In the world of modern construction, efficiency and flexibility have become paramount. Among the many technological innovations shaping the industry, the changeable U purlin roll forming machine stands out as a versatile and indispensable tool. In this article, we will delve into the intricacies of this remarkable machine, exploring its features, benefits, applications, and much more.

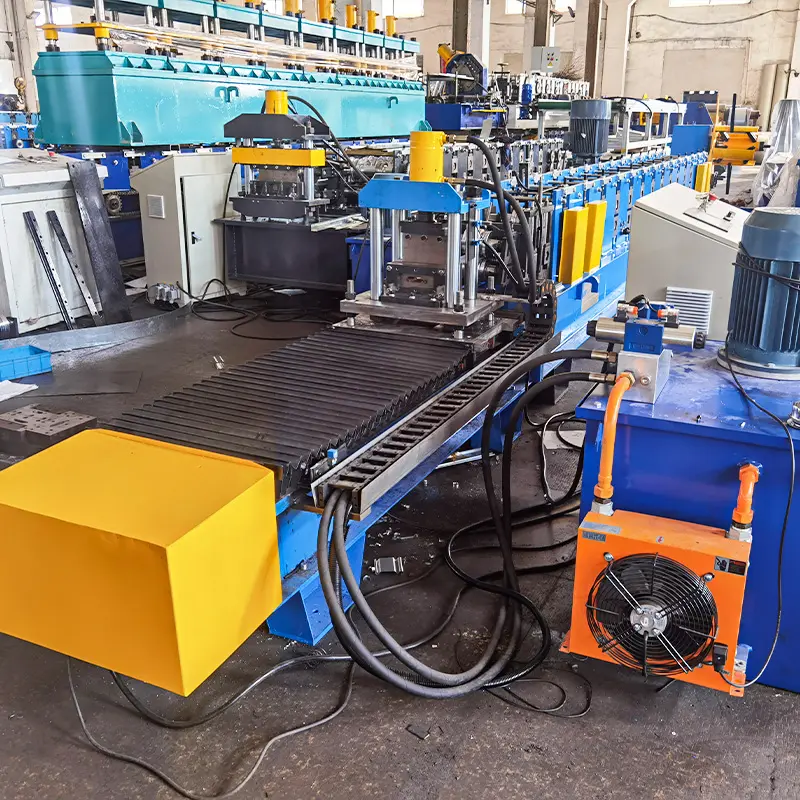

Introduction to Changeable U Purlin Roll Forming Machine

Roll forming machines have revolutionized the production of various construction components. U purlins, a common structural element used in roofing and wall systems, have traditionally been manufactured using fixed roll forming machines. However, the introduction of changeable U purlin roll forming machines has brought a new level of adaptability and efficiency to the process.

In construction, U purlins play a critical role in providing structural support and stability. They are essential components in projects ranging from residential buildings to industrial complexes. The advent of changeable roll forming machines has marked a significant shift in how these essential elements are produced.

Understanding the Changeable U Purlin Roll Forming Machine

The changeable U purlin roll forming machine is a state-of-the-art piece of equipment designed to streamline the production of U purlins. Unlike traditional fixed machines that are set to produce a specific size and profile, the changeable machine offers a dynamic approach. It allows operators to swiftly switch between different sizes and configurations of U purlins, catering to the diverse needs of construction projects.

Key Features of the Changeable U Purlin Roll Forming Machine

Flexibility in Producing Different Sizes of U Purlins

The primary advantage of the changeable machine is its ability to produce U purlins of varying sizes with minimal downtime. This feature is particularly valuable in projects that require multiple sizes of purlins, eliminating the need for separate setups or machines for each size.

Quick Changeover Process

The changeable machine’s design facilitates rapid changeovers. With a well-engineered system for adjusting rollers and tooling, operators can switch from one purlin size to another in a matter of minutes, saving precious production time.

High Precision and Quality Output

Despite its adaptability, the changeable roll forming machine does not compromise on quality. Advanced manufacturing techniques ensure that each purlin produced maintains the required dimensions and structural integrity.

