With the rapid expansion of renewable energy, electric vehicles (EVs), and industrial power storage, the demand for battery storage systems has never been higher. Battery racks are critical for organizing and securing lithium-ion, lead-acid, and industrial battery units in data centers, solar farms, telecom facilities, and EV charging stations.

To meet this increasing demand, manufacturers are turning to Battery Rack Roll Forming Machines, which enable high-speed, cost-effective, and precision-based production of battery storage racks. These machines ensure uniformity, structural integrity, and compliance with safety standards while significantly reducing manual labor and production costs.

In this guide, we’ll explore the applications, pricing, key features, advantages, and why Wuxi Sunway Machinery is leading the industry in battery rack roll-forming solutions.

What Are Battery Rack Roll Forming Machines?

ক Battery Rack Roll Forming Machine is a specialized industrial system designed to manufacture metal shelving and rack systems used for battery storage in energy facilities, EV charging stations, and industrial applications. These machines allow for continuous, automated production of customized battery racks with high load-bearing capacity, corrosion resistance, and modular assembly features.

Key Features of Battery Rack Roll Forming Machines

- Customizable Rack Designs – Supports the production of adjustable, modular, and heavy-duty battery storage systems.

- Material Versatility – Works with galvanized steel, stainless steel, and aluminum alloys to ensure durability and corrosion resistance.

- High Precision Engineering – Ensures uniform rack dimensions for seamless assembly in battery storage facilities.

- Automated Hole Punching and Cutting – Enables precise mounting points for battery modules and wiring integration.

- Anti-Corrosion and Fire-Resistant Coatings – Produces racks with protective finishes to prevent rust and fire hazards.

- উচ্চগতির উৎপাদন – Supports mass production of battery racks, significantly reducing manufacturing time and costs.

- IoT and Smart Integration – Allows for real-time monitoring, defect detection, and predictive maintenance.

Applications of Battery Rack Roll Forming Machines

Battery racks are essential for efficient space utilization, ventilation, and safety compliance in various industries. Battery Rack Roll Forming Machines enable manufacturers to produce customized storage solutions for the following applications:

1. Renewable Energy Storage Systems

- Use Case: Manufacturing battery racks for solar farms and wind energy storage facilities.

- Why It’s Essential: Provides organized, scalable storage for large-scale energy backup systems.

2. EV Charging Stations and Battery Swapping Facilities

- Use Case: Producing racks for lithium-ion battery storage and EV charging hubs.

- Why It’s Beneficial: Ensures secure, modular storage for electric vehicle battery packs.

3. Data Centers and Uninterruptible Power Supply (UPS) Systems

- Use Case: Fabricating battery racks for backup power solutions in data centers.

- Why It’s Important: Supports continuous power supply and prevents downtime in critical IT infrastructure.

4. Industrial and Telecom Battery Storage

- Use Case: Producing battery racks for telecom towers, industrial backup systems, and off-grid power solutions.

- Why It’s Necessary: Ensures reliable power storage to prevent operational disruptions.

5. Battery Manufacturing and Recycling Facilities

- Use Case: Manufacturing storage racks for battery production plants and recycling centers.

- Why It’s Innovative: Enables safe handling, organization, and processing of battery modules.

6. Military and Aerospace Energy Storage

- Use Case: Producing high-strength, impact-resistant battery racks for military and aerospace applications.

- Why It’s Critical: Ensures secure energy storage for defense and aviation infrastructure.

Key Features of Wuxi Sunway Battery Rack Roll Forming Machines

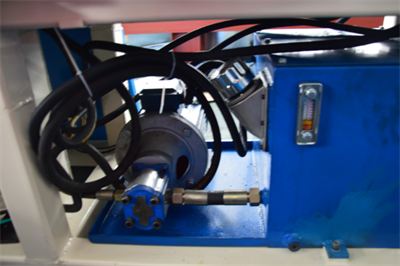

Wuxi Sunway Machinery is a global leader in battery rack roll-forming technology, offering high-performance, precision-engineered solutions for energy storage manufacturers. Their machines are designed to optimize production, reduce costs, and enhance structural integrity.

1. Customizable Rack Profiles and Load Capacities

- What It Offers: Machines equipped with adjustable tooling for producing racks with different weight capacities.

