্দিষ্ট সুবিধাগুলি উচ্চমানের হালকা ইস্পাত পণ্য উৎপাদনের জন্য খরচ-কার্যকর, বহুমুখী এবং দক্ষ বিকল্প করে তোলে। উৎপাদকরা হালকা ইস্পাত রোলফর্ম মেশিনগুলির নমনীয়তা, নির্ভুলতা এবং বর্জ্য হ্রাস থেকে উপকৃত হতে পারেন, যা শেষ পর্যন্ত দক্ষতা বৃদ্ধি এবং গুণমান উন্নয়নে নিয়ে যায়।

অটোমেশন এবং নিয়ন্ত্রণ ব্যবস্থা কীভাবে হালকা ইস্পাত রোলফর্ম মেশিনগুলির দক্ষতা বাড়ায়

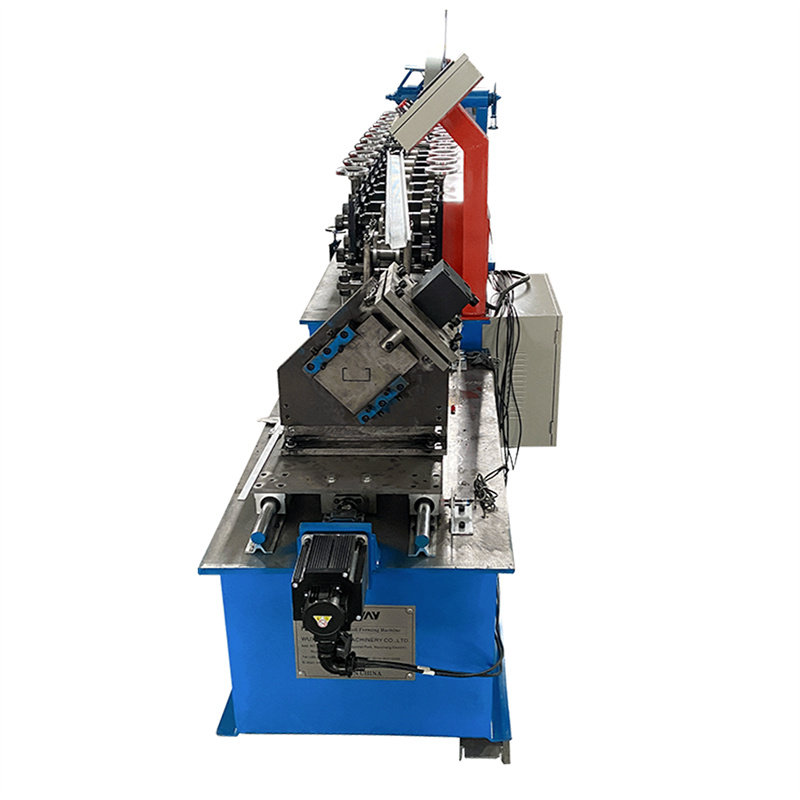

অটোমেশন এবং নিয়ন্ত্রণ ব্যবস্থা হালকা ইস্পাত রোলফর্ম মেশিনগুলির দক্ষতা আরও বাড়ানোর জন্য অত্যন্ত গুরুত্বপূর্ণ। এই ব্যবস্থাগুলি সেন্সর, প্রোগ্রামযোগ্য লজিক কন্ট্রোলার (পিএলসি) এবং হিউম্যান-মেশিন ইন্টারফেস (এইচএমআই) ব্যবহার করে উৎপাদন প্রক্রিয়া রিয়েল-টাইমে পর্যবেক্ষণ এবং নিয়ন্ত্রণ করে।

হালকা ইস্পাত রোলফর্ম মেশিনগুলিতে সেন্সরগুলি মেশিনের অবস্থা, প্রক্রিয়াজাত উপকরণ এবং চূড়ান্ত পণ্য পর্যবেক্ষণ করে। এই সেন্সরগুলি উপকরণ জ্যাম, টুল ওয়্যার এবং পণ্য ত্রুটির মতো সমস্যা সনাক্ত করতে পারে। তারা নিয়ন্ত্রণ ব্যবস্থাকে রিয়েল-টাইম ফিডব্যাক প্রদান করে, যা সমস্যা সমাধানের জন্য মেশিন সেটিংস সামঞ্জস্য করে।