Stay tuned for the next part of the article, where we will continue to explore the benefits and applications of the changeable U purlin roll forming machine. Whether you’re a construction professional or simply intrigued by innovative machinery, this technology is worth your attention.

Benefits of Using a Changeable Roll Forming Machine

The adoption of a changeable U purlin roll forming machine offers numerous advantages that can significantly impact both the efficiency and cost-effectiveness of construction projects.

Cost-Effectiveness in Production

Traditional fixed roll forming machines require separate setups for different purlin sizes, leading to increased labor costs and setup times. In contrast, the changeable machine’s ability to handle various sizes in a single setup reduces labor requirements and minimizes production downtime.

Time-Saving Due to Rapid Adjustments

Time is of the essence in construction projects, and the changeable roll forming machine excels in this aspect. Its quick changeover process ensures that production can swiftly adapt to evolving project requirements, enabling contractors to meet tight deadlines without sacrificing quality.

Reduction in Material Wastage

Customization often results in material wastage, but the changeable machine tackles this issue effectively. By producing precise quantities of each purlin size as needed, it minimizes excess inventory and material losses, contributing to a more sustainable construction process.

Applications of Changeable U Purlin Roll Forming Machine

Versatility in Construction Projects

Construction projects come in various shapes and sizes, and the ability to adapt to these differences is invaluable. The changeable roll forming machine caters to the needs of diverse projects, from residential homes to large-scale commercial structures, making it a versatile asset for contractors.

Meeting Varying Design Requirements

Architectural designs often call for unique purlin sizes and profiles to achieve specific aesthetics or structural goals. The changeable machine empowers builders to realize these design aspirations efficiently, ensuring that the constructed building aligns with the architect’s vision.

Step-by-Step Guide to Operating the Machine

Preparation and Setup

Begin by preparing the machine for operation. Ensure that it is clean, properly lubricated, and all safety measures are in place. Check that the required tooling for the desired purlin sizes is available.

Material Loading and Feeding

Load the raw material, typically steel coils, onto the machine’s feeding system. The machine will automatically feed the material into the forming stations.

Adjusting for Different Sizes

Using the machine’s intuitive control panel, select the desired purlin size and configuration. The machine will then adjust its rollers and tooling accordingly.

রোল ফর্মিং প্রক্রিয়া

Initiate the roll forming process. The machine will guide the material through a series of forming stations, gradually shaping it into the chosen purlin profile. The precision of this process ensures consistent results.

Stay tuned for the next part of the article, where we will delve into the maintenance and care of the changeable U purlin roll forming machine. Proper maintenance is essential to ensure the longevity and reliability of this advanced equipment.

Maintenance and Care of the Machine

Ensuring the longevity and optimal performance of a changeable U purlin roll forming machine requires regular maintenance and diligent care.

নিয়মিত পরিদর্শন এবং পরিষ্কার

Frequent inspections help identify any signs of wear, damage, or misalignment. Dust and debris can accumulate over time, affecting the machine’s precision. Regular cleaning prevents these issues and maintains consistent quality.

Lubrication of Critical Components

Proper lubrication of moving parts is essential to prevent friction-related problems. Follow the manufacturer’s guidelines for lubrication intervals and use recommended lubricants to keep the machine running smoothly.

Addressing Common Issues

Stay vigilant for common issues such as jammed material, misaligned rollers, or irregular forming. Timely troubleshooting and adjustments can prevent minor problems from escalating into costly downtime.

Comparing Changeable and Fixed Roll Forming Machines

Advantages of Fixed Machines

Fixed roll forming machines are well-suited for projects that require a single consistent purlin size. They are generally simpler in design and may have a lower upfront cost.

Situations Favoring Changeable Machines

Changeable machines shine when dealing with projects that demand versatility. If your construction projects involve varying purlin sizes or require frequent design changes, the investment in a changeable machine can yield substantial returns in terms of time, efficiency, and reduced wastage.

Market Trends and Future Prospects

Growing Demand for Customized Construction Solutions

As construction projects become more complex and designs more customized, the demand for adaptable manufacturing solutions like changeable roll forming machines is on the rise.

