ভূমিকা

In the world of modern manufacturing, precision and efficiency are paramount. Industries relying on sheet metal production seek reliable methods to meet their demands for high-quality products with consistent shapes and dimensions. This is where the trapezoidal roll forming machine steps in as a game-changer. In this article, we explore the functionalities, advantages, and applications of this versatile machine.

What is a Trapezoidal Roll Forming Machine?

A trapezoidal roll forming machine is an automated production line designed to shape sheet metal into trapezoidal profiles. This machine takes flat metal coils and gradually bends them into the desired trapezoidal shape through a series of rolling stands. The process ensures precise forming and consistency throughout the length of the material.

How Does a Trapezoidal Roll Forming Machine Work?

The roll forming process starts with an uncoiler, where the metal coil is loaded onto the machine. The material is then fed through a series of rollers, each responsible for specific bending and forming operations. These rollers are strategically positioned to gradually shape the metal into the desired trapezoidal profile. The final product is then cut to the required length before being collected.

Advantages of Using a Trapezoidal Roll Forming Machine

Trapezoidal roll forming machines offer several advantages over traditional bending and shaping methods:

- উচ্চ দক্ষতা: The continuous and automated process ensures a high production rate, reducing manufacturing time significantly.

- সামঞ্জস্যপূর্ণ গুণমান: The machine’s precision and repeatability guarantee uniform products without variations in shape or dimensions.

- উপাদান সাশ্রয়: Minimal scrap generation due to accurate forming reduces material wastage and saves costs.

- নমনীয়তা এবং কাস্টমাইজেশন: These machines can be tailored to produce various trapezoidal profiles, meeting diverse customer needs.

- Labor Reduction: Automated operation reduces the need for extensive manual labor, saving on workforce expenses.

- Integration with Other Processes: Roll-formed trapezoidal profiles seamlessly fit into downstream assembly and construction processes.

- Reduced Lead Times: Quick production turnaround enables faster project completion and delivery.

Types of Trapezoidal Roll Forming Machines

Trapezoidal roll forming machines come in various configurations to cater to different production requirements:

Single Station Roll Forming Machine

The single station machine performs all forming steps in one place, ideal for low to medium production volumes.

ডুপ্লেক্স রোল ফর্মিং মেশিন

The duplex machine has two independent roll forming stations, allowing simultaneous production of two different profiles.

Triplex Roll Forming Machine

This type has three forming stations and offers even greater flexibility and higher production capacity.

Automated Roll Forming Lines

Automated lines combine multiple roll forming machines with additional processes like punching and notching, streamlining the entire production workflow.

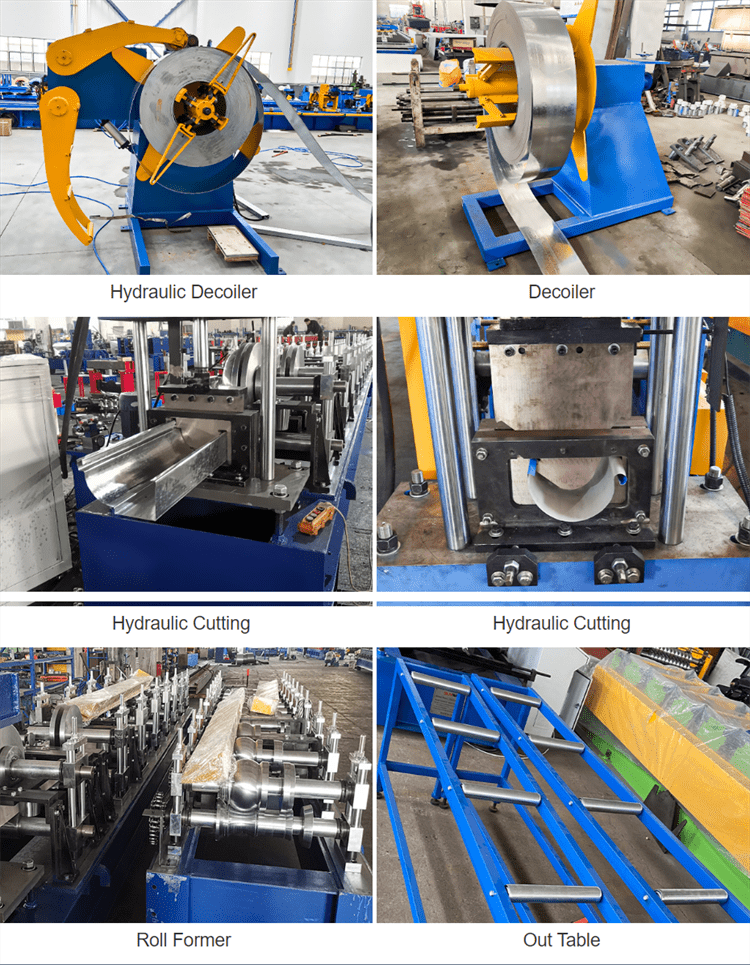

Key Components of a Trapezoidal Roll Forming Machine

To understand the intricacies of the machine’s operation, it’s essential to know its key components:

আনকোয়লার

The uncoiler holds the metal coil and feeds it into the roll forming machine gradually.

