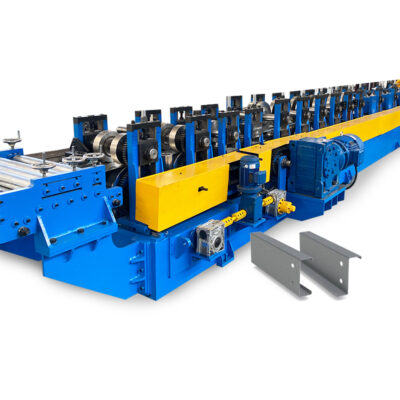

সি চ্যানেল রোল তৈরির মেশিন বিভিন্ন শিল্পে উচ্চ-মানের, স্থির সি-আকৃতির চ্যানেল উৎপাদনের জন্য ব্যবহৃত হয়। এই মেশিনগুলি নির্মাণ, অটোমোটিভ এবং যন্ত্রপাতি শিল্পের মতো উচ্চ পরিমাণের সি চ্যানেল প্রয়োজনীয় ব্যবসায়ের জন্য অপরিহার্য। তবে, আপনার সি চ্যানেল রোল ফর্মিং মেশিন থেকে সর্বোচ্চ লাভের জন্য এর দক্ষতা সর্বোচ্চ করা গুরুত্বপূর্ণ।

বর্তমান বাজারে প্রতিযোগিতামূলক থাকার জন্য যেকোনো ব্যবসার জন্য দক্ষতা অপরিহার্য। আপনার সি চ্যানেল রোল ফর্মিং মেশিনের দক্ষতা সর্বোচ্চ করে সময় সাশ্রয়, বর্জ্য কমানো এবং আউটপুট বাড়ানো যায়, যা আপনার লাভ-লোকসান উন্নত করতে সাহায্য করে। আপনার সি চ্যানেল রোল ফর্মিং মেশিনের কর্মক্ষমতা অপ্টিমাইজ করে কম সময়ে আরও অংশ উৎপাদন, উপাদানের বর্জ্য কমানো এবং পণ্যের সামগ্রিক মান উন্নত করা সম্ভব।

এই লেখায় আমরা আপনার সি চ্যানেল রোল ফর্মিং মেশিনের দক্ষতা সর্বোচ্চ করার কিছু মূল কৌশল আলোচনা করব। আমরা সঠিক রক্ষণাবেক্ষণ, উপাদান নির্বাচন, রোল ডিজাইন, ফিড নির্ভুলতা, গতি নিয়ন্ত্রণ, মান নিয়ন্ত্রণ, অটোমেশন এবং প্রশিক্ষণ ও শিক্ষার মতো বিষয় কভার করব। এই কৌশলগুলি প্রয়োগ করে আপনি নিশ্চিত করতে পারেন যে আপনার সি চ্যানেল রোল ফর্মিং মেশিন তার সর্বোচ্চ সম্ভাবনায় কাজ করে, যা সবচেয়ে দক্ষ উপায়ে উচ্চ-মানের, স্থির সি চ্যানেল উৎপাদন করতে সাহায্য করে।

সি চ্যানেল রোল ফর্মিং মেশিনের সঠিক রক্ষণাবেক্ষণ

আপনার সি চ্যানেল রোল ফর্মিং মেশিনের সর্বোত্তম কর্মক্ষমতা নিশ্চিত করার জন্য সঠিক রক্ষণাবেক্ষণ অত্যাবশ্যক। নিয়মিত রক্ষণাবেক্ষণ মেশিনের খারাপ অবস্থা প্রতিরোধ করে, ডাউনটাইম হ্রাস করে এবং মেশিনের আয়ু বৃদ্ধি করে। এখানে কয়েকটি গুরুত্বপূর্ণ রক্ষণাবেক্ষণ অনুশীলনের বিবরণ দেওয়া হলো:

- নিয়মিত পরিষ্কার: সি চ্যানেল রোল ফর্মিং মেশিনকে ভালো অবস্থায় রাখার জন্য নিয়মিত পরিষ্কার অপরিহার্য। ময়লা, ধুলোবালি এবং অন্যান্য দূষকগুলি মেশিনের উপাদানগুলিতে ক্ষয় সৃষ্টি করতে পারে, যা তার সামগ্রিক কার্যক্ষমতা হ্রাস করে। রোলার, গাইড এবং অন্যান্য উপাদানসহ মেশিনটি নিয়মিত পরিষ্কার করুন।