- Why It’s Critical: Supports a diverse range of energy storage configurations and structural requirements.

2. Multi-Material Processing Capabilities

- What It Processes:

- গ্যালভানাইজড ইস্পাত – Provides high strength and corrosion resistance.

- স্টেইনলেস স্টিল – Ensures fire resistance and long-term durability.

- Aluminum Alloys – Lightweight and rust-resistant for outdoor applications.

- Why It’s Essential: Accommodates various industry requirements and environmental conditions.

3. High-Speed, Automated Production

- What It Achieves: Processes up to 60 meters of metal per minute with minimal manual intervention.

- Why It’s Efficient: Meets high-volume production demands while maintaining consistent quality.

4. Integrated Hole Punching and Slot Cutting

- What It Enables: Pre-drilled mounting points for easy battery module installation.

- Why It’s Beneficial: Reduces manual labor and enhances rack assembly efficiency.

5. Anti-Corrosion and Fireproof Coatings

- What It Delivers: Machines capable of applying protective coatings during production.

- Why It’s Beneficial: Ensures longer lifespan and compliance with industrial safety standards.

6. Smart Monitoring and IoT-Enabled Quality Control

- What It Integrates: Real-time defect detection, predictive maintenance, and remote machine monitoring.

- Why It’s Innovative: Reduces waste, minimizes downtime, and enhances operational efficiency.

Pricing of Battery Rack Roll Forming Machines

এর খরচ Battery Rack Roll Forming Machine depends on features, production capacity, and customization options. Below is a general pricing guide for 2025:

| মেশিনের প্রকার | Capabilities | মূল্য পরিসীমা (ইউএসডি) |

|---|---|---|

| স্ট্যান্ডার্ড মেশিন | Basic battery rack production | 250,000–250,000–250,000–600,000 |

| অ্যাডভান্সড মেশিন | High-speed production with automated hole punching | 600,000–600,000–600,000–1,500,000 |

| Customizable Smart Machines | Fully automated, IoT-connected Industry 4.0 solutions | 1,500,000–1,500,000–1,500,000–3,000,000 |

For personalized pricing and financing options, reach out to Wuxi Sunway Machinery.

Real-World Success Stories: How Battery Rack Roll Forming Machines Are Transforming Energy Storage

From solar farms to data centers and EV charging infrastructure, Battery Rack Roll Forming Machines are making battery storage more efficient, cost-effective, and scalable. Below are real-world examples showcasing how these machines are enhancing energy storage solutions worldwide.

1. Solar Energy Storage in the United States

Client: A leading solar energy company specializing in large-scale battery storage solutions.

Challenge: Needed custom battery racks for a 2 GWh solar energy storage project.

Solution: Wuxi Sunway Machinery provided a high-speed roll-forming system with automated hole punching and corrosion-resistant coatings.

Outcome:

- Reduced production costs by 30%, making solar storage more affordable.

- Increased rack durability, ensuring long-term outdoor performance.

- Accelerated installation by 40%, improving project completion timelines.

2. EV Charging Infrastructure Expansion in Europe

Client: একটি automotive company deploying EV battery swapping stations.

Challenge: Required high-strength, modular battery racks for fast battery swapping at charging hubs.

Solution: Wuxi Sunway delivered a custom roll-forming machine optimized for heavy-duty, impact-resistant steel racks.

Outcome:

- Manufactured 10,000+ battery racks in six months.

- Improved battery retention and safety, ensuring secure storage for high-voltage battery modules.

- Reduced production time by 50%, accelerating EV infrastructure growth.

3. Data Center UPS Backup Systems in Asia

Client: ক tech company operating cloud computing and data centers.

Challenge: Needed custom battery racks for uninterruptible power supply (UPS) systems in mission-critical environments.

Solution: Wuxi Sunway provided a roll-forming machine with precision engineering, allowing for tight space optimization and seamless rack assembly.

Outcome:

- Increased storage density by 25%, maximizing floor space efficiency.

- Ensured fire-resistant, corrosion-proof racks, reducing maintenance costs.

- Enabled 24/7 power reliability, preventing data losses and downtime.