ফিডিং সিস্টেম

The feeding system guides the material through the machine and ensures smooth, even feeding.

Roll Forming Unit

The heart of the machine, the roll forming unit, consists of multiple rollers that shape the material step by step.

কাটিং সিস্টেম

The cutting system, typically using flying shears, trims the formed profile to the desired length.

Control Panel and Software

The control panel allows operators to set various parameters, while the software governs the machine’s operation.

Factors to Consider When Choosing a Trapezoidal Roll Forming Machine

Selecting the right roll forming machine for your specific needs requires careful consideration of the following factors:

উপাদান সামঞ্জস্যতা

Ensure the machine is compatible with the types and thicknesses of metal you intend to use.

উৎপাদন গতি

Consider the required production rate and choose a machine that meets your volume demands.

কাস্টমাইজেশন অপশন

Check if the machine can be adjusted to produce various trapezoidal profiles to cater to different customer requirements.

মেশিনের আকার এবং স্থানের প্রয়োজনীয়তা

Determine the available space in your facility and select a machine that fits appropriately.

Budget and Cost Considerations

Balance your budget constraints with the desired features and capabilities of the machine.

Maintenance and Care for a Trapezoidal Roll Forming Machine

To ensure the longevity and optimal performance of the machine, regular maintenance is essential. Some maintenance tips include:

Regular Inspection and Cleaning

Frequent inspections and cleaning help identify and address potential issues before they escalate.

Lubrication of Moving Parts

Proper lubrication of the machine’s moving parts, such as rollers and bearings, ensures smooth operation and reduces wear and tear.

Replacing Worn-Out Components

Regularly check for worn-out or damaged components and replace them promptly to prevent further damage and maintain efficiency.

Safety Precautions While Operating a Trapezoidal Roll Forming Machine

Safety should always be a top priority when operating any industrial machinery. Here are some essential safety precautions for using a trapezoidal roll forming machine:

Operator Training and Certification

Only trained and certified operators should be allowed to run the machine to avoid accidents and ensure proper handling.

Proper Use of Personal Protective Equipment (PPE)

Operators should wear appropriate PPE, including safety glasses, gloves, and ear protection, to protect themselves from potential hazards.

Emergency Stop Procedures

The machine should be equipped with easily accessible emergency stop buttons to halt operations in case of an emergency.

Lockout/Tagout Procedures

Establish lockout/tagout procedures to ensure the machine is safely shut down during maintenance or repair work.

Common Quality Issues and Troubleshooting in Roll Forming

Despite its efficiency, roll forming may encounter some quality issues. Understanding common problems and their solutions is crucial:

Uneven Material Feeding

Inconsistent material feeding can lead to irregular profiles. Check the feeding system for misalignments and adjust accordingly.

Forming Defects

Address issues like improper roll settings or worn-out rollers to eliminate forming defects.

Cutting Irregularities

If the cutting system produces uneven cuts, examine the blades and replace them if necessary.

Electrical and Software Issues

Regularly inspect the control panel and software for any malfunctions, and consult a technician for timely repairs.

Applications of Trapezoidal Roll Forming Machines

The versatility of trapezoidal roll forming machines allows for a wide range of applications in various industries:

Roofing and Cladding Sheets

Trapezoidal profiles are commonly used in roofing and cladding systems for their durability and weather resistance.

Wall Panels

The machine can produce aesthetically pleasing wall panels used in architectural and construction applications.

Purlins and Girts

In the construction of steel structures, trapezoidal profiles serve as essential components like purlins and girts.

শেল্ফিং এবং র্যাকিং সিস্টেম

The precise forming capability of the machine makes it ideal for manufacturing shelving and racking systems used in warehouses and storage facilities.

Automotive and Aerospace Components

Trapezoidal roll forming machines play a vital role in producing components for automotive and aerospace industries, where precision and consistency are critical.

Future Trends in Trapezoidal Roll Forming Technology

As technology advances, so does the roll forming industry. Some future trends to look out for include:

- Advanced Materials: Roll forming machines will adapt to process new materials, such as lightweight alloys and advanced composites.

- Smart Automation: Integration of artificial intelligence and machine learning will enhance machine efficiency and productivity.

- শক্তি দক্ষতা: Roll forming machines will incorporate energy-saving features to reduce their environmental impact.