- উপাদান পরিদর্শন: মেশিনের উপাদানগুলি নিয়মিত পরিদর্শন করুন, কোনো ক্ষয়, ক্ষতি বা অ্যালাইনমেন্টের সমস্যার চিহ্ন খুঁজুন। এর মধ্যে রোলার, গাইড, বিয়ারিং এবং অন্যান্য চলমান অংশগুলি অন্তর্ভুক্ত। সমস্যাগুলি প্রথম দিকেই শনাক্ত করে মেরামত করলে পরবর্তীতে বড় সমস্যা এড়ানো যায়।

- লুব্রিকেশন: মেশিনের উপাদানগুলির সঠিক লুব্রিকেশন মসৃণ কার্যকরণ নিশ্চিত করতে এবং অতিরিক্ত ক্ষয় প্রতিরোধ করতে অত্যন্ত গুরুত্বপূর্ণ। প্রস্তুতকারকের সুপারিশকৃত লুব্রিকেশন সময়সূচি অনুসরণ করুন এবং প্রত্যেক উপাদানের জন্য সঠিক ধরনের লুব্রিকেন্ট ব্যবহার করুন।

- ক্ষতিগ্রস্ত বা ক্ষয়প্রাপ্ত অংশ প্রতিস্থাপন: কোনো ক্ষতিগ্রস্ত বা ক্ষয়প্রাপ্ত অংশ যত তাড়াতাড়ি সম্ভব প্রতিস্থাপন করুন। এমন অংশগুলি মেশিনের অদক্ষ কার্যকরণ ঘটাতে পারে, যা নিম্নমানের পণ্য এবং বাড়তি ডাউনটাইমের কারণ হয়।

- ক্যালিব্রেশন: নির্ধারিত সহনশীলতার মধ্যে কার্যকরণ নিশ্চিত করতে মেশিনটি নিয়মিত ক্যালিব্রেট করুন। এর মধ্যে মেশিনের অ্যালাইনমেন্ট পরীক্ষা এবং প্রয়োজনীয় সমন্বয় অন্তর্ভুক্ত।

এই রক্ষণাবেক্ষণ অনুশীলনগুলি অনুসরণ করে আপনি আপনার সি চ্যানেল রোল ফর্মিং মেশিনের সর্বোচ্চ সম্ভাবনায় কার্যকরণ নিশ্চিত করতে পারেন। নিয়মিত রক্ষণাবেক্ষণ ব্রেকডাউন প্রতিরোধ করে, ডাউনটাইম কমায় এবং মেশিনের আয়ু বাড়ায়, যা উচ্চমানের পণ্য এবং বাড়তি কার্যক্ষমতা প্রদান করে।

সি চ্যানেল রোল ফর্মিং মেশিনের রোল ডিজাইন

রোলের ডিজাইন আপনার সি চ্যানেল রোল ফর্মিং মেশিনের কার্যক্ষমতা নির্ধারণে একটি গুরুত্বপূর্ণ কারণ। রোলের আকার এবং কনফিগারেশন শেষ পণ্যের গুণমান, উপাদান ব্যবহারের হার এবং মেশিনের সামগ্রিক কার্যক্ষমতাকে প্রভাবিত করে। এখানে রোল ডিজাইনের কয়েকটি মূল বিবেচনা উল্লেখ করা হলো:

- রোল কনফিগারেশন: রোল কনফিগারেশন উৎপাদিত সি চ্যানেলের আকার এবং প্রোফাইল নির্ধারণ করে। সঠিক রোল কনফিগারেশন নির্বাচন করে মেশিনের কার্যক্ষমতায় উল্লেখযোগ্য প্রভাব ফেলা যায়। উদাহরণস্বরূপ, অতিরিক্ত ফর্মিং ধাপযুক্ত রোল ব্যবহার করলে মেশিন ধীর হয়ে যায় এবং স্ক্র্যাপ উপাদান বাড়ে।

- উপাদান নির্বাচন: ব্যবহৃত উপাদানের ধরন এবং মোটা-ফিনা প্রয়োজনীয় রোলের আকার এবং আকৃতি নির্ধারণ করে। রোলগুলি এমনভাবে ডিজাইন করা উচিত যাতে প্রয়োজনীয় সহনশীলতা এবং গুণমান বজায় রেখে উপাদানের পরিমাণ কমানো যায়।

- অ্যালাইনমেন্ট: রোলের সঠিক অ্যালাইনমেন্ট মেশিনের দক্ষ কার্যকরণ নিশ্চিত করতে অত্যাবশ্যক। অ্যালাইনমেন্টহীন রোল উপাদানকে অসমানভাবে টেনে নিতে পারে, যা নিম্নমানের পণ্য এবং উপাদানের অপচয় ঘটায়।