Technological Advancements in Roll Forming

The roll forming industry continues to evolve, incorporating technologies such as automation, data analytics, and improved material handling. This points toward a future where changeable machines could become even more sophisticated and efficient.

Real-life Case Studies

Examples of Successful Projects Using Changeable U Purlin Machines

Several construction projects have reaped the benefits of changeable roll forming machines. These machines have contributed to accelerated timelines, reduced production costs, and enhanced design flexibility, ultimately leading to satisfied clients and contractors.

Positive Impact on Project Timelines and Budgets

In a competitive construction market, the ability to save time without compromising on quality is a game-changer. Changeable machines have consistently demonstrated their capability to expedite project timelines and keep budgets in check.

Stay tuned for the next section, where we will guide you through the process of selecting the right changeable U purlin roll forming machine for your specific needs. Making an informed decision is crucial to maximizing the benefits of this technology.

Selecting the Right Machine for Your Needs

Choosing the appropriate changeable U purlin roll forming machine requires careful consideration of various factors to ensure it aligns with your project requirements.

Assessing Project Requirements

Evaluate the scope of your construction projects. Consider factors such as the range of purlin sizes you commonly use, the volume of production, and the expected frequency of design changes.

Considering Production Volume and Design Variability

For projects with high production volumes and varying design needs, a more advanced and capable changeable machine may be necessary. Conversely, smaller projects with limited variability may find a simpler model more cost-effective.

Expert Insights and Recommendations

Quotes from Industry Experts

Industry experts emphasize the importance of embracing adaptable manufacturing solutions in the construction sector. Their insights underscore how changeable roll forming machines can enhance competitiveness and deliver superior results.

Factors to Consider When Investing in a Roll Forming Machine

Experts recommend analyzing the long-term benefits of reduced setup times, lower material wastage, and the ability to take on diverse projects. These considerations can guide your decision-making process.

Common Misconceptions About Changeable Roll Forming Machines

Addressing Concerns About Complexity and Reliability

Some skeptics may worry that changeable machines are complex and prone to breakdowns. However, technological advancements have addressed these concerns, making modern changeable machines reliable and user-friendly.

Clarifying Benefits Through Concrete Examples

By sharing success stories and illustrating the tangible advantages of changeable machines, these misconceptions can be dispelled, giving a clearer picture of their value to construction projects.

Economic and Environmental Aspects

Energy Efficiency in Roll Forming

Changeable roll forming machines contribute to energy efficiency by optimizing production processes and minimizing material wastage. This aligns with the construction industry’s growing emphasis on sustainability.

Contribution to Sustainable Construction Practices

Reduced material wastage and efficient resource utilization not only benefit project budgets but also contribute to eco-friendly construction practices, reducing the environmental impact of building projects.

উপসংহার

The advent of changeable U purlin roll forming machines marks a turning point in the construction industry’s approach to producing essential structural components. Their flexibility, efficiency, and adaptability position them as indispensable tools for modern construction projects.

In a landscape where time, quality, and customization are paramount, the advantages of changeable machines are undeniable. Whether you’re an architect, builder, or investor, exploring the potential of changeable roll forming machines can unlock new avenues for success in the dynamic world of construction.

প্রায়শই জিজ্ঞাসিত প্রশ্ন (এফএকিউ)

- প্রশ্ন: Are changeable roll forming machines suitable for small-scale projects?

- উত্তর: Yes, changeable machines can benefit projects of all sizes by reducing production time and material wastage.

- প্রশ্ন: How complex is the changeover process between different purlin sizes?

- উত্তর: Modern changeable machines are designed for quick and user-friendly changeovers, often taking only minutes.

- প্রশ্ন: Can changeable machines maintain the same quality as fixed machines?

- উত্তর: Absolutely, changeable machines use advanced technology to ensure consistent and high-quality results.

- প্রশ্ন: What types of industries beyond construction could benefit from changeable roll forming machines?

- উত্তর: Industries involved in manufacturing similar profiles, such as automotive or appliance production, could also benefit from these machines.

- প্রশ্ন: Are changeable machines more expensive than fixed roll forming machines?

- উত্তর: While changeable machines might have a higher upfront cost, their versatility and efficiency can lead to long-term cost savings.