4. Industrial Battery Recycling Facilities in South America

Client: ক battery recycling plant specializing in lead-acid and lithium-ion battery disposal.

Challenge: Needed custom racks for safely handling, sorting, and transporting used batteries.

Solution: Wuxi Sunway delivered a roll-forming machine with reinforced steel processing for high-load-bearing battery racks.

Outcome:

- Enhanced worker safety, ensuring secure stacking of heavy battery units.

- Reduced operational costs, improving material handling efficiency.

- Enabled scalable expansion, allowing for higher recycling capacity.

Future Trends in Battery Rack Manufacturing for 2025

As industries shift toward clean energy, smart grid technology, and high-density battery storage, manufacturers are adopting new production techniques and materials to stay competitive. Below are the key trends shaping the future of Battery Rack Roll Forming Machines.

1. Lightweight and High-Strength Materials

- Trend: Increased use of aluminum and composite materials for lighter yet stronger battery racks.

- Impact on Machines: Roll-forming machines will be optimized for multi-material processing.

2. Modular and Expandable Rack Designs

- Trend: Growth in modular, stackable battery racks that can be expanded as energy needs grow.

- Impact on Machines: Machines will focus on producing adaptive, easy-to-assemble components.

3. AI-Driven Smart Manufacturing

- Trend: Integration of AI-based defect detection and automated quality control in production.

- Impact on Machines: Machines will feature real-time monitoring and predictive maintenance.

4. Corrosion-Resistant and Heat-Dissipating Coatings

- Trend: More stringent fire safety and corrosion resistance requirements for battery storage.

- Impact on Machines: Machines will incorporate integrated coating systems for enhanced durability.

5. Sustainable and Recyclable Manufacturing

- Trend: Shift toward eco-friendly materials and reduced manufacturing waste.

- Impact on Machines: Roll-forming systems will feature waste reduction strategies and energy-efficient processing.

Innovations in Battery Rack Roll Forming Machines for 2025

To meet evolving industry demands, Battery Rack Roll Forming Machines are evolving with advanced automation, smart monitoring, and sustainability-focused designs. Below are some of the latest innovations:

1. AI-Powered Precision Engineering

- What It Enables: AI-driven systems automatically adjust forming parameters for optimal production.

- Why It’s Revolutionary: Reduces scrap rates and ensures consistent rack dimensions.

2. Heat-Dissipating and Fireproof Coatings

- What It Adds: Machines capable of applying multi-layer coatings for heat resistance and fireproofing.

- Why It’s Valuable: Enhances battery safety and longevity.

3. Portable On-Site Roll Forming Machines

- What It Offers: Mobile roll-forming units for on-site battery storage infrastructure manufacturing.

- Why It’s Game-Changing: Reduces transportation costs and accelerates project timelines.

4. Smart Monitoring and Predictive Maintenance

- What It Integrates: IoT-enabled sensors for real-time production monitoring and predictive maintenance scheduling.

- Why It’s Essential: Minimizes downtime and prevents costly production interruptions.

Why Wuxi Sunway Machinery Leads the Battery Rack Industry

1. Decades of Expertise

With years of experience, Wuxi Sunway has a proven track record of excellence in industrial roll-forming solutions.

2. Cutting-Edge Technology

Incorporates advanced features like AI, IoT-driven automation, and high-speed roll-forming.

3. Customization Excellence

Offers tailored solutions for battery storage manufacturers, renewable energy firms, and EV infrastructure developers.

4. Global Industry Leadership

Trusted by energy companies, automotive manufacturers, and industrial suppliers worldwide.

5. Comprehensive Support

Provides consultation, installation, training, and after-sales services for seamless operation.

Visit their official website to explore their offerings or request a customized battery rack roll-forming solution tailored to your needs.

Final Thoughts: The Future of Battery Storage with Roll Forming Technology

With the global shift toward energy storage solutions, Battery Rack Roll Forming Machines are revolutionizing how battery racks are manufactured and deployed. Whether for solar power, EV infrastructure, or industrial backup systems, these machines ensure efficient, scalable, and high-quality solutions.

Looking to enhance your battery rack production capabilities? Partner with Wuxi Sunway Machinery and take your energy storage manufacturing to the next level.