- Increased Customization: Machines will offer more flexible customization options to cater to diverse customer demands.

Environmental Impact and Sustainability Considerations

Manufacturers are increasingly focusing on sustainability and reducing their environmental footprint. Trapezoidal roll forming machines contribute to sustainability in several ways:

- Material Efficiency: The minimal waste generated during roll forming reduces the overall material consumption.

- শক্তি দক্ষতা: Automation and advanced technology lead to more energy-efficient operations.

- Recyclability: Many materials used in roll forming, such as steel, are highly recyclable, promoting a circular economy.

- Reduced Emissions: By optimizing production processes, roll forming machines can help reduce greenhouse gas emissions.

উপসংহার

The trapezoidal roll forming machine is a remarkable innovation that has revolutionized the sheet metal production industry. Its efficiency, consistency, and versatility make it a valuable asset for various applications. As technology continues to advance, we can expect even more developments in roll forming machinery, further driving efficiency and sustainability in the manufacturing sector.

প্রায়শই জিজ্ঞাসিত প্রশ্ন (এফএকিউ)

Q1: Can a trapezoidal roll forming machine produce other shapes besides trapezoids?

A1: Yes, depending on the machine’s design and adjustments, it can produce various other profiles, such as corrugated sheets or custom shapes.

Q2: Is it necessary to have specialized training to operate a trapezoidal roll forming machine?

A2: Yes, operating the machine requires specialized training to ensure safe and proper handling. Certified operators are essential for efficient and accident-free production.

Q3: What are the typical materials used in trapezoidal roll forming?

A3: Common materials include steel, aluminum, and other metals with good formability. The choice depends on the specific application and desired properties.

Q4: Can a trapezoidal roll forming machine handle thick materials?

A4: Yes, some machines can handle thick materials, but it depends on the machine’s capacity and design. It’s crucial to choose a machine that suits the material thickness you intend to work with.

Q5: Are trapezoidal roll forming machines suitable for small-scale production?

A5: Yes, trapezoidal roll forming machines come in various sizes, including models suitable for small-scale or custom production requirements.

Frequently Asked Questions (Supplemental)

1) What coil specifications yield the best results on a Trapezoidal Roll Forming Machine?

- Use galvanized or Zn-Al-Mg coated steel per ASTM A653/A792 in 0.35–0.8 mm for roofing/cladding, thickness tolerance ±0.02–0.03 mm, yield 230–550 MPa depending on span/wind load. For painted sheets, PVDF/PE topcoat 18–25 μm, backcoat 5–10 μm with protective film.

2) How can I minimize oil-canning and panel waviness on wide trapezoidal profiles?

- Calibrate entry guides and first three passes, ensure stand parallelism, balance roll gaps left/right, control line tension with a bridle, and use anti-wrinkle passes or crowned rolls where needed. Keep roll surface finish Ra ≤ 0.8 μm for pre-painted coils.

3) Should I choose hydraulic or servo-electric flying shear for trapezoidal panels?

- Hydraulic is robust for thicker gauges (>0.8–1.0 mm) and lower cost. Servo-electric offers higher speed, tighter length tolerance (±0.5–0.8 mm at 25–40 m/min), cleaner edges, and lower energy use—ideal for painted roofing.

4) What inline quality controls are recommended for trapezoidal profiles?

- Laser length gauges, vision systems for rib height and step depth, thickness/width measurement pre-entry, and encoder-based closed-loop cut control. Log SPC (Cp/Cpk) against rib height and length to stabilize first-pass yield.

5) How many forming stations are required for typical trapezoidal roofing?

- Simple trapezoidal panels in 0.4–0.6 mm often need 8–12 stations; deeper ribs, high-strength steel, or wider cover widths may require 12–18. Simulation can frequently reduce stations while maintaining tolerances.

2025 Industry Trends for Trapezoidal Roll Forming Machine

- Rapid changeover and recipe control: Quick-change cassettes with digital presets cut changeovers to 20–45 minutes, maintaining CpK targets without lengthy trial runs.

- Electrification: Servo-driven punches and shears reduce energy intensity 10–20% versus hydraulic-only lines, with regenerative drives recovering braking energy.

- Smart QC: Inline laser and vision inspection is becoming standard, pushing first-pass yield to 98–99% for painted trapezoidal panels.

- Sustainable materials: Increased adoption of Zn-Al-Mg coatings and cool-roof PVDF systems for longer life in marine/industrial atmospheres.

- Safety compliance: Safety PLCs meeting ISO 13849-1 (PL d/e) and CE/UKCA conformity are now baseline requirements among global buyers.