- উপাদান লুব্রিকেশন: রোলের লুব্রিকেশন উপাদানের আটকে যাওয়া বা বাইন্ডিং প্রতিরোধ করতে অপরিহার্য। সঠিক লুব্রিকেশন রোলের ক্ষয় কমায় এবং স্ক্র্যাপ উপাদান হ্রাস করে।

- রোল উপাদান: রোলের স্থায়িত্ব এবং কর্মক্ষমতার জন্য সঠিক উপাদান নির্বাচন অত্যন্ত গুরুত্বপূর্ণ। রোলগুলি উচ্চমানের উপাদান দিয়ে তৈরি হওয়া উচিত যা রোল ফর্মিং প্রক্রিয়ার চাপ এবং স্ট্রেস সহ্য করতে পারে।

সঠিক রোল কনফিগারেশন নির্বাচন, সঠিক অ্যালাইনমেন্ট নিশ্চিতকরণ এবং উচ্চমানের উপাদান ব্যবহার করে আপনি আপনার সি চ্যানেল রোল ফর্মিং মেশিনের কার্যক্ষমতা সর্বোচ্চ করতে পারেন। স্ক্র্যাপ উপাদান কমিয়ে এবং কম সময়ে উচ্চমানের চ্যানেল উৎপাদন করে আপনি মেশিনের আউটপুট বাড়াতে এবং খরচ কমাতে পারেন। সঠিক রোল ডিজাইন মেশিনের সর্বোচ্চ সম্ভাবনায় কার্যকরণ নিশ্চিত করে, যা উন্নত কার্যক্ষমতা এবং উচ্চমানের পণ্য প্রদান করে।

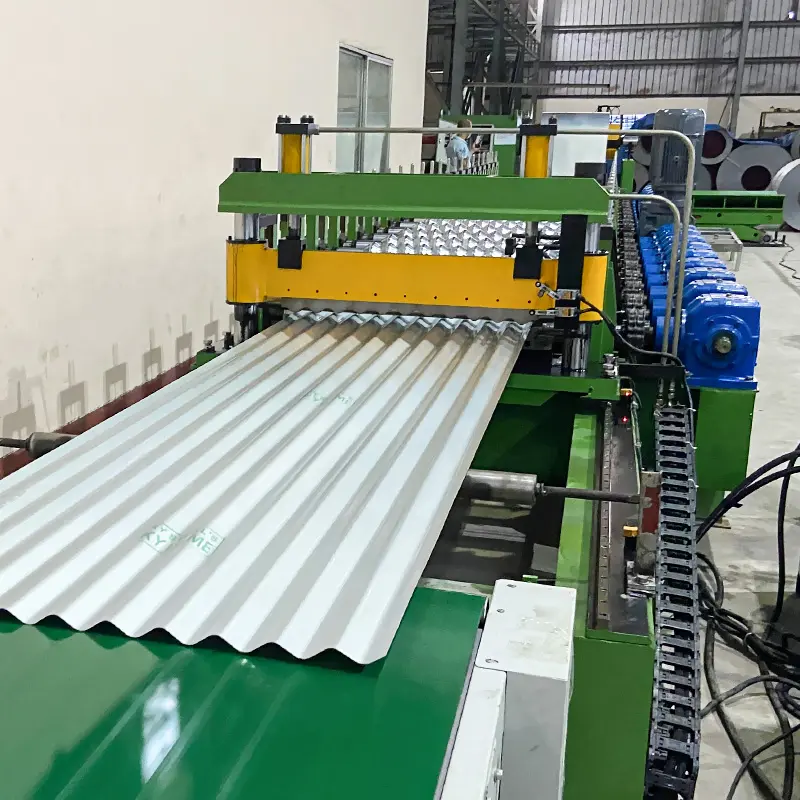

ফিড নির্ভুলতা সি চ্যানেল রোল ফর্মিং মেশিনের কার্যক্ষমতা উন্নয়ন

সঠিক এবং স্থির উপাদান ফিডিং বজায় রাখা আপনার সি চ্যানেল রোল ফর্মিং মেশিনের কার্যক্ষমতা সর্বোচ্চ করার জন্য অপরিহার্য। অনির্ভুল ফিডিং অস্থির পণ্যমান, বাড়তি স্ক্র্যাপ এবং হ্রাসপ্রাপ্ত মেশিন আউটপুটের কারণ হয়। সঠিক উপাদান ফিডিং বজায় রাখার জন্য এখানে কয়েকটি মূল বিবেচনা:

- ফিডিং প্রক্রিয়ার সঠিক সমন্বয়: ফিডিং প্রক্রিয়াটি সঠিকভাবে সমন্বিত হওয়া উচিত যাতে স্থির এবং নির্ভুল উপাদান ফিডিং নিশ্চিত হয়। মেশিনের ফিড রোলারগুলির সঠিক টেনশন সেট করুন এবং ফিড করা উপাদানের পুরুত্বের সাথে মিলিয়ে তাদের মধ্যবর্তী দূরত্ব সমন্বয় করুন।

- উপাদানের পুরুত্ব পর্যবেক্ষণ: ফিড করা উপাদানের পুরুত্ব পর্যবেক্ষণ সঠিক এবং স্থির ফিডিং বজায় রাখতে অত্যাবশ্যক। পুরুত্ব গেজ ব্যবহার করে উপাদানের পুরুত্ব নিয়মিত পরীক্ষা করুন এবং প্রয়োজনে ফিডিং প্রক্রিয়া সমন্বয় করুন।

- উপাদানের সোজাসুজি: উপাদানটি মেশিনে ফিড করার আগে সোজা এবং কোনো বাঁকা বা কুঞ্চিত থেকে মুক্ত হওয়া উচিত। বাঁকা বা কুঞ্চিত উপাদান অসমান ফিডিং সৃষ্টি করে, যা নিম্নমানের পণ্য এবং বাড়তি স্ক্র্যাপের কারণ হয়।

- উপাদানের গুণমান: মেশিনে ফিড করা উপাদানের গুণমান রোল ফর্মিং প্রক্রিয়ার কার্যক্ষমতাকে প্রভাবিত করে। উচ্চমানের উপাদান জ্যাম বা অন্যান্য সমস্যা কম সৃষ্টি করে, যা মসৃণ ফিডিং এবং বাড়তি মেশিন আউটপুট নিশ্চিত করে।

- স্থির ফিড হার বজায় রাখা ফিড হার উচ্চমানের, স্থির পণ্য উৎপাদনের জন্য অপরিহার্য। মেশিনের নিয়ন্ত্রণ ব্যবহার করে স্থির ফিড হার বজায় রাখুন এবং সর্বোত্তম কর্মক্ষমতা নিশ্চিত করতে ফিডিং প্রক্রিয়া সমন্বয় করুন।

সঠিক এবং স্থির উপাদান ফিডিং বজায় রেখে আপনি আপনার সি চ্যানেল রোল ফর্মিং মেশিনের কার্যক্ষমতা উন্নত করতে পারেন। এর মধ্যে ফিডিং প্রক্রিয়ার সঠিক সমন্বয়, উপাদানের পুরুত্ব পর্যবেক্ষণ, উপাদানের সোজাসুজি নিশ্চিতকরণ, উচ্চমানের উপাদান ব্যবহার এবং স্থির ফিড হার বজায় রাখা অন্তর্ভুক্ত। স্ক্র্যাপ কমিয়ে এবং কম সময়ে উচ্চমানের চ্যানেল উৎপাদন করে আপনি মেশিনের আউটপুট বাড়াতে এবং খরচ কমাতে পারেন।

উপসংহারে, আপনার সি চ্যানেল রোল ফর্মিং মেশিনের কার্যক্ষমতা সর্বোচ্চ করতে বেশ কয়েকটি গুরুত্বপূর্ণ কারণের দিকে নজর দেওয়া প্রয়োজন। সঠিক রক্ষণাবেক্ষণ, উপাদান নির্বাচন, রোল ডিজাইন, ফিড নির্ভুলতা, গতি নিয়ন্ত্রণ, গুণমান নিয়ন্ত্রণ, অটোমেশন এবং প্রশিক্ষণ ও শিক্ষা সবই মেশিনের সর্বোচ্চ সম্ভাবনায় কার্যকরণ নিশ্চিত করতে অপরিহার্য। এই কৌশলগুলি অনুসরণ করে আপনি অপচয় কমাতে, আউটপুট বাড়াতে এবং সবচেয়ে দক্ষ উপায়ে উচ্চমানের, স্থির সি চ্যানেল উৎপাদন করতে পারেন। শেষ পর্যন্ত, সি চ্যানেল রোল ফর্মিং মেশিনের কার্যক্ষমতা সর্বোচ্চ করা আপনার ব্যবসাকে আজকের বাজারে প্রতিযোগিতামূলক রাখতে এবং লাভবৃদ্ধি ঘটাতে সাহায্য করতে পারে।