PLCগুলি অটোমেশন সিস্টেমের মূল চিন্তাকেন্দ্র। এরা সেন্সর থেকে প্রাপ্ত তথ্য ব্যবহার করে মেশিনের গতিপথ নিয়ন্ত্রণ করে, প্রক্রিয়ার পরামিতি সমন্বয় করে এবং উৎপাদন প্রক্রিয়া পর্যবেক্ষণ করে। PLCগুলি রিয়েল-টাইম ডেটার ভিত্তিতে সিদ্ধান্ত গ্রহণ করে এবং পারফরম্যান্স অতিষ্ঠান করতে, বর্জ্য হ্রাস করতে এবং গুণমান উন্নয়ন করতে প্রক্রিয়া সমন্বয় করে।

HMIগুলি অপারেটরদের জন্য মেশিন এবং নিয়ন্ত্রণ ব্যবস্থার সাথে মানববান্ধব ইন্টারফেস প্রদান করে। অপারেটর উৎপাদন প্রক্রিয়া পর্যবেক্ষণ করতে, মেশিন সেটিংস সমন্বয় করতে এবং অ্যালার্ম বা সতর্কতার প্রতিক্রিয়া জানাতে পারেন। HMIগুলি প্রক্রিয়ার অবস্থা সম্পর্কে রিয়েল-টাইম প্রতিক্রিয়া প্রদান করে, যা অপারেটরদের উৎপাদন প্রক্রিয়া সম্পর্কে সচেতন সিদ্ধান্ত গ্রহণে সহায়তা করে।

হালকা ইস্পাত রোলফর্ম মেশিনে অটোমেশন এবং নিয়ন্ত্রণ ব্যবস্থার ব্যবহার উৎপাদন প্রক্রিয়ার দক্ষতা বাড়াতে পারে ডাউনটাইম হ্রাস, বর্জ্য न्यूনতমকরণ এবং পণ্যের গুণমান উন্নয়নের মাধ্যমে। রিয়েল-টাইমে প্রক্রিয়া পর্যবেক্ষণ করে নিয়ন্ত্রণ ব্যবস্থা উল্লেখযোগ্য সমস্যায় পরিণত হওয়ার আগেই সমস্যা শনাক্ত করে এবং প্রতিক্রিয়া জানাতে পারে। এতে ডাউনটাইম কমে এবং মেশিনের সামগ্রিক দক্ষতা বৃদ্ধি পায়।

অতিরিক্তভাবে, অটোমেশন এবং নিয়ন্ত্রণ ব্যবস্থা রিয়েল-টাইমে ত্রুটি শনাক্ত এবং সংশোধন করে বর্জ্য হ্রাস করতে পারে। প্রক্রিয়ার পরামিতি পর্যবেক্ষণ করে এবং প্রয়োজনে সমন্বয় করে ব্যবস্থা উৎপাদন প্রক্রিয়ায় উৎপন্ন বর্জ্যের পরিমাণ ন্যূনতম করতে পারে।

সারাংশে, হালকা ইস্পাত রোলফর্ম মেশিনে অটোমেশন এবং নিয়ন্ত্রণ ব্যবস্থার ব্যবহার মেশিনের দক্ষতা আরও বাড়াতে পারে। সেন্সর, PLC এবং HMI ব্যবহার করে রিয়েল-টাইমে প্রক্রিয়া পর্যবেক্ষণ এবং নিয়ন্ত্রণ করে উৎপাদকরা ডাউনটাইম হ্রাস, বর্জ্য ন্যূনতমকরণ এবং পণ্যের গুণমান উন্নয়ন করতে পারেন।

উপসংহারে, হালকা ইস্পাত রোলফর্ম মেশিন উচ্চমানের হালকা ইস্পাত পণ্য উৎপাদনে খরচ-কার্যকর, দক্ষ এবং বহুমুখী বিকল্প প্রদান করে। লীন ম্যানুফ্যাকচারিং, সিক্স সিগমা এবং টোটাল কোয়ালিটি ম্যানেজমেন্টের মতো নীতি ব্যবহার করে দক্ষতার জন্য ডিজাইন করলে উৎপাদন প্রক্রিয়া আরও অতিষ্ঠান করা যায়। অটোমেশন এবং নিয়ন্ত্রণ ব্যবস্থা ডাউনটাইম হ্রাস, বর্জ্য ন্যূনতমকরণ এবং পণ্যের গুণমান উন্নয়ন করে দক্ষতা বাড়াতে পারে। এই কৌশলগুলি বাস্তবায়ন করে উৎপাদকরা হালকা ইস্পাত রোলফর্ম মেশিনের নমনীয়তা, নির্ভুলতা এবং বর্জ্য হ্রাসের সুবিধা পেয়ে শেষ পর্যন্ত দক্ষতা বৃদ্ধি এবং উন্নত গুণমান অর্জন করতে পারেন।