Benchmark Table: Trapezoidal Lines Performance (2023 vs 2025)

| KPI | 2023 Typical | 2025 Best-in-Class | Driving Machine/Parts Change | Source |

|---|---|---|---|---|

| Changeover time (profile/coil) | 90–180 min | 20–45 min | Quick-change cassettes, digital recipes | The Fabricator; OEM data https://www.thefabricator.com |

| Length tolerance @30 m/min | ±1.2–1.8 mm | ±0.5–0.8 mm | Servo flying shear, high-res encoders | OEM datasheets |

| First-pass yield (painted) | 95–97% | 98–99% | Inline laser/vision SPC, calibrated first passes | ISO 22514 https://www.iso.org |

| Energy use (kWh/ton) | 120–150 | 95–120 | Servo actuation, regen drives | World Steel Association https://worldsteel.org |

| Coating defect rate | 1.0–1.5% | 0.3–0.6% | Polished/nitrided rolls, film, clean conveying | Industry case reports |

Note: Best-in-class assumes trained operators, preventive maintenance, and documented setup sheets by gauge/coating.

Latest Research Cases

Case Study 1: Servo Shear + Vision Inspection on Trapezoidal Panels (2025)

Background: A Middle East cladding manufacturer faced variable cut length and rib-height deviation on 0.5 mm PVDF-coated steel.

Solution: Retrofitted servo-electric flying shear, added laser length gauge and AI-assisted vision to measure rib height and step depth; implemented recipe-linked roll gap presets.

Results: Length tolerance improved from ±1.6 mm to ±0.7 mm at 35 m/min; rib-height Cpk rose from 1.05 to 1.55; repaint claims down 48%; energy per ton reduced 12%.

Case Study 2: Zn-Al-Mg Coil Transition with Anti-Scratch Process (2024)

Background: A coastal-region roofing supplier adopted Zn-Al-Mg for corrosion resistance but saw increased surface scuffs during forming.

Solution: Polished/nitrided critical rolls, added felt wipers and UHMW-PE supports at exit, enforced roll cleaning SOP and protective film usage.

Results: Surface defect rate fell from 1.4% to 0.5%; salt-spray warranty extended by 5 years; throughput increased 10% with no defect rise.

Expert Opinions

- Dr. Stefanie Müller, Professor of Metal Forming, RWTH Aachen University

Viewpoint: “For trapezoidal profiles, the entry guide and first two stations dominate panel flatness. Simulation-led pass design and careful roll surface finish are decisive for painted coil quality.” Source: https://www.rwth-aachen.de - Michael Kolisnyk, VP Engineering, Roll-Kraft

Viewpoint: “Documenting roll gaps and guide positions by gauge/coating reduces oil-canning and speeds troubleshooting. Quick-change cassettes pay back rapidly in mixed-SKU environments.” Source: https://www.roll-kraft.com - Kevin Bennett, Functional Safety Assessor, TÜV Rheinland

Viewpoint: “Modern roll forming lines should validate stop categories and interlocks under ISO 13849-1 PL d/e—mandatory for CE/UKCA and vital for safe maintenance.” Source: https://www.tuv.com

Practical Tools and Resources

- COPRA RF (data M) – Pass design/simulation for trapezoidal panels: https://www.datam.de

- Roll-Kraft Resource Center – Setup charts and troubleshooting: https://www.roll-kraft.com/roll-forming-resource-center

- The Fabricator – Roll forming best practices and case studies: https://www.thefabricator.com

- ISO Standards – ISO 13849-1 (functional safety), ISO 22514 (SPC): https://www.iso.org

- World Steel Association – Coated steel and energy benchmarks: https://worldsteel.org

- Keyence and Cognex – Inline laser length and vision inspection: https://www.keyence.com | https://www.cognex.com

Target keyword integration examples:

- Upgrading a Trapezoidal Roll Forming Machine with servo-electric shear and vision inspection improves accuracy and reduces coating defects.

- Preventive maintenance on a Trapezoidal Roll Forming Machine—especially rolls, entry guides, and shear blades—stabilizes FPY and protects painted surfaces.

- Quick-change cassettes make a Trapezoidal Roll Forming Machine suitable for high-mix, medium-volume environments.

Citations and further reading:

- The Fabricator: Roll forming fundamentals and roofing applications https://www.thefabricator.com

- World Steel Association: Material and energy data https://worldsteel.org

- ISO: Functional safety and SPC standards https://www.iso.org

Last updated: 2025-10-24

Changelog: Added 5 supplemental FAQs; 2025 trend analysis with benchmark table; two recent trapezoidal-specific case studies; expert viewpoints with sources; tools/resources and keyword integration for Trapezoidal Roll Forming Machine.

Next review date & triggers: 2026-05-20 or earlier if OEMs release new quick-change cassette systems, ISO 13849/22514 updates publish, or Zn-Al-Mg/PVDF coating specs alter typical pass designs.